PRE2024 3 Group5

Random Ideas and General Notes

TRIDENT (Tactical Robotic Inspection & Detection for Enhanced Nautical-hull Testing)

Tasks for this week:

- Luuk - Localization on the hull

- Anh - Ultra sonic sensor

- Simon - Use case

- Anton - Continue writing about the MFL

- Luca - Physics for the simulation

Group Members

| Name | Student ID | Department | |

|---|---|---|---|

| Anton Veshnyakov | 1866508 | Electrical Engineering | a.veshnyakov@student.tue.nl |

| Luuk Kool | 1883542 | Electrical Engineering | l.j.c.kool@student.tue.nl |

| Anh That Tuan Ton | 1816209 | Electrical Engineering | a.ton.that.tuan.anh@student.tue.nl |

| Luca Rutz | 1781294 | Electrical Engineering | l.d.rutz@student.tue.nl |

| Simon van Valkengoed | 1881361 | Electrical Engineering | s.h.v.valkengoed@student.tue.nl |

Problem Statement (NEEDS AN UPDATE!!!)

Inspecting the hull of a ship is a critical step in insuring its safety and operability, be it a small fishing boat or a giant ocean crossing cargo ship. Traditionally, those inspections were done using divers[1]. As technology progressed, the role of hull inspections shifted from humans to ROVs (Remotely Operated Vehicles) and other autonomous robotic systems. However, currently the available solutions operate primarily while the ship is in the shallow waters of a port or while it is already docked[2]. This means, that if a ship incurred some damage, it will be discovered relatively late in its journey, which in turn will delay the repairs and keep the ship docked for longer than necessary. Our system aims to make the discovery of possible faults in advance, while the ship is still at sea, allowing for faster turn around time and potentially reduced ecological impact.

Deliverable and goals (NEEDS AN UPDATE!!!)

The deliverable of this project will be a simulation of a robot that inspects the hulls of ships. This simulation will include the sensing part of a robot (measure its location and dynamics, measure the hull integrity and process it), but will not include actuators such as wheels or thrusters. The simulation should work for every (smooth) model of a ship hull.

The main goals are:

- Measure location with suitable precision and map this position on the manifold of the hull.

- Sense for defects in the hull.

- Implement the robot in a simulation software.

- Find the relevant user requirements and uses.

Planning

| Week | Tasks |

|---|---|

| 1 | Initial group set-up and task planing. |

| 2 | Literature research. |

| Reach out to a specialist in the field. | |

| 3 | Research subgoals |

| 4 | Implement subgoals |

| 5 | Implement subgoals |

| Draw conclusions and possible future improvements. | |

| 6 | Create the final presentation. |

| 7 | Finalize the wiki page. |

Users requirements summery

After talking to various companies in the field of ship construction and maintenance, the following requirements were formulated for more efficient ship inspection:

- A small and cost effective system.

- Corrosion detection.

- Dent detection.

- Fracture detection.

- Ability to perform its mission underwater.

- Ability to perform its mission in a timely manner.

State of the art

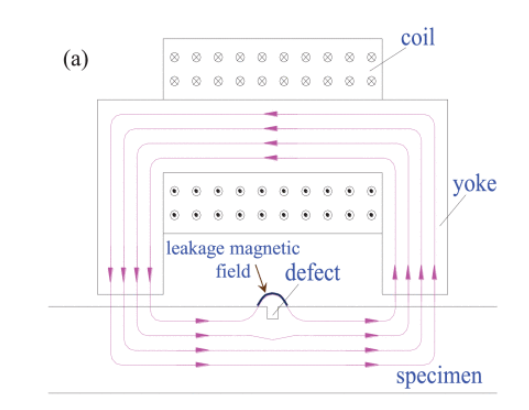

Magnetic Flux Leakage (MFL) detection

Today, the main energy sources that most people rely on, such as gas and oil, are being transported using pipes running in all kinds of environments. It is crucial to maintain the structural integrity of the pipes as a leak can potentially cause a catastrophe. However, it is impossible to inspect hundreds of thousands of kilometers of pipes visually, both due to the sheer size of them and also due to the fact that some of them run under ground or under water. To tackle this problem, engineers came up with a robot that can enter a pipe and scan it from the inside, looking for potential abnormalities. One of the main tools to accomplish this task is using the Magnetic Flux Leakage technique. Since most pipes are built out of steel, which is ferromagnetic, meaning it conducts magnetic fields within itself, it is possible to recognize a defect in the pipe by measuring the magnetic field that passes through a certain point in a pipe[4]. In a similar manner, this technology can be used on the hulls of ships since they are also made of ferromagnetic materials, usually steel and steel alloys. Since the idea of using MFL for ships is quite novel, little research has been done on implementing the system on a robot or similar machine to carry out the inspection. As a result, we base our research on models and experiments that have been conducted on land based objects, such as pipes and train rails. The assumption here is that using the equations that govern those models and experiments, it is possible to adjust the technique to be used under water.

What is Magnetic Flux Leakage?

In order to understand what magnetic flux leakage is and how it can be useful for detecting cracks and metal defects, we first need to understand the concept of magnetic flux in general. Magnetic flux is the measure of the total magnetic field passing through a given area. Mathematically, magnetic flux is defined as : Φ = B × A × cos(θ), where B is the magnetic field strength [Tesla], A is the area [m2], and cos(θ) is the angle between the area and the magnetic field. Magnetic flux is measured in units of Weber and can be created by magnets that are put in-line with the ferromagnetic material, or by using current carrying wires that induce a magnetic field as can be seen in Fig. 1. While most of the magnetic flux is following the shape of the ferromagnetic material, some of it will jump through the gaps that are present in the loop, which is called leakage or fringing. As can be seen in Fig. 1, a surface defect, such as a crack, will cause some of the flux to "leak" or take a different path than the straight line it should usually follow. Small amounts of leakage also happen in the gaps between the flux producing yoke and the specimen itself but those can be neglected as we assume that the yoke would be in full contact with the ship body.

Permeability

The permeability of a material measures how easily it supports the formation and passage of a magnetic field through it. Higher permeability allows for easier passage of magnetic field which increases the flux density. Permeability is used to calculate the flux density flowing through a material, which in turn allows to calculate if any leakage is happening, thus discovering defects.

Guided Ultrasonic Wave inspection

One of the most representative non-destructive testing methods for the inspection of ship hull is the Ultrasonic Testing. In general, this method utilizes the propagation of ultrasonic waves to detect cracks or deformation in a solid body. Within this method, various techniques were developed[2]:

- Ultrasonic Thickness Measurement (UTM): UTM is a non-destructive technique that measures the local thickness of a structure by analyzing the difference in arrival times between direct and reflected waves. This method requires ultrasonic sensors to be in direct contact with the hull surface, which must be cleaned of coatings, corrosion, and biofouling. The final measurement locations are chosen based on a comprehensive survey to ensure they represent the average hull condition.

- Pulse-Echo Ultrasonic Testing (PEUT): PEUT is used to analyze internal defects within a structure. It employs a system where one sensor generates and receives ultrasonic waves. By examining the maximal amplitude and velocity of echoes reflected by defects, the size, location, and nature of the defects can be determined. This technique is commonly used for inspecting hull welds, constituent materials, and measuring thickness.

- Phased Array Ultrasonic Testing (PAUT): PAUT is advantageous for complex structures as it uses an array of ultrasonic elements to focus and scan the area of interest without moving the probe. By controlling each element in the array, the energy of the wavefront can be bent, deflected, and focused to produce cross-sectional images of defects, making it easier to analyze intricate structures.

- Guided Wave Ultrasonic Testing (GWUT): GWUT is designed for long plate-like structures and uses guided ultrasound waves, such as Lamb waves, to detect and locate defects at remote locations. These waves can propagate over significant distances with minimal attenuation and energy loss, making them suitable for inspecting thin-wall structures. However, GWUT may not be applicable to curved structures or those with varying geometries.

- Time-of-Flight Diffraction (TOFD) Ultrasonic Testing: TOFD determines the position and size of defects by measuring the time of flight of ultrasonic pulses rather than the amplitude of the reflected signal. This method uses a pair of ultrasonic probes, with the transmitter emitting a pulse and the receiver picking it up. If a crack is present, the waves are diffracted from the crack tip, allowing the size of the crack to be calculated.

- Air-Coupled Ultrasonic Testing (ACUT): ACUT uses air as the coupling medium instead of traditional liquid couplants like water or gel. This non-contact method eliminates the drawbacks of contact ultrasonic testing, making it more efficient for health monitoring and non-destructive testing. ACUT is particularly suitable for inspecting large-scale hulls made of metal or composite materials.

Logbook

| Name | Total Time (Hours) | Work Description |

|---|---|---|

| Anton Veshnyakov | 7 | Attended lecture (3h), Organized and structured the wiki page (1h), Group meeting (1h), Organizing the planning chart (1h), Research of problem statement and objectives (1h) |

| Luuk Kool | 7 | Attend lecture (3h), search for papers (1h) / meeting (1h)/ research sensors(2h) |

| Anh That Tuan Ton | 5 | Searched for relevant articles (1h), research paper (4h) |

| Luca | 2 | meeting (1h), research on needed components (1h) |

| Simon | 5 | meeting, reading about non-destructive inspection techniques for ship inspection. |

| Name | Total Time (Hours) | Work Description |

|---|---|---|

| Anton Veshnyakov | 10 | Meeting with group and company research (4h), Research of relevant literature (4h), Second group meeting (2h), |

| Luuk Kool | 8 | Meeting with group (4h), meet again (1h), read papers (3h) |

| Anh That Tuan Ton | 7 | Meeting with group (4h), research for additional company (1h), second group meeting (2h) |

| Luca | Meeting with group (4h), messaging companies (1h) | |

| Simon | 9 | meeting with group (4h), communicating with the company Damen (1h) research for the cost of the actual inspections of the ships (4h) |

| Name | Total Time (Hours) | Work Description |

|---|---|---|

| Anton Veshnyakov | 18 | Meeting with group (4h), Robot simulation software research (4h), Meeting with simulation researcher (2h), Second meeting with the group (2h), Research and summery of MFL (6h) |

| Luuk Kool | 4 | Meeting with group (4h) |

| Anh That Tuan Ton | 12 | Meeting with group (4h), second meeting with group (2h), research on ultrasonic testing methods (4h), study other state of the art papers (2h) |

| Luca | Meeting with group(4h), getting familiar with gazebo (3h), creating a 3d model for the robot(1h) | |

| Simon |

| Name | Total Time (Hours) | Work Description |

|---|---|---|

| Anton Veshnyakov | ||

| Luuk Kool | ||

| Anh That Tuan Ton | ||

| Luca | ||

| Simon |

| Name | Total Time (Hours) | Work Description |

|---|---|---|

| Anton Veshnyakov | ||

| Luuk Kool | ||

| Anh That Tuan Ton | ||

| Luca | ||

| Simon |

| Name | Total Time (Hours) | Work Description |

|---|---|---|

| Anton Veshnyakov | ||

| Luuk Kool | ||

| Anh That Tuan Ton | ||

| Luca | ||

| Simon |

| Name | Total Time (Hours) | Work Description |

|---|---|---|

| Anton Veshnyakov | ||

| Luuk Kool | ||

| Anh That Tuan Ton | ||

| Luca | ||

| Simon |

Sensors

Hull

Camera for visual inspection

ultrasonic for thickness measurements

Rail robot

Determine position along rail:

Estimate position with encoder on the wheel, this will drift due to slip. Position can be reset with periodic magnets in the rail and hall effect sensors.

Inspecting robot

Determine position along line

Determine speed

Determine angle

Determine depth

Might be possible to track these with an imu on the robot, subtracting with an imu on the rail robot to compensate for the movement of the ship. Can work in conjunction with an encoder on the wheels or a mapping to the ship topology for more accurate results (kalman filter)

chains?

Articles summary

https://tuenl-my.sharepoint.com/:w:/r/personal/a_ton_that_tuan_anh_student_tue_nl/Documents/Documents/Year%203/Quartile%203/0LAUK0/Article%20summary.docx?d=w072622aab5a34691aa5c9248b16dc866&csf=1&web=1&e=gP4b5P

Simulation software

Simulink 3D animation can be used. This system can interact in Unreal Engine.

Documentation:

https://nl.mathworks.com/products/3d-animation.html https://nl.mathworks.com/help/driving/unreal-engine-scenario-simulation.html https://nl.mathworks.com/videos/series/using-unreal-engine-with-simulink.html https://nl.mathworks.com/help/vdynblks/ug/customize-scenes-using-simulink-and-unreal-editor.html

Gazebo can also be used for simulations. It is open source. https://gazebosim.org/home

Bibliography

- ↑ Song, C., Cui, W. Review of Underwater Ship Hull Cleaning Technologies. J. Marine. Sci. Appl. 19, 415–429 (2020). https://doi.org/10.1007/s11804-020-00157-z

- ↑ 2.0 2.1 Bosen Lin, Xinghui Dong, Ship hull inspection: A survey, Ocean Engineering, Volume 289, Part 1, 2023, 116281, ISSN 0029-8018, https://doi.org/10.1016/j.oceaneng.2023.116281.

- ↑ E. Li, Y. Chen, Z. Yuan and J. Wang, "Train Wheel Magnetic Flux Leakage Testing Method Based on Local Magnetization Enhancement," in IEEE Transactions on Instrumentation and Measurement, vol. 72, pp. 1-9, 2023, Art no. 6002409, doi: 10.1109/TIM.2023.3251393.

- ↑ Y. Long et al., "A Novel Crack Quantification Method for Ultra-High-Definition Magnetic Flux Leakage Detection in Pipeline Inspection," in IEEE Sensors Journal, vol. 22, no. 16, pp. 16402-16413, 15 Aug.15, 2022, doi: 10.1109/JSEN.2022.3190684.

- ↑ Ferreira, C.Z., Yuri, G., Conte, C., Avila, J.P., Pereira, R.C., Morais, T., & Ribeiro, C. (2013). UNDERWATER ROBOTIC VEHICLE FOR SHIP HULL INSPECTION: CONTROL SYSTEM ARCHITECTURE.

- ↑ Cardaillac, Alexandre & Skjetne, Roger & Ludvigsen, Martin. (2024). ROV-Based Autonomous Maneuvering for Ship Hull Inspection with Coverage Monitoring. Journal of Intelligent & Robotic Systems. 110. 10.1007/s10846-024-02095-2.

- ↑ Negahdaripour, Shahriar & Firoozfam, Pezhman. (2006). An ROV Stereovision System for Ship-Hull Inspection. Oceanic Engineering, IEEE Journal of. 31. 551 - 564. 10.1109/JOE.2005.851391.

- ↑ A. F. Ali and M. R. Arshad, "Ship Hull Inspection using Remotely Operated Vehicle," 2022 IEEE 9th International Conference on Underwater System Technology: Theory and Applications (USYS), Kuala Lumpur, Malaysia, 2022, pp. 1-4, doi: 10.1109/USYS56283.2022.10072609. keywords: {Underwater cables;Visualization;Remotely guided vehicles;Prototypes;Inspection;Sensors;Safety;Remotely Operated Vehicle;Ship Hull Inspection;Unmanned Underwater Vehicle},

- ↑ Li, J., He, Y., Tao, W. (2025). Design and Implementation of a Modular Underwater Brush-Clearing Robot and Its Observation Module. In: Pham, D.T., Lei, Y., Lou, Y. (eds) Mechanical Design and Simulation: Exploring Innovations for the Future. MDS 2024. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-97-7887-4_35