Embedded Motion Control 2019 Group 2

Group members

| Name | Student number |

|---|---|

| Bob Clephas | 1271431 |

| Tom van de laar | 1265938 |

| Job Meijer | 1268155 |

| Marcel van Wensveen | 1253085 |

| Anish Kumar Govada | 1348701 |

Introduction

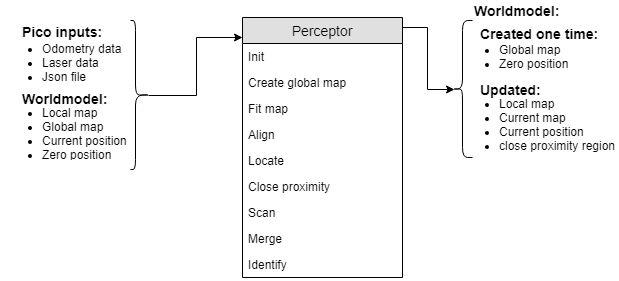

Welcome on the wiki of group 2 of the 2019 Embedded Motion Control course. During this course the group designed and implemented their own software which allows a PICO robot to complete two different challenges autonomously. The first challenge is the "Escape room challenge" where the PICO robot must drive out of the room from a given initial position inside the room. In the second challenge called the "Hospital challenge" the goal is to visit an unknown number of cabinets in a specific order, placed in different rooms. For both challenges the group designed one generic software structure that is capable of completing both challenges without changing the complete structure of the program. In figure 1 the maps of both challenges are shown to give a general idea about the challenges. On the general wiki page of the 2019 Embedded Motion Control course (link) the full details are given regarding both challenges.

Escape room challenge

The main goal of the challenge was to exit the room as fast as possible given an arbitrary initial position and orientation of PICO and the various constraints such as length of the finish line, width of the hall way, time constraints and accuracy.

Hospital challenge

The main goal of this challenge was to visit the cabinets in a particular order given by the user in limited amount of time given the various constraints. The global map consisting of rooms and cabinets and the starting room of PICO were mentioned before hand. It tested the ability of PICO to avoid static/dynamic objects and plan an optimal path dynamically.

Environment

| Challenge | Specifications |

|---|---|

| Escape room challenge | 1. Rectangular room, unknown dimensions. One opening with a corridor.

2. Starting point and orientation is random, but equal for all groups. 3. Opening will be perpendicular to the room. 4. Far end of the corridor will be open. 5. Wall will not be perfectly straight, walls of the corridor will not be perfectly parallel. 6. Finish line is at least 3 meters in the corridor, walls of the corridor will be a little bit longer. |

| Final Challenge | 1. Walls will be approx. perpendicular to each other

2. Global map is provided before competition 3. Location of cabinets is provided in global map 4. Static elements, not showed in global map, will be in the area 5. Dynamic (moving) elements will be in the area 6. Objects can have a random orientation 7. Multiple rooms with doors 8. Doors can be open or closed 9. list of "To-be-visited" cabinets is provided just before competition |

Design document

To arrive at a well thought out design of the software, the group started with creating a design document. In this document the starting point of the project is described. The given constraints and hardware is listed in an clear overview and the needed requirements and specifications of the software are shown. The last part of the design document is describing the overall software architecture and framework of the software that the group wants to design. The design document gave a solid basis for the software from where the groups started to build on during the rest of the course. The full document can be found here. Here on the wiki the most important specifications and requirements are listed here in table 1. Later on the wiki the overall software architecture is explained in full detail.

Table 1: Requirements and specifications

| Requirements | Specifications |

|---|---|

| Accomplish predefined high-level tasks | 1. Find the exit during the "Escape room challenge"

2. Reach a predefined cabinet during the "Hospital Challenge" |

| Knowledge of the environment | 1. The robot should be able to identify the following objects:

2. The map is at 2D level 3. Overall accuracy of <0.1 meter |

| Knowing where the robot is in the environment | 1. Know the location at 2D level

2. XY with < 0.1 meter accuracy 3. Orientation (alpha) with <10 degree accuracy |

| Being able to move | 1. Max. 0.5 [m/s] translational speed

2. Max 1.2 [rad/sec] rotational speed 3. Able to reach the desired position with <0.1 meter accuracy 4. Able to reach the desired orientation with <0.1 radians accuracy |

| Avoid obstacles | 1. Never bump into an object

2. Being able to drive around an object when it is partially blocking the desired path |

| Standing still | 1. Never stand still for longer than 30 seconds |

| Finish as fast as possible | 1. Within 5 minutes (Escape room challenge)

2. Within 10 minutes (Hospital Competition) |

| Coding language | 1. Only allowed to write code in C++ coding language

2. GIT version control must be used |

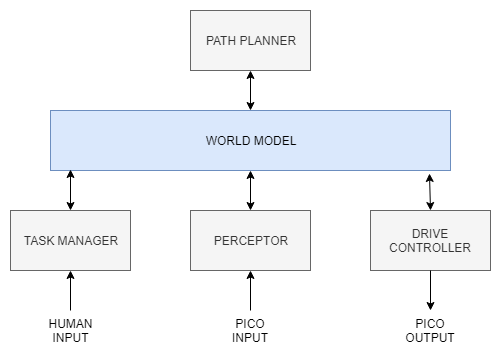

General software architecture and interface

A generic software architecture was implemented as discussed in the lectures during the course. The software architecture is split into several building blocks such as the Task manager, World model, Perceptor, Path planner, Drive controller and the respective data flow between them as shown in figure 2:

The task manager helps in structuring the program flow by setting appropriate block modes based on received block statuses to perform a particular task. It mainly focuses on the behavior of the program and segments the challenge into a step by step process/task division taking into account the fall back scenarios. It manages high level tasks which are discussed further. The perceptor is primarily used for converting the input sensor data into usable information for the PICO. It creates a local map, fits it onto the global map and then aligns it when required. The path planner mainly focuses on planning an optimal path for the PICO to reach the required destination. This optimal path is performed using Dijkstra algorithm. The drive controller focuses on driving the PICO to the required destination by giving a motor set point in terms of translational and rotational velocity. The world model is basically used to store all the information and acts as a medium of communication between the other blocks. Detailed explanations of each block can be found in software blocks section.

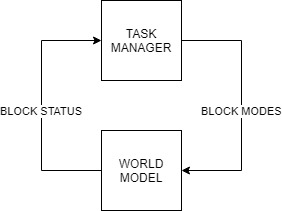

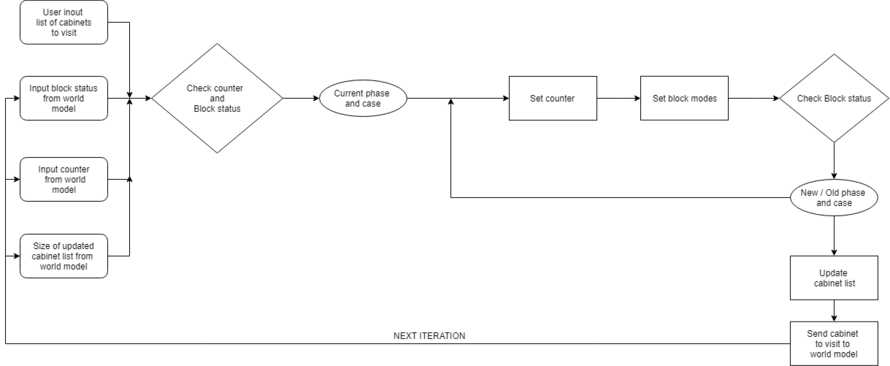

Block modes & Block Statuses

Block statuses and modes are primarily used for communication between the task manager and the other blocks. It also helps in easy understanding of the segmentation of each task/phase. The block diagram shown below explains the transmission of block modes and statuses.

The block status that were defined are as follows :

- STATE_BUSY - Set for each block in case it is still performing the task

- STATE_DONE - Set for each block if the task is completed

- STATE_ERROR - Set for each block if it results in an error

The block modes that were defined are as follows :

- MODE_EXECUTE - defined for all the blocks

- MODE_INIT - defined for all the blocks

- MODE_IDLE - defined for all the blocks

- MODE_DISABLE - defined for all the blocks

- PP_MODE_ROTATE - defined for the path planner which directs the drive controller to change orientation of PICO

- PP_MODE_PLAN - defined for the path planner to plan an optimal path

- PP_MODE_NEXTNODE - defined for the path planner to send the next node in the path

- PP_MODE_FOLLOW - defined for the path planner follows the path

- PP_MODE_BREAKLINKS - defined for the path planner breaks the links between a node when

- PP_MODE_RESETLINKS - defined for the path planner to rest the broken links between nodes which were broken due to an object between the two nodes.

- PC_MODE_FIT - defined for the perceptor to fit the local map onto the global map

These statuses and modes are used in the execution of appropriate phases and cases discussed in the overall program flow section.

Overall program flow

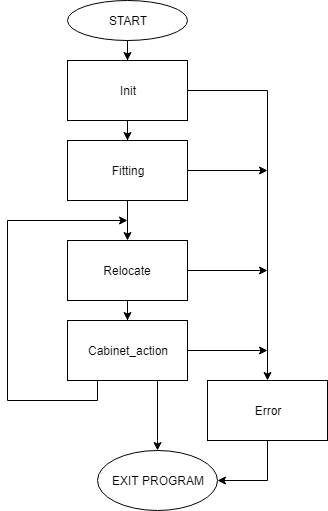

The overall software behaviour is divided in five clearly distinguished phases. During each phase all actions lead to one specific goal and when that goal is reached, a transition is made towards the next phase. The following five phases are identified and also shown in figure 3.

Initialisation phase

The software always starts in this phase. During this phase all the inputs and outputs of the robot are initialised and checked. Also all the required variables in the software are set to their correct values. At the end of the initialisation phase the software is set and ready to perform the desired tasks, the software switches to the fitting phase.

Fitting phase

During the fitting phase PICO tries to determine its initial position relative to the given map. It determines the location with the help of the laser range finder data and tries to fit the environment around the robot to the given map. In the case that the obtained laser data is insufficient to get a good, unique fit, it first starts to rotate the robot. If after the rotation still no unique fit is obtained, the robot will try to drive towards a different location and rotates again at that location. The full details on how the fitting algorithm works are described in the perceptor section of this wiki. As soon as there is an unique and good fit, the location of PICO is known and the software switched to the relocate phase.

Relocate phase

During the relocate phase the goal is to move the PICO robot to the desired cabinet. To do this, a path is calculated from the current location towards the desired cabinet in the path planner. The drive controller follows this path and avoids obstacles on its way. When it is found that the path as a whole is blocked, a new path is calculated around the blockage. As soon as the PICO robot has arrived at the desired cabinet the software switched to the cabinet action phase.

Cabinet action phase

During the cabinet action phase the PICO robot executes the required actions at the cabinet. This includes saying 'I arrived at cabinet #' and taking a snapshot of the current laser data to proof that the robot has arrived at the correct location. After performing the required actions the software determined if the PICO robot should visit another cabinet, and if so, it switched back to the relocate phase. If all the cabinets are visited the software is stopped and the challenge is successful completed.

Error phase

The error phase is different from the other phases in the sense that it is never the desired to end up in this phase. The only situation when the software switched to the error phase is when something is different from expected. This can for example happen when a required file is missing during the initialisation phase, the fitting phase has went through all the fallback mechanisms and still hasn't succeed in finding a unique fit. In all cases something unforeseen has happened and the software is out of options to recover itself. If that happens, the PICO robot is switched to a safe state e.g. all motors are disabled, and then all potential useful information for debugging is displayed to the operator. Finally the software is terminated and the possible cause can be found and fixed.

Detailed descriptions of the different phases

For all the phases detailed flowcharts and descriptions are made. In those flowcharts all the fallback mechanisms are shown and the exact behaviour is explained in full detail. During the writing of the software those flowcharts are used to create the software and to find bugs. They also helped the group to come to a clear agreement on how the software architecture should look like. Finally it also helped the group to discuss how to handle unforeseen situations and how the found solution can be fitted in the existing software.

The flowcharts with all the required details are grouped in this document.

Software blocks

World model

The world model is the block which stores all the data that needs to be transferred between the different blocks. It acts as a medium of communication between the various blocks such as perception, task manager, path planner and drive controller. It contains all the get and set functions of the various blocks to perform respective tasks.

As seen in the data flow overview in figure 4, the various input data and output data that are sent in and out of the world model are accessed using get and set functions.

Table 3: Description of data that is transmitted

| Data | Description |

|---|---|

| LRF Sensor input | Lazer range finder data is used to create the local map objects like walls and detect corners |

| ODO Sensor input | Odometery data gives the current position and orientation of PICO |

| Local map | This is the map created from the LRF data |

| Global map | This is the given map with the position of cabinets and rooms specified |

| Combined map | This is the map formed by fitting the local map on the global map |

| Close proximity region | This is the region defined around PICO in order to avoid obstacles |

| Current position | This data stores the current position of the PICO which gets updated |

| Next node | Next node to visit in the optimal planned path |

| Optimal path | Shortest path created by Dijkstra algorithm |

| Desired destination/ next cabinet node | This stores the current cabinet number that needs to be visited by the PICO |

| Block modes | Used by every block to help PICO perform a certain action |

| Block status | This is the status of each block such as Done/busy/error and based on which a particular block modes are set and the required task is performed |

Input to the world model :

- Updated high level tasks - Task manager

- Block modes - Task manager

- Block statuses - All blocks

- Close proximity region - Perceptor

- Current position - Perceptor

- Zero position - Perceptor

- Global map - Perceptor

- Local map - Perceptor

- Combined map - Perceptor

- Next node - Path planner

- Path from Dijkstra algorithm - Path planner

Output from the world model :

- High level tasks - Task manager

- Block statuses - Task manager

- Block modes - Drive controller, Perceptor and Path planner

- Close proximity region - Drive controller

- Current location - Drive controller, Path planner

- Desired location/ next node - Drive controller

- Current position - Perceptor

- Zero position - Perceptor

- Global map - Perceptor

- Local map - Perceptor

- Combined map - Path Planner

- Desired destination/ next cabinet node - Path planner

Task manager

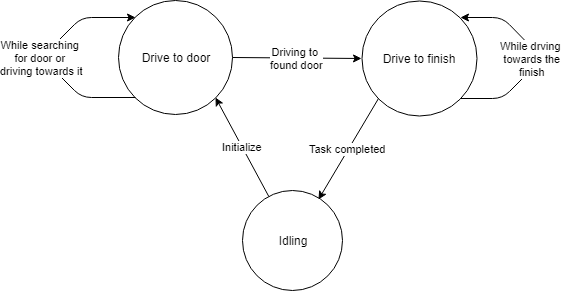

The task manager functions as a finite state machine which switches between different tasks/states, as shown in figure 5. It focuses mainly on the behavior of the whole program rather than the execution. It determines the next operation phase and case based on the current phase, current case, current block statuses and counters in which the corresponding block modes of the perceptor, path planner and drive controller are set for the upcoming execution. It communicates with the other blocks via the World model.

Since the "Escape room challenge" and the "Hospital competition" require a complete different approach in terms of cooperation between the blocks, the task planner is completely rewritten for both challenges.

ESCAPE ROOM CHALLENGE

In this challenge the job of the task manager was to ensure PICO executes the tasks in a sequential manner. As the goal of the task was to exit the room, two block modes were assigned namely, “Drive_to_door” and “Drive_to_exit”. So the task manager initially sets the mode of the path planner to drive to the door and based on the received status of the blocks it either chooses to stay in the same state or drives to the exit. After the task is completed all the blocks are set to Idle mode.

INITIALIZATION:

The path planner is given a command “Drive_to_door” while the drive controller and the preceptor are given a command “Execute” as a part of the initialization process.

EXECUTION:

The high-level tasks “Drive_to_door”, “Drive_to_exit”, “Execute”, “Idle” and “Disable” were given to appropriate blocks as shown in figure 9. If the status of the Path planner is driving to a possible door or is searching for a door, the task manager sets the mode of path planner to drive to door. If the status of the path planner is driving to a found door and the Drive controller is done driving, then the path planner is set to drive to exit. If the status of the Path planner is driving to a possible exit or is searching for a exit or if the drive controller is busy driving, the task manager sets the mode of all the blocks to Idle.

HOSPITAL ROOM CHALLENGE

The task manager is completely revamped for the hospital challenge. It functions as a state machine and handles the behavior of the program in a well structured manner considering various fall back scenarios which can be edited when ever needed. The list of cabinets to visit are initially read by the task manager and sent to the world model. It works primarily on setting appropriate block modes, setting counter variables and changing from a particular phase and case of the program to another in order to perform a required task based on the block statuses it receives. The various phases and cases are discussed further in the overall program flow section. The functions of the task manager are described in the flowchart and can also be seen in description in overall program flow section. :

The function description can be found here : Task manager description

Visualization

To make the debugging of the program faster and more effective a new class in the software is added. This visualization class draws an empty canvas of a given size. With one line of code the defined objects can be added to this canvas. Each loop iteration the canvas is cleared and can be filled again with the updated or new objects. The visualization class is excluded from the software architecture. There is chosen to not include this class in the software architecture, because this class has no real functionality except for debugging. Any other software block can make use of the visualization to quickly start debugging. However, the visualization is especially used in the main to keep the program structured. All objects that are visualized in the main have to exist in the world model.

The visualization makes use of the opencv library and a few of its basic functionalities such as imshow, newcanvas, Point2d, circle, line and putText. The struct "object" that can be added to the visualization is as defined in the code snippet "class definition". The object struct can contain an object type ("wall","door","path"), points, connection between those points and the properties of the points. For example, in the visualization can be seen if points are connected (blue) or not (white). Moreover, darker blue points indicate that the corner is concave, light blue points indicate convex corners with respect to the robot. The maps as defined in the world model can also be visualized. The map struct contains a vector of objects, such as walls, cabinets, nodes, doors, path etc..

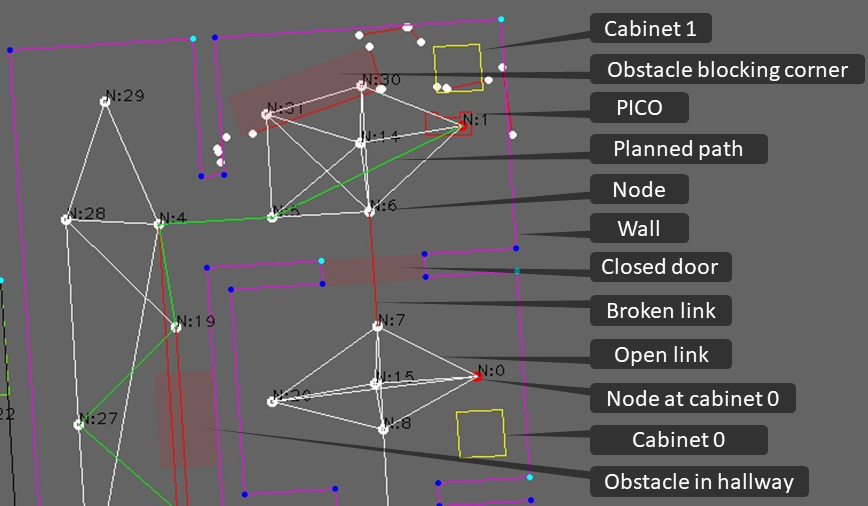

In figure 7 example objects are visualized. The global map is created by the perceptor from the Json file, the walls of the global map are visualized with purple lines. The walls of the room pico starts in are defined by the black lines. The laser range finder data can be visualized as red dots. The close proximity region is visualized using red and green dots. A green dot indicates a direction which contains no objects, and a red dot indicates an object is within the defined close proximity region. Furthermore, arrows are used to visualize how close the object is to the robot. This region is used by the drive controller for the potential field algorithm. Using the LRF data the current scan is created. The data points from the LRF are converted into line points and visualized as red lines. The local map is stored in the worldmodel and contains multiple current scan lines merged over time. Moreover, the local map is visualized as green lines and the corner points of these lines contain properties, such as convex, concave or not connected. Once the software block path planner planned a path it can be added to the global map. Therefore, the planned path can also be visualized by visualizing the global map. The planned path normally has a green color, therefore it is not advised to use it together with the local map, which has a green color for the walls. The next node the robot has set as destination becomes dark blue on this path. The final destination, a cabinet node, is set to red on the path. If needed the nodes and link from one node to another node can be visualized as well (normally white). Often only the nodes from the planned path are visualized, to prevent a chaotic canvas. Of course the previous named objects not all the objects that can be visualized, if a certain object is made in a function this object can easily be added to the visualization if debugging is required.

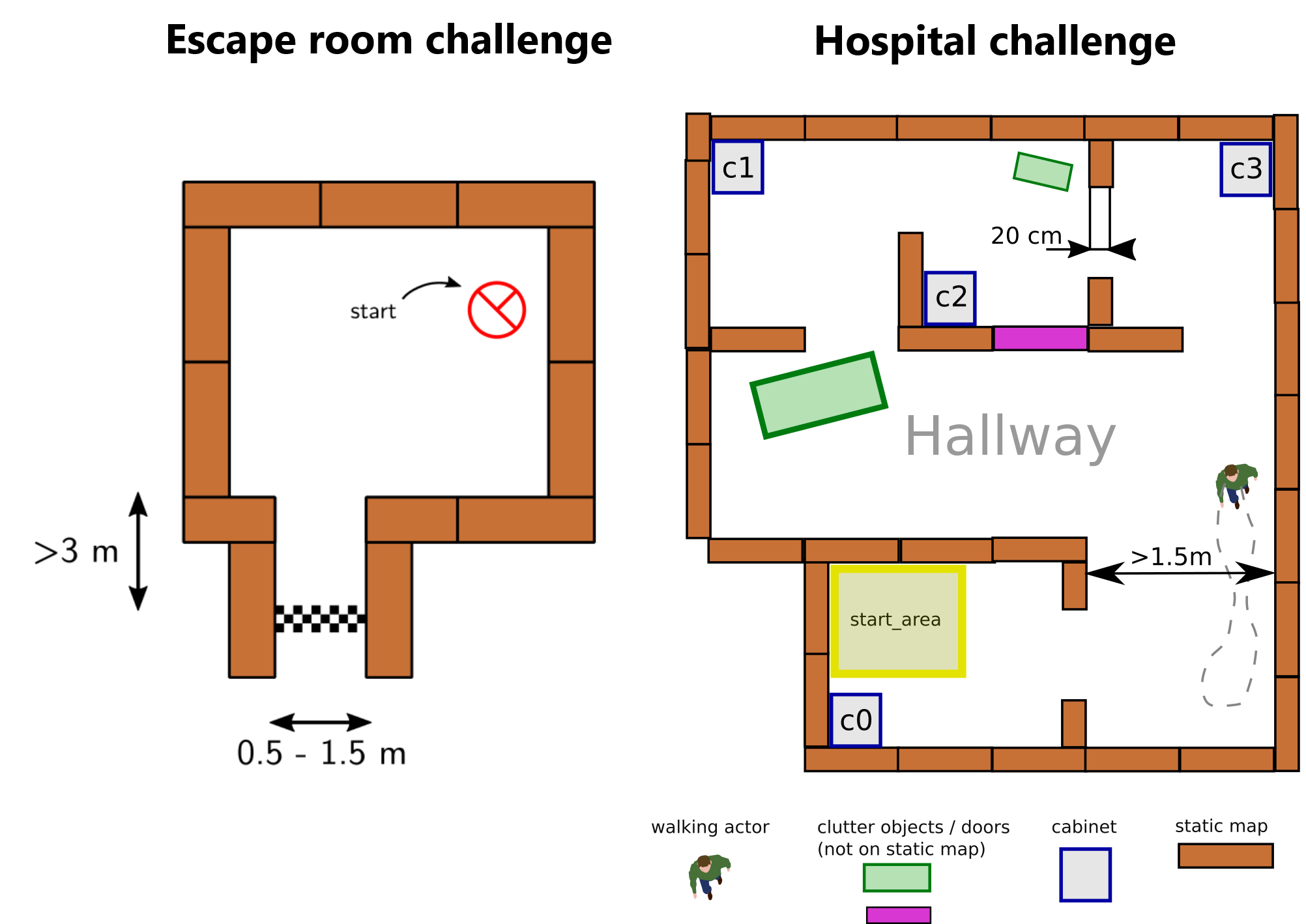

Perceptor

The perceptor receives all of the incoming data from the pico robot and converts the data to useful data for the worldmodel. The incoming data exists of odometry data obtained by the wheel encoders of the pico robot and the laserdata obtained by the laser scanners. A Json file containing the global map and location of the cabinets, this file is provided a week before the hospital challenge. Moreover, the output of the perceptor to the world model consists of the global map, a local map, a current map, the current/zero position and a close proximity region. The incoming data is handled within the perceptor by the functions described below.

The inputs and outputs of the perceptor are shown in the following figure:

The data structures used in the perceptor can be viewed in the following document: Perceptor data structures.

Init position

The pico robot saves the absolute driven distance since its startup. Therefore, when the software

starts it needs to reinitialize the current position of the robot. If the robot receives its first odometry

dataset it saves this position and sets it as zero position for the worldmodel. Later this zero position can be subtracted from the new odometry data, to obtain the position of pico with respect to position were it initialized. The initialization of the odometry data only happens once in the program, when the software is started.

create global map

A json file containing information of the global map is read in the perceptor once when the program is started. The json file is read, the information is directly transformed into the data structure used by the program. The global map contains all the walls of the hospital challenge, as well as , the nodes and links between each node. Furthermore, the the starting area of the robot is defined. The definition of this area is needed to make a more accurate and faster fit of the global map onto the local map.

Close proximity

Dynamic objects are not measured by the local map. To prevent collisions between the robot and another object (dynamic or static), a close proximity region is determined. This region is described as a circle with the configured radius around the robot. The function returns a vector describing the measured distances of a filtered set of laser range finder data points to the worldmodel.

Locate

This function makes use of the zero-frame which is determined by the init function. Once the

odometry data is read a transformation is used to determine the position of the robot with respect to

the initialized position. Other functions need the position of the robot to navigate trough the maps. Therefore, this current position is outputted to the worldmodel.

Fit map

For the pico robot to know where it is located on the given global map, a fit function is created. This fit function is used when the perceptor receives the ‘PC_MODE_FIT’ command from the task manager which only happens in the beginning of the program as described in the task manager section. The way this function works is by picking one object (with 2 points thus basically a line) from the global map and one from the local map. Next it rotates the global map such that the two lines are parallel, this happens 2 times for one set of objects, and thereafter translates the global map such that the middle points of these lines are on top of each other. When this is done the number of lines and points ‘on top’ of each other is determined. Two lines are on top of each other when the angle difference is smaller than a defined bound and when the distance between there middle points is smaller than a defined bound. To make the function more robust, also point properties such as convex and concave are taken into account and should match. A fit score is calculated based on the combined angle and distance errors of the matched walls. If there are static objects placed inside the initial room only parts of the walls can be observed in the local map. Therefore, the shorter walls of the local map are made equal in length to the global map so they can be tested if they match the global map walls. Furthermore, the fitscore is only based on walls that are matched, in combination with the extending of the shorter walls from the local map this ensures robustness to static objects in the initial room. When the number of matching walls is higher or equal to that of another iteration then this transformation, number of matching walls and fit score is saved. The global map is transformed back to how it was, and another set of objects is tested. Once all the combinations of objects from the local map and global map are tested, the best transform is used to transform the global map. This transformation only happens if the global map matches correctly with the global map. In figure ... the fitting of the map can be seen. Initially the robot cannot match enough walls with a good fitscore, therefore, the robots starts rotating. Once the robot added enough walls to the local map which he is able to match the global map the transformation is saved. Lastly, this transformation is executed and the global map is transformed on the local map, even with the two static objects in the initial room.

Align

Once the global map is fitted onto the local map, the align function is used to keep the two maps on top of each other. The way this works is by checking the average angle difference and average offset between the current scan map and the global map. To do this, first it is checked which of the lines from the current scan map are ‘on top’ of the lines from the global map. In this case on top is slightly different as defined in the fit function. Here it means that 2 lines should be roughly parallel, there parallel distance should be small and they should have no gap between them. When two lines are on top of each other, the angle error and parallel distance is summed up onto the total angle and total distance error. After all the all the objects are checked against each other this total error is divided by the number of matching walls and used to translate the global map to match the current scan.

Scan

The laserdata is read from the sensor, however, this data is in polar coordinates. Therefore, the data

is first transformed to Cartesian coordinates. Next, the data is resampled so there is a minimum set

distance between all of the data points. This resampled data is used to calculate the angles between

all the consecutive points. To determine which data points represent a wall the data is split in

different clusters. The data is splitted using an average angle of the cluster and the angle of the next

point. Therefore, the data is split at the corners of each wall. Lastly, the points of each cluster are

marked as a wall with floating points at both sides of the walls also the position of these floating

points is stored as well. This stored information of the end points of walls is defined as current map.

Merge

In this function the new laser data is merged with an existing map to form a more robust and

complete map of the environment. Therefore, laser data in the form of a current map created by the

scan function is imported. Furthermore, the previous created output of the merge function is

imported as well, which is called the local map. Firstly, the previous created map is transformed to

the current position of the robot. Secondly, similar walls are merged. Walls are considered to be

similar if they are parallel to each other, have a small difference in angle or are split into two pieces.

If two walls are close to each other but one has a smaller length they are merged as well. The merge

settings are stored in the configuration file. The different merge cases can be seen in figure … . Once

similar walls are merged, the endpoints of walls are connected to form the corners points of the

room. Each point of a wall has a given radius, and if another point has a distance to this point which is

smaller than its radius then the points will be connected. To improve the robustness of the local map

the location of these corner points is mainly based on the location of the corner points from the

previous local map, which ensures rejection of measurement errors in the laser data. Furthermore,

the wall points that are not merged or connected at the end of the function will be removed.

Therefore, the local map will only consist of walls which are connected to each other.

Identify

The functionality of this function is to identify the property of the points in the local map. For

instance corner points can be convex or concave. This property is later used to help identify doors,

objects or cabinets in the local map. The position of the robot determines if the corner point is

convex or concave. With this property information the map is scanned for doors. For the escape

room challenge a door is identified as two convex points close to each other. A door is defined

between two walls, these walls should be approximately in one line. Also, the corner points cannot

be from the same wall to further increase the robustness of the map. It is unlikely that the local map

immediately contains two convex points which can form a door. Therefore, a possible door is

defined, so the robot can drive to the location and check if there is a real door at this position. There

are multiple scenarios where a possible door can be formed. Such as, one convex point and one loose

end, two loose ends or a loose end facing a wall. Concave points can never form a door and are

therefore excluded. When forming a possible door the length of the door and the orientation of the

walls is important as well.

Path planner

For planning paths the choice is made to use nodes that are placed at the following locations:

- In front of a door (one at each side)

- In front of a cabinet

- In the starting area

- Distributed over each room in order to plan around objects, eg. in the middle

Gridding the map is also considered but was not chosen because of the higher complexity and with separate nodes debugging is easier as well. The path planner determines the path for the PICO robot based on the list of available nodes and the links between these nodes. For planning the optimal path, Dijkstra's algorithm is used and the distance between the nodes is used as a cost. The choice for Dijkstra is based on the need for an algorithm that can plan the shortest routhe from one node to another. Also it was selected on being sufficient for this application, the extra complexity of the A* algorithm was not needed. The planned path is a set of positions that the PICO robot is going to drive towards, this set is called the ‘next set of positions’. This next set of positions is saved in the world model and used by the task manager to send destination points to the drive controller. In figure 7 is shown how the path planner behaves in case of a closed door: the link is broken and a new path around the closed door is planned.

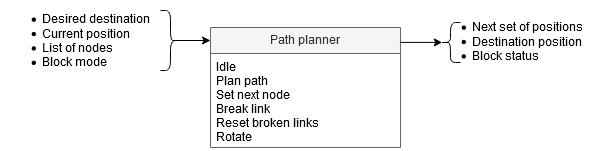

The path planner takes the desired destination, current position, list of all available nodes and the path planner block mode as inputs. The functions of the path planner are idling, planning a path, setting the next node of the planned path as current destination position, breaking a link between nodes, resetting all broken links and rotating the PICO robot. This results in the planned path (next set of positions), the destination position and the path planner block status. The inputs, functions and outputs of the path planner are visualized in the following figure:

All functions of the path planner are explained below.

Idle

When idling, all variables are set to their initial value and the path planner waits for the task manager to set the block mode.

Plan paths

In this function all possible paths to the desired destination are planned based on the list of nodes and the links between these nodes. Links between nodes can be open or broken, where broken means that it is unavailable. The links between the nodes and links are determined by hand before the challenge and placed on the global map. To plan a path, Dijkstra's algorithm is used and the distance between the nodes is used as a cost. This results in the shortest possible path from the robot to the location of the desired cabinet. The optimal path consists of a list of nodes, which are positions that the PICO robot has to drive towards in order to reach the desired cabinet. This optimal path is stored in the world model as 'next set of positions', which is used during the following phase of the program.

Set next node

Once all possible paths are planned, PICO has to follow it. To do this, the list of nodes from the created path is followed. The next node is set if the task manager changes the mode of the path planner to set next node, which happens when the last node is reached.

Break link

If PICO is not able to reach a node, the link between the current destination node and the last node must be broken. This is done when the task manager sets the block mode to break link.

Reset broken links

When there is no possible path because all links are broken, the broken links are set to open again and a path is planned. This is implemented in case a dynamic obstacle was blocking the path. This function is called when the task manager changes the block mode to reset broken links or when the plan path function cannot create a path towards the given destination.

Rotate

When PICO has to scan the room, it must be able to rotate. Using the rotate function the desired destination of PICO is changed, where the angle is adjusted by the in this function inserted value.

Drive controller

The drive controller software block ensures that the pico robot drives to the desired location. it receives the current and desired location and automatically determines the shortest path towards the desired location. While driving it also avoids small obstacles on it's path. If the object is too large, or the path is blocked by a door for example, the drive controller signals this to the path planner which calculated an alternative path.

To avoid objects and ensure the PICO robot does not hit a wall or object, two algorithms are considered. The first algorithm takes a fixed radius around the robot and checks if each each laser data point on that radius is blocked or not. The algorithm then finds an direction that is as close as possible facing towards the actual goal with all free directions. The second algorithm that is considered is the potential field algorithm. In this algorithm the distance towards the object close to the robot is also taken into account instead of only blocked/not blocked. This second algorithm is more complex but will ensure a smoother driving of the PICO robot. Eventually the potential field algorithm is implemented because of the smoother driving behaviour.

The potential field algorithm uses two types of forces which are added and used to find a free direction. The first force is an attractive force towards the desired location. Secondly all the objects (walls, static and dynamic objects) that are close to the robot have a repellent force away from them. The closer the object, the larger the repellent force. All the forces are added together and the resulting direction vector is determined. This new direction is used as a desired direction at that time instance. In the gif shown here the repellent forces are visualised and it can be seen that Pico uses this to drive around an object in its path. The green points are showing the free directions and in red the directions towards an object, together with an arrow visualising the repellent force.

More details of the Drive Controller, including function descriptions and a detailed flowchart can be found in the Drive Controller functionality description document here. In the code snippet section of this wiki the actual potential field algorithm is found.

Challenges

Escape Room Challenge

Our strategy for the escape room challenge was to use the software structure for the hospital challenge as much as possible. Therefore, the room is scanned from its initial position. From this location a local map of the room is created by the perceptor. Including, convex or concave corner points, doors and possible doors (if it is not fully certain the door is real). Based on this local map the task manager gives commands to the drive controller and path planner to position in front of the door. Once in front of the the possible door and verified as a real door the path planner sends the next position to the world model. Which is the end of the finish line in this case, which is detected by two lose ends of the walls. Also the robot is able to detect if there are objects in front of the robot to eventually avoid them.

Simulation and testing

Multiple possible maps where created and tested. In most of the cases the robot was able to escape the room. However, in some cases such as the room in the escape room challenge the robot could not escape. The cases were analyzed but there was enough time to implement these cases. Furthermore, the software was only partly tested with the real environment at the time of the escape room challenge. Each separate function worked, such as driving to destinations, making a local map with walls, doors and corner points, driving trough a hallway and avoiding obstacles.

What went good during the escape room challenge:

The robot was made robust, it could detect the walls even though a few walls were placed under a small angle and not straight next to each other. Furthermore, the graphical feedback in from of a local map was implemented on the “face” of the Pico. The Pico even drove to a possible door when later realizing this was not a door.

Improvements for the escape room challenge:

Doors can only be detected if it consists of convex corners, or two loose ends facing each other. In the challenge it was therefore not able to detect a possible door. The loose ends were not facing each other as can be seen in the gif below. Furthermore, there was not back up strategy when no doors where found, other then scanning the map again. Pico should have re-positioned itself somewhere else in the room or the pico could have followed a wall. However, we are not intending to use a wall follower in the hospital challenge. Therefore, this does not correspond with our chosen strategy. Another point that can be improved is creating the walls. For now walls can only be detected with a minimal number of laser points. Therefore, in the challenge it was not able to detect the small wall next to the corridor straight away. This was done to create a robust map but therefore also excluded some essential parts of the map.

In the simulation environment the map is recreated including the roughly placed walls. As expected in this simulation of the escape room the pico did not succeed to find the exit, the reasons are explained above.

Hospital Challenge

During the hospital challenge a list of cabinets in a hospital must be visited to pick and place medicine. The given order of cabinets was 0, 1 and finally 3. Before this challenge a global map of the hospital with coordinates of the cabinets and walls was given. However there are doors that might be closed and unknown objects in the hospital. These objects can be either static or dynamic. The PICO robot must be able to handle these uncertainties.

The software for the hospital challenge is an improved version of the software used during the escape room challenge. The same block structure is used and as much as possible software is reused and adjusted where necessary. Major changes are done to the path planner and task manager since the complexity of the hospital challenge is much higher for those two blocks compared to the escape room challenge.

Video

The full and higher quality version of the video can be found here: Hospital challenge - video group 2 - 2019

What went well

The things that went well where being able to detect various objects such as walls and doors correctly. Next to that the closed door and static object were detected properly. Furthermore being able to plan a path around the closed door and static obstacles was no problem. Planning around objects is done by breaking the links between nodes, such that the path planning algorithm does not use these broken links anymore while planning a path. The broken links during the hospital challenge are visible in Figure 8 where all red lines between nodes indicate a broken link, white lines indicate a open link and the green lines indicate the planned path. Also did the localization work well, once it had determined the starting position correctly. This made it possible to determine the correct position of the PICO robot in the hospital during the challenge. Also was the localization robust against disturbances that were blocking it from detecting corners of rooms. This is also visible in Figure 8, where an object was blocking the top left corner of the room where PICO was in at that moment while visiting cabinet 1.

Improvements for the hospital challenge

The things that we would improve are improving the initial localization robustness since during the first try the localization was off, resulting in PICO getting stuck in the hallway. Luckily it did work correctly after a restart and we were able to finish. Also did we slightly hit the obstacle in the hallway, which was unexpected since a protection mechanism to avoid running into objects is implemented. Why this happened has to be investigated. The last improvement is reducing the total time to finish the challenge. The driving speed was lowered during the challenge to improve the accuracy of the localization, because the detected walls and doors were slightly off. If the robustness of the localization is improved, the driving speed can be increased as well to finish the hospital challenge faster. The time duration can also be decreased by removing the delay while waiting at a cabinet, since this delay was set to 5 seconds.

Code snippets

Looking back at the project

What went good

When looking back at the project, several things went well. Firstly, a good structure was set up before we started coding. Once the whole structure was clear to everyone, parts could more easily be divided amongst the team members. Secondly, the data flow (input and output) was defined before coding of a specific part started. This ensured easy coupling of different parts. Lastly, larger algorithms and challenges are discussed amongst team members to ensure the algorithms are thought trough and work as specified.

What could be improved

In the beginning of the course we mainly focused on setting up a good general structure, which is a good thing. However, it made it harder to finish the Escape room challenge because less time was devoted to making and especially testing vital functions to finish this challenge. Thus, in the beginning the focus could have been shifted towards finishing this challenge first. Next to that, not all functions made were needed in the end. Although the structure of the whole program was clear, not every detail as how to solve a specific challenge was discussed upfront. This meant that there were some redundant functions. Finally, all parts of the code are made by our own, only the EMC and a few other standard libraries (opencv, stdio, cmath, fstream, list, vector, string, cassert) are used. This meant we had a lot of control in the functionality but on the other hand does it take more time, thus it would be better if we first searched for libraries that met our requirements and only make it ourselves if no matching library could be found.

Overall conclusion

Improvements can be made to the current status of the software to make it more robust. And in the beginning of the project the focus could have been more towards the escape room challenge.Nevertheless, a working piece of software is created with a good structure and when implemented on the PICO robot is able to finish the hospital challenge.