From Control Systems Technology Group

Jump to navigation

Jump to search

Group Members

Planning

| Week: |

|

| Feb 18 - Feb 24 |

|

| - Qualitative analysis of robot

|

| - Derivation of kinematics and dynamics (Leroy, Erik)

|

| - Preparation of first experiment session (Wouter, Koen)

|

| - Investigate different control-design

|

| - Group meeting

|

| Feb 25 - Mar 3 |

|

| - FRF-measurement and analyse (Wouter,Leroy (Tuesday))

|

| - Coupled/decoupled experiment (Wouter,Koen (Friday))

|

| - Nonlinearity experiment (Wouter,Koen (Friday))

|

| - Static friction experiment (Wouter,Koen (Friday))

|

| - Group meeting (Friday)

|

| Mar 4 - Mar 10 |

|

| - Continue making FRF-measurements

|

| - Design PID controllers for all joints

|

| - Trajectory planning for all joints

|

| - Group meeting

|

| Mar 11 - Mar 17 |

|

| - Verify trajectory planning (minimum time trajectory)

|

| - Group meeting

|

| Mar 18 - Mar 24 |

|

| - Design feedforward controller

|

| - Group meeting

|

Progress

Week 1

- The first step in this project was to identify the pizza-robot by creating a list of all the (straightforward) (design) requirements of the pizza-robot (to design experiments) such as:

- The pizza is not allowed to fall during transport, therefore the maximum acceleration (horizontally and vertically) is limited

- The robot is not allowed to touch the pizza holding brackets, the trajectory design must prevent crashes

- 3 pizza's must be transported and the pizzas must be transported as fast as possible (approx. 10-15 sec), and thus the fastest trajectory must be found

- The controller must stabilize the system

- Controller output is limited, no saturation

- The accuracy of the pizza-robot end-effector when obtaining a pizza from the brackets should be approx. 5mm

- Controller output is limited, keep saturation of motors in mind

- A next step was to identify the limitations of the pizza-robot such as

- Degrees of freedom to specify the workspace of the end-effector

- The maximum input signals [V] of the motors of the pizza-robot and consequently the maximum velocity/acceleration of each joint

- To identify the pizza-robot in a more specific way:

- The kinematics of the pizza-robot are derived which are helpfull for the trajectory design and determining the dynamics of the pizza-robot using the DH convention.

- A simple model (dynamics) of the pizza-robot is determined to possibly use model-based control design (dynamics of the pizza-robot in terms of the generalized coordinates is difficult, consider a simple model for each joint seperately)

- FRF-measurement experiments are prepared (designing a ref. trajectory, a stabilizing controller)

- Different types of feedback-control are considered which are usable (and possible with the knowledge of the groupmembers)

Week 2

- As already mentioned in week 1, a simple model is proposed to (possibly) use for model-based control design instead of the dynamics of the pizza-robot in terms of its generalized coordinates since this is too complex and not usable as model-based control design. (for every joint a model, with disturbances from other joints)

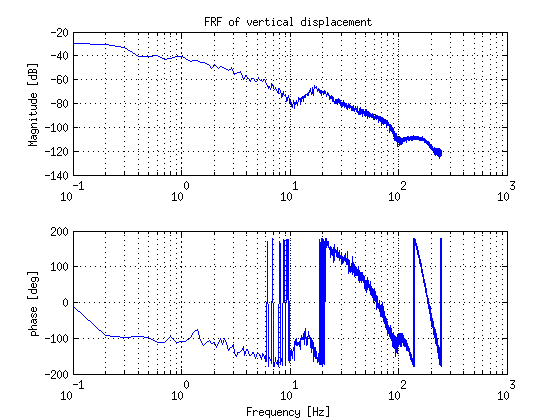

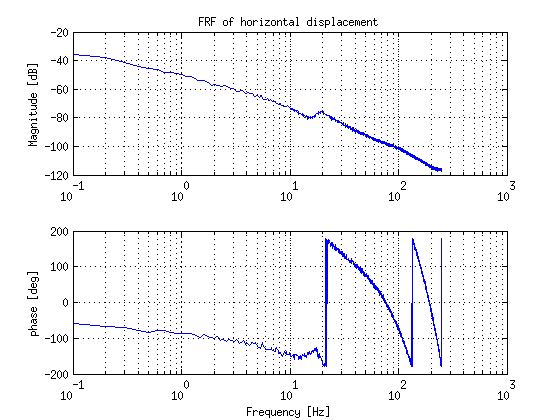

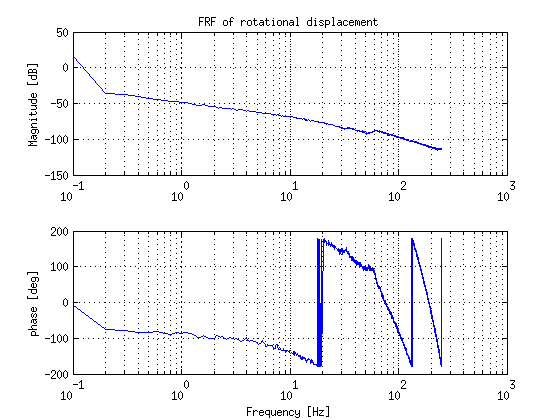

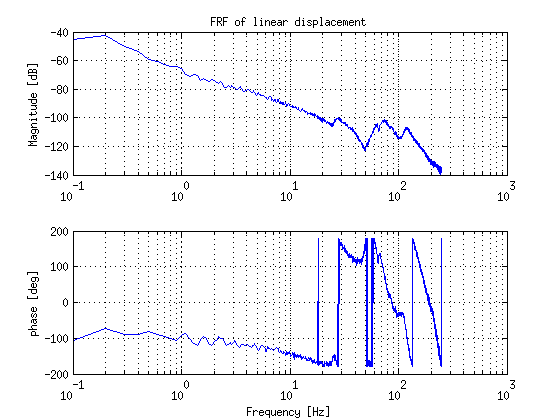

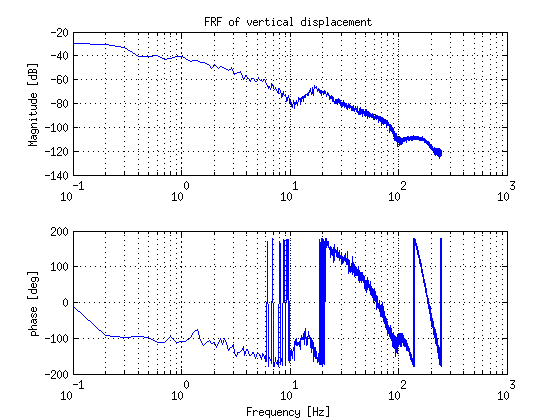

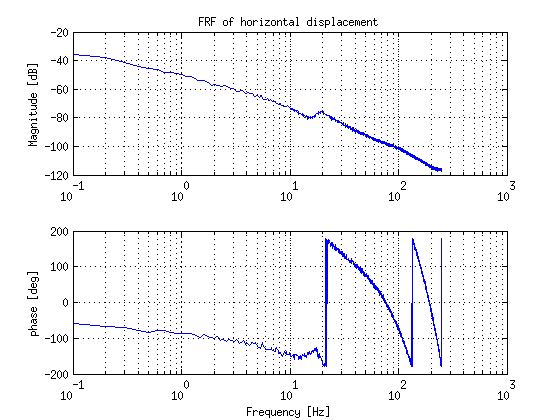

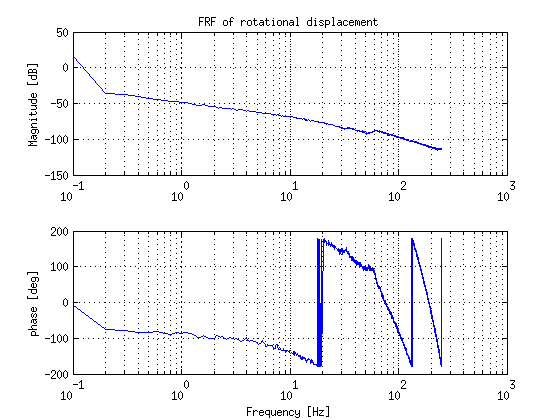

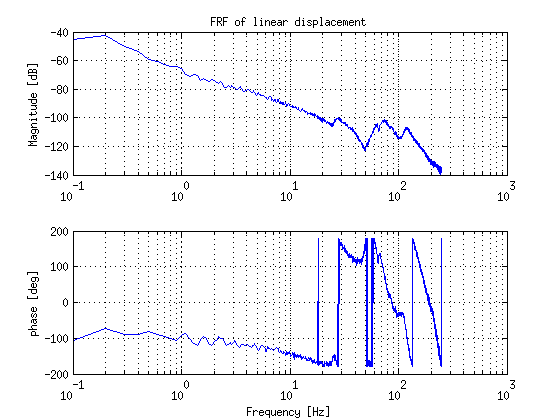

- FRF-measurements are performed of each joint with a stabilizing controller and a specific reference trajectory, however large friction is encountered which seems to be not constant along the trajectory of each joint. This influence the FRF-measurements at low frequency. (improve FRF-measurements)

Week 3

- It took a bit more time for doing the FRF-measurements. Finally we have all FRF's of the joints and all group members designed a stable controller for two joints.

| Vertical displacement

|

Horizontal displacement

|

|

|

| Rotational displacement

|

Linear displacement

|

|

|