PRE2022 3 Group11

| Name | Student number | Study |

|---|---|---|

| Vietlinh Pham | 1616420 | Industrial Engineering |

| Lars Nobbe | 1746111 | Applied Mathematics |

| Paul van Geest | 146326 | Electrical Engineering |

| Aloysia Prakso | 1693514 | Industrial Design |

| Mauritius van Maurik | 1600426 | Automotive Technology |

Problem Statement and Objectives

As the world’s population continues to grow, the amount of arable land we have will not. In the future this will lead to food shortages as conventional farming cannot keep up with the increasing demand. Furthermore, conventional farming comes with a multitude of problems for both humans and nature. Issues like food safety, ecosystem disruption and water wastage make expansion of this type of farming unreasonable to solve food shortage problem. It is therefore needed to make farming more compact, more efficient and safer. The most prominent method to meet these improvements is indoor farming. By growing crops in an indoor and controlled environment, crop gain is higher while requiring less resources; less pesticides are needed because disease, animals and other harmful plants are less likely to enter the farm and the irrigation can be more efficient. Instead of using soil to plant the crops in, methods like hydroponics, aeroponics and aquaponics can be used, which are proven to increase production while also eliminating soil-related problems. Sunlight is also not needed for indoor farms, instead using LED lighting optimized for plant growth. Because of this, indoor farms can also be used in areas where there is not enough sunlight and/or rainfall to accommodate conventional farming. With the use of the previously mentioned hydro- aero- and aquaponics, indoor farms also take up less vertical space; crops do not need to dig their roots deep into soil to be able to absorb a good amount of nutrients. Combined with the fact that the plants do not need exposure to sunlight, it is possible to stack multiple indoor farms on top of each other, drastically increasing the amount of crops grown per square meter. This concept is known as vertical farming, and it is the focus of this project.

Most implementations of vertical farming house their farms in a large building specifically built for these types of farms. However, vertical farms can also be situated in a typical home, albeit on a smaller scale. In an ideal scenario, every home could have a vertical farm providing fresh produce to the people living in it, reducing the need and cost of food products from standard farms. Excess crops harvested from a vertical farm could also be sold locally at a drastically decreased price, since transportation makes up a majority of food cost (citation needed). In reality it is not that easy to have every person house a farm in their residence. Studies have found that many people are abrasive to the new technology, the biggest reason for which being the monetary and time investment of a vertical farm. There are also different target groups to market to which have varying demands of such a system:

- People who would want a vertical farm purely for the benefit of farming their own produce → want cheapest system while requiring the least time investment.

- People who enjoy gardening and want to spent more time taking care of the farm, i.e. hobbyists, retirees → want a system which allows for more freedom and time investment whilst not being overbearing.

- People who want to use the farm for educational purposes, i.e. teachers at high school/college level → want a system to teach about farming technology with, does not need to be optimized for crop gain.

For this project, it has been decided to focus primarily on the group of hobbyists. These are people most likely to accept the new technology into their homes, but for whom there still isn’t a model catered exactly to their needs (for a reasonable price). As such it is the goal of this project to design a vertical farming system that is both inexpensive and user friendly for this group.

State of the Art

Vertical farming is growing sector. In this section the characteristics and features of already existing vertical farming systems will be discussed. There are two main methods to grow plants in a vertical farm: hydroponics and aeroponics. Both methods share the characteristic that plants grow without soil, but the way in which nutrients are supplied differs. In hydroponics, crops are provided with nutrients through a nutrient-rich water solution (Khan, Purohit, Sadharia, 2020). Efficient growth depends on finding a good nutrient solution and optimizing climatic factors such as pH, light, humidity and temperature. Aeroponics instead exposes plant roots to aerosol drops that contain nutrients, (Eldridge, Bethany, 2020). Specific parameters to consider include droplet size, oxygen concentration in the area of the roots and droplet decomposition, (Eldridge, Bethany, 2020). We have decided to focus on hydroponic growth, because it is the more widely used method and more easily to implement in small scale systems. Therefore, the technology of hydroponics will mainly be discussed in this state of the art section.

There are multiple advantages of hydroponic growth compared to traditional soil-based agriculture. One of the main benefits is that it reduces the impact of soil-related cultivation problems such as insects, fungus and bacteria, (Al-Kodmany, 2018). It is also a low-maintenance farming method, since weeding, tilling and dirt removal a non-issues, (Al-Kodmany, 2018). Furthermore, the circumstances in a hydroponic vertical can be controlled very precisely. In the project, temperature, pH and humidity sensors will be added to the prototype, in order to keep track of the climate.

Irrigation system

Every hydroponic vertical farm must have an irrigation system. There various methods is which water can be supplied to the vertical farm. One of them is the nutrient film technique (NFT), (Khan, Purohit and Sadharia, 2020). In NFT, plants are arranged in narrow water gullies filled with a thin nutrient solution (Mohammed, 2016). This nutrient solution is constantly pumped through the system, to prevent depletion. NFT is suitable for a large variety of crops such as lettuce, leafy plants and herbs (Mohammed, 2016).

Another way to supply water and nutrients are flood and drain systems. In this technique, the growing area is flooded with a nutrient solution for 5 to 10 minutes and then drained away (Khan, Purohit, Sadharia, 2020). Flood and drain irrigation is mainly used in hobby systems, because they are hard to scale up, (Khan, Purohit, Sadharia, 2020).

Drip systems are a suitable irrigation technique to grow long-term crops such as cucumbers, tomatoes and unions, (Khan, Purohit, Sadharia, 2020). Drip emitters spray nutrient solution directly at the roots of a crop. This makes the technique very precise. There are two types drip systems: recovery and non-recovery. In recovery systems, the nutrient solution is returned to a reservoir, while in non-recovery systems used solution is thrown away. Recovery systems obviously use water more efficiently, but they come with extra challenges like maintaining pH balance and constant nutrient concentration, (Khan, Purohit, Sadharia, 2020).

Aquaponics stands out compared to other irrigation methods. It combines fish farming with plant growth. The goal is to create a symbiotic relationship between the fish and the crops. Fish, like all animals, excrete nutrient-rich waste, (Al-Kodmany, 2018). This waste can be used to fertigate plants. The plants in turn remove nutrient “waste” from the fish water. Making it possible to constantly recirculate the same water through the system. Although, aquaponics can be really sustainable, it is complex technique. Therefore, it isn’t suitable for small-scale home vertical farms.

Hydroponics will be utilized in this project because of the added complexity of aquaponic systems for the users due to the need to manage both plant and fish, and thus requiring more time than the hydroponics system and is therefore not suitable for the timeline of this course. Aeroponic systems, on the other hand, are more challenging to establish, require more supplies and maintenance, and hence incur higher costs than hydroponic systems, making them even less appealing to consumers. Moreover, hydroponic systems has a higher growth rate than the traditional soil based system (Gashgari et al., 2018). Additionally, Verdoliva et al. (2021) research revealed increase water use efficiency in hydroponic system compared with conventional agriculture. Flood and drain irrigation is the irrigation technique that will be used in the project. This choice will be explained in the prototype section.

Home vertical farms

The goal of this project is to design a home vertical farm that is both affordable and user friendly. There are already roughly two kinds of vertical farming systems on the consumer market: cheap systems with limited functionalities and more expensive ones that include all kinds of automatic features. The final prototype should contain some of these features, while costing way less than thousands of dollars. Which features the prototype should have like temperature control and automatic watering will be determined by a user study.

The Plantcube (120cm x 62.5cm x 46cm) is one of the more advanced vertical farms on the consumer market. The system keeps track of which plants are grown in the cube and determines the optimal climatic conditions. Temperature, lighting, humidity and watering are all automated. The cheapest version of the Plantcube costs 1299 euro plus an additional subscription of 45 euro per month for the app feature. A similar advanced system is the Gardenchef, its functionalities include automatic water and nutrient supply, pH and TDS sensors, humidity and lighting control. It is even more expensive with prizes ranging from 9500 till 19500 euro depending on the number of stories. These systems aren’t fully comparable to the envisaged prototype though, since they don’t use hydroponic growth.

The Farmself is a hydroponic vertical farming system made for the consumer market. Its dimensions are 190cm height, 102cm width and 55cm dept. One of the survey questions will be about the maximum amount space the participants are willing to allocate to the a vertical farm. Like the other farms discussed above, the biggest obstacle for the buying the Farmself is its price, 5000 euro + 70 euro monthly subscription. But is does come with all sorts of handy features like automatic water circulation, a camera, pH and PDS sensors and an app. Farmself uses drip irrigation to supply nutrients to the plants.

Who are the users

Primary users

Those who use home vertical farming systems for personal use, typically to grow fresh produce for themselves and their families. The main beneficiaries of sustainable food production and indoor growing opportunities offered by the system. This is mostly anyone who is interested in indoor gardening, expirementing with growing produce using technology.

- City person: People who live in apartments with limited outdoor space in urban areas. They may be interested in vertical farming as a way to grow their own fresh produce without the need for outdoor land.

- Gardeners: Home gardeners who are interested in experimenting with new growing techniques and maximizing their indoor space may find home vertical farming systems to be an appealing option.

- Environmentalists: People who are interested in reducing their environmental impact and promoting sustainable food production may be drawn to home vertical farming as a way to reduce reliance on industrial agriculture.

- Health-conscious individuals: People who prioritize health and nutrition may be interested in home vertical farming as a way to ensure a consistent supply of fresh produce throughout the year.

- Technology enthusiasts: Home vertical farming systems incorporate advanced technology, which may appeal to tech enthusiasts who are interested in experimenting with new technologies and methods of food production

Secondary users

Those who use the home vertfical farming system for other purposes, such as education, community outreach and expirementation.

- Schools and other educational entities: Home vertical farming systems can be used in schools and educational institutions to teach students about sustainable food production and encourage healthy eating habits.

- Restaurants: Small-scale vertical farming systems can be used by restaurants and cafes to grow fresh herbs and vegetables for use in their dishes.

- Communities: Home vertical farming systems can be used by community organizations to provide fresh produce to local residents and promote sustainable food production.

- Gardening enthusiasts: People who are interested in indoor gardening or horticulture may use home vertical farming systems as a way to experiment with new growing techniques or grow exotic or hard-to-find plants.

Tertiary users

Those who benefit from the positive externalities that result from the use of the system, often at a broader societal or systemic level.

- Health insurance companies: Health insurance companies may indirectly benefit from home vertical farming systems by promoting healthy eating habits among their policyholders, potentially reducing healthcare costs associated with diet-related diseases.

- Real estate developers: Real estate developers may indirectly benefit from home vertical farming systems by promoting sustainable and eco-friendly features in their buildings, potentially increasing property values and attracting environmentally conscious buyers.

- Local governments: Local governments may indirectly benefit from home vertical farming systems by promoting sustainable food production practices, potentially reducing the burden on municipal waste management systems, promoting local economic development, and improving community health outcomes.

Downsides

- High cost: The technology used can be expensive. This could be a barrier to entry for some individuals, limiting acces to the benefits of indoor farming.

- Energy usage: This system requires constant source of energy to power lights, climate control, and potential other equipment. This could therefore lead to a higher energy usage and energy bill.

- Limited crop variety: The crops that can be grown are limited to the space available in the farming system. Crops with large roots, big canopies or bushes are quickly limited in space.

- Maintenance: Home vertical farming systems require regular maintance and monitoring to ensure propwer growing conditions and prevent pests and disease. This can be time consuming and may require a specialized skill.

- Technical challenges: This system may involve complex technical systems and equipment, which can be challenging to setup and troubleshoot for individuals without any prior technical experience.

While there are many potential users of this project, our main focus is on hobbyists. According to Stebbins (1982), hobbyists are individuals who approach their pursuits with a high level of commitment and take them seriously, even though they are not compelled to engage in them by any sense of obligation or necessity. In the case of this hydroponics system, hobbyists are individuals who are interested and involved in the agriculture sector.

Research by Jansen et al. (2016) found that individuals with expertise in this particular field tend to be less reliant on automated systems. However, participants in the study also mentioned that lack of time often prevented them from properly taking care of their plants. Therefore, a partially automated system that involves the user but does not fully rely on them would be most appropriate.

However, the research also revealed that participants were not willing to acquire such a system at the moment due to cost concerns. The objectives of this project are to address these particular problems, especially for hobbyists who want to be involved but have time constraints.

Survey

To get a better view the target group preferences, a user study has been done. The participants of this study filled in a survey. The survey consists of thirteen question: the first seven are about the users general attitude towards vertical farming, question 8 is about the type of vertical farm they prefer, the ninth about the features it should contain and 10-13 about the investment they are willing to make. There were four participants of this user study. They all have an interest in gardening or farming and are thus members of the target group. Two did study biology in college and the other two are enthusiastic hobby gardeners.

Results

The partcipants attitude towards the technology of vertical farming is generally positive, the main reason being that it saves space. Higher crop yield, positive environmental impact and the easy to reach height of a vertical are mentioned as additional advantages of vertical farming compared to traditional methods. Listed drawbacks are the start-up costs, high energy consumption due to the lack of sunlight and vertical farming not being a natural way to grow plants.

The opinions on the preferred type of vertical farm vary. Two participants prefer hydroponic soil, while the other two would like to see a land based soil. The potential users would like to grow all sorts of products such as vegetables, herbs and microgreens. One participant indicated that the farm shouldn’t have sharp corners, because it would make cleaning much harder. Another would like the vertical farm to have the shape of a Ferris wheel.

The four participants also indicated which potential features of a vertical farm they would like to be autonomous and which could be more interactive. Water- nutrient supply, light- temperature- and humidity- control should be autonomous and are all necessary features of an efficient vertical farming system acoording to the participants. Planting, seeding and crop health monitoring don’t have to be autonomous. An mobile app to monitor the system is nice bonus but not absolutely necessary for most participants.

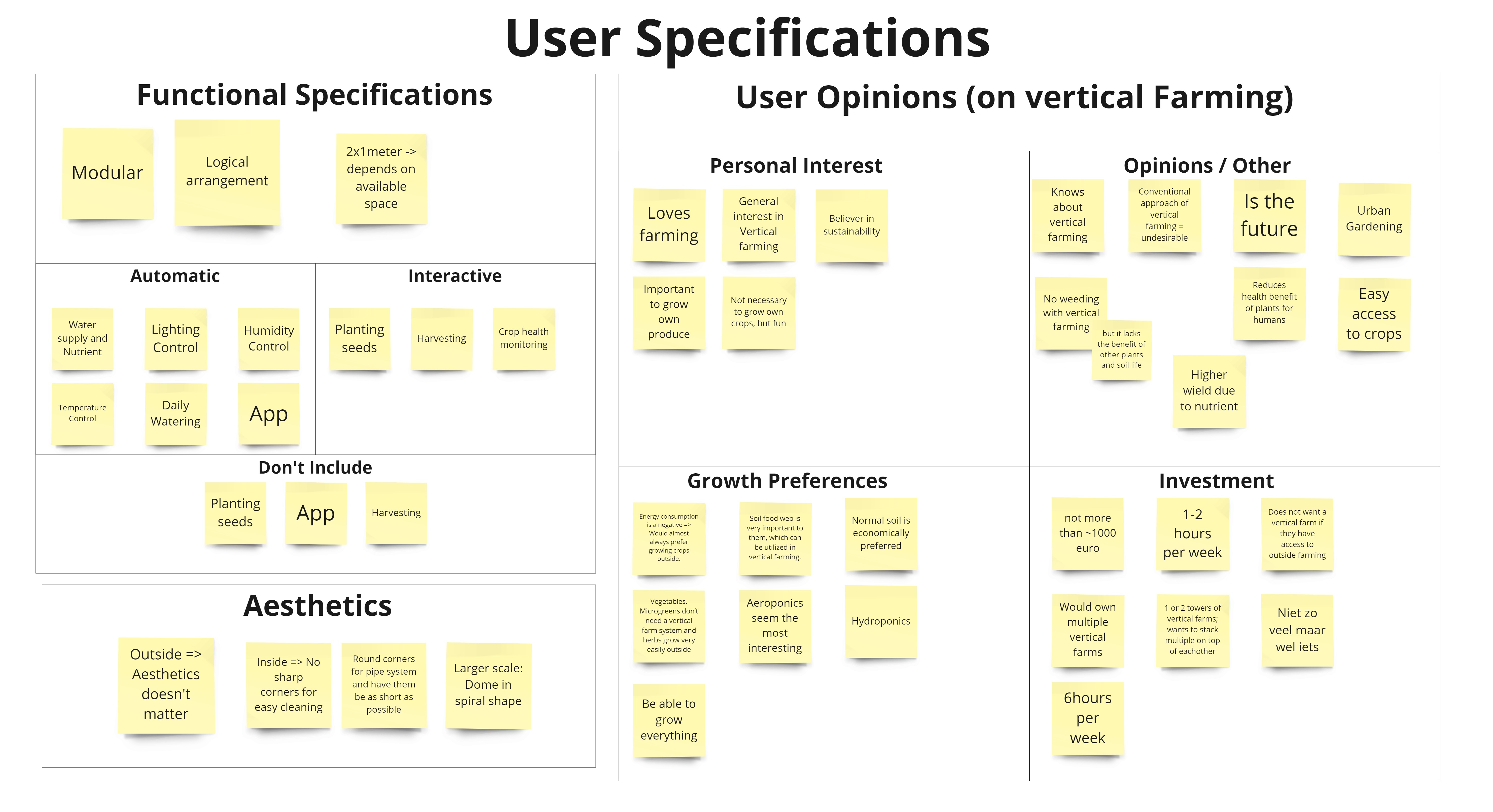

The monetary investment that the participants are willing to make isn’t high compared to existing vertical farms with automatic functions. Two participants didn’t want to spend more than 100-150 euros on a vertical farm, one didn’t mention a concrete amount but said it shouldn't be too much and the last would spend up to 1000 euros if an outside garden wasn’t available. The existence of free or cheap regular gardens (moestuintje) is probably the main reason. Investment in time varies between two and six hours per week and the vertical farm shouldn’t cover more space than a few square meters. Three out four would prefer the system to be modular. Because this makes it easier to buy an extension. The result of the survey are summarized in the following affinity diagram.

What do they require

- Lighting: Indoor plants require artificial lighting to supplement natural sunlight. LED grow lights are a popular choice for home vertical farming systems due to their energy efficiency and ability to provide the right spectrum of light for plant growth.

- Growing medium: Plants in a vertical farming system require a growing medium to support root growth and provide access to nutrients. Common growing media include soilless mixes, such as coconut coir or perlite, or hydroponic systems, such as nutrient-rich water solutions.

- Nutrient delivery system: Plants in a vertical farming system require a consistent source of nutrients to support growth and development. Nutrient delivery systems can vary depending on the type of growing medium and system, and may involve automated dosing systems or manual nutrient solutions.

- Ventilation: Adequate air circulation and ventilation is important for maintaining healthy growing conditions and preventing the buildup of moisture and odors. Fans or other ventilation systems may be needed to ensure proper air flow.

- Temperature and humidity control: Indoor environments can be prone to temperature and humidity fluctuations, which can affect plant growth and development. Home vertical farming systems may require temperature and humidity control systems, such as heaters, air conditioning units, or humidifiers.

- Monitoring and control systems: Home vertical farming systems may include sensors or monitoring systems to track environmental conditions, such as temperature, humidity, and nutrient levels. Automated control systems can adjust lighting, nutrient delivery, and other factors as needed to optimize plant growth.

- Structure and support: A vertical farming system requires a structure to support the growing components, such as shelving units or vertical grow towers. The structure must be sturdy and stable to support the weight of plants and equipment.

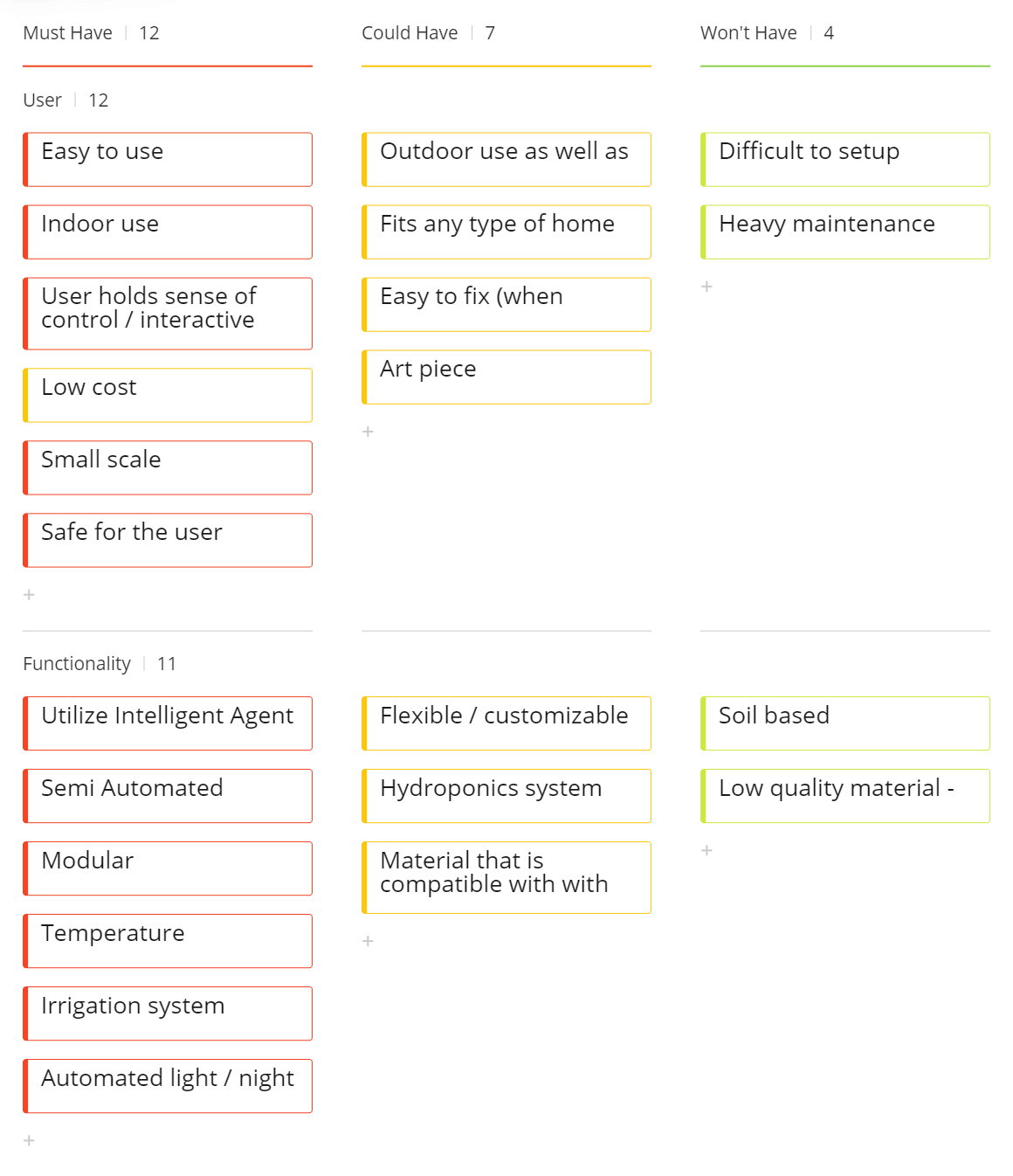

The requirements will be established via the MoSCow method, it is a prioritizing technique to determine the importance of project requirements. The requirements, in this case, are based on the users relevant for this product. The name "MoSCow" is an acronym for:

- Must have: are essential requirements and must be included in the project. Without implementing these requirements, the project cannot be considered succesful.

- Should have: are important requirements but not as critical as the must have requirements. If these requirements are not included, it will still be considered succesful.

- Could have: are desirable requirements, but not necessary. They are nice-to-haves, and can be included if time and resources allow it.

- Won't have: are requirements are those that will not be included in the project, either because they are not important or because they are out of the scope of this project.

The MoSCow method is helpful, because it helps us to prioritize requirements and make informed decisions about what to include in the project. The requirements for this project can be seen in figure ..., the should-have part is integrated with the must-have section. The requirements are mainly based on the user research and the survey conducted, as it is of importance to know what the user want.

Prototype

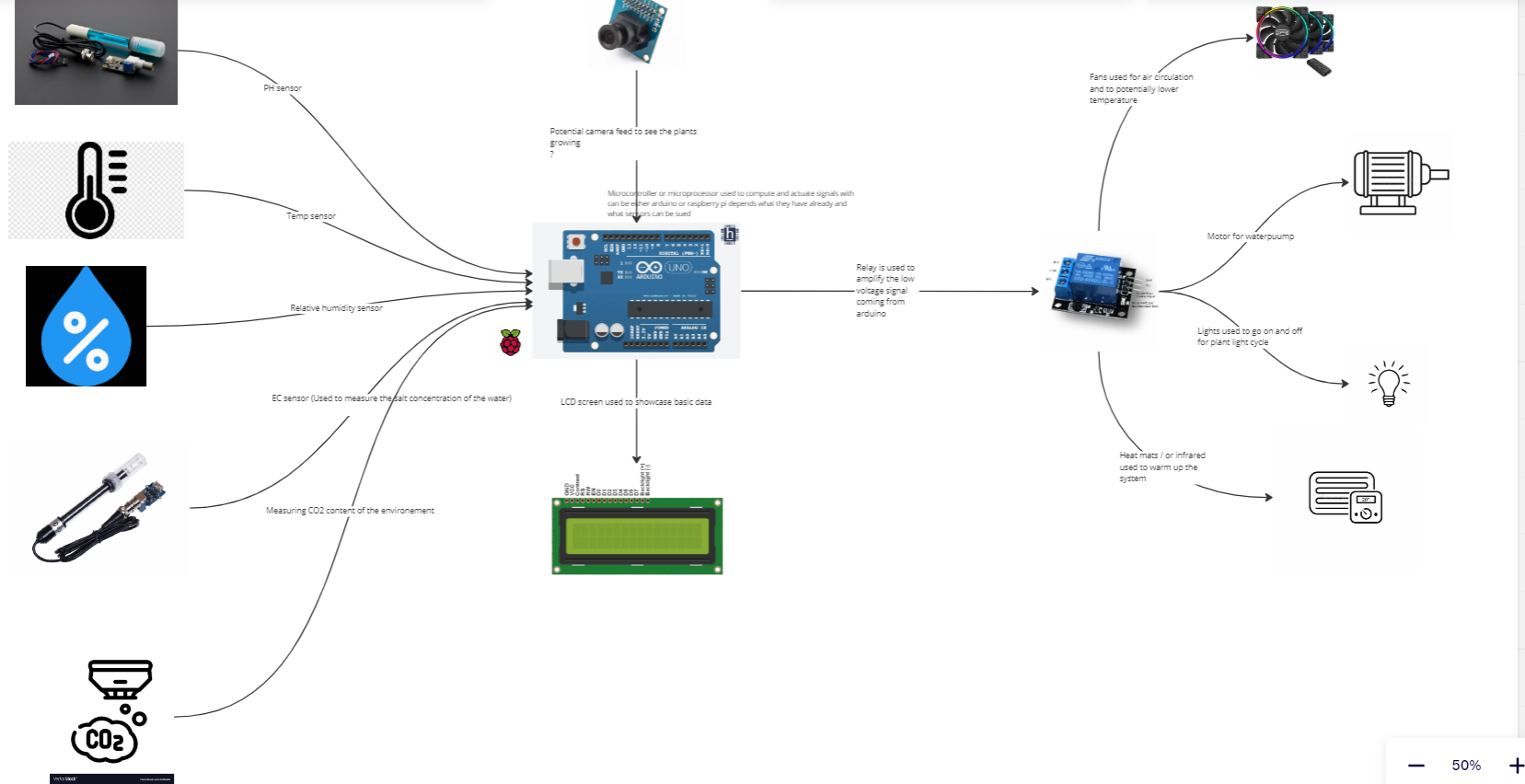

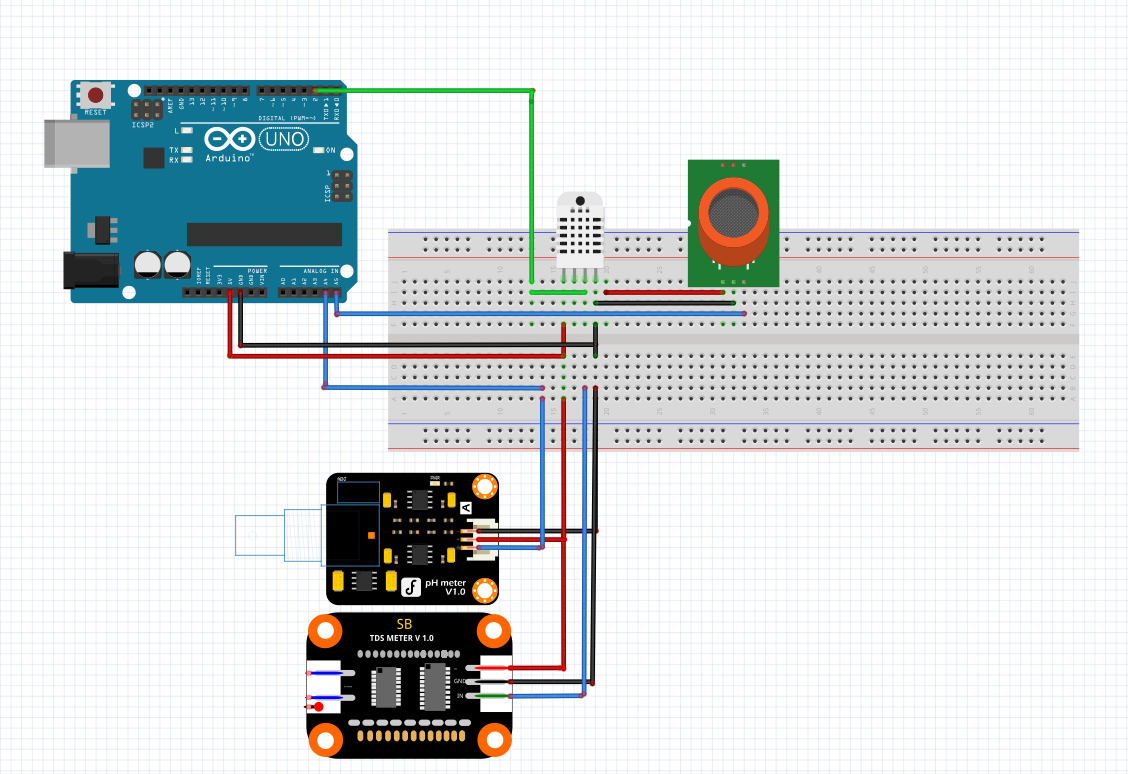

Hardware

Sensors

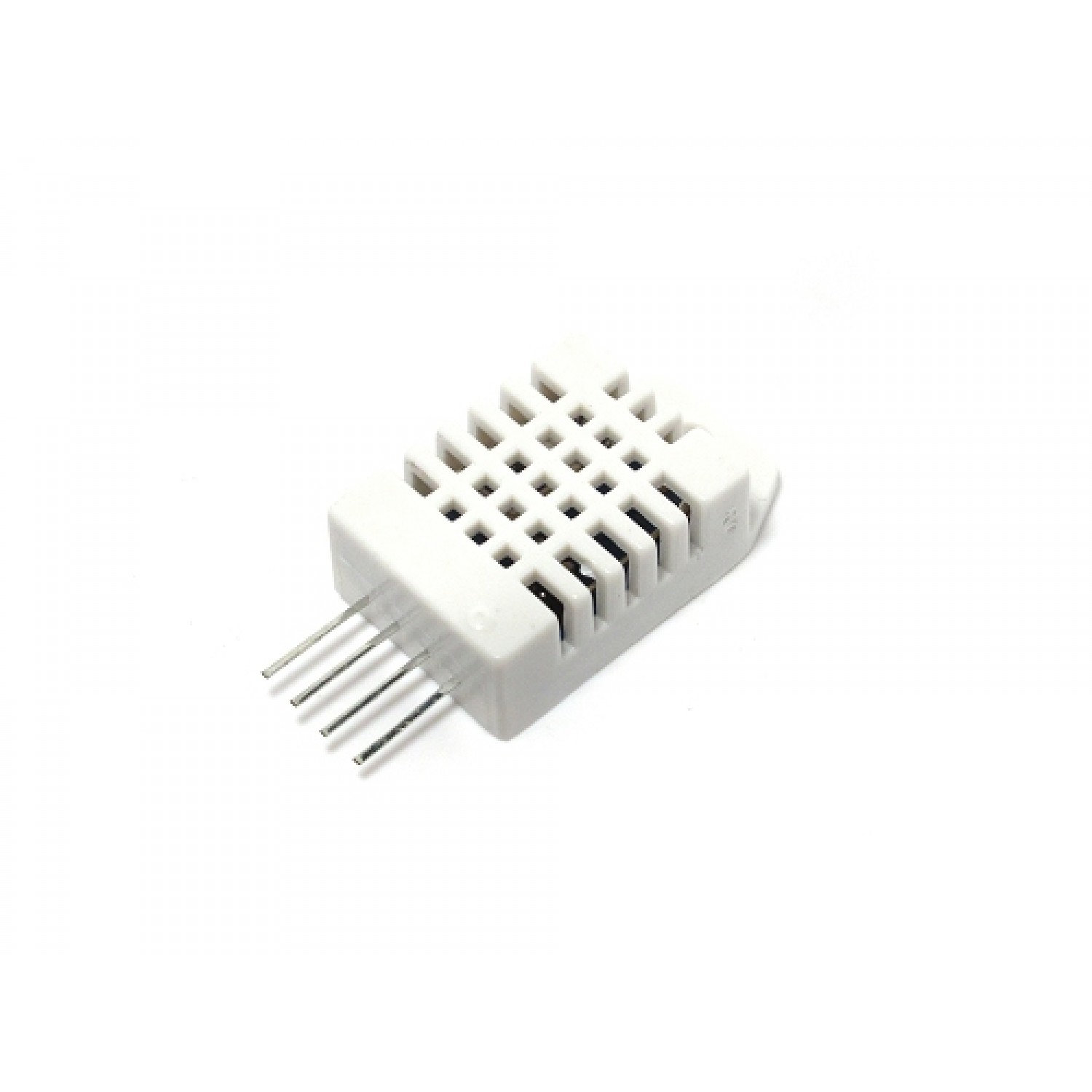

- Temperature/Humidity Sensor

Maintaining an optimal temperature is crucial for the growth of microgreens as it affects the rate of germination and growth of the crops (Allred & Mattson, 2021). To ensure that the temperature conditions are suitable for the microgreens, we have incorporated a temperature sensor into our setup. Moreover, the sensor also features a humidity sensor. The humidity levels can significantly influence the germination and growth of the plants, just like the temperature. For microgreens, achieving an optimal humidity level of around 100% relative humidity is critical for successful germination (Rusu et al., 2021). This indicates that high humidity is necessary for successful germination, thus, crucial in the system. After germination, microgreens flourish with humidity levels between 40 and 60% (Abajeeh, kingston, Harty, 2023). Temperature levels should be around room temperature, approximately 18°C at night and 20°C at daytime (Khan, Vadsaria, 2020). Furthermore, increasing the temperature and humidity past its optimal boundaries raises the risk of pest and disease issues.

- PH Sensor

The ideal pH level plays an essential role for growing microgreens as it impacts the nutrient accessibility in the substrate, ultimately influencing the growth and nutritional value of the microgreens (Palmitessa et al., 2020; Renna et al., 2020). Moreover, according to Palmitessa et al.’s (2020) a variety in nutrient solution strength had an effect on yield and quality parameters, along with physiological behavior and certain quality characteristics of the microgreens. Adequate pH range between 5.5 and 6.5. Because of its importance, we have chosen to implement a pH sensor into the system. If pH levels are too low, alkaline drops can be added to the nutrient solution. This pH control isn't automated.

- CO2 Sensor

Another important factor to consider when growing microgreens is the level of CO2. CO2 is widely recognized as a crucial component in the process of photosynthesis. Studies have shown that increasing CO2 levels can increase the yield and nutritional value of microgreens (Eissa et al., 2019). However, it must be noted that too much CO2 can also have negative effects on the plant growth and quality. Thus, it is essential to maintain an optimal CO2 levels using sensors.

Computing

- Arduino Uno

The Arduino is a microcontroller-based platform that provides an easy-to-use and versatile environment for building electronic systems. Its main purpose is to act as a brain for electronic systems by processing input signals from various sensors and generating output signals to control various actuators. The sensors measure various physical and environmental parameters. These signals can be processed by the Arduino to activate certain actuators. The selected microcontroller for this project is the Arduino Uno, as it meets all the necessary requirements as demonstrated in figure ....

Actuators

- Water pump

The hydroponic system during this project utilizes an ebb and flow method. Ebb and flow system can regulate the water according to the needs of the crops, thus contributing to a reduction in overall water consumption (Ferrarezi et al., 2015). Furthermore, Thomas (1993) states ebb and flow systems have been linked to a reduced incidence of foliar diseases, as well as lower risk of water contamination. This method involves two distinct phases: flooding and draining. During the flooding phase, water is pumped from the reservoir to the microgreens. This process continuous until a predetermined point, which is determined by the valve's height, is reached. Subsequently, the water is drained back into the reservoir.

Therefore, the water pump chosen, see figure ..., is of importance as it circulates water to the plants.

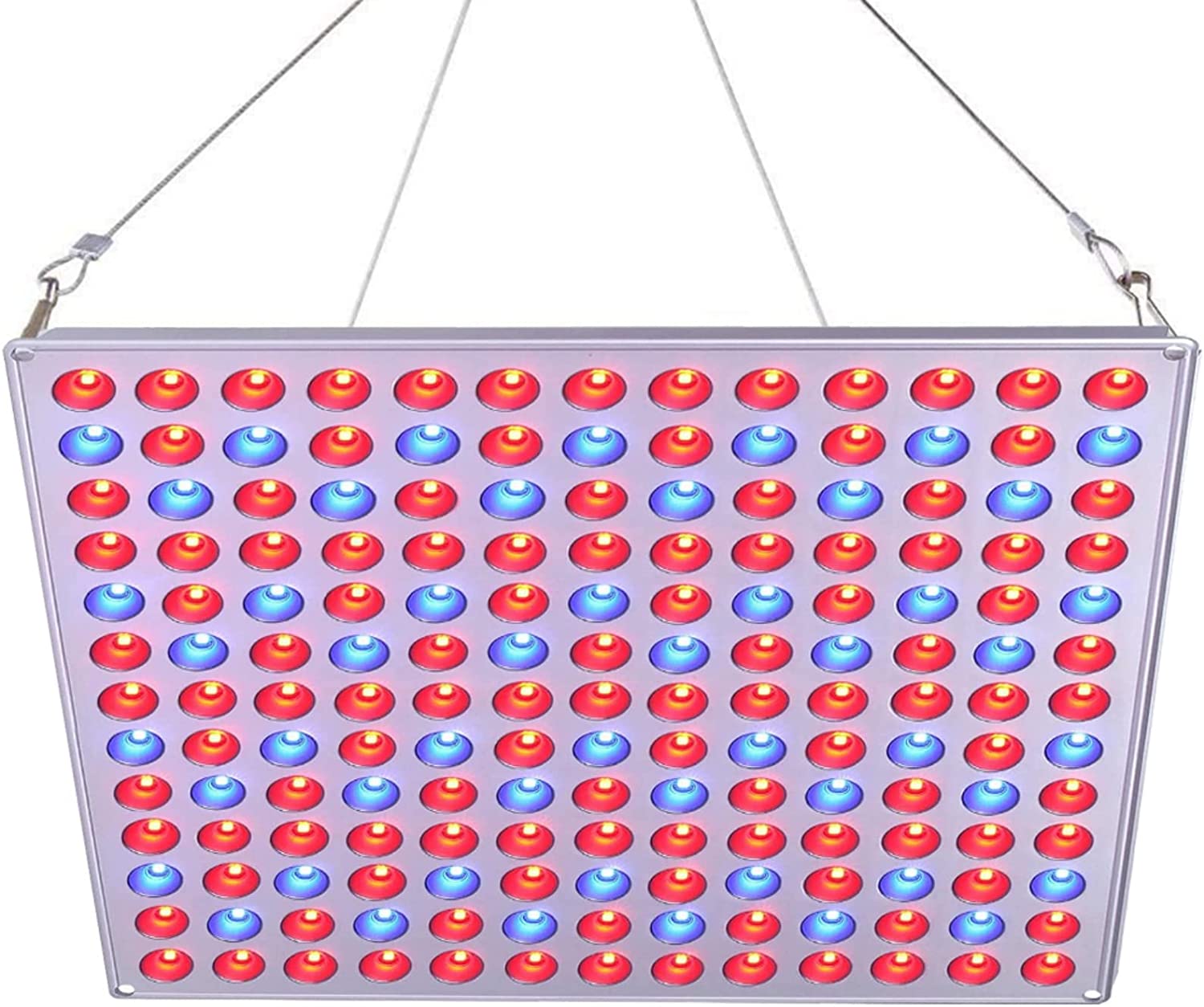

- Light

While no light is required during germination phase of microgreens, similar to other plants, they require light for the process of photosynthesis, which promotes their growth and flavor development. During this project, specifically LED lights are chosen, due to the low radiant heat emission, high emissions of monochromatic light, photon efficiency, long life expectancy, flexibility and mechanical robustness (D'Souza et al., 2015). In addition, given the increasing energy costs, the employment of LED lightning may be advantageous owning to its energy efficiency (Yeh & Chung, 2009). No definitive light cycle has been identified by literature as the most optimal, thus during this project the most common light cycle profiles are provided for the user. Previous research has shown, that light quality and quantity both exert significant effect on the plants morphology (Cope & Bugbee, 2013; Bantis, 2021). Regarding light quality, the growth of plants is mainly influenced by red and blue regions of light as they are the wavelengths where chlorophyll pigments absorb the most (Lin et al., 2013). The lights chosen for this project, see figure ..., have a combination of both red and blue lights. Additionally, the height of the light is important as this determines the light intensity. During her cultivation journey, Saša (2021) determined that the optimal height, for LED lights, for a variety of microgreens was approximately 22cm. Lastly, Utilizing LED lights can be regarded as an efficient and promising strategy to cultivate microgreens with higher nutritional value, therefore it has been decided to choose artificial lights.

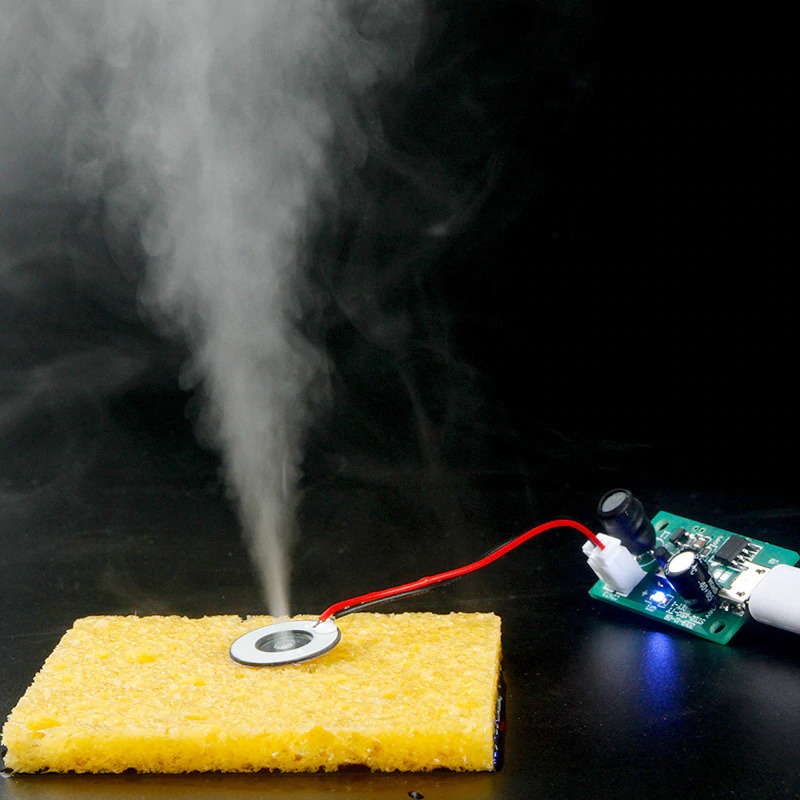

- Humidifier

In order to regulate the humidity in the vertical farm, a humidifier was acquired (see figure ...). The humidifier consists of a round ultrasonic module attached to a power supply. The module is placed on a wet surface, for example a sponge. It creates high frequency ultrasonic vibrations, which causes the water to break up in droplets. Because of their large surface area, these droplets will absorb heat from the surrounding air, causing them to evaporate. Since evaporation costs energy, a turned on humidifier will cause the system to cool down.

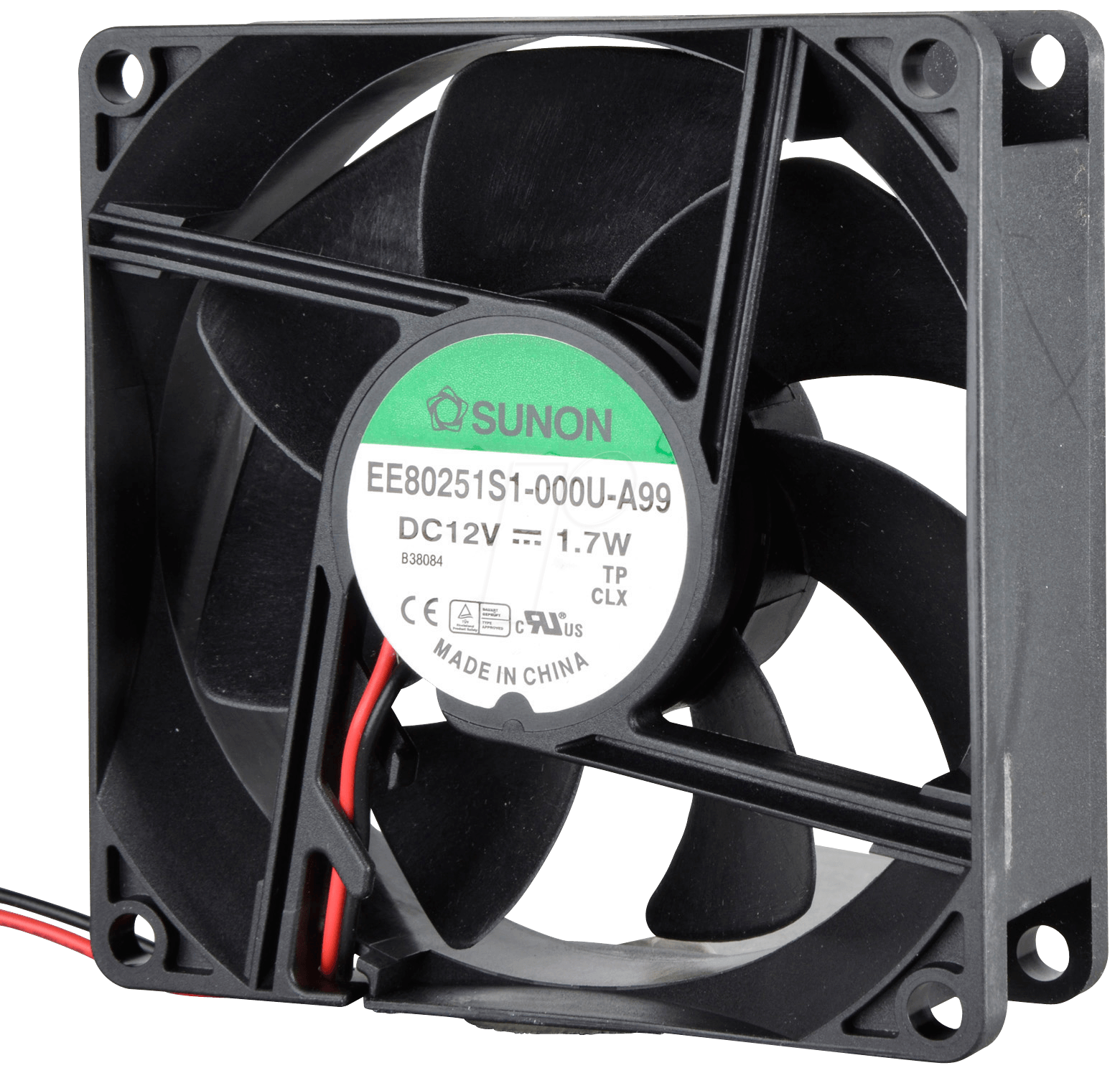

- Fans

The fans utilized in the current system are illustrated in figure .... These fans play a critical role in regulating temperature, humidity, and air circulation within the system, thereby contributing to the overall success of the cultivating process. They create an air flow in and out of the system, causing the climatic conditions inside to be more similar to the outside space. For example, after the germination the fans can be turned on the lower humidity of the vertical farm.

Other

- LCD Screen

The project's objective of ensuring user-friendliness led to the adoption of an LCD screen. The LCD screen provides a platform for the user to the view data from all sensors and to interact with. For instance, if the LCD screen displays that the pH water is deviating from the optimal point, the user can decide to refresh the water. By default, the LCD displays the measured temperature, humidity, gas sensor value and PH level of the water.

Implications

- stacking

The current system is designed to be modular, allowing for the boxes to be stacked on top of each other, and the user can decide on the number of levels based on various factors, including their living space, desired crop yield, and financial constraints. At present, the prototype includes several actuators that are linked to an Arduino. However, connecting multiple levels to a single Arduino presents a challenge due to limited inputs. One possible solution is to install four sensors for each level, placing them in each corner and averaging the data to simplify the stacking process rather than duplicating sensors for each level.

- clogging of tubes

Although the clogging of tubes is not one of the common problems of vertical farms, it should still be considered. In the current hydroponics system, the possible causes of tube clogging could be, algae bloom or loose growing medium. The factors that contribute to the growth and multiplication of algae are environmental conditions such elevated water temperature, exposure to sunlight, and an ample sumply of nutritions. As these are hydroponic requirements, it makes it a favorable place for algae to grow and develop. Furthermore, from the growing mat it is possible that small particles disintegrate in the system, and when accumulating over time this might clog the tubes. This requires the user to clean the tubes of the system and other necessary components, which might be not as user-friendly.

Software

Control

- Arduino control

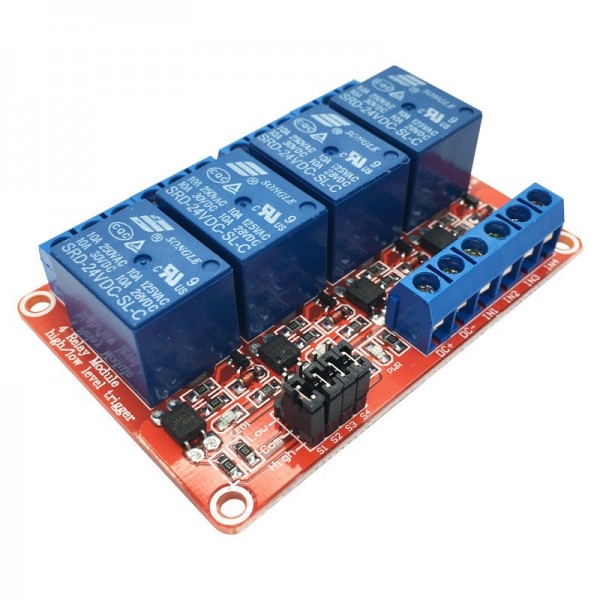

The Arduino Uno is the sole system responsible for receiving sensor inputs and providing actuator outputs. All sensors are connected to the Arduino by two power pins and a signal pin. The actuators can be split into two groups: The 12V DC actuators and the AC actuators. The 12V DC actuators are the fans, pump and humidifier. They are connected with an external 12V DC voltage source to a switch circuit utilizing an NPN transistor, the gate of which is connected to the Arduino. Only when the Arduino sends a high input signal to this transistor will it conduct, causing the actuator(s) to turn on. Using multiple of these circuits its possible for the Arduino to individually turn actuators on or off according to the sensor inputs and desired levels. The AC actuators include the lights and heat mats of the farm. Because they require high AC voltages, they cannot be controlled by a simple transistor circuit. Therefore they are controlled via a relay. A relay is an electronically operated switch that permits the control of high current loads with a small electrical current. Due to the high current demands of some actuators, a relay is essential as it provides a secure and efficient means of switching such loads. The specific relay can be seen in figure ....

- PID control

It was originally planned to utilize PID controllers for regulating temperature and humidity within the vertical farm. This form of controller would be effective at minimizing errors and deviations from a certain set point of a parameter. However, it was later decided to not have any integral or derivative control. The reason for this is because of the actuators, which are not suitable for this type of control. In order to properly regulate i.e. the temperature, the controller would send PWM signals of varying duty cycles, which actuators like the fans are not optimized for. Instead all actuators in the vertical farm should either be turned fully on or fully off. PID control is also very useful for maintaining a singular value for a parameter, which is in contrast with our design choice to have temperature and humidity be regulated within a certain range of values. In conclusion, there is no possibility nor need for such an accurate controller in the system.

- Control Loop:

Humidity Control Feedback Loop: The basic feedback loop for controlling humidity in a vertical farm involves a sensor that measures the humidity levels in the air, a controller that receives input from the sensor and determines if the humidity is too high or too low, and an actuator that adjusts the humidity levels to achieve the desired setpoint.

The controller compares the current humidity level with the desired range of humidity. If the measured humidity is too low, the controller will turn the humidifier on. If it is too high, the controller will turn the fans on to circulate less humid air from outside the farm in. If the humidity is within acceptable range, both actuators are off by default.

Temperature Control Feedback Loop: The feedback loop for controlling temperature in a vertical farm is similar to the humidity control feedback loop. A sensor measures the temperature in the air, a controller receives input from the sensor, and an actuator adjusts the temperature to achieve the desired setpoint.

The controller compares the current temperature with the desired range for temperature. If the measured temperature is too low, the controller will turn on the heat pads at the base of the farms upper level. If it is too high, the controller will turn on the fans to circulate the warm air out of the farm. If the temperature is within acceptable range, both actuators are off by default.

It is of note that both the temperature and humidity control loops utilize the fans to regulate their respective levels. This could case a clash in control; In a situation were the air inside the farm is too hot but has a low humidity, the fans should be turned on to lower the temperature, while at the same time the humidifier should be on and the fans turned off, to not ventilate the newly humidified air. It was decided that for the fans to be turned on, both the temperature and humidity have to be above preferred levels at the same time.

CO2 Control Feedback Loop: The feedback loop for controlling CO2 levels in a vertical farm is a bit more complex than the previous two. A sensor measures the CO2 levels in the air, a controller receives input from the sensor, and an actuator adjusts the CO2 levels to achieve the desired setpoint. However, an actuator to regulate the CO2 levels was not implemented in the prototype, but the system does relay a warning message when CO2 levels get too high.

The controller compares the current CO2 level with the desired setpoint and calculates the error. The controller then sends a signal to the actuator, which can be a system that injects CO2 into the air or a system that vents out excess CO2, to adjust the CO2 level accordingly. The controller continuously monitors the CO2 level and makes adjustments as needed to maintain the desired setpoint.

Overall, the feedback loops for controlling humidity, temperature, and CO2 levels in a vertical farm using climate control are essential for maintaining optimal growing conditions for plants. By continuously monitoring and adjusting these variables, the feedback loops ensure that the plants receive the ideal conditions for growth and yield.

Code

The code for the Arduino is fairly straightforward and can be viewed here: https://github.com/paulx25/vertical_farm_final . It consists of a few distinct parts:

- Time: At the start of each loop, the Arduino reads the current time from an external source.

- Read: Next, the Arduino updates the values for measured temperature, humidity, PH and gas levels from the sensors.

- Display: The LCD display is updated, showing the most recent value for temperature, humidity, PH and gas levels.

- Control: Through a series of simple if-else statements, the actuators are turned on or off depending on the previous variables. Warning messages are printed if the PH or gas levels are inconsistent. The lights and pump are turned on or off depending on the time of day.

Because the lights and pump are turned on or off based on a 24 hour cycle, it is of importance for the Arduino to always have the current time. The Arduino cannot do this by itself, meaning that an external module is needed for this. For the prototype this was simply a laptop to which the Arduino was connected, but a smaller standalone module such as a DS1307 real-time clock chip would be better.

Crops

During this project is has been decided to grow microgreens, mainly due to the time constraints of this course. The growth time of leafy greens depends on the type of plants and growing conditions.

Albert (2022) provides an overview of commonly grown vegetables, with some taking as little as 30-50 days to mature and others taking even 8-10 weeks or longer. Furthermore, McGinnis and Garden-Robinsons (2022) provide a detailed analysis of lettuce, categorizing it into five groups based on maturity times, with looseleaf lettuce being the shortest at 40 to 50 days and ice berg lettuce taking up to 80 days. In contrast, microgreens have a growing period of only 7-28 days (Di Gioia et al., 2017), making them more suitable for this project’s timeframe. Furthermore, microgreens possess more nutritional value than their mature counterparts. For instance, Weber’s (2017) research demonstrated that hydroponically grown broccoli microgreens had higher nutrient content than the vegetables. Since it takes less time, fewer resources are also needed. Weber (2017) supports this by reporting a reduction in water usage by a factor of 158-236 when comparing the same nutritionally equivalent amount of mature broccoli to hydroponically grown broccoli microgreens. Specifically, radish microgreens (figure ...) will be cultivated during this project, as it has higher nutritional density than their matured counterpart (Xiao et al., 2012) an a short crop cycle. According to the research of Mlinarić et al. (2023) the radish microgreens were ready to be harvested on the seventh day, when they reached the stage with fully developed cotyledons. Jagdish’s (2020) in-depth blog about radishes shows that radish seeds germinate most readily when exposed to constant temperatures of 12 to 23°C and sprout at temperatures as low as 4°C and as high as 29°C. Regarding pH levels, radishes have a high percentage of germination in pH levels 4 to 12, whereas a very low percentage of germination in pH levels 1 tot 3 and pH level 13-14. Most microgreens grow well in relative humidity levels of around 40-60% (Morton & Stretch, 2018). During the germination phase, it is necessary to maintain a higher level of humidity. Finally, it is recommended to maintain a minimum CO2 concentration of 330 ppm during plant growth, as concentrations below this level can seriously impede plant growth and general health (F., 2014). Freddy F. (2014) also states that increasing CO2 concentration levels can lead to higher growth rates and yields. However, the “CO2 Calculator for Grow Room or indoor greenhouse” indicates that a maximum CO2 level of 1500 ppm should not be exceeded, as concentrations above this value can become toxic to plants.

Moreover, to promote a hetereogeneous cultivation, the decision has been made to also cultivate the microgreen cress (Figure ...). Similarly as the radish microgreen, it has a short crop cyle. More precisely, the selected cress microgreens depicted in Figure ... have a cultivation period ranging from 3 to 6 days. There are currently not many scientific papers indicating any optimal values for the microgreens cress, however, as many microgreens have similar optimal values we assume and apply the optimal values of the radishes to the microgreen cress.

Although microgreens are being grown for this project, it doe not imply that the system is exclusively restricted to microgreens. The system is capable of cultivating various other crops as well, but some adjustments may be required to optimize the growth of specific crops. For example, cucumbers require other climatic conditions. The temperature inside the farm should be higher, and the medium more alkaline (Singh et al.). It takes more time before cultivation, around 65 days. Furthermore, cucumber plants need quite a lot space, possibly making it necessary to built a bigger vertical farm.

Discussion

- what could have gone better

- in terms of functionalities what could be implemented in the future

- etc.

Images and a video of the prototype have been shown to the participants of the user study, in order to gather feedback on the end result of the project. They confirmed that all the features that were necessary in their opinion were implement in the prototype. These features include: water and nutrient supply; light-, temperature- and humidity control. Furthermore, the colored LED light and the small viewing window were appreciated. The potential users also mentioned some improvements of the prototype. Firstly, that the model could be more compact. The prototype still contains quite some empty space, making it bigger than absolutely necessary. They additionally indicated that the use wood could be problematic. This was also noticed during the testing of the prototype, in which the wood quickly became wet. In an actual product, wood should be isolated better or different materials can be used. Because the prototype was built as a proof of concept, it only contains one story. Yield per area can be improved by stacking multiple stories on top of each other. The user feedback has been used to create a CAD model of a new prototype, it is displayed below in figure (…). The structure of the new prototype is made of metal and the sides are covered by white acrylic. Material costs of the new prototype are estimated to be around €400. This is more expensive than the original design, but still a lot cheaper than alternatives.

There various new functionalities that could be implemented a future prototype. One of them is a mobile app, that is connected to the sensors inside the farm. The app makes it possible for the user to monitor the conditions in the farm like temperature and humidity, while being away from home. A more advanced app could also make it possible to change these climatic conditions from a distance. Furthermore, there can be programmed growth cycles for various plant species inside the app. After selecting the right growth cycle the system will automatically alter the temperature and light cycle to optimal conditions for that specific crop. Installing a camara inside the system is also useful. The camara makes it easier to look closely at the crops, via a display or an app. The device could also be implemented to monitor plant health. For example, to detect drought, fungus or abnormal discoloration. This does require some kind of deep learning image detection algorithm though, (Kulkarni, 2018).

Approach, milestones and deliverables

Week 1 (06/02/23 -> 13/02/23):

- Brainstorm about topic

Week 2 (13/02/23 -> 20/02/23):

- Narrow down to specific concept

- Write out some aspects of the topic

CARNAVAL BREAK

Week 3 (27/02/23 -> 06/03/23):

- Conducting user surveys and MoSCoW

- Research regarding components and crops

- Early prototype designs

Week 4 (06/03/23 -> 13/03/23):

- Obtaining survey results and analyzing feedback

- Ordering components

- Starting on prototype construction

Week 5 (13/03/23 -> 20/03/23):

- Adding research done on wiki

- Creating code for the electronics

- Continuing on prototype construction

Week 6 (20/03/23 -> 27/03/23):

- Creating an electronic system

- Continuing on prototype construction

- Start growing the seeds

- Working on presentation

Week 7 (27/03/23 -> 03/04/23):

- Finalizing Prototype

- Presentation

Week 8 (03/04/23 -> 10/04/23):

- Finalizing Wiki

Task Division

| Name | Total | Breakdown week 1 |

|---|---|---|

| Vietlinh Pham | 2 | Meeting (1h), Group formation (1h) |

| Lars | 2 | Meeting (1h), Group formation (1h) |

| Wilbur | ||

| Mauritius | 2 | Meeting (1h), Group formation (1) |

| Paul | 2 | Meeting (1h), Group formation (1) |

| Aloysia | 2 | Meeting (1h), group formation (1h) |

Week 2

| Name | Total | Breakdown week 2 |

|---|---|---|

| Vietlinh Pham | 5 | Literature study(3), Meeting(2h) |

| Lars | 5 | Literature study (3h), Meeting (2h) |

| Wilbur | ||

| Mauritius | 6 | Literature study (4), Meeting (2) |

| Paul | 5 | Literature study (3h), Meeting (2h) |

| Aloysia | 6 | Literature study (4h), Meeting (2h) |

Week 3

| Name | Total | Breakdown week 3 |

|---|---|---|

| Vietlinh Pham | 4 | Research/Define Users (2h), Meeting (2h) |

| Lars | 6 | Meeting (2h), Problem statement (1h), research crop yields (2h), survey (1h) |

| Wilbur | ||

| Mauritius | Research sensor feedback loop system & research irrigation system (4h), miro | |

| Paul | 5 | Writing problem statement (2h), Meeting (2h), making survey (1h) |

| Aloysia | 12 | Sketching + research for sketch (3h), Meeting Carnaval (2h), Research + preliminary criteria per potential user group (0.5h), Miro (4h), Sketching (2.5h) |

Week 4

| Name | Total | Breakdown week 4 |

|---|---|---|

| Vietlinh Pham | Meeting (2h), searching sensors (2h), literature sensors (2h) | |

| Lars | 4 | Meeting (2h), Taking surveys (2h) |

| Wilbur | ||

| Mauritius | Meeting (2h), Designing irrigation system (2h), Ordering parts and picking up (1), designing sensor system (2h), looking at system integration (2h) | |

| Paul | 6 | meeting (2h), taking surveys (2h), writing arduino code (1h), researching lighting (1h) |

| Aloysia | 4.5 | Miro (1.5h), Sketching (3h) |

Week 5

| Name | Total | Breakdown week 5 |

|---|---|---|

| Vietlinh Pham | Meeting (1h), Research and Writing out Wiki; Actuators(4h) | |

| Lars | 5 | Meeting (1h), results survey (1h), stota (3h) |

| Wilbur | ||

| Mauritius | ||

| Paul | Meeting (1h), writing arduino code (3h), implementing sensors/actuators (2h) | |

| Aloysia | 16 | Meeting w/Mauritius (1h), CAD (14h spread out), Research for CAD (1h) |

Week 6

| Name | Total | Breakdown week 6 |

|---|---|---|

| Vietlinh Pham | Research and Writing out Wiki; Crops(4h), Adding all purchased components to Wiki (1h) | |

| Lars | ||

| Wilbur | ||

| Mauritius | ||

| Paul | meeting (2h), Writing arduino code (4h), implementing sensors/actuators (4h) | |

| Aloysia | 13h | Meeting (10mins?), Building Monday (5h), Building Thursday (8h) |

Week 7

| Name | Total | Breakdown week 7 |

|---|---|---|

| Vietlinh Pham | Building Thursday (4h), Building Friday (7.5h) | |

| Lars | ||

| Wilbur | ||

| Mauritius | ||

| Paul | ||

| Aloysia | 20.5 | Building Monday (6h), Building Thursday (4h), Building Friday (7.5h), CAD (3h) |

SotA: Literature study

Literature study

In a vertical farm there is not enough room for plants to grow on a standard soil. There are two main methods to solve this issue hydroponics and aeroponics. In hydroponics plants are grown in a nutrient water solution. Aeroponics instead uses no growing medium, the crops live an enclosed box filled with nutrient-rich air.

The primary advantage of hydroponics relative to regular agriculture is the reduction of soil-related cultivation problems such as insects, bacteria and fungus (Al-Kodmany,2018). This means that the need to use pesticides largely disappears. Furthermore, the method is requires a low level of maintenance, since there is no weeding or dirt removal (Al-Kodmany, 2018). Plants grow in a controlled environment, which means that aeration, pH and nutrient levels can optimized much more easily.

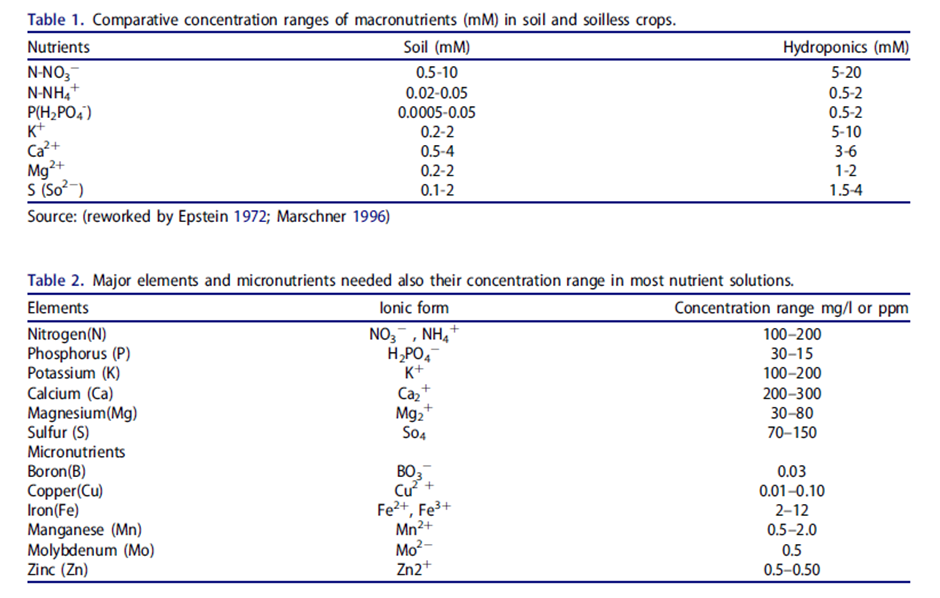

Hydroponics preferably uses reverse osmosis filtered water (Khan, Purohit and Vadsaria, 2021). This water contains little to none salts and has a neutral pH level. This makes it easier to add the right amount of nutrients later. There are ready made nutrient mixtures for hydroponics available online, it is also possible to make your own mixture. The appropriate concentration of several minerals are listed in the tables below.

Of course, crops in a vertical farm also need light in order to grow. Because the system is placed indoors, this lighting will largely come from artificial sources. Hence, there will be substantial energy to operate a vertical farm. LED is used the most, but induction lighting is also an option, (Al-Kodmany, 2018). It is found that most greenhouse crops grow optimally with a light intensity between 50000 and 70000 lux, (Khan, Purohit and Vadsaria, 2021). But there has to be a right tradeoff between energy costs and crop yield. Since low light intensities are used more efficiently, it can be beneficial to use constant low light intensity instead of a more natural rhythm, (Khan, Purohit and Vadsaria, 2021).

Maximum fruit production is generally achieved with a day temperature of 20°C and night temperature of 18°C. Because this almost perfectly corresponds to room temperature, there is no need to heat our vertical farm system.

Mau:

1.

Article: http://27.109.7.66:8080/xmlui/handle/123456789/682

The article highlights the efforts being made to automate the labor-intensive agriculture industry through the use of robots and machines. A vision-based row guidance method is proposed for autonomous farming robots to navigate through row crops in a field, using machine vision to detect the offset and heading angle in real-time. The robot platform is designed with an open architecture and a control scheme for row guidance. The focus of the robot is to monitor the health of the plants by observing their leaf color and height, as well as the surrounding environmental conditions such as temperature, moisture, and humidity. The information collected is then used to determine the health of the plant, which is displayed on an LCD screen.

2.

Article: https://ieeexplore.ieee.org/abstract/document/9080736

This paper discusses the how wireless sensor network can be used to detect weeds. However, when a lot of static sensors are present the project becomes expensive and chaotic. Therefore the researches decided to make use of autonomous bots which are equipped with ultrasonic sensors and cameras that can detect weeds. The camera input is then processed using a neural network and image segmentation. Once weeds were detected, herbicides were sprayed on them using solenoid valves.

3.

Article: https://link.springer.com/chapter/10.1007/978-90-481-9277-9_20#Abs1

The text discusses the demand for advances in automation in agriculture, horticulture, and forestry due to high labor costs. The focus is on the potential of robotic outdoor systems to increase efficiency and make operations economically viable. The chapter provides examples of autonomous crop protection operations that are likely to be commercially available in the near future. These operations, such as scouting and monitoring, can be automated for increased efficiency, but current systems still have drawbacks, including a lack of robust and safe behaviors. The use of high-precision targeting based on individual weed plant detections holds the potential to greatly reduce the use of resources, such as herbicides.

4.

Article:An overview of smart irrigation systems using IoT - ScienceDirect

The paper provides an overview of the field of agricultural robotics, which has become a popular topic of research and development in recent years. It highlights the critical challenges faced by the agriculture industry, such as labor shortages and the need for environmentally friendly practices, and how agricultural robotics can address these issues. The paper also presents an overview of the current state-of-the-art in agricultural robotics, including individual robots for specific tasks and cooperative teams of robots for farming tasks. The paper concludes by discussing the challenges that still need to be addressed in order to fully automate agricultural production, which is seen as a promising solution for sustaining the growing human population

5.

Article: https://www.mdpi.com/2073-4395/11/9/1818

This paper discusses how agricultural sustainability can be enhanced by integrating technology. Improving of irrigation systems is of importance and IoT and sensory systems could habilitate this. Automated irrigation systems are important for conserving water. IoT and automation are linked to agriculture and farming techniques for making processes more effective and efficient. Moreover, sensory systems improve farmers' understanding of crops and reduce environmental impact and conserve resources.

Vietlinh:

1.

The paper reviews recent advancements in the application of automation and robotics in precision agriculture. The aim of precision agriculture is to maximize agriculture produce while minimizing environmental impact through precise farm management using modern technology. The paper highlights challenges and provides suggestions for the design of efficient autonomous agricultural robotic systems that consider all possibilities and challenges in different types of agriculture operations and take into account development cost to make it affordable for farmers.

2.

Article: https://ieeexplore.ieee.org/document/9243253

This paper reviews three important developments in the field of autonomous robotics in agriculture. These developments include navigation using GPS technology and vision-based navigation, harvesting systems with sensors and actuators, and a soil analysis system to provide farmers with information about the land. The paper presents successful research and applications in these areas and highlights the needs for additional research and development to bring this technology to developing countries where it is not widely used in agriculture.

3.

Article: https://www.sciencedirect.com/science/article/pii/S1110982321000582

This paper focuses on new approaches in smart farming and highlights the importance of data gathering, transmission, storage, and analysis in solving the challenges of food shortage and population growth. IoT is crucial in smart systems, and the smart irrigation systems uses sensors for monitoring water level, irrigation efficiency, and climate. The use of unmanned aerial vehicles (UAVs) and robots in agriculture is also discussed, and their applications include harvesting, seeding, weed detection, irrigation, and pest control. The paper also mentions the role of artificial intelligence (AI), deep learning (DL), machine learning (ML), and wireless communications in smart farming. The paper highlights the challenges in implementing smart farming in developing countries and the need for government and private sector support, as well as the use of Smart Decision Support Systems (SDSS) for real-time analysis and soil mapping to support proper decision making.

4.

Article: https://ieeexplore.ieee.org/abstract/document/9003290

This paper examines the impact of IoT and smart computing technologies on agriculture and farming. It highlights how these technologies have revolutionized the industry and are now widely used for tasks such as monitoring crops and soil moisture. However, the paper also warns of the cybersecurity threats and vulnerabilities that come with using IoT and smart communication technologies in the smart farming environment. The paper provides a holistic study of the security and privacy issues in a smart farming ecosystem, outlining a multi-layered architecture and discussing potential cyber-attack scenarios. The paper also identifies open research challenges and future directions in the field.

5.

Article: https://onlinelibrary.wiley.com/doi/full/10.1002/aepp.13177

The paper describes the potential benefits and regulatory challenges of using autonomous crop equipment in agriculture. The paper aims to summarize the primary regulatory issues related to the use of autonomous equipment for crop production and its impact on the development and adoption of this technology. The paper covers three main objectives:

1. Summarizing the lessons learned from regulation of autonomous equipment in other sectors of the economy

2. Describing the current status of regulation related to autonomous crop equipment

3. Providing an example from the United Kingdom of how regulation can affect the development of autonomous equipment in crop production.

The paper also argues that regulation will have a major impact on the type of autonomous crop equipment that is commercialized and the pattern of its adoption.

Aloysia:

Articles 1-5 can help justify the need for the development of vertical farming (without focusing on vertical farming itself). Articles 6-9 discuss the benefits and drawbacks of vertical farming. Articles 7-12 discusses crops / most efficient input→ output in food/farming.

1: Rundlöf, M., Edlund, M., & Smith, H. G. (2010). Organic farming at local and landscape scales benefits plant diversity. Ecography, Ecography(3), 514–522. https://doi.org/10.1111/j.1600-0587.2009.05938.x

The article examined the effects of organic farming on plant diversity at both local and landscape scales. They hypothesizes that the consequences of organic farming would differ depending on the scale of uptake in a particular landscape. The study utilizes a landscape scale approach and found that the local effect of organic farming was consistently stronger, with higher diversity in borders adjoining organic fields. The results showed that “forb richness” was higher in borders located in landscapes with higher proportion of organic land (potentially due to dispersal of mainly annual plant species from the organic fields). The study highlights the importance of considering multiple scales, including local and landscape factors, to better understand biodiversity patterns, and the potential benefits of organic farming.

2: Lobley, M., Butler, A., & Reed, M. (2009). The contribution of organic farming to rural development: An exploration of the socio-economic linkages of organic and non-organic farms in England. Land Use Policy, 26(3), 723–735. https://doi.org/10.1016/j.landusepol.2008.09.007

The article explores the socio-economic link between organic and non-organic farms, and the contribution of organic farming to rural development (in England). The study found that organic farms tend to employ more people and differ in characteristics (to non-organic farms). Differences in local economic connections between the two were miniscule. The authors argue that a more nuances approach is needed when considering the rural development benefits of organic farming, where other factors such as the type of enterprises on the farm and the marketing strategies adopted by the business should also be taken into account. The focus of debate shifted from equating organic production with local supply and assuming a local economic benefit to a broader understanding of the local “agro-food” economy and the connections between different types of farms and local and export markets.

3: Lipper, L., Thornton, P., Campbell, B. M., Baedeker, T., Braimoh, A., Bwalya, M., Caron, P., Cattaneo, A., Garrity, D., Henry, K., Hottle, R., Jackson, L., Jarvis, A., Kossam, F., Mann, W., McCarthy, N., Meybeck, A., Neufeldt, H., Remington, T., … Torquebiau, E. F. (2014). Climate-smart agriculture for food security. Nature Climate Change, 4(12), 1068–1072. https://doi.org/10.1038/nclimate2437

The paper discusses “Climate-smart agriculture” which is a strategy aimed at ensuring food security with regards to Climate change. Changes in rainfall and temperature patterns have been affecting agriculture. The livelihoods of those dependent on agriculture become more vulnerable, especially the poor. CSA aims to reduce these risks by increasing the adaptive capacity of farmers and improving resilience and resource use efficiency in agriculture. This would involve efforts from farmers, researchers, the private sector, civil society, and policy makers, with focus on; building evidence, increasing local institutional effectiveness, fostering policy coherence, and linking financing.

4: Ortiz, A. M., Outhwaite, C. L., Dalin, C., & Newbold, T. (2021). A review of the interactions between biodiversity, agriculture, climate change, and International Trade: Research and policy priorities. One Earth, 4(1), 88–101. https://doi.org/10.1016/j.oneear.2020.12.008

A section that I focused on discusses the impact of international trade on biodiversity and the environment. Nearly 1 billion people consume internationally traded food products, which leads to environmental impacts in the country of origin, mostly in developing countries. International trade drives 25% of bird species loss and more than half of the biodiversity impacts due to loss of suitable habitat from soybean production in the Brazilian Cerrado. Life cycle assessment (LCA) is emerging as a method for evaluating the end-to-end environmental impact of products and can link a final commodity to its associated biodiversity loss. However, it can be challenging to measure and aggregate impacts across a product's life cycle. The impact of international trade on biodiversity through climate change has not been considered, but countries could design trade policies that consider climate change and biodiversity to reduce damages. International trade also contributes to climate change through GHG emissions associated with traded commodities and their transport, which make up a small percentage of the total GHG emissions from food production. There is still a need for research to understand how international trade can be used to mitigate negative impacts or take advantage of benefits of climate change.

5: Lal, R. (2020). Home Gardening and urban agriculture for advancing food and nutritional security in response to the COVID-19 pandemic. Food Security, 12(4), 871–876. https://doi.org/10.1007/s12571-020-01058-3

The article states that the world cereal (?) production increased by 2.3% in 2019(?????), but the number of people facing severe food insecurity may double to 265 million by the end of 2020 due to the COVID-19 pandemic. The problem is severe in urban areas where the global population is projected to increase, causing food supply chain disruptions and increase in food waste. To address the issue, there is a need for more resilient food systems, reduced food waste, and strengthened local food production. Home gardening and urban agriculture can play an important role in advancing food and nutritional security and improving ecosystem services, but risks of soil contamination by heavy metals must be addressed.

6: Jansen, G., Cila, N., Kanis, M., & Slaats, Y. (2016). Attitudes towards vertical farming at home. Proceedings of the 2016 CHI Conference Extended Abstracts on Human Factors in Computing Systems. https://doi.org/10.1145/2851581.2892474

This paper aimed to gain insights into people's attitudes towards small scale vertical farming technology for growing food at home. A prototype was developed that incorporated sensor and LED technology and was tested in a user study. The results of the study showed that people generally had a positive attitude towards the system, although a fully autonomous system was not preferred and concerns about food safety were raised.

7: Benke, K., & Tomkins, B. (2017). Future food-production systems: Vertical Farming and controlled-environment agriculture. Sustainability: Science, Practice and Policy, 13(1), 13–26. https://doi.org/10.1080/15487733.2017.1394054

This paper discusses the current challenges policy makers face with regards to providing food for the growing world population (expected to be 9.7billion by 2050). The issue of declining fertile land per person due to increasing population, urbanization and climate change was discussed. The paper highlights urban vertical farming as a potential solution because it involves the use of technology and automation for “land-use optimization.” Vertical farming aims to both increase productivity and reduce the environmental impact, whilst providing benifits (clean food source, biosecurity, protection from pests, droughts, and reduced transportation - using less fuel/less emissions). The article discusses pros and cons of vertical farming.

8. Banerjee, C., & Adenaeuer, L. (2014). Up, up and away! the economics of Vertical Farming. Journal of Agricultural Studies, 2(1), 40. https://doi.org/10.5296/jas.v2i1.4526

This article discusses the economic feasibility of Vertical farming. This was done by designing and simulating a 37 floor farm. The results showed that the farm could yield 3,500 tons of fruits and vegetables, and 140 tons of tilapia fillets, which is 516 times more productive than a traditional 0.25ha farm. The estimated costs were estimated to be 200million euros. The farm itself would require 80million litres of water and 3.5GWh of power power year. The cost of the produced food was estimated to be about 3.50euros to 4euros per kg. The article also states that more research is needed to optimize the production process to reap the full economic, environmental, and social benefits.

9. Al-Kodmany, K. (2018). The Vertical Farm: A review of developments and implications for the Vertical City. Buildings, 8(2), 24. https://doi.org/10.3390/buildings8020024

This paper discusses the growing need for vertical farming caused by food security concerns, urban population growth, limited farmland, and “food miles” (how far the food travels from farm to plate). The paper suggests that urban agriculture is a solution to these problems. Vertical farms combines food production and consumption in one place, and is stated to be suitable and an efficient option for urban areas where land is limited (and/or expensive). Advances in greenhouse technologies such as hydroponics, aeroponics, and aquaponics have made vertical farming more promising. Like the other papers mentioned prior to this one, this paper acknowledges obstacles with implementing vertical farms such as; economic feasibility, regulations, and lack of expertise.

10. Uphof, J. C. T. (1961). Dictionary of economic plants. The Quarterly Review of Biology, 36(4), 294–294. https://doi.org/10.1086/403521

This book/paper provides a comprehensive list of information on plants containing over 6000 economic plant species. Thee plants are listed alphabetically, includes scinitifc names, and descriptions. The book also includes groups of plants such as fungi, fiber sources, food plants, medicinal plants and food plants for livestock.

11. Hunt, R. (1990). Basic growth analysis. https://doi.org/10.1007/978-94-010-9117-6

This book is an introductory guide for students on the principles and practice of plant growth analysis. It provides a quantitive approach to describing and interpreting the performance of plant systems grown under various conditions. The methods described require simple experimental data and facilities.

12. Wöhrle, R. E., & Wöhrle, H. J. (2017). Basics designing with plants. Birkhäuser.

Helps understand how to design with plants where plants have specific needs and requirements. Although is more focused on designing WITH plants, can be useful to learn how they learnt about the limitations of plants.

Paul:

Morgan, B., Stocker, M. D., Valdes-Abellan, J., Kim, M. S., & Pachepsky, Y. (2020). Drone-based imaging to assess the microbial water quality in an irrigation pond: A pilot study. Science of the Total Environment, 716, 135757. https://doi.org/10.1016/j.scitotenv.2019.135757

This article covers a way to determine the quality of the water used for irrigation on farms. By using a small Unmanned Aerial Vehicle (sUAV) with several ways of capturing images while above a body of water and a regression tree algorithm, the E. coli concentration of the water can be determined quite accurately.

Al-Rami, B. ., Alheeti, K. M. A. ., Aldosari, W. M., Alshahrani, S. M. ., & Al-Abrez, S. M. . (2022). A New Classification Method for Drone-Based Crops in Smart Farming. International Journal of Interactive Mobile Technologies (iJIM), 16(09), pp. 164–174. https://doi.org/10.3991/ijim.v16i09.30037

This paper covers a method for crop classification on farms using drone imagery. To do this it uses a Convolutional Neural Network (CNN), as well as using methods commonly found other image processing algorithms. They could reliably identify crops in a field with a variety of plants as well as diseases on plants, classified by small details like spots on leaves.

Sri, M.S., Nikita, V.M., Bhargavi, S.D., Muneeruddin, M., Pragthi, K., & Kranthi, T. (2021). APP BASED AUTOMATIC IRRIGATION SYSTEM.

The article describes a simple water management system for farms using WiFi. Using data from soil measurers underneath the ground were crops are, more water can either manually or automatically be irrigated to the specific areas, depending on the users preference. The automatic model compares the current moisture levels with standard expected values and either switches the water on or off withing acceptable ranges.

Olujimi, A., Aaron, I., Adebayo, O., Afolarin, A., Jonathan, E. (2022). Smart solar powered irrigation system. Journal Européen des Systèmes Automatisés, Vol. 55, No. 4, pp. 535-540. https://doi.org/10.18280/jesa.550413

This article considers an expanded and more sophisticated system for automatic irrigation compared to the previous article. Using a solar powered system which besides moisture levels also considers weather forecasts and soil temperatures, It can optimize water usage for crops on a farm, while not requiring any energy other than that generated by its solar panels. This means it is a valuable tool on farms without easy access to energy.

Mauri, P. V., Yousfi, S., Parra, L., Lloret, J., & Marin, J. M. (2022). The Usefulness of Drone Imagery and Remote Sensing Methods for Monitoring Turfgrass Irrigation. Advances in Intelligent Systems and Computing, 913–923. https://doi.org/10.1007/978-3-030-90633-7_78

This paper discusses various methods for drones to aid in monitoring crop health. Using IR sensors to acquire soil temperatures, RGB cameras for crop identification, and moisture sensors on the ground whose data can be logged by the drone, it was found that these low cost drones were very efficient and accurate in their readings. It is especially useful for grassland management, were large areas need to be monitored daily.

Lars:

1 C.W. Bac, E.J. van Henten, J. Hemminga , Y. Edan (2014); Harvesting robots for high-value crops: state-of-the-art review and challenges ahead, https://edepot.wur.nl/327202#page=19.

This article investigates the use of robots in the harvesting of crops. It has two main objectives: reviewing the state-of-the-art technology in automatic harvesting and formulating challenges for future research in the field. The performance of the harvesting robots are determined by various factors such as localization, speed, successful harvesting and probability of damage. It was found that the fruits were harvested successfully 66% of the time. The main challenge is dealing with the dynamic environment of a crop farm. Future research should be focused on this aspect.

2 Henten, Hemming, Tuijl, Kornet, Meuleman, Bontsema, van Os (2002); An Autonomous Robot for Harvesting Cucumbers in Greenhouses, https://link.springer.com/article/10.1023/A:1020568125418.

This article is about an automatic cucumber harvesting robot. The goal is to design a robot that is both fast and accurate. In order to achieve this goal the environment in which the robot operates is specified, greenhouses. The next step is to formulate concrete design specifications. For example, how the griper should like and vision system of the robot. Using these design requirement a prototype was built. It had an accuracy of 80% and needed 45s on average to harvest a cucumber.

3 Henten, Bontsema (2009); Time-scale decomposition of an optimal control problem in greenhouse climate management, https://www.sciencedirect.com/science/article/abs/pii/S0967066108001019.

A model to regulate the climate in greenhouses is proposed in this article. It should maximize the effectiveness of greenhouses. To do this, the optimal trade-off between food production and energy consumption needs to be found. A hierarchical system is used in the model. This means that the components of the systems are linked to each other in a hierarchical manner from top to bottom. The proposed model should be able to deal with fast changing weather conditions and the slow food growing process simultaneously.

4 V. Dharmaraj* and C. Vijayanand (2018); Artificial Intelligence (AI) in Agriculture.

This paper analyses the role of AI in farming. It sees AI technologies as a way to improve food production and ensure that the growing world population can be fed. There are various technologies that are useful in an agricultural context such as disease detection, checking the ripeness of crops, field management and automatic irrigation. This should make farming both more profitable and sustainable in foreseeable future.

5 Selvaraj, Vergara, Ruiz, Safari, Elayabalan, Ocimati, Blomme (2019); AI-powered banana diseases and pest detection, file:///C:/Users/20213415/Downloads/s13007-019-0475-z.pdf.

An AI models for detecting diseases in banana crops are designed and tested. The AI use (dcnn) deep convolutional neural networks and are trained with transfer learning. Transfer learning is a method to train AI in which the program is shown many pictures of a certain phenomenon, in this case crop diseases. Afterwards it should be able to detect new pictures of the same theme. The best AI were able to detect diseases in banana crop more than 90% of the time.

Wilbur

1. Wan-Soo Kim, Dae-Hyun Lee, Yong-Joo Kim, Taehyeong Kim, Rok-Yeun Hwang, Hyo-Jai Lee, Path detection for autonomous traveling in orchards using patch-based CNN, https://www.sciencedirect.com/science/article/pii/S0168169920301460?casa_token=BwbBLKZ8TM0AAAAA:1jAKheg64XZ_z5pxpEC1h2AtTO9SAmJpv9Dcfrr8zTqB8gMNM7kfBAcgTmA6CGWYgGUrRXUylg

This paper proposes a novel and efficient patch-based approach for autonomous path detection in semi-structured environments such as orchards. The focus was on a perspective path-detection approach that uses CNN-based image-patch classification. The proposed path-detection approach can segment the path area by partial area classification, and can be implemented with a shallow CNN model trained with small datasets, in contrast to segmentation learning with pixel-based classification.

2. H.Pota, R.Eaton, J.Katupitiya, S.D.Pathirana (11 August 2007), Agricultural Robotics: A Streamlined Approach to Realization of Autonomous Farming, https://ieeexplore.ieee.org/abstract/document/4579153?casa_token=LPLd5q2w97UAAAAA:T-hI_iSqFUk1YijQi6EJMqti9HKGgMGrIfU9pEAde-2FmZNQeTScUBp6k6Mig_EautjvUutp

This paper discusses an approach that will lead to the development of future Precision Autonomous Farming Systems. A farming system has a number of sub-systems that operate at a lower level. Most of the time only minor changes take place to the boundaries of the farm although major restructuring can still take place within the allocated land. Thus, the emphasis is on the restructuring of the existing farms so that they become amenable to autonomous farming.

This paper presents the requirements of a future autonomous farming system. It emphasized the need to introduce a strict structure and the importance of taking into considerations the farm system parameters in developing an a priori PFDS that is continuously used by each precision autonomous farming unit. The PFDS is primarily used for machinery navigation and seeding.

3. K. D. Sowjanya, R. Sindhu, M. Parijatham, K. Srikanth and P. Bhargav, "Multipurpose autonomous agricultural robot," 2017 International conference of Electronics, Communication and Aerospace Technology (ICECA), Coimbatore, India, 2017, pp. 696-699, doi: 10.1109/ICECA.2017.8212756.

All kinds of agricultural robots have been researched and developed to implement a number of agricultural products in many countries. This Agribot can performs basic elementary functions like harvesting, planting and spray the pesticides. The application of agricultural machinery in precision agriculture has experienced an increase in investment and research due to the use of robotics applications in the machinery design and task executions. Multipurpose autonomous agricultural robot has successfully implemented and tested for various functions like ploughing, seeding, leveling and water spraying. The advantages of multipurpose agricultural robots are reducing human intervention, ensuring proper irrigation and efficient utilization of resources. The proposed system is mainly used for crop establishment, plant care and selective harvesting.

4.R. Rahmadian and M. Widyartono, "Autonomous Robotic in Agriculture: A Review," 2020 Third International Conference on Vocational Education and Electrical Engineering (ICVEE), Surabaya, Indonesia, 2020, pp. 1-6, doi: 10.1109/ICVEE50212.2020.9243253.