PRE2024 3 Group5: Difference between revisions

Tag: 2017 source edit |

|||

| (91 intermediate revisions by 5 users not shown) | |||

| Line 1: | Line 1: | ||

== '''General Notes''' == | <div class="floatleft" style="width: 85%; margin-left: auto; margin-right: auto;"> | ||

<!-- == '''General Notes''' == | |||

'''TRIDENT''' ('''T'''actical '''R'''obotic '''I'''nspection & '''D'''etection for '''E'''nhanced '''N'''autical-hull '''T'''esting) | '''TRIDENT''' ('''T'''actical '''R'''obotic '''I'''nspection & '''D'''etection for '''E'''nhanced '''N'''autical-hull '''T'''esting) | ||

| Line 32: | Line 33: | ||

<u>Movement & Sensor integration:</u> Anton and Anh will inform Luca and Luuk about how fast the robot can travel for robust crack detection. (Look at eddifys site) | <u>Movement & Sensor integration:</u> Anton and Anh will inform Luca and Luuk about how fast the robot can travel for robust crack detection. (Look at eddifys site) | ||

<u>Localization & Sensor integration:</u> Anton and Anh will look into how much data can be captured by the robot at once and tell Luuk so he can know how to localize the data on the model of the ship. | <u>Localization & Sensor integration:</u> Anton and Anh will look into how much data can be captured by the robot at once and tell Luuk so he can know how to localize the data on the model of the ship. --> | ||

== '''Group Members''' == | == '''Group Members''' == | ||

| Line 69: | Line 70: | ||

== '''Problem Statement''' == | == '''Problem Statement''' == | ||

The hull of an ocean-going vessel is subjected to immense forces and the unforgiving conditions of the ocean. As a result, these vessels must undergo hull inspections twice within every five-year period in a dry dock. These regulations originate from the SOLAS convention and are overseen by the Maritime Safety Committee of the IMO<ref>International Maritime Organization. (n.d.). ''Maritime Safety Committee (MSC)''. IMO. Retrieved March 15, 2025, from <nowiki>https://www.imo.org/en/MediaCentre/MeetingSummaries/Pages/MSC-Default.aspx</nowiki></ref>. For bulk carriers and oil tankers, an example is Resolution MSC.461(101), which mandates that their hulls be inspected twice every five years in a dry dock, with certain exceptions<ref name=":3" />. | The hull of an ocean-going vessel is subjected to immense forces and the unforgiving conditions of the ocean. As a result, these vessels must undergo hull inspections twice within every five-year period in a dry dock. These regulations originate from the SOLAS convention and are overseen by the Maritime Safety Committee of the IMO<ref>International Maritime Organization. (n.d.). ''Maritime Safety Committee (MSC)''. IMO. Retrieved March 15, 2025, from <nowiki>https://www.imo.org/en/MediaCentre/MeetingSummaries/Pages/MSC-Default.aspx</nowiki></ref>. For bulk carriers and oil tankers, an example is Resolution MSC.461(101), which mandates that their hulls be inspected twice every five years in a dry dock, with certain exceptions<ref name=":3">THE MARITIME SAFETY COMMITTEE. (2019). RESOLUTION MSC.461(101) (adopted on 13 June 2019) AMENDMENTS TO THE INTERNATIONAL CODE FOR THE ENHANCED PROGRAMME OF INSPECTIONS DURING SURVEYS OF BULK CARRIERS AND OIL TANKERS, 2011 (2011 ESP CODE). https://wwwcdn.imo.org/localresources/en/KnowledgeCentre/IndexofIMOResolutions/MSCResolutions/MSC.461(101).pdf</ref>. | ||

A key challenge for shipyards conducting these inspections is the inability to accurately predict how long a vessel will remain in dry dock. This uncertainty stems from what the inspection would uncover, as the extent of necessary repairs remains unknown until the inspection | A key challenge for shipyards conducting these inspections is the inability to accurately predict how long a vessel will remain in dry dock. This uncertainty stems from what the inspection would uncover, as the extent of necessary repairs remains unknown until the inspection process is completed. Consequently, it is difficult for shipyards to efficiently plan and allocate their dry dock facilities. | ||

To mitigate this issue, it would be advantageous for shipyards to conduct preliminary inspections that identify serious structural concerns in advance. This proactive approach would allow shipyards to anticipate potential repair needs, improve scheduling, and optimize dry dock usage. | To mitigate this issue, it would be advantageous for shipyards to conduct preliminary inspections that identify serious structural concerns in advance. This proactive approach would allow shipyards to anticipate potential repair needs, improve scheduling, and optimize dry dock usage. | ||

| Line 77: | Line 78: | ||

[https://www.eddyfi.com/en/application/ships Non Destructive Testing on Ships & Boats – Marine NDT | Eddyfi] - can be integrated into the problem statement as it is nicely worded. --> | [https://www.eddyfi.com/en/application/ships Non Destructive Testing on Ships & Boats – Marine NDT | Eddyfi] - can be integrated into the problem statement as it is nicely worded. --> | ||

<!--== '''Deliverable and goals (Maybe some small tweaks)''' == | |||

== '''Deliverable and goals (Maybe some small tweaks)''' == | |||

The deliverable of this project will be a simulation of a robot that inspects the hulls of ships. This simulation will include the sensing part of a robot (measure its location and dynamics, measure the hull integrity and process it), but will not include actuators such as wheels or thrusters. The simulation should work for every (smooth) model of a ship hull. | The deliverable of this project will be a simulation of a robot that inspects the hulls of ships. This simulation will include the sensing part of a robot (measure its location and dynamics, measure the hull integrity and process it), but will not include actuators such as wheels or thrusters. The simulation should work for every (smooth) model of a ship hull. | ||

| Line 86: | Line 86: | ||

* Research non destructive testing for observing a hull underwater. | * Research non destructive testing for observing a hull underwater. | ||

* Implement movement of the robot in a simulation software. | * Implement movement of the robot in a simulation software. | ||

* Find the relevant user requirements and uses. | * Find the relevant user requirements and uses.--> | ||

<!--== '''Objectives''' == | <!--== '''Objectives''' == | ||

In order to demonstrate that the system is feasible, usable, and needed, the following steps will be taken: | In order to demonstrate that the system is feasible, usable, and needed, the following steps will be taken: | ||

| Line 95: | Line 94: | ||

* The impact of delayed defect discovery on the turn around time of a ship. | * The impact of delayed defect discovery on the turn around time of a ship. | ||

* Develop the control software needed to execute the mission.--> | * Develop the control software needed to execute the mission.--> | ||

<!--== '''Planning''' == | |||

== '''Planning''' == | |||

{| class="wikitable" | {| class="wikitable" | ||

|+ | |+ | ||

| Line 128: | Line 126: | ||

|7 | |7 | ||

|Finalize the wiki page. | |Finalize the wiki page. | ||

|} | |}--> | ||

<!--== '''Questions for USErs''' == | <!--== '''Questions for USErs''' == | ||

| Line 145: | Line 142: | ||

# What hull issues are ship owners most concerned with, and which aspects still require human inspection?--> | # What hull issues are ship owners most concerned with, and which aspects still require human inspection?--> | ||

== '''User Interview''' == | |||

== '''User | |||

=== Damen Group === | === Damen Group === | ||

To better understand what the industry, and thus the users of this product, would want, it was decided to reach out to the Damen Group here in the Netherlands because of their vast knowledge in building, inspecting, and using dry docks. | To better understand what the industry, and thus the users of this product, would want, it was decided to reach out to the Damen Group here in the Netherlands because of their vast knowledge in building, inspecting, and using dry docks. | ||

After reaching out to them we came into | After reaching out to them we came into contact with Klaas Kuper how is a Area Sales Manger of the Netherlands, Poland and the Baltic states. Mr. Kuper kindly answered our questions via the email and invited us for a teams meeting which we gladly accepted. | ||

In the team meeting, we discussed the potential use cases for an underwater hull inspection robot. Specifically, we explored the advantages of a survey robot that can assess the structural integrity of a ship's hull with greater accuracy than the current robots, which rely on cameras. | In the team meeting, we discussed the potential use cases for an underwater hull inspection robot. Specifically, we explored the advantages of a survey robot that can assess the structural integrity of a ship's hull with greater accuracy than the current robots, which rely on cameras. | ||

| Line 210: | Line 206: | ||

== '''Users requirements summery''' == | == '''Users requirements summery''' == | ||

After talking to various companies in the field of ship construction and maintenance, the following requirements were formulated for the different users. | The primary users for this product would be the ship owners and the shipyards. | ||

The shipyards want to keep the cost as low as possible since they are the ones paying for the preliminary inspection. For this inspection, it is important to the shipyards that the data collected allows them to make an informed prediction about how long the vessel will remain in dry dock and what materials will be needed to repair the hull. The required data includes measurements of hull thickness as well as information on both superficial and internal metallurgical fractures. | |||

Shipowners and operators have different priorities than shipyard owners. Their main concern is the amount of time the vessel will be out of service for the inspection. Minimizing inspection time is a top priority for them. Ideally, the inspection would be carried out while the ship is docked in port or waiting to enter, to avoid disrupting operations. For shipowners in particular, it is also important that inspections utilize non-destructive testing methods to prevent any damage to the vessel. | |||

Secondary users could include insurance companies or potential buyers of the vessel. Their requirements would align closely with those of the shipyard owners, as cost is also a significant factor for them—especially since the inspection is not essential for their purposes, but rather an added advantage. | |||

<!--After talking to various companies in the field of ship construction and maintenance, the following requirements were formulated for the different users. | |||

The shipyards: | The shipyards: | ||

| Line 216: | Line 220: | ||

* Cost effective system. | * Cost effective system. | ||

* Corrosion detection. | * Corrosion detection. | ||

* superficial and inner metallurgical fracture observation. | * superficial and inner metallurgical fracture observation. | ||

The ship owner: | The ship owner: | ||

* Time-effective to the point that it does not disrupt the normal shipping process. (that it can be done while a ship is loading/unloading or while it is waiting to dock) | * Time-effective to the point that it does not disrupt the normal shipping process. (that it can be done while a ship is loading/unloading or while it is waiting to dock) | ||

* That the test are Non destructive. | * That the test are Non destructive. | ||

--> | |||

[[File:Large class crawler.jpg|thumb|366x366px|This is a VT-M480 Crawler capable of hull inspections from Eddyfi. Capable of using alternating current field measurements and ultrasound testing<ref>Eddyfi. (n.d.). ''VT-M460, Large Class Crawler''. <nowiki>https://www.eddyfi.com/doc/ProductsDetails/Magg-480.jpg</nowiki></ref><ref name=":9">''Eddyfi Technologies VersaTrax<sup>TM</sup> inspection crawlers''. (n.d.). Eddyfi. Retrieved March 3, 2025, from <nowiki>https://www.eddyfi.com/en/product/versatrax-inspection-crawlers#OnSpec</nowiki></ref>.]] | |||

== '''State of the art''' == | |||

The current state of the art for remote underwater inspections can be subdivided into two types of submersibles, Hull crawlers and free-floating submersibles. The main difference between these technologies is that free-floating submersibles have a greater mobility and can better reach the entirety of the hull of a vessel, whereas hull crawlers have a distinct advantage when it comes to preforming testing onto the hull of a vessel because it makes direct contact with the hull. | |||

==== Hull crawler ==== | |||

Two examples of state of the art crawlers are the MAG Crawler of Deep Trekker<ref name=":10">''MAG Utility Crawler For Sale | Deep trekker''. (n.d.). Deep Trekker. Retrieved March 13, 2025, from <nowiki>https://www.deeptrekker.com/products/utility-crawlers/dt640-mag-utility-crawler</nowiki></ref> and the VERSATRAX M480 of Eddyfi<ref name=":9" />. These crawlers use magnetic forces to attach themselves to metal structures like the hull of ships. This gives the crawlers also a distinct advantage above free-floating submersibles because these crawlers can both operate above and below the waterline as long as the can attach themselves to a ferrous surfaces. | |||

With there close proximity to the hull these robots typically use a type of ultrasound and or a magnetic based probe which usually a alternating current field measurement sensor (ACFM), and while these robots are also usually equipped with cameras for visual inspection it is not there strongest point because of the aforementioned mobility of these robots. | |||

[[File:Deep trekker dt640 mag magnetic crawler wireframe.webp|thumb|367x367px|Wire diagram of the MAG crawler of Deep Trekker<ref name=":10" />.]] | |||

==== Deep Trekker MAG Crawler ==== | |||

The MAG Crawler of Deep Trekker is a battery-operated crawler that uses a pair of rear earth magnetic wheels to move around. While the robot is battery-operated it still needs a tether for data transmission to a control station for operation. This is because the radio signals which are usually used to operate remote controlled vehicles like drones attenuate significantly faster in water then in air. For this reason, almost all remote-controlled submersibles use a tether to stay connected to control station from which they are operated. | |||

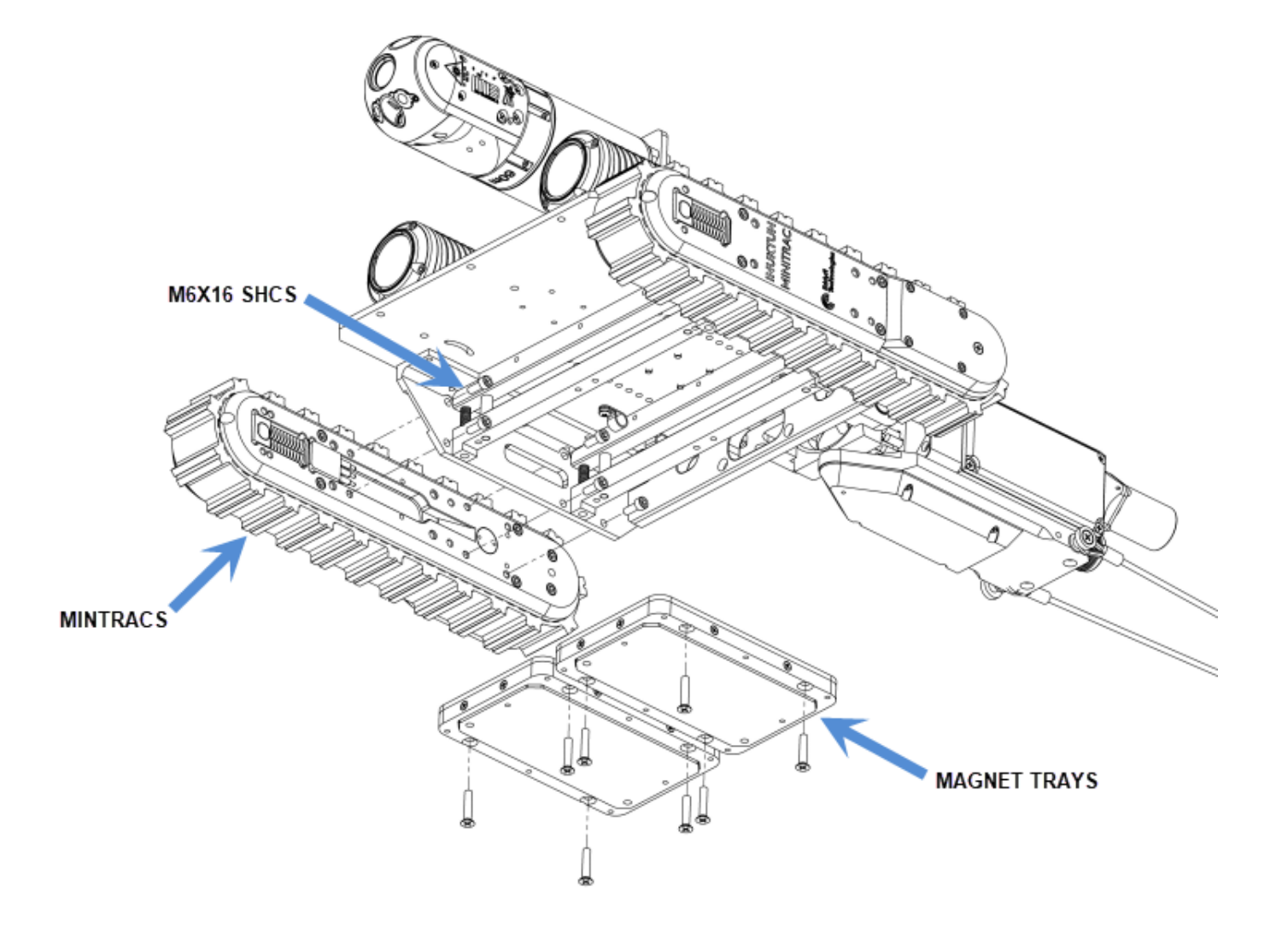

The MAG Crawler has a footprint of 710 mm by 406 mm with a height of 228 mm and a mass of 16.6 kg. The robot is rated for a depth of 50 meter and the tether has a maximum length of 400 meters<ref name=":10" />. It comes standard equipped with a camera and can be equipped with other tools and sensor. These can be mounted on top of the frond side of the robot. This makes it more than suitable of inspecting small ocean-going vessels. The biggest drawback of the MAG crawler approach to crawlers is that it has a limited operational time because of the battery which makes it more difficult to inspect larger ships and to equip it with more energy intensive probing like ACFM. [[File:Bottem Magnets of the VT-M460.png|thumb|281x281px|Underside of the VT-M480 depicting the removal of the magnet holders on the bottom and the track system on the side.<ref name=":11">Eddyfi Technologies. (2023). Getting started with VERSATRAXTM M480. In ''Eddyfi''. Retrieved March 16, 2025, from <nowiki>https://content.eddyfi.com/m/5ac27488f7ff1423/original/VersaTrax-M480-User-Manual.pdf?_gl=1*2hsnay*_ga*MTc1MTQ4MjY0LjE3NDQxNDE5NjE.*_ga_HHBGC3FWLF*MTc0NDI4NDAzMy4zLjAuMTc0NDI4NDAzMy42MC4wLjExMDk2OTA1OA..*_ga_Q4YHE7GCQH*MTc0NDI4NDAzMy4yLjAuMTc0NDI4NDAzMy42MC4wLjA</nowiki>.</ref>]] | |||

==== VersaTrax VT-M480 (Eddyfi Technologies) ==== | |||

he VersaTrax M480 from Eddyfi Technologies is a high-end, magnetically adhering crawler designed for more advanced inspections then the MAG Crawler on large steel structures such as ship hulls, storage tanks, and offshore platforms. Like other hull crawlers, it uses rare earth magnets to secure itself to ferrous surfaces, allowing it to operate on vertical and inverted surfaces both above and below the waterline. | |||

The crawler’s chassis is robust and designed to accommodate vertical payloads of up to 24 kg. The robot itself is around 480mm wide and around a mass of 36 kg<ref name=":11" />, with the length dependent on the configuration. It uses tracked propulsion for movement which gives it greater traction than the wheel-based crawlers. The magnetic adhesion in combination with the tracked propulsion enables the vehicle to support heavier inspection payloads while maintaining a stable position on the inspection surface. | |||

The VT-M480 is powered through a tethered system that supplies high voltage DC power (400 VDC) and supports data transmission for camera feeds, control signals and real-time probing information. Because of this tether-based design, the VT-M480 can operate at depths up to 60 meters and has a maximum tether length of 1000 meters<ref name=":11" />, making it suitable for inspecting large, ocean-going vessels. It is controlled via a surface station using Eddyfi’s ICON™ software, which also handles real-time HD video, camera control, and NDT data logging. | |||

Like the MAG Crawler, the VT-M480’s close contact with the hull allows it to support a range of non-destructive testing tools. These include for the VersaTrax series ultrasonic thickness probes, eddy current arrays, and alternating current field measurement (ACFM) sensors<ref>Eddyfi Technologies. (n.d.). Remote visual inspection and ultrasonic testing for corrosion assessment. In ''Eddyfi''. Retrieved March 16, 2025, from <nowiki>https://content.eddyfi.com/m/4ab1dcdcf15db316/original/VersaTrax-NDT-Technical-Specification-Sheet.pdf?_gl=1*2on9at*_ga*MTc1MTQ4MjY0LjE3NDQxNDE5NjE.*_ga_HHBGC3FWLF*MTc0NDE0MTk2MC4xLjEuMTc0NDE0MjE3OS4xOS4wLjQ3MjgxNjczOQ..*_ga_Q4YHE7GCQH*MTc0NDE0MTk2MC4xLjEuMTc0NDE0MjE3OS4xOS4wLjA</nowiki>.</ref>. | |||

Overall, the VT-M480’s combination of strong adhesion, heavy payload support, high-quality imaging, and NDT integration make it one of the most capable and versatile hull crawlers available on the market today, particularly well-suited for thorough and reliable hull inspections on large vessels.[[File:Blueye X1.webp|thumb|The Blueye made X1 one-man portable ROV to interact with the underwater environment. Quick and user-friendly inspection of your assets below the surface<ref>Blueye Robotics. (n.d.). ''Blueye X1 | Underwater drone with gripper''. <nowiki>https://www.blueyerobotics.com/rov/x1</nowiki></ref>.]] | |||

=== Free-floating submersible === | |||

Free-floating submersibles, often referred to as ROVs (Remotely Operated Vehicles), inspection platforms that can navigate freely through the water column. Their primary advantage over hull crawlers lies in their superior mobility and ability to access difficult-to-reach areas, including complex geometry sections of ships where hull crawlers can’t navigate over. These submersibles are not reliant on direct contact with the hull, allowing them to inspect both ferrous and non-ferrous surfaces. However, because they lack physical attachment to the structure, they are generally not used for conducting physical tests like ultrasonic thickness measurement or ACFM, which require stable surface contact. | |||

Most free-floating ROVs are equipped with high-definition cameras, onboard lighting, and sensors for navigation and imaging. Some models also support sonar systems and limited payloads for environmental monitoring. Their control is typically achieved through a tether that transmits video, command signals and sometimes also power. Some newer models are experimenting with wireless communications in water<ref>''Achieving 1-Mbps/300-m underwater transmission and wireless remotely operated vehicle (ROV) using underwater acoustic communication- Progress towards the Extreme Coverage Extension that 6G-IOWN is aiming for - | Press Release | NTT''. (2022, November 1). NTT | Nippon Telegraph and Telephone Corporation. <nowiki>https://group.ntt/en/newsrelease/2022/11/01/221101a.html</nowiki></ref>. | |||

== '''Our concept''' == | |||

=== The idea === | |||

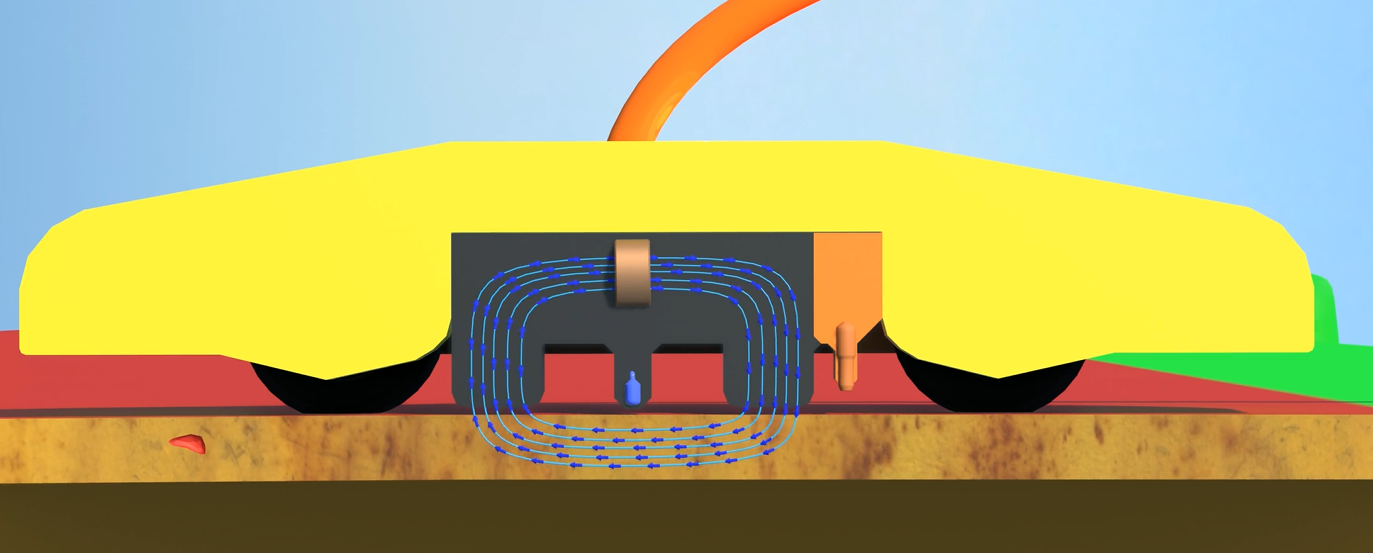

[[File:Robot crossection.png|thumb|362x362px|Crossection of the robot model. The grey part is the elctromagnet, the blue piece below that is the MFL sensor, and the orange piece on the right is the ultrasonic sensor.]]To solve the problem of uncertainties, the team decided to create a robot that could do preliminary inspections. This would ensure that the dry-docked inspectors knew what they would have to deal with. User research showed that the most common hull defects are cracks, dents, punctures, and cavitations. Due to this, it was decided that the team would create a robot that would be able to detect those defects. State of the art showed that there are two main ways of inspecting the ship, either with a hull crawler or with a free-floating submersible. The hull crawler was chosen as the best design because the sensors that detect the most common defects need to be very close to the hull of the ship. This meant that the free-floating submersible was not a good option. The sensors that can detect hull defects are the ultrasonic sensor, the AC field measurement sensor, and the magnetic flux leakage sensor. The last two sensors both use magnetic fields to detect defects. The big difference is in the field they create; the AC field measurement sensor needs an alternating field, and the magnetic flux leakage sensor uses a constant magnetic field. Due to the properties of magnetic fields, both of those sensors can operate when lifted slightly off the hull, while the ultrasound needs to touch the hull to operate. For these reasons, the magnetic flux leakage sensor was chosen as the main sensor. The ultrasonic sensor was chosen as the secondary sensor and would only be used once a crack is already detected by the main sensor. Another reason why the magnetic flux leakage sensor was chosen was because the robot needs to stick to the hull. The robot can be pushed against the hull with either magnetic attraction or propellers, and because the magnetic flux leakage sensor already needs a big magnetic field, the best option was to use that magnetic field for sticking to the hull as well. To move over the hull, the robot uses wheels, which can easily be steered to go in a specific direction. When the wheels have springs, they also allow driving over bigger bumps without being stopped. | |||

The final design consists of a smooth outer shell, four wheels, a magnetic flux leakage sensor, an ultrasonic sensor, an electromagnet, and a tether. The outer shell has a streamlined shape that reduces drag while driving through the water. Furthermore, the four wheels are located on the corners of the robot, and all allow rotation for better movability. The electromagnet and the sensor are placed in the center of the robot because they are heavy, and by having them in the center, the robot stays balanced. The electromagnet and the magnetic flux leakage sensor are placed slightly in front of the center, and the ultrasonic sensor is placed right after them. This setup allows the magnetic flux leakage sensor to detect the crack first, and the ultrasonic sensor can be used right after that. Lastly, the robot is connected with a tether to the control station. This tether provides the robot with power and can also be used to send data to and from the robot. | |||

=== Robot operation === | |||

The robot would operate as follows. First, an operator would take the robot to the hull off the ship. The operator then places the robot in a predetermined location on the ship. The coordinates of this location are known to the robot and operator and can later be used for localization. By placing the robot on the hull, the robot magnet turns on, and the robot would stick to the hull. The operator would then move back to the control station and press the start button. After pressing the start button, the robot would initialize its variables and start driving. The robot would drive in a vertical zigzag pattern over the ship. When the robot reaches an edge, it turns 90 degrees, moves a bit, and turns 90 degrees back. This pattern would repeat over the entire hull or a specified part. While driving over the hull, the robot uses the Magnetic Flux Leakage sensor to check for any cracks or other hull problems. When a crack is found, the crack position and the Magnetic Flux Leakage data are saved in the robot. The robot then moves a bit forward and positions the ultrasonic sensor above the crack and uses the sensor the take another measurement. This measurement is also saved, and together with the other crack data, it is sent to the operator over the tether. The operator then receives a notification that a crack is found and that data is available. After sending the data, the robot would continue its course and keep sensing for more hull defects. During operation, the robot could be stopped at any time and removed from the hull. The robot's scanning area could also be changed while the robot is operating. When the robot finishes scanning the specified area, it would stop all its movement and upload all the data to the control station. In the control station, a full list of all cracks with data is created and shared with the operator. After this, the operator can go back to the robot, turn off the magnet, and grab the robot from the hull. The robot can then be stored for later use. | |||

== '''Robot forces''' == | |||

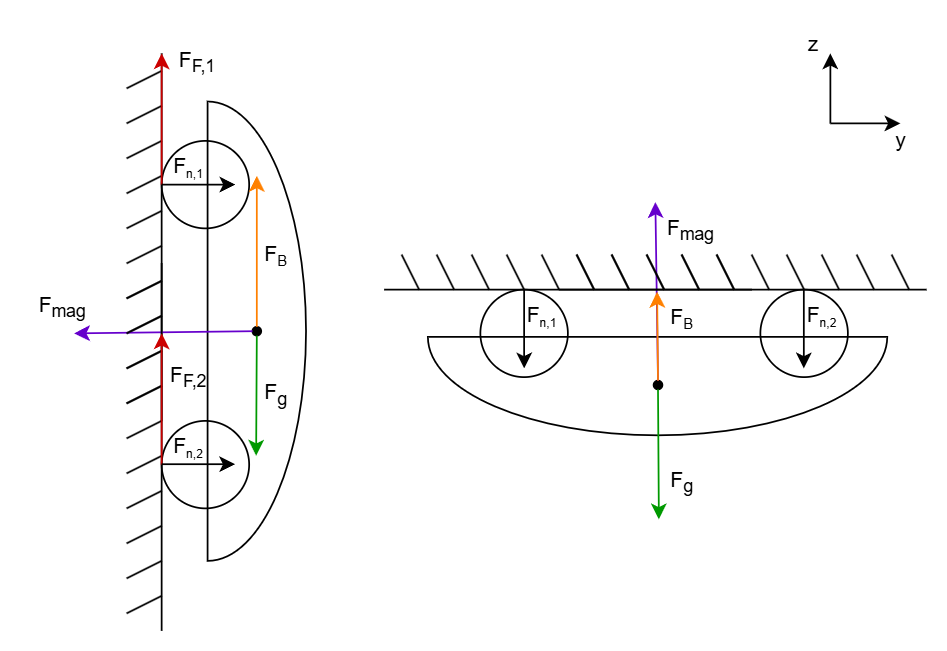

[[File:USE Forces.png|thumb|456x456px|Figure of the forces acting on the robot with a 90 degree and 180 degree hull]] | |||

tTo check whether it is possible to use a(n) (electro)magnet, a force analysis was done. The force analysis tries to specify the needed magnetic force in order for the robot to stick to the hull and keep its position. This analysis is done for two scenarios one where the robot is placed against a vertical hull and one where the robot is place on the underside of the hull. For the analysis the robot was assumed to have a mass of 20 kg and a volume of 0.026 m<sup>3</sup>. The volume was obtained by taking a rough estimate of the volume of the robot 3d model. For both scenarios the velocity and acceleration are assumed to be zero. | |||

The first scenario can be characterized by the following equations. | |||

(1) ΣF<sub>z</sub> = F<sub>F</sub> + F<sub>B</sub> - F<sub>g</sub> = 0 | |||

(2) ΣF<sub>y</sub> = F<sub>n</sub> - F<sub>mag</sub> = 0 | |||

(3) F<sub>F</sub> = F<sub>F,1</sub> + F<sub>F,2</sub> = μF<sub>n</sub> | |||

(4) F<sub>n</sub> = F<sub>n,1</sub> + F<sub>n,2</sub> | |||

(5) F<sub>g</sub> = mg | |||

(6) FB = ρVg | |||

Where F<sub>F</sub> is the friction force, F<sub>n</sub> is the normal force, F<sub>g</sub> is the gravitational force, F<sub>B</sub> is the buoyancy force, and F<sub>mag</sub> is the magnetic force. The robot mass is represented by m and the robot volume is represented by V. μ is the friction coefficient of the tire, which in this case is set to 0.1. This coefficient is the same as the coefficient of a wet car tire. ρ is the density of water, which is 1000 kg/m<sup>3</sup> at a temperature of 4<sup>o</sup> C. Lastly, g is the gravitational acceleration, which is 9.81 m/s<sup>2</sup>. Solving these formulas gives that the needed magnetic force 588.6 N. Solving the formulas also shows that the friction is in the wrong direction, because the buoyancy force is larger then the gravity. | |||

The second scenario can be characterized in the same way as the first scenario. The only difference is with the sum of the forces in the y and z direction. The resulting equations are described below. | |||

(7) ΣF<sub>z</sub> = F<sub>mag</sub> +F<sub>B</sub> - F<sub>g</sub> - F<sub>n</sub> = 0 | |||

(8) ΣF<sub>y</sub> = 0 | |||

When the buoyancy, the gravity and the magnetic force are in perfect equilibrium the normal force will be zero, because the normal force scales with the resulting force applied on the hull. Given this the magnetic force can be calculated with equation 7. Solving the equations show that the buoyancy force is bigger than the gravitational force, meaning that there is no magnetic force needed. However it is always useful to have a magnetic force in the up direction to make sure the robot stays still when being pushed by currents. | |||

In conclusion, the magnetic force needs to be at least 588.6 N to fulfill the requirements in scenario one. This amount is reasonable (proof can be read in the next section), meaning that the concept of using a magnet to stick to the hull is useable. | |||

== '''Magnetic Flux Leakage (MFL) detection''' == | == '''Magnetic Flux Leakage (MFL) detection''' == | ||

| Line 234: | Line 301: | ||

Today, the main energy sources that most people rely on, such as gas and oil, are being transported using pipes running in all kinds of environments. It is crucial to maintain the structural integrity of the pipes as a leak can potentially cause a catastrophe. However, it is impossible to inspect hundreds of thousands of kilometers of pipes visually, both due to the sheer size of them and also due to the fact that some of them run under ground or under water. To tackle this problem, engineers came up with a robot that can enter a pipe and scan it from the inside, looking for potential abnormalities. One of the main tools to accomplish this task is using the Magnetic Flux Leakage technique. Since most pipes are built out of steel, which is ferromagnetic, meaning it conducts magnetic fields within itself, it is possible to recognize a defect in the pipe by measuring the magnetic field that passes through a certain point in a pipe<ref name=":5">Y. Long et al., "A Novel Crack Quantification Method for Ultra-High-Definition Magnetic Flux Leakage Detection in Pipeline Inspection," in IEEE Sensors Journal, vol. 22, no. 16, pp. 16402-16413, 15 Aug.15, 2022, doi: 10.1109/JSEN.2022.3190684.</ref>. In a similar manner, this technology can be used on the hulls of ships since they are also made of ferromagnetic materials, usually steel and steel alloys. Since the idea of using MFL for ships is quite novel, little research has been done on implementing the system on a robot or similar machine to carry out the inspection. As a result, we base our research on models and experiments that have been conducted on land based objects, such as pipes and train rails. The assumption here is that using the equations that govern those models and experiments, it is possible to adjust the technique to be used under water. | Today, the main energy sources that most people rely on, such as gas and oil, are being transported using pipes running in all kinds of environments. It is crucial to maintain the structural integrity of the pipes as a leak can potentially cause a catastrophe. However, it is impossible to inspect hundreds of thousands of kilometers of pipes visually, both due to the sheer size of them and also due to the fact that some of them run under ground or under water. To tackle this problem, engineers came up with a robot that can enter a pipe and scan it from the inside, looking for potential abnormalities. One of the main tools to accomplish this task is using the Magnetic Flux Leakage technique. Since most pipes are built out of steel, which is ferromagnetic, meaning it conducts magnetic fields within itself, it is possible to recognize a defect in the pipe by measuring the magnetic field that passes through a certain point in a pipe<ref name=":5">Y. Long et al., "A Novel Crack Quantification Method for Ultra-High-Definition Magnetic Flux Leakage Detection in Pipeline Inspection," in IEEE Sensors Journal, vol. 22, no. 16, pp. 16402-16413, 15 Aug.15, 2022, doi: 10.1109/JSEN.2022.3190684.</ref>. In a similar manner, this technology can be used on the hulls of ships since they are also made of ferromagnetic materials, usually steel and steel alloys. Since the idea of using MFL for ships is quite novel, little research has been done on implementing the system on a robot or similar machine to carry out the inspection. As a result, we base our research on models and experiments that have been conducted on land based objects, such as pipes and train rails. The assumption here is that using the equations that govern those models and experiments, it is possible to adjust the technique to be used under water. | ||

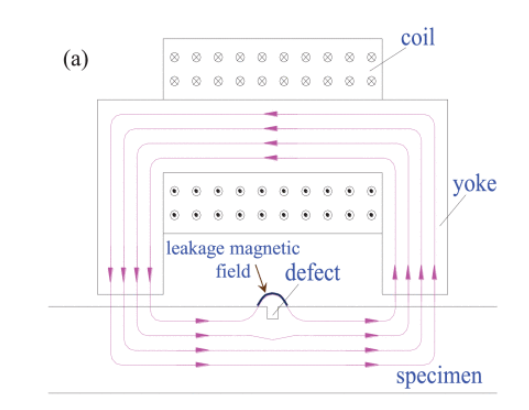

'''<u>What is Magnetic Flux Leakage?</u>''' | === '''<u>What is Magnetic Flux Leakage?</u>''' === | ||

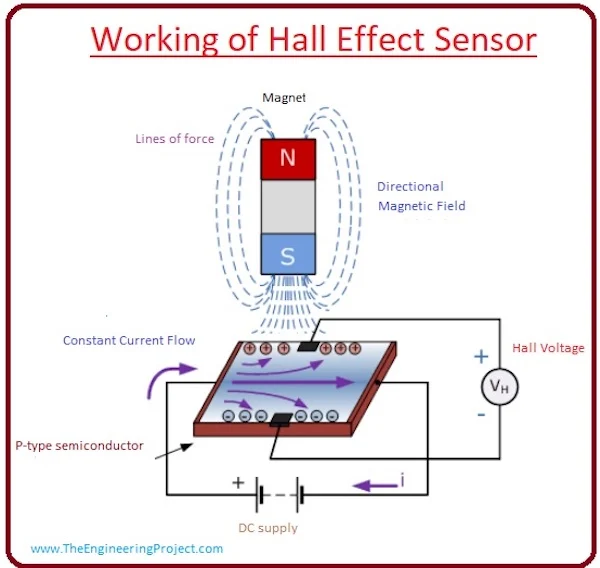

In order to understand what magnetic flux leakage is and how it can be useful for detecting cracks and metal defects, we first need to understand the concept of magnetic flux in general. Magnetic flux is the measure of the total magnetic field passing through a given area. Mathematically, magnetic flux is defined as: '''''Φ = B · A · cos(θ)''''', where '''''B''''' is the magnetic field strength [Tesla], '''''A''''' is the area [m<sup>2</sup>], and '''''cos(θ)''''' is the angle between the area and the magnetic field. Magnetic flux is measured in units of Weber and can be created by magnets that are put in-line with the ferromagnetic material, or by using current carrying wires that induce a magnetic field as can be seen in Figure 1. While most of the magnetic flux is following the shape of the ferromagnetic material, some of it will jump through the gaps that are present in the loop, which is called leakage or fringing. As can be seen in Figure 1, a surface defect, such as a crack, will cause some of the flux to "leak" or take a different path than the straight line it should usually follow. Small amounts of leakage also happen in the gaps between the flux producing yoke and the specimen itself but those can be neglected as they are not usually picked up by the sensors. The sensor used to detect the magnetic field leakage is called a Hall Effect Sensor. | In order to understand what magnetic flux leakage is and how it can be useful for detecting cracks and metal defects, we first need to understand the concept of magnetic flux in general. Magnetic flux is the measure of the total magnetic field passing through a given area. Mathematically, magnetic flux is defined as: '''''Φ = B · A · cos(θ)''''', where '''''B''''' is the magnetic field strength [Tesla], '''''A''''' is the area [m<sup>2</sup>], and '''''cos(θ)''''' is the angle between the area and the magnetic field. Magnetic flux is measured in units of Weber and can be created by magnets that are put in-line with the ferromagnetic material, or by using current carrying wires that induce a magnetic field as can be seen in Figure 1. While most of the magnetic flux is following the shape of the ferromagnetic material, some of it will jump through the gaps that are present in the loop, which is called leakage or fringing. As can be seen in Figure 1, a surface defect, such as a crack, will cause some of the flux to "leak" or take a different path than the straight line it should usually follow. Small amounts of leakage also happen in the gaps between the flux producing yoke and the specimen itself but those can be neglected as they are not usually picked up by the sensors. The sensor used to detect the magnetic field leakage is called a Hall Effect Sensor. | ||

'''<u>Hall Effect Sensor</u>''' | === '''<u>Hall Effect Sensor</u>''' === | ||

[[File:HallEff.png|thumb|Fig 2 | [[File:HallEff.png|thumb|Fig. 2: Hall effect sensor inner workings.<ref>"Roundup: Automotive Hall Effect Sensors Find New Life," ''All About Circuits'', accessed March 19, 2025. [Online]. Available: <nowiki>https://www.allaboutcircuits.com/news/roundup-automotive-hall-effect-sensors-find-new-life/</nowiki></ref>|255x255px]] | ||

To pick up the magnetic leakage from a defect on a surface, a Hall Effect sensor is utilized. The hall effect is the interaction between a current carrying conductor and a perpendicularly moving magnetic field, when the later exerts a force on the moving charge, making it concentrate on one side of the conductor. As a result of that concentration, a voltage can be created and measured on the transverse side of the conductor. By utilized a Hall effect sensor, it is possible to detect not only the presence of a magnetic field, but also its strength, as it would be proportional to the strength of he induced voltage. The Hall Effect voltage is described by the following equation: '''''V<sub>H</sub> = IB / qnd''''', where '''''I''''' is the current through the conductor, '''''B''''' is the magnetic field strength, '''''q''''' is the charge of an electron, '''''n''''' is the charge carrier density, and '''''d''''' is the thickness of the conductor in the direction of the magnetic field. | To pick up the magnetic leakage from a defect on a surface, a Hall Effect sensor is utilized. The hall effect is the interaction between a current carrying conductor and a perpendicularly moving magnetic field, when the later exerts a force on the moving charge, making it concentrate on one side of the conductor. As a result of that concentration, a voltage can be created and measured on the transverse side of the conductor. By utilized a Hall effect sensor, it is possible to detect not only the presence of a magnetic field, but also its strength, as it would be proportional to the strength of he induced voltage. The Hall Effect voltage is described by the following equation: '''''V<sub>H</sub> = IB / qnd''''', where '''''I''''' is the current through the conductor, '''''B''''' is the magnetic field strength, '''''q''''' is the charge of an electron, '''''n''''' is the charge carrier density, and '''''d''''' is the thickness of the conductor in the direction of the magnetic field. | ||

=== '''<u>MFL application in the industries</u>''' === | |||

Magnetic flux leakage (MFL) detection is one of the most popular methods of inspection of structures made out of ferromagnetic materials. It is a nondestructive testing technique which uses magnetic sensitive sensors to detect the magnetic leakage field of defects on both the internal and external surfaces of given structures. <ref>Shi Y, Zhang C, Li R, Cai M, Jia G. Theory and Application of Magnetic Flux Leakage Pipeline Detection. Sensors (Basel). 2015 Dec 10;15(12):31036-55. doi: 10.3390/s151229845. PMID: 26690435; PMCID: PMC4721765.</ref> The inspection of those structure is often important due to the safety and health risk that small fatigue cracks can cause, especially when talking about oil and gas pipes, or the tanks of a oil carrier ship. IN addition to fatigue cracks, MFL can be used to detect such things as corrosion, erosion and metal loss, although there are more reliable and easier methods to go about detecting those defects. For the pipeline reliant industries, MFL is useful as it can be mounted on a special robot that goes inside the pipe and by suing the MFL can detect defects both on the inside and outside of the pipe without requiring a direct human access to the entirety of the pipe. In the train industry, MFL can be used to detect early-stage fatigue cracks on the wheels, which is crucial for the safety of the train and its passengers, as broken wheels can lead to derailments and catastrophic consequences.<ref name=":1" /> | Magnetic flux leakage (MFL) detection is one of the most popular methods of inspection of structures made out of ferromagnetic materials. It is a nondestructive testing technique which uses magnetic sensitive sensors to detect the magnetic leakage field of defects on both the internal and external surfaces of given structures. <ref>Shi Y, Zhang C, Li R, Cai M, Jia G. Theory and Application of Magnetic Flux Leakage Pipeline Detection. Sensors (Basel). 2015 Dec 10;15(12):31036-55. doi: 10.3390/s151229845. PMID: 26690435; PMCID: PMC4721765.</ref> The inspection of those structure is often important due to the safety and health risk that small fatigue cracks can cause, especially when talking about oil and gas pipes, or the tanks of a oil carrier ship. IN addition to fatigue cracks, MFL can be used to detect such things as corrosion, erosion and metal loss, although there are more reliable and easier methods to go about detecting those defects. For the pipeline reliant industries, MFL is useful as it can be mounted on a special robot that goes inside the pipe and by suing the MFL can detect defects both on the inside and outside of the pipe without requiring a direct human access to the entirety of the pipe. In the train industry, MFL can be used to detect early-stage fatigue cracks on the wheels, which is crucial for the safety of the train and its passengers, as broken wheels can lead to derailments and catastrophic consequences.<ref name=":1" /> | ||

'''<u>Influence of crack orientation on MFL</u>''' | === '''<u>Influence of crack orientation on MFL</u>''' === | ||

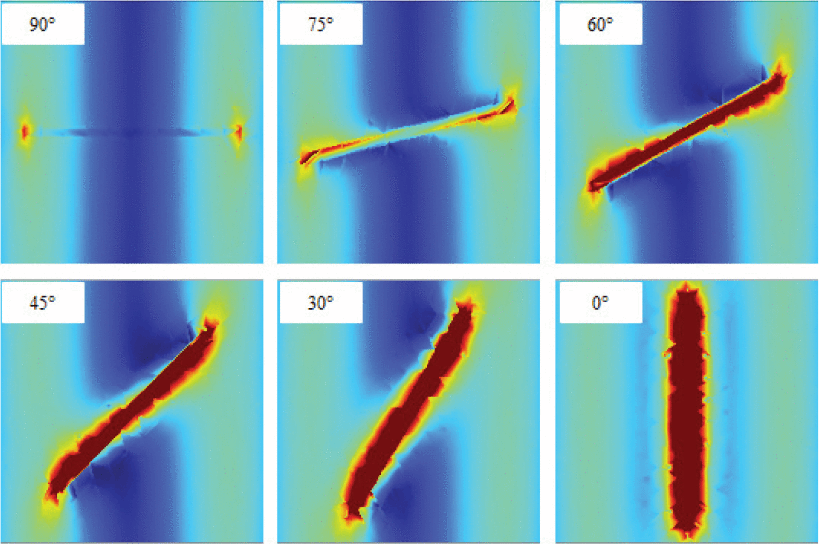

[[File:Crack orientation.png|thumb|281x281px|Fig. 3: MFL scan results of a crack from different angles. <ref name=":2">W. Gong, M. F. Akbar, G. N. Jawad and F. Zhang, "Surface Crack Size Estimation Based on Quantification and Decoupling of Magnetic Flux Leakage (MFL) Signals of Circular Array Sensors," in ''IEEE Sensors Journal'', vol. 24, no. 10, pp. 16752-16762, 15 May15, 2024, doi: 10.1109/JSEN.2024.3379401.</ref>]] | [[File:Crack orientation.png|thumb|281x281px|Fig. 3: MFL scan results of a crack from different angles. <ref name=":2">W. Gong, M. F. Akbar, G. N. Jawad and F. Zhang, "Surface Crack Size Estimation Based on Quantification and Decoupling of Magnetic Flux Leakage (MFL) Signals of Circular Array Sensors," in ''IEEE Sensors Journal'', vol. 24, no. 10, pp. 16752-16762, 15 May15, 2024, doi: 10.1109/JSEN.2024.3379401.</ref>]] | ||

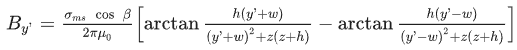

Due to the 3D nature of our world, cracks can be created and then propagate in different direction in the material. When using one MFL sensor it is sometimes hard or impossible to get a strong enough leakage so that it can be detected by the sensor. Additionally, even when using a linear arrangement of of sensors it is still not enough if the crack is perpendicular to the sensor array. <ref name=":2" /> As stated in the research paper <ref name=":2" />, it is advised to use a circular sensor array in order to achieve the best crack detection and orientation. Figure 3 demonstrates the different digitalized read-outs from the MFL sensor with relation to the angle of the crack to the sensors. The difference of the crack detection as a result of its orientation is explained by the following equation: '''''B' = B · cos(β)''''', where '''''B'''''' is the resulting magnetic flux density across the crack, '''''B''''' is the original flux density, and '''''β''''' is the crack's relative angle with respect to the magnetization direction. Additionally, it has been shown that deeper or wider cracks result in stronger leakage fields, as well as changing the amplitude and spatial distribution of the signal, which makes FML highly suitable for detecting cracks <ref>Feng B, Wu J, Tu H, Tang J, Kang Y. A Review of Magnetic Flux Leakage Nondestructive Testing. Materials (Basel). 2022 Oct 20;15(20):7362. doi: 10.3390/ma15207362. PMID: 36295427; PMCID: PMC9610001.</ref>. | Due to the 3D nature of our world, cracks can be created and then propagate in different direction in the material. When using one MFL sensor it is sometimes hard or impossible to get a strong enough leakage so that it can be detected by the sensor. Additionally, even when using a linear arrangement of of sensors it is still not enough if the crack is perpendicular to the sensor array. <ref name=":2" /> As stated in the research paper <ref name=":2" />, it is advised to use a circular sensor array in order to achieve the best crack detection and orientation. Figure 3 demonstrates the different digitalized read-outs from the MFL sensor with relation to the angle of the crack to the sensors. The difference of the crack detection as a result of its orientation is explained by the following equation: '''''B' = B · cos(β)''''', where '''''B'''''' is the resulting magnetic flux density across the crack, '''''B''''' is the original flux density, and '''''β''''' is the crack's relative angle with respect to the magnetization direction. Additionally, it has been shown that deeper or wider cracks result in stronger leakage fields, as well as changing the amplitude and spatial distribution of the signal, which makes FML highly suitable for detecting cracks <ref>Feng B, Wu J, Tu H, Tang J, Kang Y. A Review of Magnetic Flux Leakage Nondestructive Testing. Materials (Basel). 2022 Oct 20;15(20):7362. doi: 10.3390/ma15207362. PMID: 36295427; PMCID: PMC9610001.</ref>. | ||

| Line 253: | Line 318: | ||

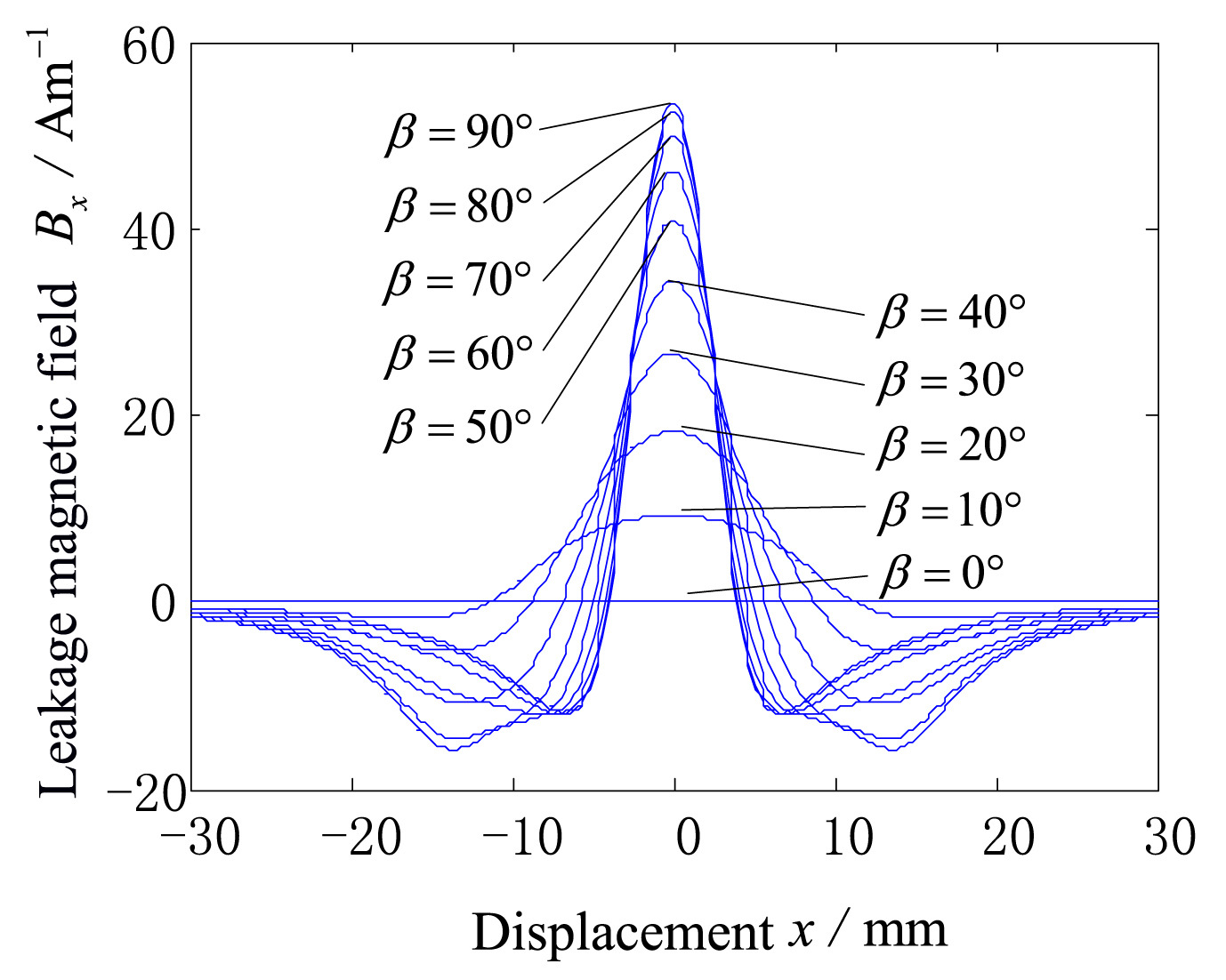

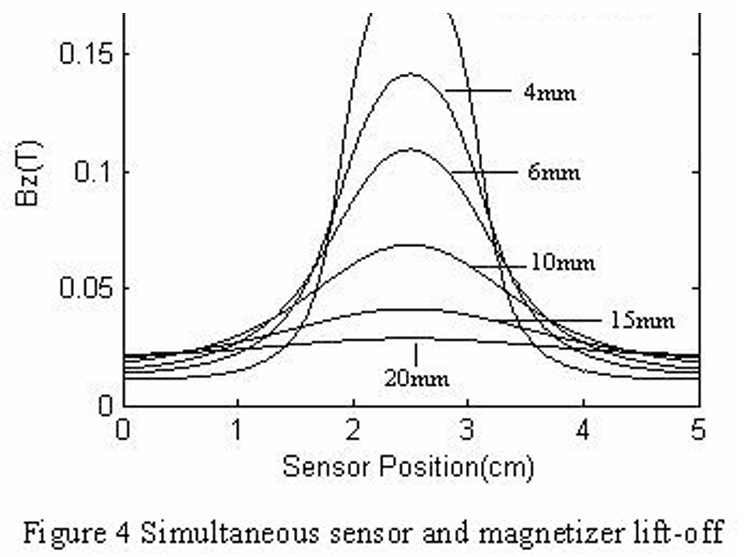

Expanding the equation for the magnetic flux across the crack, the strength of the flux can be expressed as demonstrated in Figure 4. The flux strength relies further on other parameters of the crack, such as its width, length, and depth, where '''β''' is the most important variable <ref name=":0" />. Figure 5 Shows how the orientation of the crack in relation to a linear detector influences the strength of the detected flux leakage. | Expanding the equation for the magnetic flux across the crack, the strength of the flux can be expressed as demonstrated in Figure 4. The flux strength relies further on other parameters of the crack, such as its width, length, and depth, where '''β''' is the most important variable <ref name=":0" />. Figure 5 Shows how the orientation of the crack in relation to a linear detector influences the strength of the detected flux leakage. | ||

'''<u>Sensor placement and Scanning techniques</u>''' | === '''<u>Sensor placement and Scanning techniques</u>''' === | ||

When utilizing MFL for crack detection, there are a variety of different ways to position the sensors. The simplest way is to arrange the sensors in a linear array which allows for a large area coverage while requiring minimal space utilization, making the entire scanner fairly compact. Researchers have built such a sensor array and demonstrated that it can detect cracks in mild steel plates with ease <ref>Mohd Aufa Hadi Putera Zaini, Mohd Mawardi Saari, Nurul A'in Nadzri, Zulkifly Aziz, Detection of crack on a mild steel plate by using a magnetic probe incorporating an array of fluxgate sensors, Materials Today: Proceedings, Volume 109, 2024, Pages 74-80, ISSN 2214-7853, <nowiki>https://doi.org/10.1016/j.matpr.2023.06.428</nowiki>.</ref>. Furthermore, the detection can indicate the depth and orientation of the crack as signals reach sensors at different times. Another way to arrange the sensors is in a circular pattern. As shown in Figure 3, a circular array of sensors will allow not only for crack detection but also for easier orientation detection. But "looking" at a crack from multiple angles, the circular array can at once indicate the crack orientation without the need to swab the whole area, unlike the linearly arranged sensors <ref name=":2" />. Another less common, and as of yet experimental, way to use MFL is called Pulsed MFL, or PMFL. By pulsing the external magnetic field by means of an electromagnet, PMFL offers better defect localization and sizing by using features in the time-frequency domain. A research paper on the topic showed that it is the best solution overall for both on-surface and sub-surface crack detection, which makes it suitable for applications where access is limited to only one side of the inspected surface <ref>Ali Sophian, Gui Yun Tian, Sofiane Zairi, Pulsed magnetic flux leakage techniques for crack detection and characterisation, Sensors and Actuators A: Physical, Volume 125, Issue 2, 2006, Pages 186-191, ISSN 0924-4247, <nowiki>https://doi.org/10.1016/j.sna.2005.07.013</nowiki>.</ref>. | When utilizing MFL for crack detection, there are a variety of different ways to position the sensors. The simplest way is to arrange the sensors in a linear array which allows for a large area coverage while requiring minimal space utilization, making the entire scanner fairly compact. Researchers have built such a sensor array and demonstrated that it can detect cracks in mild steel plates with ease <ref>Mohd Aufa Hadi Putera Zaini, Mohd Mawardi Saari, Nurul A'in Nadzri, Zulkifly Aziz, Detection of crack on a mild steel plate by using a magnetic probe incorporating an array of fluxgate sensors, Materials Today: Proceedings, Volume 109, 2024, Pages 74-80, ISSN 2214-7853, <nowiki>https://doi.org/10.1016/j.matpr.2023.06.428</nowiki>.</ref>. Furthermore, the detection can indicate the depth and orientation of the crack as signals reach sensors at different times. Another way to arrange the sensors is in a circular pattern. As shown in Figure 3, a circular array of sensors will allow not only for crack detection but also for easier orientation detection. But "looking" at a crack from multiple angles, the circular array can at once indicate the crack orientation without the need to swab the whole area, unlike the linearly arranged sensors <ref name=":2" />. Another less common, and as of yet experimental, way to use MFL is called Pulsed MFL, or PMFL. By pulsing the external magnetic field by means of an electromagnet, PMFL offers better defect localization and sizing by using features in the time-frequency domain. A research paper on the topic showed that it is the best solution overall for both on-surface and sub-surface crack detection, which makes it suitable for applications where access is limited to only one side of the inspected surface <ref>Ali Sophian, Gui Yun Tian, Sofiane Zairi, Pulsed magnetic flux leakage techniques for crack detection and characterisation, Sensors and Actuators A: Physical, Volume 125, Issue 2, 2006, Pages 186-191, ISSN 0924-4247, <nowiki>https://doi.org/10.1016/j.sna.2005.07.013</nowiki>.</ref>. | ||

'''<u>Remanent Magnetic Flux Leakage</u>''' | === '''<u>Remanent Magnetic Flux Leakage</u>''' === | ||

Another way to use magnetic flux leakage is to rely on a property of ferromagnetic materials called remanent magnetization. Remanent magnetization occurs when ferromagnetic materials are exposed to strong magnetic fields. When the external magnetic field is removed, instead of going back to being neutrally magnetically charged, ferromagnets will retain some of the magnetic filed and will become "magnetized" themselves <ref name=":6">Haotian Wei, Shaohua Dong, Lushuai Xu, Fan Chen, Hang Zhang, Xingtao Li, Internal inspection method for crack defects in ferromagnetic pipelines under remanent magnetization, Measurement, Volume 242, Part A, 2025, 115907, ISSN 0263-2241, <nowiki>https://doi.org/10.1016/j.measurement.2024.115907</nowiki>.</ref>. When a crack is present in a ferromagnetic material, it may be hard to detect it with regular MFL detection techniques due to the already high magnetic field present in the observed section and the inherent flux leakage that happens in all materials. However, when the external magnetic field is removed but the material remains magnetized, the flux leakage across the crack will be more pronounced in relation to the weakened background magnetization. This allows sensors to pick up any cracks and defects easier, even if their size is fairly small <ref name=":6" />. | Another way to use magnetic flux leakage is to rely on a property of ferromagnetic materials called remanent magnetization. Remanent magnetization occurs when ferromagnetic materials are exposed to strong magnetic fields. When the external magnetic field is removed, instead of going back to being neutrally magnetically charged, ferromagnets will retain some of the magnetic filed and will become "magnetized" themselves <ref name=":6">Haotian Wei, Shaohua Dong, Lushuai Xu, Fan Chen, Hang Zhang, Xingtao Li, Internal inspection method for crack defects in ferromagnetic pipelines under remanent magnetization, Measurement, Volume 242, Part A, 2025, 115907, ISSN 0263-2241, <nowiki>https://doi.org/10.1016/j.measurement.2024.115907</nowiki>.</ref>. When a crack is present in a ferromagnetic material, it may be hard to detect it with regular MFL detection techniques due to the already high magnetic field present in the observed section and the inherent flux leakage that happens in all materials. However, when the external magnetic field is removed but the material remains magnetized, the flux leakage across the crack will be more pronounced in relation to the weakened background magnetization. This allows sensors to pick up any cracks and defects easier, even if their size is fairly small <ref name=":6" />. | ||

'''<u>Current applications</u>''' | === '''<u>Current applications</u>''' === | ||

While being available for some time already and having some substantial research done on it, not many companies have developed MFL sensors that re available of the shelf. The most prominent company to integrate MFL sensors into its products is Eddyfi. According to the company's website, Eddyfi provides the highest performance Non-Destructive Testing (NDT) inspection technologies in the world, helping OEMs, asset owners and service companies enhance productivity, save lives, and protect the environment <ref>Eddyfi Technologies, “About Us.” [Online]. Available: <nowiki>https://www.eddyfi.com/en/aboutus</nowiki>. [Accessed: Mar. 23, 2025].</ref>. | While being available for some time already and having some substantial research done on it, not many companies have developed MFL sensors that re available of the shelf. The most prominent company to integrate MFL sensors into its products is Eddyfi. According to the company's website, Eddyfi provides the highest performance Non-Destructive Testing (NDT) inspection technologies in the world, helping OEMs, asset owners and service companies enhance productivity, save lives, and protect the environment <ref>Eddyfi Technologies, “About Us.” [Online]. Available: <nowiki>https://www.eddyfi.com/en/aboutus</nowiki>. [Accessed: Mar. 23, 2025].</ref>. | ||

| Line 269: | Line 331: | ||

For example, the Pipescan HD is a portable sensor array that can be used for pipe inspections. According to Eddyfi, Pipescan HD is the highest resolution MFL scanner on the market. With a high Probability of Detection (PoD), the Pipescan HD is an effective and reliable pipe inspection solution for corrosion and pitting detection <ref>Eddyfi Technologies, “Pipescan HD.” [Online]. Available: <nowiki>https://www.eddyfi.com/en/product/pipescan-hd</nowiki>. [Accessed: Mar. 23, 2025].</ref>. The scanner module requires almost no surface preparation and no couplant, which is a substance that helps transmit energy. Scanning speed of the Pipescan HD can be up to 1m/s, and it has an adjustable reporting threshold to define the depth at which the scanner works. | For example, the Pipescan HD is a portable sensor array that can be used for pipe inspections. According to Eddyfi, Pipescan HD is the highest resolution MFL scanner on the market. With a high Probability of Detection (PoD), the Pipescan HD is an effective and reliable pipe inspection solution for corrosion and pitting detection <ref>Eddyfi Technologies, “Pipescan HD.” [Online]. Available: <nowiki>https://www.eddyfi.com/en/product/pipescan-hd</nowiki>. [Accessed: Mar. 23, 2025].</ref>. The scanner module requires almost no surface preparation and no couplant, which is a substance that helps transmit energy. Scanning speed of the Pipescan HD can be up to 1m/s, and it has an adjustable reporting threshold to define the depth at which the scanner works. | ||

<u>''' | === <u>'''Maximal theoretical speed of movement'''</u> === | ||

In a paper published by a research team from Nanjing University of Aeronautics and Astronautics, China, the speed limits of detection using MFL were explored <ref name=":7">Ping Wang, Yunlai Gao, GuiYun Tian, Haitao Wang, Velocity effect analysis of dynamic magnetization in high speed magnetic flux leakage inspection, NDT & E International, Volume 64, 2014, Pages 7-12, ISSN 0963-8695, <nowiki>https://doi.org/10.1016/j.ndteint.2014.02.001</nowiki>.</ref>. In their test setup, the researchers used a spinning wheel, which had pre-made cracks for simulation purposes, as their test subject. Near the wheel, 2 magnetizing yokes were attached with their polarities being opposite to each other. Three perpendicular Hall Effect sensors were attached to the yoke that is placed against the direction of the spinning wheel. That way, the wheels surface is first magnetized by the yoke without the sensors and then the polarity of the magnetization is reversed by the yoke with the sensors, which increases the flux leakage and makes it easier for the hall sensors to pick it up. In testing, the team spun the wheel in speeds ranging from 5 m/s (18 km/h) up to 55 m/s (198 km/h) and recorded the results. The results indicate that the flux leakage detection is getting better, although non-linearly, as the speed was increased <ref name=":7" />, meaning there is a good feasibility for high speed MFL detection to be applied in crack detection industries. | In a paper published by a research team from Nanjing University of Aeronautics and Astronautics, China, the speed limits of detection using MFL were explored <ref name=":7">Ping Wang, Yunlai Gao, GuiYun Tian, Haitao Wang, Velocity effect analysis of dynamic magnetization in high speed magnetic flux leakage inspection, NDT & E International, Volume 64, 2014, Pages 7-12, ISSN 0963-8695, <nowiki>https://doi.org/10.1016/j.ndteint.2014.02.001</nowiki>.</ref>. In their test setup, the researchers used a spinning wheel, which had pre-made cracks for simulation purposes, as their test subject. Near the wheel, 2 magnetizing yokes were attached with their polarities being opposite to each other. Three perpendicular Hall Effect sensors were attached to the yoke that is placed against the direction of the spinning wheel. That way, the wheels surface is first magnetized by the yoke without the sensors and then the polarity of the magnetization is reversed by the yoke with the sensors, which increases the flux leakage and makes it easier for the hall sensors to pick it up. In testing, the team spun the wheel in speeds ranging from 5 m/s (18 km/h) up to 55 m/s (198 km/h) and recorded the results. The results indicate that the flux leakage detection is getting better, although non-linearly, as the speed was increased <ref name=":7" />, meaning there is a good feasibility for high speed MFL detection to be applied in crack detection industries. | ||

'''<u>Design choices for ship hull inspection</u>''' | === '''<u>Design choices for ship hull inspection</u>''' === | ||

Based on the conducted research and based on already existing technological achievements that were proven to work in the field, some technical design choices can be made for the next generation of ship hull inspection robots. | Based on the conducted research and based on already existing technological achievements that were proven to work in the field, some technical design choices can be made for the next generation of ship hull inspection robots. | ||

<u>Size</u> - From the research conducted, the decision was made to use a circular array of hall sensors. The size of the array will be | <u>'''Size'''</u> - From the research conducted, the decision was made to use a circular array of hall sensors. The size of the array will be 20 [cm] to adequately cover enough area for good scanning pace and at the same time aid at both crack localization and orientation for higher quality information. The electro-magnet responsible for creating the magnetic flux will be nestled on top and around the hall sensors. The electro-magnet consists primarily of a yoke shaped core that would be divided into sections for ease of saturation. The yokes width would be also 20 [cm], the height is [5cm], and the length is [25cm]. Since the yoke is the largest part and dictates the dimensions of the sensor assembly, the final size come to be 0.25x0.2x0.05 [m]. | ||

<u>Weight</u> - The heaviest part of the sensor is the yoke that needs to provide adequate magnetic flux to saturate the underlying surface. For that purpose, 5 yokes of equal size will be used. Each of the yokes has to have a uniform cross-sectional area hence it is chosen to be 3x3 [cm]. | <u>'''Weight'''</u> - The heaviest part of the sensor is the yoke that needs to provide adequate magnetic flux to saturate the underlying surface. For that purpose, 5 yokes of equal size will be used. Each of the yokes has to have a uniform cross-sectional area hence it is chosen to be 3x3 [cm]. Each of the yokes hence would be the size of 0.25x0.03x0.05 [m] and weigh roughly 2 [kg]. To cover the entire 20 [cm] by sufficient magnetic flux, 5 yokes are used with spacing of 1.5 [cm] to accommodate the wires required for the magnetic field. The weight of the hall sensors is very low and can be considered negligible compared to the yokes. In total, the weight of the MFL detection system can be estimated to be 11 [kg], accounting for the necessary wiring and sensors. | ||

<u>Integration into the robot</u> - The MFL sensor system is going to be mounted in the middle of the robot, slightly moved towards the front to make room for the ultrasound sensor. The decision to place the MFL system in the middle of the robot stems from the fact that it will be one of the heaviest parts in the robot assembly, hence we want to distribute its weight as equally as possible across all axis' of rotation. While ideally the MFL sensor would be mounted exactly in the middle of the robot, we need to reserve some space for the much lighter ultrasonic sensor, hence the slight shift forward. Considering that the overall length of the robot is roughly 60 [cm] and the length of the sensor assembly is 25 [cm], it would be placed | <u>'''Integration into the robot'''</u> - The MFL sensor system is going to be mounted in the middle of the robot, slightly moved towards the front to make room for the ultrasound sensor. The decision to place the MFL system in the middle of the robot stems from the fact that it will be one of the heaviest parts in the robot assembly, hence we want to distribute its weight as equally as possible across all axis' of rotation. While ideally the MFL sensor would be mounted exactly in the middle of the robot, we need to reserve some space for the much lighter ultrasonic sensor, hence the slight shift forward. Considering that the overall length of the robot is roughly 60 [cm] and the length of the sensor assembly is 25 [cm], it would be placed 12.5 [cm] from the "nose" of the robot (a 5 [cm] shift forward compared to total center position). | ||

[[File:Lift-off.png|thumb|The combined effects of magnetizer and sensor lift-off on magnetic flux leakage detection. <ref>Yang, L., Zhang, G., & Liu, G. (2008). Effect of Lift-off on Pipeline Magnetic Flux Leakage Inspection. 17th World Conference on Nondestructive Testing, Shanghai, China, 25-28 Oct 2008. ''e-Journal of Nondestructive Testing'' Vol. 13(11). <nowiki>https://www.ndt.net/?id=6674</nowiki></ref>]] | [[File:Lift-off.png|thumb|The combined effects of magnetizer and sensor lift-off on magnetic flux leakage detection. <ref>Yang, L., Zhang, G., & Liu, G. (2008). Effect of Lift-off on Pipeline Magnetic Flux Leakage Inspection. 17th World Conference on Nondestructive Testing, Shanghai, China, 25-28 Oct 2008. ''e-Journal of Nondestructive Testing'' Vol. 13(11). <nowiki>https://www.ndt.net/?id=6674</nowiki></ref>]] | ||

<u>Lift-off distance</u> - The lift-off distance of both the Hall Effect sensors and the magnetic yokes dictates how sensitive the first will be and how well the later an saturate the the hull of the ship. The further both of them are from the surface, the readings will be less accurate and more susceptible to noise and other EMI forms. We need to insure that the sensors and the yokes are close enough to the surface for good readings. That can be done by placing the sensor system roughly | <u>'''Lift-off distance'''</u> - The lift-off distance of both the Hall Effect sensors and the magnetic yokes dictates how sensitive the first will be and how well the later an saturate the the hull of the ship. The further both of them are from the surface, the readings will be less accurate and more susceptible to noise and other EMI forms. We need to insure that the sensors and the yokes are close enough to the surface for good readings. That can be done by placing the sensor system roughly 6-8 mm from the surface of the hull and installing a scraping tool that will insure that even if some biofouling is present on the hull, it will get scraped away and not interfere with the sensor. | ||

<u>Power requirements</u> - Doing some calculations to find the MMF required to generate 1.8 [T] of flux in a hull 5 [cm] in thickness and 8 [mm] lif-off distance, it is found that we need about 11500 [A · Turns]. to generate the required MMF. We will use 2000 turns of wire to keep the current low, and find that we need 5.75 [A] of current. Next, using 18awg wire and knowing the total length of the required wire (0.12 · 2000 = 240 [m]) and its cross-section, we can calculate the total resistance of the current carrying wire, which amounts to 4.95 [Ohm]. From here, using the formula P = I<sup>2</sup> · R, we get that we need roughly 165 [W] per yoke or | <u>'''Power requirements'''</u> - Doing some calculations to find the MMF required to generate 1.8 [T] of flux in a hull 5 [cm] in thickness and 8 [mm] lif-off distance, it is found that we need about 11500 [A · Turns]. to generate the required MMF. We will use 2000 turns of wire to keep the current low, and find that we need 5.75 [A] of current. Next, using 18awg wire and knowing the total length of the required wire (0.12 · 2000 = 240 [m]) and its cross-section, we can calculate the total resistance of the current carrying wire, which amounts to 4.95 [Ohm]. From here, using the formula P = I<sup>2</sup> · R, we get that we need roughly 165 [W] per yoke or 825 [W] in total to power the MFL sensors. The power required by the Hall Effect sensors themselves is miniscule and is hence neglected. | ||

<u> | <u>'''Magnetic attraction force'''</u> - Using some calculations derived from the used power in the electro magnet, we can calculate the amount of attraction force that the magnet would generate. Assuming full power is used, the attraction force between the magnet and the hull will reach roughly 5800[N]. That amount of attraction force is enough to keep the robot attached to the hull and also provide enough friction between the wheels and the hull to keep the robot attached in strong underwater currents. Since the electromagnet is relatively close to the hull, the lift-off distance doesn't impact the force in a significant way. | ||

<u>''' | <u>'''EMI shielding'''</u> - While the whole system can't really be completely isolated from EMI producing devices inside the ship, like Variable Frequency Drives (VFD) or electrical generators, a base line can be established by either passing another robot that will measure the background magnetic field strength to then filter out the noise, or by letting our robot run over the whole ship twice if the time allows it. That way, most of the EMI will be filtered out and not influence the readings of the MFL sensors. | ||

=== <u>'''Work time estimation'''</u> === | |||

Based on the conducted research, crucial parameters for the MFL detection system can be compiled to better understand its integration into the robotic system. In order to do so, some assumptions will be made, taking the largest ship possible to make a case for the "worst" possible scenario. | Based on the conducted research, crucial parameters for the MFL detection system can be compiled to better understand its integration into the robotic system. In order to do so, some assumptions will be made, taking the largest ship possible to make a case for the "worst" possible scenario. | ||

{| class="wikitable" | {| class="wikitable" | ||

| Line 304: | Line 365: | ||

<u>Total hull area:</u> 400 · 32 · 2 + 60 · 400 = 25600 + 24000 ≈ 50000 [m<sup>2</sup>]. Another 25% will be added to this area to account for things such as the bow, stern, and various extrusions such as the bow flare and hull curvature. | <u>Total hull area:</u> 400 · 32 · 2 + 60 · 400 = 25600 + 24000 ≈ 50000 [m<sup>2</sup>]. Another 25% will be added to this area to account for things such as the bow, stern, and various extrusions such as the bow flare and hull curvature. | ||

Final total hull area comes to | Final total hull area comes to 60000 [m<sup>2</sup>]. | ||

Taking an Ultra Large Container Vessel (ULCV), like the Maersk Triple E-class ships, we can correlate the total hull area to the MFL scanner effective area and the scanners speed to calculate the amount of time it would take. In the hull area calculations, the underside of the ship is also taken into account as big container ships usually have flat bottoms that the robot would be able to stick onto. | Taking an Ultra Large Container Vessel (ULCV), like the Maersk Triple E-class ships, we can correlate the total hull area to the MFL scanner effective area and the scanners speed to calculate the amount of time it would take. In the hull area calculations, the underside of the ship is also taken into account as big container ships usually have flat bottoms that the robot would be able to stick onto. | ||

| Line 321: | Line 382: | ||

|Treating the scanner as a line scanner, '''1 [m<sup>2</sup>/s]''' | |Treating the scanner as a line scanner, '''1 [m<sup>2</sup>/s]''' | ||

|} | |} | ||

Taking into account those assumptions, its possible to calculate the amount of time it would take for a robot to scan an entire ship, which calculates to roughly to | Taking into account those assumptions, its possible to calculate the amount of time it would take for a robot to scan an entire ship, which calculates to roughly to 17 hours. | ||

That amount of time accounts solely for the ability of the MFL sensor to reliably pick up cracks and defects on the hull of the ship. In practice, the system might be limited by other, more mechanical, factors. With that in mind, the MFL sensor would not present a technical limit on the speed of work of the robot. | That amount of time accounts solely for the ability of the MFL sensor to reliably pick up cracks and defects on the hull of the ship. In practice, the system might be limited by other, more mechanical, factors. With that in mind, the MFL sensor would not present a technical limit on the speed of work of the robot. | ||

| Line 343: | Line 404: | ||

|'''Power requirement''' | |'''Power requirement''' | ||

|875 [W] | |875 [W] | ||

|- | |||

|'''Attraction force''' | |||

|~6000 [N] | |||

|- | |- | ||

|'''Maximum speed''' | |'''Maximum speed''' | ||

| Line 352: | Line 416: | ||

=='''Non-destructive inspection using ultrasound system'''== | =='''Non-destructive inspection using ultrasound system'''== | ||

Ultrasonic testing (UT) is a non-destructive testing method widely used for ship hull inspection that enables thorough assessment without damaging the vessel structure. This technique employs high-frequency sound waves (typically 0.5-25 MHz) to detect internal flaws, measure thickness, and evaluate material integrity of hull plating and structural members. The process relies on the principle that sound waves travel through homogeneous materials at predictable velocities but reflect or scatter when encountering interfaces, discontinuities, or defects. Within this method, various techniques were developed<ref>Bosen Lin, Xinghui Dong, Ship hull inspection: A survey, Ocean Engineering, Volume 289, Part 1, 2023, 116281, ISSN 0029-8018, <nowiki>https://doi.org/10.1016/j.oceaneng.2023.116281</nowiki>.</ref>: | |||

#'''<u>Ultrasonic Thickness Measurement (UTM)</u>''': UTM is a non-destructive technique that measures the local thickness of a structure by analyzing the difference in arrival times between direct and reflected waves. This method requires ultrasonic sensors to be in direct contact with the hull surface, which must be cleaned of coatings, corrosion, and biofouling. The final measurement locations are chosen based on a comprehensive survey to ensure they represent the average hull condition. | #'''<u>Ultrasonic Thickness Measurement (UTM)</u>''': UTM is a non-destructive technique that measures the local thickness of a structure by analyzing the difference in arrival times between direct and reflected waves. This method requires ultrasonic sensors to be in direct contact with the hull surface, which must be cleaned of coatings, corrosion, and biofouling. The final measurement locations are chosen based on a comprehensive survey to ensure they represent the average hull condition. | ||

| Line 360: | Line 424: | ||

# '''<u>Time-of-Flight Diffraction (TOFD) Ultrasonic Testing</u>''': TOFD determines the position and size of defects by measuring the time of flight of ultrasonic pulses rather than the amplitude of the reflected signal. This method uses a pair of ultrasonic probes, with the transmitter emitting a pulse and the receiver picking it up. If a crack is present, the waves are diffracted from the crack tip, allowing the size of the crack to be calculated. | # '''<u>Time-of-Flight Diffraction (TOFD) Ultrasonic Testing</u>''': TOFD determines the position and size of defects by measuring the time of flight of ultrasonic pulses rather than the amplitude of the reflected signal. This method uses a pair of ultrasonic probes, with the transmitter emitting a pulse and the receiver picking it up. If a crack is present, the waves are diffracted from the crack tip, allowing the size of the crack to be calculated. | ||

#'''<u>Air-Coupled Ultrasonic Testing (ACUT)</u>''': ACUT uses air as the coupling medium instead of traditional liquid couplant like water or gel. This non-contact method eliminates the drawbacks of contact ultrasonic testing, making it more efficient for health monitoring and non-destructive testing. ACUT is particularly suitable for inspecting large-scale hulls made of metal or composite materials. | #'''<u>Air-Coupled Ultrasonic Testing (ACUT)</u>''': ACUT uses air as the coupling medium instead of traditional liquid couplant like water or gel. This non-contact method eliminates the drawbacks of contact ultrasonic testing, making it more efficient for health monitoring and non-destructive testing. ACUT is particularly suitable for inspecting large-scale hulls made of metal or composite materials. | ||

=== '''<u>Working principle of UTM</u>''' === | |||

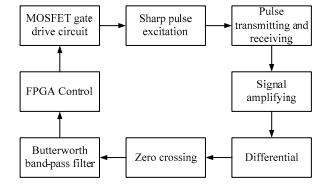

In this project, it is decided that the MFL is used for localization of cracks and deformations on the vessel due to its advantages mentioned above. However, it is quite difficult to measure the depth of deformation, or the thickness loss due to corrosion with just MFL. Such challenge is resolved by using a simpler yet robust method: the UTM technique. There exists three main principle of UTM: resonance method, Lamb Law method and pulse reflection method. In the first method, by emitting ultrasonic waves of varying frequencies onto a workpiece, resonance occurs when the thickness equals a multiple of half the wavelength<ref>Shi Yiwei. Ultrasonic detection[M]. Beijing: Mechanical Industry Press, 2005:94-96.</ref>. This method achieves high accuracy (≤0.1mm) with smooth surface finishes, which is not always the case for ship hull due to biofouling. For the second one, Lamb waves occur when ultrasonic frequency relates to both incident angle and workpiece thickness. These waves propagate in thin plates with wavelengths that are comparable to the plate thickness. The key to thickness measurement is that their propagation characteristics (velocity, dispersion) depend directly on the frequency-thickness product<ref>K. R. Leonard, E. V. Malyarenko, and M. K. Hinders, “Ultrasonic lamb wave tomography,” Inverse Problems, vol. 18, no. 6, p. 1795, nov 2002. [Online]. Available: <nowiki>https://dx.doi.org/10.1088/0266-5611/18/6/322</nowiki></ref>. While they excel at measuring thin materials, when Lamb wave modes propagate in a fluid medium, they may suffer leakage by mode conversion into the fluid. Lastly, the pulse echo method sends ultrasound through homogeneous materials, with propagation time proportional to thickness. This method works on rougher surfaces, making it versatile for various material conditions. | In this project, it is decided that the MFL is used for localization of cracks and deformations on the vessel due to its advantages mentioned above. However, it is quite difficult to measure the depth of deformation, or the thickness loss due to corrosion with just MFL. Such challenge is resolved by using a simpler yet robust method: the UTM technique. There exists three main principle of UTM: resonance method, Lamb Law method and pulse reflection method. In the first method, by emitting ultrasonic waves of varying frequencies onto a workpiece, resonance occurs when the thickness equals a multiple of half the wavelength<ref>Shi Yiwei. Ultrasonic detection[M]. Beijing: Mechanical Industry Press, 2005:94-96.</ref>. This method achieves high accuracy (≤0.1mm) with smooth surface finishes, which is not always the case for ship hull due to biofouling. For the second one, Lamb waves occur when ultrasonic frequency relates to both incident angle and workpiece thickness. These waves propagate in thin plates with wavelengths that are comparable to the plate thickness. The key to thickness measurement is that their propagation characteristics (velocity, dispersion) depend directly on the frequency-thickness product<ref>K. R. Leonard, E. V. Malyarenko, and M. K. Hinders, “Ultrasonic lamb wave tomography,” Inverse Problems, vol. 18, no. 6, p. 1795, nov 2002. [Online]. Available: <nowiki>https://dx.doi.org/10.1088/0266-5611/18/6/322</nowiki></ref>. While they excel at measuring thin materials, when Lamb wave modes propagate in a fluid medium, they may suffer leakage by mode conversion into the fluid. Lastly, the pulse echo method sends ultrasound through homogeneous materials, with propagation time proportional to thickness. This method works on rougher surfaces, making it versatile for various material conditions. | ||