The Whole Drone Package System Concept: Difference between revisions

| (56 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

This page reveals information about the system as a whole. It gives a relative view on how the components fit together, where this pick-up system could be located, possible costs coupled to it, and future considerations. | |||

{| border="1" cellpadding="5" cellspacing="0" align="right" width="40%" | |||

|+ '''Quick Links''' | |||

|- | |||

! style="background: #ffdead;" | Project Trajectory | |||

! colspan="3" style="background: #ffdead;" | Project Pages | |||

|- | |||

| [[PRE_Groep1| Home]] | |||

| [[Problem Definition]] | |||

| [[Opening]] | |||

| [[Scenarios]] | |||

|- | |||

| [[Planning & Milestones|Planning and Milestones]] | |||

| [[Background Research]] | |||

| [[Chimney]] | |||

| [[Rules & Regulations]] | |||

|- | |||

| [[Meetings]] | |||

| [[Requirements]] | |||

| [[Chimney to Cubby]] | |||

| | |||

|- | |||

| [[Design Methodology| Design Method(s)]] | |||

| [[Brainstorm]] | |||

| [[Cubby to Person]] | |||

| | |||

|- | |||

| [[Personal Logs]] | |||

| [[Concepts Chosen]] | |||

| [[Software]] | |||

| | |||

|- | |||

|style="border-bottom: 3px solid grey;" | [[Peer Review & Reflection]] | |||

|style="border-bottom: 3px solid grey;" | | |||

|style="border-bottom: 3px solid grey;" | [[The Whole Drone Package System Concept| Whole System]] | |||

|style="border-bottom: 3px solid grey;" | | |||

|} | |||

=Facts & Assumptions= | =Facts & Assumptions= | ||

| Line 11: | Line 49: | ||

! width="20%" | Weight | ! width="20%" | Weight | ||

|- valign="top" | |- valign="top" | ||

|- valign="top" | |- valign="top" | ||

| Average | | Average | ||

| Line 27: | Line 54: | ||

| 15 cm | | 15 cm | ||

| 26 cm | | 26 cm | ||

| 1.5 kg | | 1.5 kg <sub> (max 2.3 kg)</sub> | ||

|} | |} | ||

<sub>Specs were estimated from looking at the Amazon Prime Air video since no real dimensions could be found, currently.</sub><ref>Allain, R.(2013).Physics of the Amazon Octocopter Drone.Wired Science Blogs.<http://www.wired.com/2013/12/physics-of-the-amazon-prime-air-drone/></ref><br> | <sub>Specs were estimated from looking at the Amazon Prime Air video since no real dimensions could be found, currently.</sub><ref>Allain, R.(2013).Physics of the Amazon Octocopter Drone.Wired Science Blogs.<http://www.wired.com/2013/12/physics-of-the-amazon-prime-air-drone/></ref><br> | ||

<br> | <br> | ||

Tote has | Tote has an RFID tag located in bottom right corner of the tote on the front face. | ||

Assumptions | Assumptions | ||

* | * Drone has obstacle deflection capabilities. | ||

* While the system is in the act of transporting a package, the elevator will not let any other package into the system. | |||

* The system is equipped with a few sensors so that in case the package gets stuck somewhere, the system will have a good estimate of where it will be. | |||

* Each pick-up system has a designated code and GPS coordinates coupled to it for drone delivery and and customer delivery-location selection. | |||

= The System = | |||

== What it Looks like == | |||

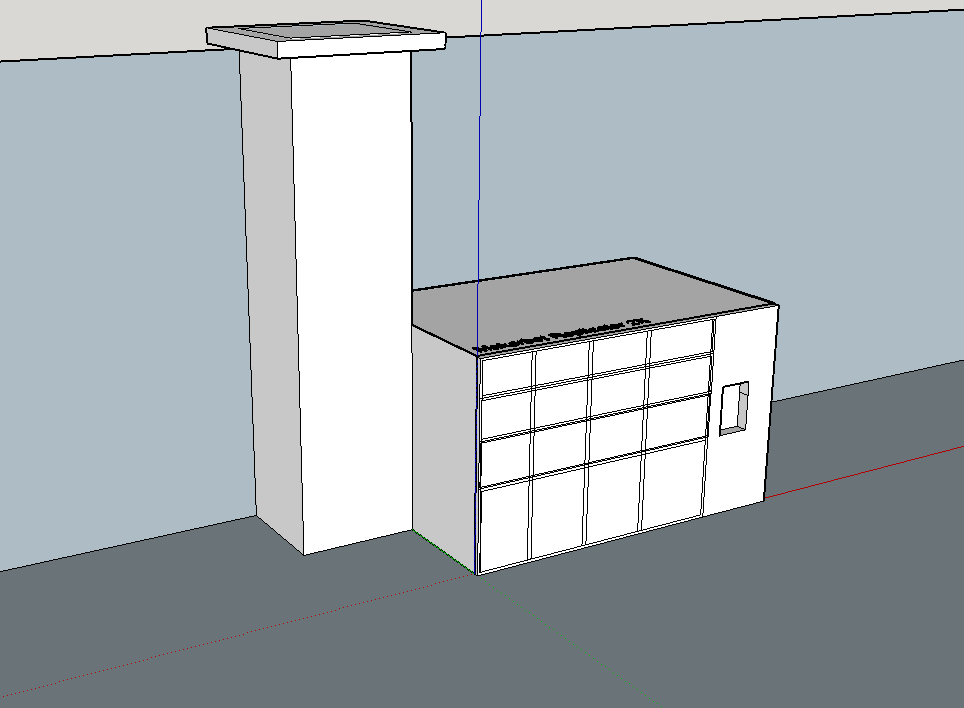

[[File:Group1-WholeSystem.png|thumb|left|Rough Drawing of how the whole system would look]] | |||

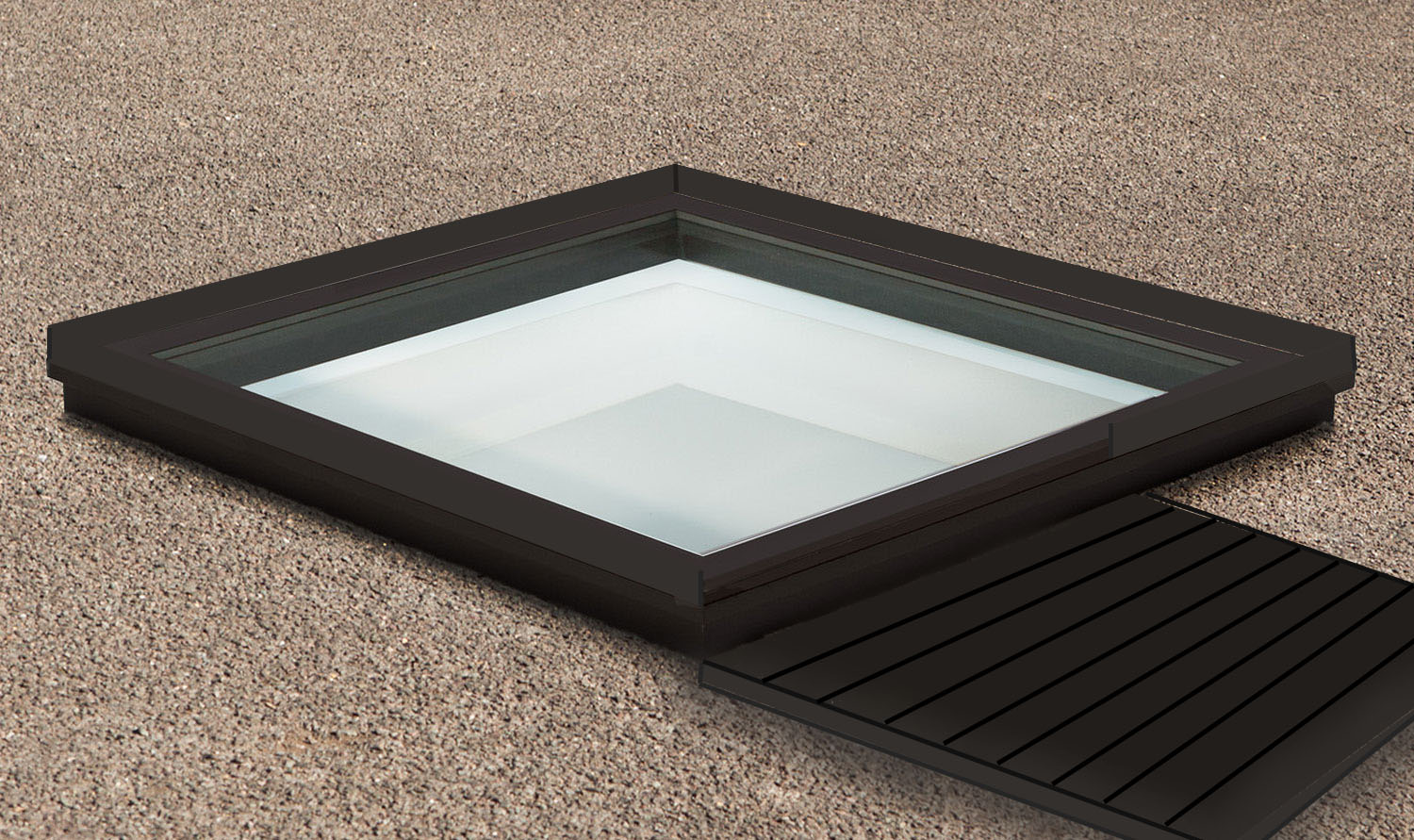

[[File:Locker.jpg|thumb|right|Type of locker system that could be mimicked]] | |||

[[File:Roof.jpg|thumb|right|Rough Drawing of the opening platform]] | |||

Basically, our system consists of four parts, the landing platform on the roof, the chimney, the conveyor belts and the lockers. The landing platform will not be visible for most and it will not be very big or notable. It is a mostly flat structure which will be placed on the roof of the supermarket. The chimney will be visible for customers as it is located next to the lockers as seen in the picture. It will have a simple rectangular shape and can be covered by paint or/and posters. The lockers will be very similar to the amazon locker system, except the arrangement of the lockers will differ slightly as can be read in the [[Chimney to Cubby | Chimney to Cubby part]]. The conveyor system which gets the package to the right locker will be behind the lockers and is therefore not visible to customers. | |||

<br> | |||

<br> | |||

The idea for our system is to make it modular. We will have predefined columns with big lockers, small lockers and lockers specific for drone delivered packages. When the system gets implemented in supermarkets, not every supermarket will need the same amount of lockers. There may be multiple supermarkets in the area with the same system which will require less lockers, or it could be the only one at a highly populated area. To make the system more flexible for these different situations we have decided to make it modular. More rows can be added at any time and will be relatively simple to implement. | |||

== How it Works == | |||

When a person orders a package that fits the requirements, it will be prepared for drone delivery at a Amazon location as seen in the [http://www.amazon.com/b?node=8037720011 video]. Of course whether or not the package can be delivered at that moment depends on availability, weather and other details. But if it is possible, the user receives an email saying the package can be picked up at the nearest supermarket within an hour. The drone can find the drop point based on GPS coordinates, detailed information about this process can be found in the [[Opening|opening]] page. The drone will fly to the supermarket, where it arrives at the [[Opening | Opening]]. The drone will release the package, which will be taken into the system. The package will be moved into the chimney where its RFID tag is scanned. The system will now decide which locker will accept the package and it will send an email with the number of the locker and the unlock code to the person that ordered the package. The elevator will move to the right height and move the package to the conveyor belt. This is where the package will be again scanned using an RFID reader. The system will first open the backdoor of the locker where the package is supposed to go, then the conveyor belt will start moving. The package will slide into the locker after which the conveyor belt stops moving and the door closes. Inside the locker, the package will be scanned again to verify that it has arrived. The package is now ready for the pick-up.<br><br> | |||

The lockers have a control panel as seen in the image. Here, the user will enter the code from the email. The locker will now open, the user can take his package and close the door. <br> | |||

The lockers that are not used for drone delivery have their package delivered by regular mailmen. We do not know exactly how this system works but it already exists and is in use by Amazon. The pick-up is equal to the previously explained pick-up for packages delivered by drones. | |||

<br><br> | |||

Click '''''[[Media:opening.gif | here]]''''' for an animation of the opening part.<br> | |||

Click '''''[[Media:conveyor.gif | here]]''''' for an animation of the conveyor part. | |||

== Location == | |||

===Amazon lockers === | |||

<br> | |||

Amazon already uses a locker system which is in some aspects similar to what we are designing. These lockers are located in retail stores, mostly at 7-Elevens. Amazon chose these stores as they have over 50.000 locations and are open most of the time. Details about the deal between 7-Eleven and Amazon are not public but most likely Amazon pays a fee for allowing the system in their stores. <br> | |||

Customers can order a package without worrying about being home at the time of the delivery. Once the package has arrived, they get an email after which they have three business days to pick up the package. At the system, the customer either enters a code or scans a bar code received in the email. The locker with the customer's package opens and the delivery is complete. | |||

[http://online.wsj.com/news/articles/SB10000872396390443545504577567763829784538?mg=reno64-wsj&url=http%3A%2F%2Fonline.wsj.com%2Farticle%2FSB10000872396390443545504577567763829784538.html%2F article about amazon lockers] | |||

<br> [http://www.wired.com/2012/08/amazons-lockers-move-frontlines-of-retail-war-to-back-of-7-eleven/ another article about amazon lockers] | |||

===Supermarkets === | |||

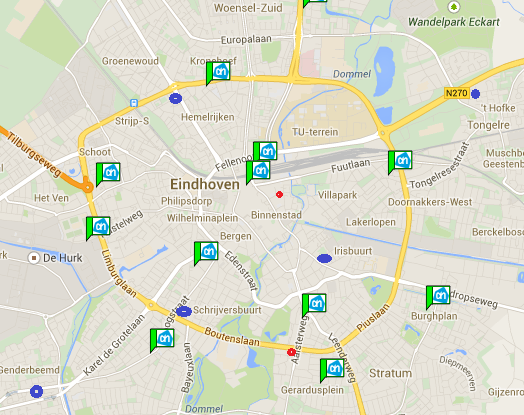

[[File:supermarkets.png|thumb|right]] | |||

In The Netherlands we do not have a such a large chain of stores. Of course Albert Heijn for example has many locations, but to reach every customer in The Netherlands effectively, we would need to use multiple chains. <br> | |||

<br> In The Netherlands the average distance to a supermarket is 0.9 Km. In big cities residents can choose from 3 major supermarkets within 1 kilometer. [http://www.cbs.nl/nl-NL/menu/themas/dossiers/nederland-regionaal/publicaties/artikelen/archief/2010/2010-3189-wm.htm cbs statistics of supermarkets] | |||

<br> In Eindhoven this distance is on average 0.7 Km, and the amount of supermarkets within 3 Km is 16.5 supermarkets. [http://statline.cbs.nl/StatWeb/publication/?DM=SLNL&PA=70904ned&D1=114-115&D2=11661,11786-11787&D3=a&VW=T statistics Eindhoven] | |||

<br> | |||

In the picture you see the major supermarkets in Eindhoven. The AH logos stand for Albert Heijn supermarkets, the blue circles for Jumbos and the red circles for Jan Linders. As can be seen, if all of these supermarkets would have locker systems, no one would have to travel far for their package. | |||

Picture of Eindhoven & its grocery store locations | |||

Explanation of who can be reached and why this is effective. | |||

<br> The AH logo's are the Albert Heijns in Eindhoven. | |||

<br> The blue circles the Jumbo's and the red circles the Jan linders. | |||

== Requirements Assessment == | |||

Green == addressed when designing this concept | |||

<br> | |||

Yellow == partially addressed when designing this concept and would need testing | |||

<br> | |||

No Fill == either external factors that why need consideration or requirements that cannot be assessed without further testing, which was not approachable in our time span | |||

<br> | |||

{| border="1" class="wikitable" cellpadding="2" width="100%" | |||

|- valign="top" | |||

! scope="row" width="25%" | Functional | |||

! width="25%" | Process | |||

! width="25%" | Product | |||

! width="25%" | External | |||

|- valign="top" | |||

| style="background-color:#20ff74;" | The system should be able to accept a package from a drone. | |||

| style="background-color:#20ff74;" | The component should be able to identify the package & designate a cubby location. | |||

| style="background-color:#20ff74;" |The user must be able to use the system immediately without any problem by following indicated steps. | |||

| The delivery drones must be capable of moving to an exact location in x, y and z direction. | |||

|- valign="top" | |||

| style="background-color:#20ff74;" | The system should have a holding space for package(s) | |||

| style="background-color:#20ff74;" | The system must be able to receive and handle a package within a minute, so a possible other drone waiting to deliver does not have to wait too long. | |||

| style="background-color:#20ff74;" | The system should communicate with the delivery drone to provide location information. | |||

| The delivery drones must have a Wifi Signal receiver to retrieve system location information | |||

|- valign="top" | |||

| style="background-color:#faff6d;" | The system should be robust-withstand damage, break-ins debris etc. | |||

| style="background-color:#20ff74;" | The system should know when a package is on the platform and is clear to proceed. | |||

| style="background-color:#20ff74;" |The system should at all times only open the locker with the package for which the right code has been presented. | |||

| The delivery drones should be able to calculate approach and positioning | |||

|- valign="top" | |||

| style="background-color:#faff6d;" | The system should be able to report status - malfunction, full, delivery etc. | |||

| | |||

| The system should open the right locker(s) within ten seconds after verifying the code. | |||

| There must be a short manual on how to use the system, that can be hung next to the system. | |||

|- valign="top" | |||

| | |||

| | |||

| The system is allowed to be broken twice a year. It should then be repaired within 24 hours of the malfunctioning being reported. | |||

| There must be a guide on how to install the system. | |||

|- valign="top" | |||

| | |||

| | |||

| The user should feel safe when using the system. | |||

| Help must be available all days between 9.00 and 18.00 | |||

|- valign="top" | |||

| | |||

| | |||

| The user should feel their package is safe in the system. | |||

| | |||

|} | |||

= Cost Analysis = | |||

While designing this system, our construction did not really consider all of the costs involved. Looking at certain design selections such as the elevator or identification software, they reveal to be quite costly..... | |||

<br> | |||

Below are the costs of some of the components considered for this current concept: | |||

<br> | |||

<br> | |||

{| border="1" | |||

|+ '''''Costs of some components considered for this design''''' | |||

|- | |||

|width=25%| Item | |||

|width=25%| Amount | |||

|width=25%| Cost | |||

|- | |||

|Prorunner mk5 (lift) | |||

|1 | |||

| $ 9,250 <sub>Cost of standard model</sub><ref>http://www.vertical-conveyor.com/index.php?pageId=206</ref> | |||

|- | |||

|RFID Reader | |||

|11 (9 lockers & 2 check points) | |||

|~100euro p/piece <ref>http://www.rfid-technology-shop.com/rfid-tuerleser/ultralight-wandleser/mifare-ultralight-wandleser-qde-950-2.html</ref> | |||

|- | |||

| Microbelt conveyors | |||

| 3 | |||

| ~1000 euro p/piece <ref>http://www.beltconveyors.co.uk/buy-belt-conveyors-online/</ref> | |||

|- | |||

| Parcel-Locker | |||

| 1 | |||

| ~1000 | |||

|} | |||

<sub> The prices above are rough estimations of possible components, based on manufacturers websites</sub> | |||

<br> | |||

<br> | |||

As one can see, the current concept sketched in our report needs some more consideration and iteration. We are not technical specialists in this area and people with more knowledge may create a better iteration, however, the goal here was to come up with a well thought out concept which would aid in drone delivery. For example, all the capabilities that the Prorunner mk5 elevator has are not necessarily required for the feat this system is trying to perform, but this elevator does reflect the component that should be in its place. Considering our design requires some adaptation to the current locker systems, the price of production will most likely go up some compared to current parcel-lockers, this is because we have to adapt to drone delivery. Some cost considerations for an upcoming iteration would be to find/create a simpler lift mechanism and possibly find another solution to the conveyors. It, of course, depends on how much an investor wants to pay to make this system work, and if in the end the payoff will be greater than the cost. | |||

= Further Issues to Consider = | |||

The goal was to develop a starting concept that allows drones to make a delivery to a specific location where people can pick-up their package. We did not address all possible scenarios, issues or constraints. | |||

<br> | |||

<br> | |||

Some issues, constraints, etc. that we have not yet considered while designing are: | |||

* What happens to the delivery tote the drone drops off? <br> As seen in the amazon delivery clip, packages are delivered in plastic totes. If that will be the standard, then how will Amazon get these totes back? Will people take them and trash them? etc. IF amazon would want them back, a possible tote opener could be connected to the pick-up system. These totes could then only be opened at the pick-up station, adding an extra security measure for rouge totes that may be dropped. This will allow tote collection at the same pick-up system, so an extra confirmation for package delivery and an easy collection process. Also it is sustainable because one would reuse the totes for other drone deliveries. <br> This is definitely something that should be considered in the future iterations. | |||

* How many cubbies needed for an area? <br> We just conceptualized the several different stages of the pick-up system and how they would function as a whole. The convenience of this is that the cubby end is modular and can be changed to accommodate to various sizes. We, however, did not go into specific details on how many cubbies would be needed for XX people. These statistics are probably floating around somewhere, or should be collected. Either way, when placing this system at pick-up locations it is important to consider the critical mass of people on is trying to reach, and select an appropriate number of cubbies. | |||

* Malfunctions and Maintenance <br> Although we did try to think as simple as possible with the mechanisms used for this system, there is always the possibility that something breaks. What we did not consider is how these components could be fixed. For example, how does one reach the conveyor systems located behind the cubbies? These issues should be addressed in further development of this system. Some solutions may be strategic placement of an opening allowing a mechanic in or for problems on the roof, roof access through the stores could possibly be used. If the lift should get stuck, possible panel removing capabilities on the chimney may help with ease of access. What would be nice, however, is that nothing ever would break. | |||

* Which specific RFID frequency would be useful for this system? <br> In designing the identification process of the pick-up system, we did consider how it could be done (by RFID, barcode, etc.) and selected RFID due to the fact that it makes use of radiowaves. However, what was not fully thought through was what kind of RFID reader the system would need. These readers have different frequencies, which have different traits such as the range of reading, if it is effected by metals etc. <ref>http://www.improvement-it.nl/nl/hardware/rfid?gclid=CjwKEAjwwo2iBRCurdSQy9y8xWcSJABrrLiSP4IeN6jNslQDqc3OwBTN-lMEWZ60A6DTEd2_no9e0hoC5ynw_wcB</ref> When further developing, specific choice of RFID is necessary for it effects the design. | |||

* Cost <br> As can be seen above from our cost-analysis, it can be noted that we looked for current technology that suited our needs and purposes and manipulated that into our system regardless of price. In further developments, current lifts and conveyors and scanners used can be simplified, re-engineered or selected based on the more detailed specifications and constraints of a company. | |||

''N.B. There may be more issues and constraint, but these are currently the main ones we have come up with.'' | |||

<br> | |||

<br> | |||

<br> | |||

<br> | |||

'''''[[Software| BACK: Software]]''''' | |||

<br> | |||

'''''[[Scenarios| NEXT: Scenarios]]''''' | |||

=References= | =References= | ||

<references/> | <references/> | ||

Latest revision as of 15:06, 21 October 2014

This page reveals information about the system as a whole. It gives a relative view on how the components fit together, where this pick-up system could be located, possible costs coupled to it, and future considerations.

Facts & Assumptions

| Drone Tote | Height | Width | Depth | Weight |

|---|---|---|---|---|

| Average | 12 cm | 15 cm | 26 cm | 1.5 kg (max 2.3 kg) |

Specs were estimated from looking at the Amazon Prime Air video since no real dimensions could be found, currently.[1]

Tote has an RFID tag located in bottom right corner of the tote on the front face.

Assumptions

- Drone has obstacle deflection capabilities.

- While the system is in the act of transporting a package, the elevator will not let any other package into the system.

- The system is equipped with a few sensors so that in case the package gets stuck somewhere, the system will have a good estimate of where it will be.

- Each pick-up system has a designated code and GPS coordinates coupled to it for drone delivery and and customer delivery-location selection.

The System

What it Looks like

Basically, our system consists of four parts, the landing platform on the roof, the chimney, the conveyor belts and the lockers. The landing platform will not be visible for most and it will not be very big or notable. It is a mostly flat structure which will be placed on the roof of the supermarket. The chimney will be visible for customers as it is located next to the lockers as seen in the picture. It will have a simple rectangular shape and can be covered by paint or/and posters. The lockers will be very similar to the amazon locker system, except the arrangement of the lockers will differ slightly as can be read in the Chimney to Cubby part. The conveyor system which gets the package to the right locker will be behind the lockers and is therefore not visible to customers.

The idea for our system is to make it modular. We will have predefined columns with big lockers, small lockers and lockers specific for drone delivered packages. When the system gets implemented in supermarkets, not every supermarket will need the same amount of lockers. There may be multiple supermarkets in the area with the same system which will require less lockers, or it could be the only one at a highly populated area. To make the system more flexible for these different situations we have decided to make it modular. More rows can be added at any time and will be relatively simple to implement.

How it Works

When a person orders a package that fits the requirements, it will be prepared for drone delivery at a Amazon location as seen in the video. Of course whether or not the package can be delivered at that moment depends on availability, weather and other details. But if it is possible, the user receives an email saying the package can be picked up at the nearest supermarket within an hour. The drone can find the drop point based on GPS coordinates, detailed information about this process can be found in the opening page. The drone will fly to the supermarket, where it arrives at the Opening. The drone will release the package, which will be taken into the system. The package will be moved into the chimney where its RFID tag is scanned. The system will now decide which locker will accept the package and it will send an email with the number of the locker and the unlock code to the person that ordered the package. The elevator will move to the right height and move the package to the conveyor belt. This is where the package will be again scanned using an RFID reader. The system will first open the backdoor of the locker where the package is supposed to go, then the conveyor belt will start moving. The package will slide into the locker after which the conveyor belt stops moving and the door closes. Inside the locker, the package will be scanned again to verify that it has arrived. The package is now ready for the pick-up.

The lockers have a control panel as seen in the image. Here, the user will enter the code from the email. The locker will now open, the user can take his package and close the door.

The lockers that are not used for drone delivery have their package delivered by regular mailmen. We do not know exactly how this system works but it already exists and is in use by Amazon. The pick-up is equal to the previously explained pick-up for packages delivered by drones.

Click here for an animation of the opening part.

Click here for an animation of the conveyor part.

Location

Amazon lockers

Amazon already uses a locker system which is in some aspects similar to what we are designing. These lockers are located in retail stores, mostly at 7-Elevens. Amazon chose these stores as they have over 50.000 locations and are open most of the time. Details about the deal between 7-Eleven and Amazon are not public but most likely Amazon pays a fee for allowing the system in their stores.

Customers can order a package without worrying about being home at the time of the delivery. Once the package has arrived, they get an email after which they have three business days to pick up the package. At the system, the customer either enters a code or scans a bar code received in the email. The locker with the customer's package opens and the delivery is complete.

article about amazon lockers

another article about amazon lockers

Supermarkets

In The Netherlands we do not have a such a large chain of stores. Of course Albert Heijn for example has many locations, but to reach every customer in The Netherlands effectively, we would need to use multiple chains.

In The Netherlands the average distance to a supermarket is 0.9 Km. In big cities residents can choose from 3 major supermarkets within 1 kilometer. cbs statistics of supermarkets

In Eindhoven this distance is on average 0.7 Km, and the amount of supermarkets within 3 Km is 16.5 supermarkets. statistics Eindhoven

In the picture you see the major supermarkets in Eindhoven. The AH logos stand for Albert Heijn supermarkets, the blue circles for Jumbos and the red circles for Jan Linders. As can be seen, if all of these supermarkets would have locker systems, no one would have to travel far for their package.

Picture of Eindhoven & its grocery store locations

Explanation of who can be reached and why this is effective.

The AH logo's are the Albert Heijns in Eindhoven.

The blue circles the Jumbo's and the red circles the Jan linders.

Requirements Assessment

Green == addressed when designing this concept

Yellow == partially addressed when designing this concept and would need testing

No Fill == either external factors that why need consideration or requirements that cannot be assessed without further testing, which was not approachable in our time span

| Functional | Process | Product | External |

|---|---|---|---|

| The system should be able to accept a package from a drone. | The component should be able to identify the package & designate a cubby location. | The user must be able to use the system immediately without any problem by following indicated steps. | The delivery drones must be capable of moving to an exact location in x, y and z direction. |

| The system should have a holding space for package(s) | The system must be able to receive and handle a package within a minute, so a possible other drone waiting to deliver does not have to wait too long. | The system should communicate with the delivery drone to provide location information. | The delivery drones must have a Wifi Signal receiver to retrieve system location information |

| The system should be robust-withstand damage, break-ins debris etc. | The system should know when a package is on the platform and is clear to proceed. | The system should at all times only open the locker with the package for which the right code has been presented. | The delivery drones should be able to calculate approach and positioning |

| The system should be able to report status - malfunction, full, delivery etc. | The system should open the right locker(s) within ten seconds after verifying the code. | There must be a short manual on how to use the system, that can be hung next to the system. | |

| The system is allowed to be broken twice a year. It should then be repaired within 24 hours of the malfunctioning being reported. | There must be a guide on how to install the system. | ||

| The user should feel safe when using the system. | Help must be available all days between 9.00 and 18.00 | ||

| The user should feel their package is safe in the system. |

Cost Analysis

While designing this system, our construction did not really consider all of the costs involved. Looking at certain design selections such as the elevator or identification software, they reveal to be quite costly.....

Below are the costs of some of the components considered for this current concept:

| Item | Amount | Cost |

| Prorunner mk5 (lift) | 1 | $ 9,250 Cost of standard model[2] |

| RFID Reader | 11 (9 lockers & 2 check points) | ~100euro p/piece [3] |

| Microbelt conveyors | 3 | ~1000 euro p/piece [4] |

| Parcel-Locker | 1 | ~1000 |

The prices above are rough estimations of possible components, based on manufacturers websites

As one can see, the current concept sketched in our report needs some more consideration and iteration. We are not technical specialists in this area and people with more knowledge may create a better iteration, however, the goal here was to come up with a well thought out concept which would aid in drone delivery. For example, all the capabilities that the Prorunner mk5 elevator has are not necessarily required for the feat this system is trying to perform, but this elevator does reflect the component that should be in its place. Considering our design requires some adaptation to the current locker systems, the price of production will most likely go up some compared to current parcel-lockers, this is because we have to adapt to drone delivery. Some cost considerations for an upcoming iteration would be to find/create a simpler lift mechanism and possibly find another solution to the conveyors. It, of course, depends on how much an investor wants to pay to make this system work, and if in the end the payoff will be greater than the cost.

Further Issues to Consider

The goal was to develop a starting concept that allows drones to make a delivery to a specific location where people can pick-up their package. We did not address all possible scenarios, issues or constraints.

Some issues, constraints, etc. that we have not yet considered while designing are:

- What happens to the delivery tote the drone drops off?

As seen in the amazon delivery clip, packages are delivered in plastic totes. If that will be the standard, then how will Amazon get these totes back? Will people take them and trash them? etc. IF amazon would want them back, a possible tote opener could be connected to the pick-up system. These totes could then only be opened at the pick-up station, adding an extra security measure for rouge totes that may be dropped. This will allow tote collection at the same pick-up system, so an extra confirmation for package delivery and an easy collection process. Also it is sustainable because one would reuse the totes for other drone deliveries.

This is definitely something that should be considered in the future iterations. - How many cubbies needed for an area?

We just conceptualized the several different stages of the pick-up system and how they would function as a whole. The convenience of this is that the cubby end is modular and can be changed to accommodate to various sizes. We, however, did not go into specific details on how many cubbies would be needed for XX people. These statistics are probably floating around somewhere, or should be collected. Either way, when placing this system at pick-up locations it is important to consider the critical mass of people on is trying to reach, and select an appropriate number of cubbies. - Malfunctions and Maintenance

Although we did try to think as simple as possible with the mechanisms used for this system, there is always the possibility that something breaks. What we did not consider is how these components could be fixed. For example, how does one reach the conveyor systems located behind the cubbies? These issues should be addressed in further development of this system. Some solutions may be strategic placement of an opening allowing a mechanic in or for problems on the roof, roof access through the stores could possibly be used. If the lift should get stuck, possible panel removing capabilities on the chimney may help with ease of access. What would be nice, however, is that nothing ever would break. - Which specific RFID frequency would be useful for this system?

In designing the identification process of the pick-up system, we did consider how it could be done (by RFID, barcode, etc.) and selected RFID due to the fact that it makes use of radiowaves. However, what was not fully thought through was what kind of RFID reader the system would need. These readers have different frequencies, which have different traits such as the range of reading, if it is effected by metals etc. [5] When further developing, specific choice of RFID is necessary for it effects the design. - Cost

As can be seen above from our cost-analysis, it can be noted that we looked for current technology that suited our needs and purposes and manipulated that into our system regardless of price. In further developments, current lifts and conveyors and scanners used can be simplified, re-engineered or selected based on the more detailed specifications and constraints of a company.

N.B. There may be more issues and constraint, but these are currently the main ones we have come up with.

BACK: Software

NEXT: Scenarios

References

- ↑ Allain, R.(2013).Physics of the Amazon Octocopter Drone.Wired Science Blogs.<http://www.wired.com/2013/12/physics-of-the-amazon-prime-air-drone/>

- ↑ http://www.vertical-conveyor.com/index.php?pageId=206

- ↑ http://www.rfid-technology-shop.com/rfid-tuerleser/ultralight-wandleser/mifare-ultralight-wandleser-qde-950-2.html

- ↑ http://www.beltconveyors.co.uk/buy-belt-conveyors-online/

- ↑ http://www.improvement-it.nl/nl/hardware/rfid?gclid=CjwKEAjwwo2iBRCurdSQy9y8xWcSJABrrLiSP4IeN6jNslQDqc3OwBTN-lMEWZ60A6DTEd2_no9e0hoC5ynw_wcB