Designing the Opening Component

Click to go to Opening.

There are many aspects that need to be considered when developing the mechanical system.

Planning

| Completion | Due Date *a little flexible | Stage |

|---|---|---|

| 29-Sept | Answered all Research Questions | |

| 29-Sept | List of Requirements the opening should fulfill | |

| 29-Sept | Set Specifications/Facts for tote & speed | |

| 1-Oct | Mechanisms and Design Decisions Done to get to final concept | |

| 6-Oct | Detailed Sketch(es) of Opening | |

| 6-Oct | Description of how it works & how to build | |

| 9-Oct | Build mini model? |

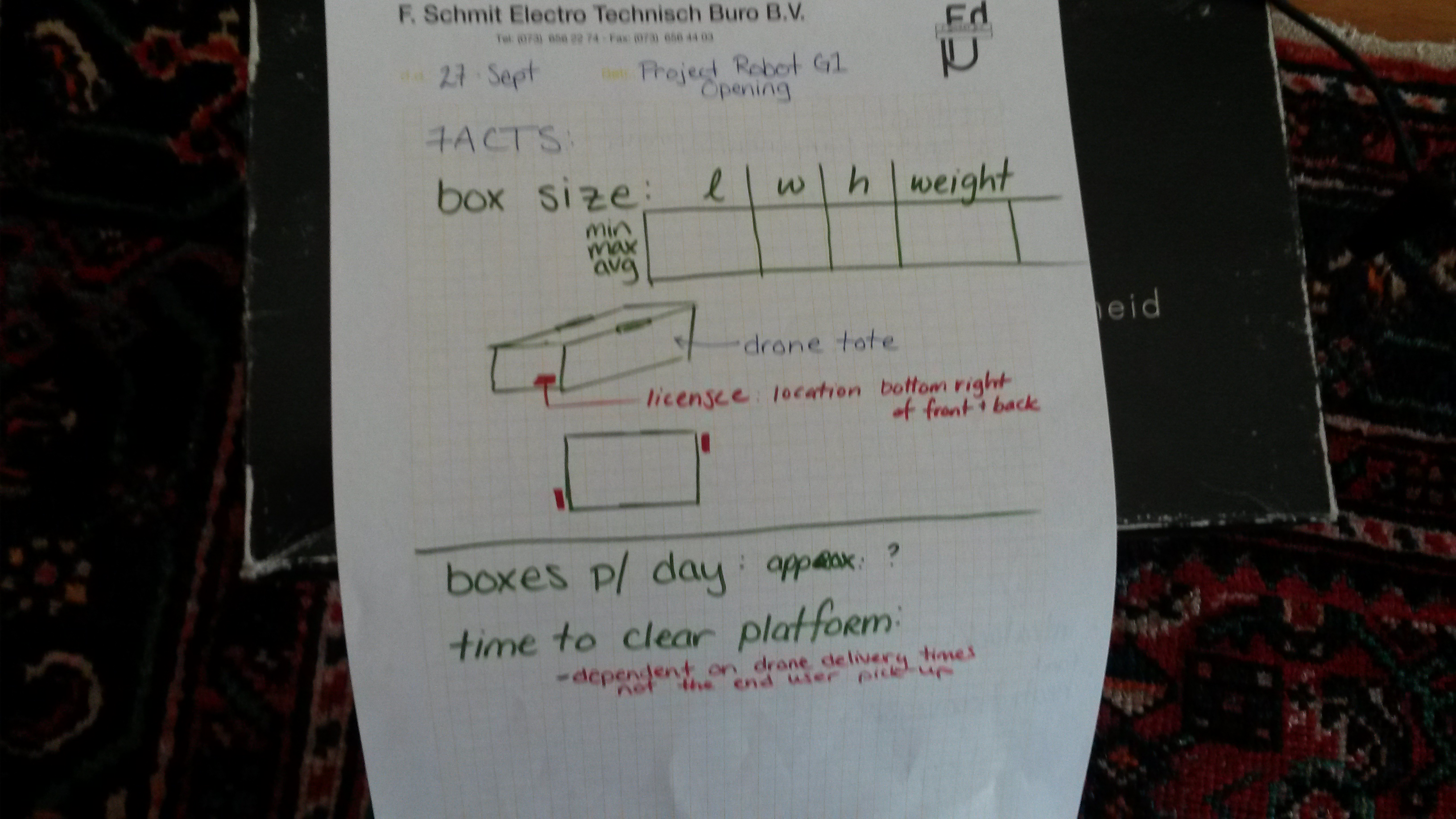

Facts

| Drone Tote | Height | Width | Depth | Weight |

|---|---|---|---|---|

| Minimum | 0.2 kg | |||

| Maximum | 5 kg | |||

| Average | 12 cm | 15 cm | 26 cm | 2.5 kg |

Totes expected to be handled p/day: 20 max

Time Spent handling a tote: 1 minute

Tote has barcode located in bottom right corner of the tote on both the front and back face, simplifies orientation problem.

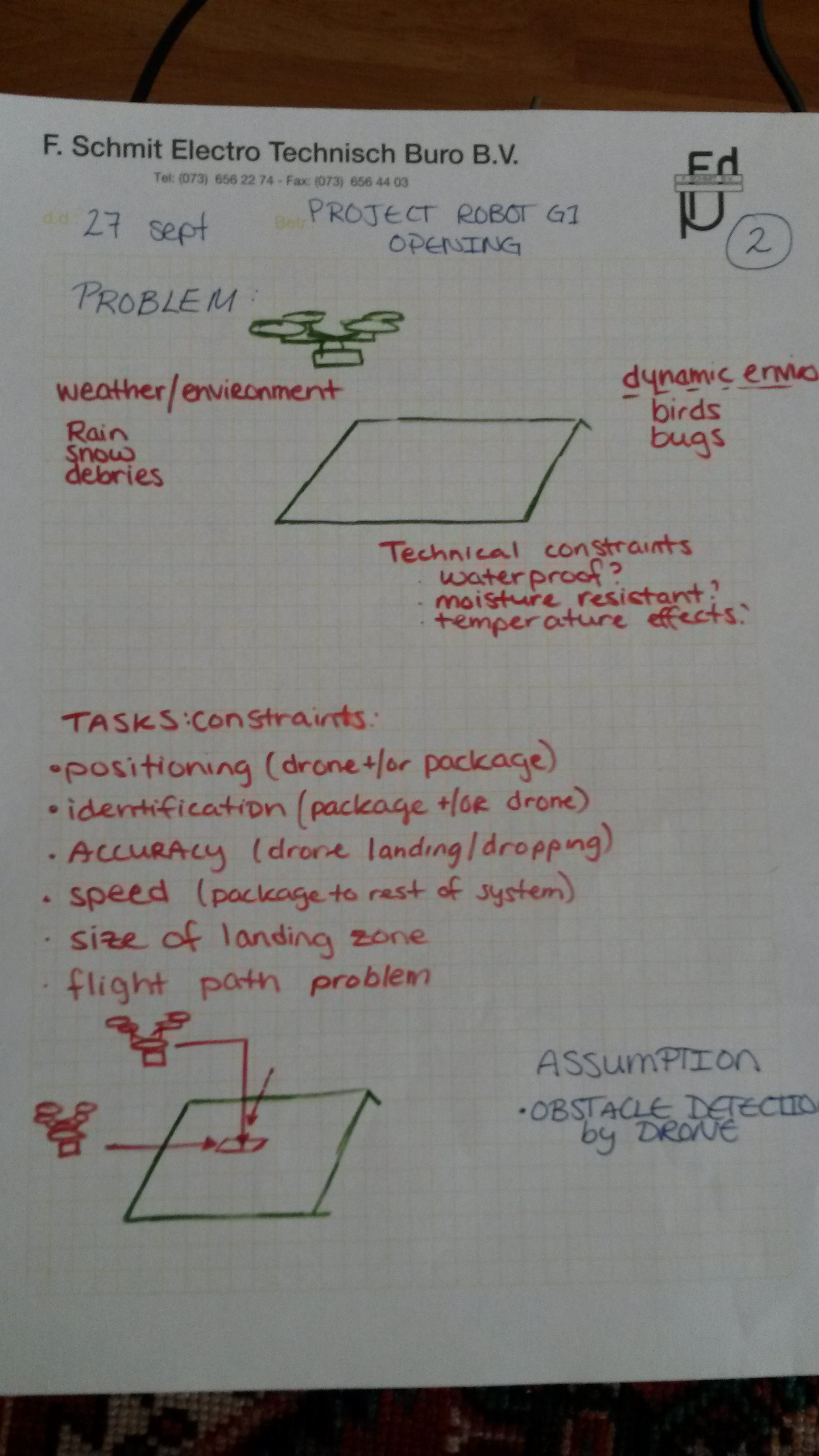

Problem Description

Goal: The goal in this stage of the system is to receive a package from a drone, have it oriented in the appropriate position for further processing, and get it to the next stage of delivery.

| Environmental Factors | Dynamic Factors | Technical Factors |

|---|---|---|

| Rain | Birds | Waterproofing? |

| Snow | Bugs | Moisture Resistance? |

| Debris | Temp. affects on function? |

| Task/Function | Description |

|---|---|

| Positioning | Drone+/or Package reaches the correct place for dropping the package or entering the system |

| Identification | package+/or drone needs to be identified by the system so that it can further handle the package |

| Accuracy | drone landing/dropping of the package should be accurately placed in the landing zone |

| Speed | The rate at which a package should be handled to the next stage of the system |

| Size of Landing Zone | The size may effect accuracy of package dropping (want to make this as large as possible) |

| Flight Path Problem | How many DoF does the drone have to approach the opening? |

Assumptions:

- Drone has Obstacle Detection to avoid objects in its way

Research Questions

Identification

Question: What kind of identification methods are there and how do they work?

Radio Frequency ID Communication - [Wiki]

transponder signals

Barcode Scanning

Omni-Directional Scanner -

Fixed Position Scanner -

Require external power sources, otherwise batteries that need replacement often

Wiki-BarCode Scanners

[UPC Codes]

[Barcodes]

Barcode Scanner(s)

- MPSi system- omnidirectional or Single scanner (CRT, speed, direction, etc)

What this research contributes to the design of this component:

(Make selection about the type of scanner that can be used & Barcode and information stored on the barcode)

Orientation / Location Finding

Question: What kind of methods are there to position robots/carts/etc. and how do they work?

Landing Radius casting -

Light Beaconing

Transponder signal?

RFID

<http://www.google.com/patents/US7636621>

<http://www.google.com/patents/US20130261870>

<http://en.wikipedia.org/wiki/Parking_sensors>

<http://en.wikipedia.org/wiki/Proximity_sensor>

<http://en.wikipedia.org/wiki/Position_sensor>

Question: What are kinds of sensors that help detect contrast or symbols?

What this research contributes to the design of this component:

(Make a selection as to which orientation method will be implemented (if any))

Ideas

-

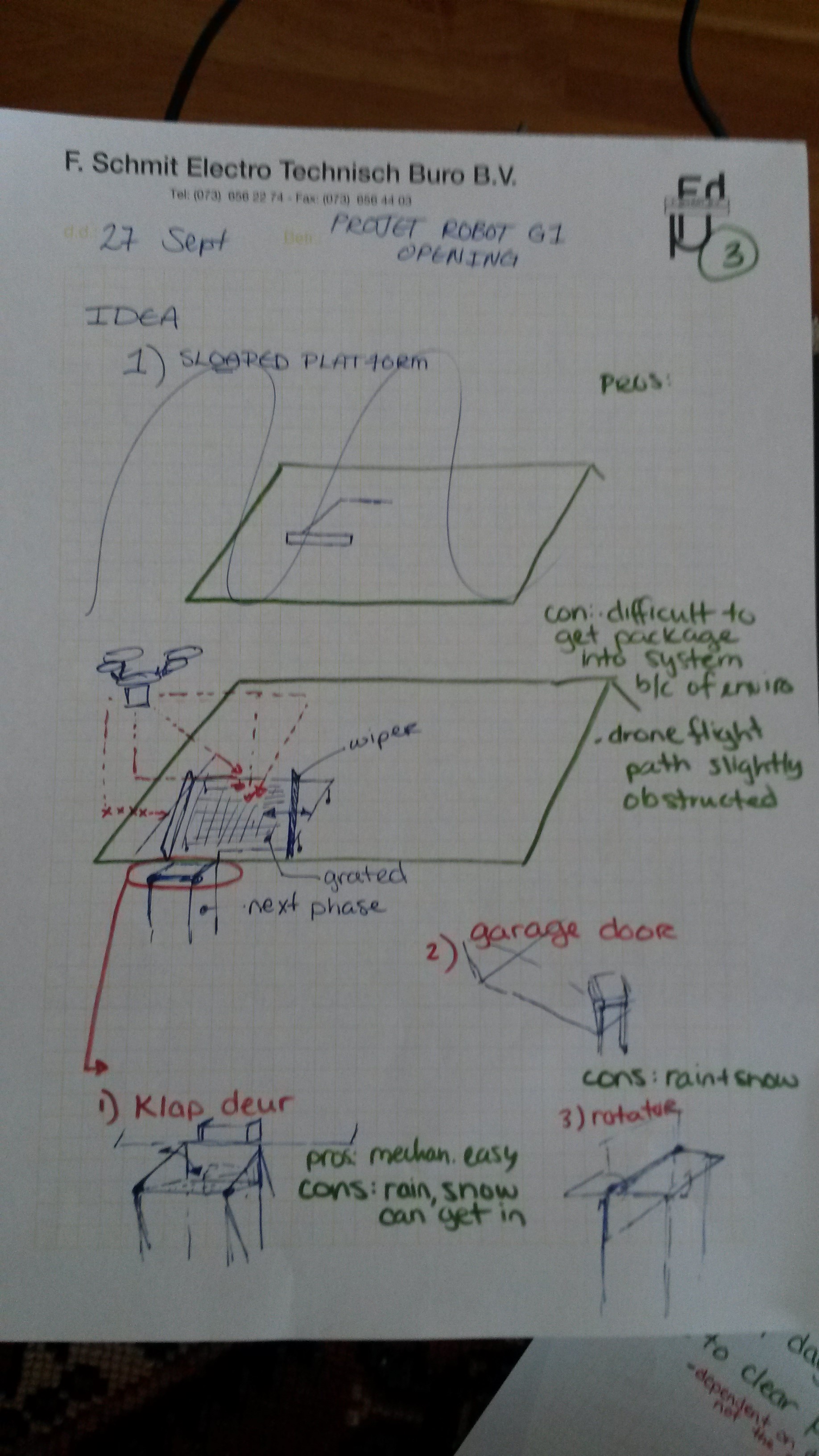

KS-OpeningP3-27-09

Sloped Platform & Door Ideas -

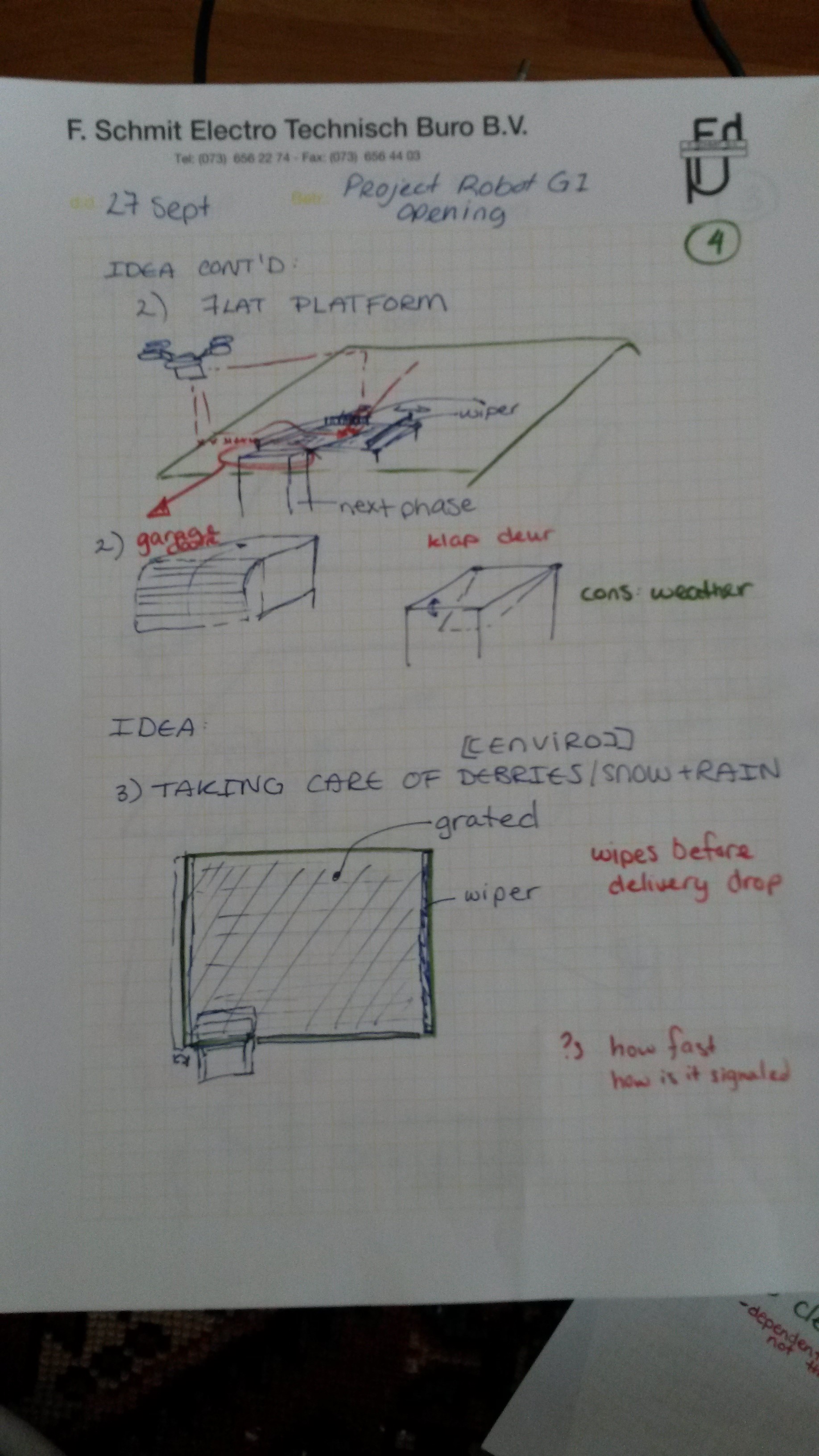

KS-OpeningP4-27-09

Flat Platform & Debris Ideas -

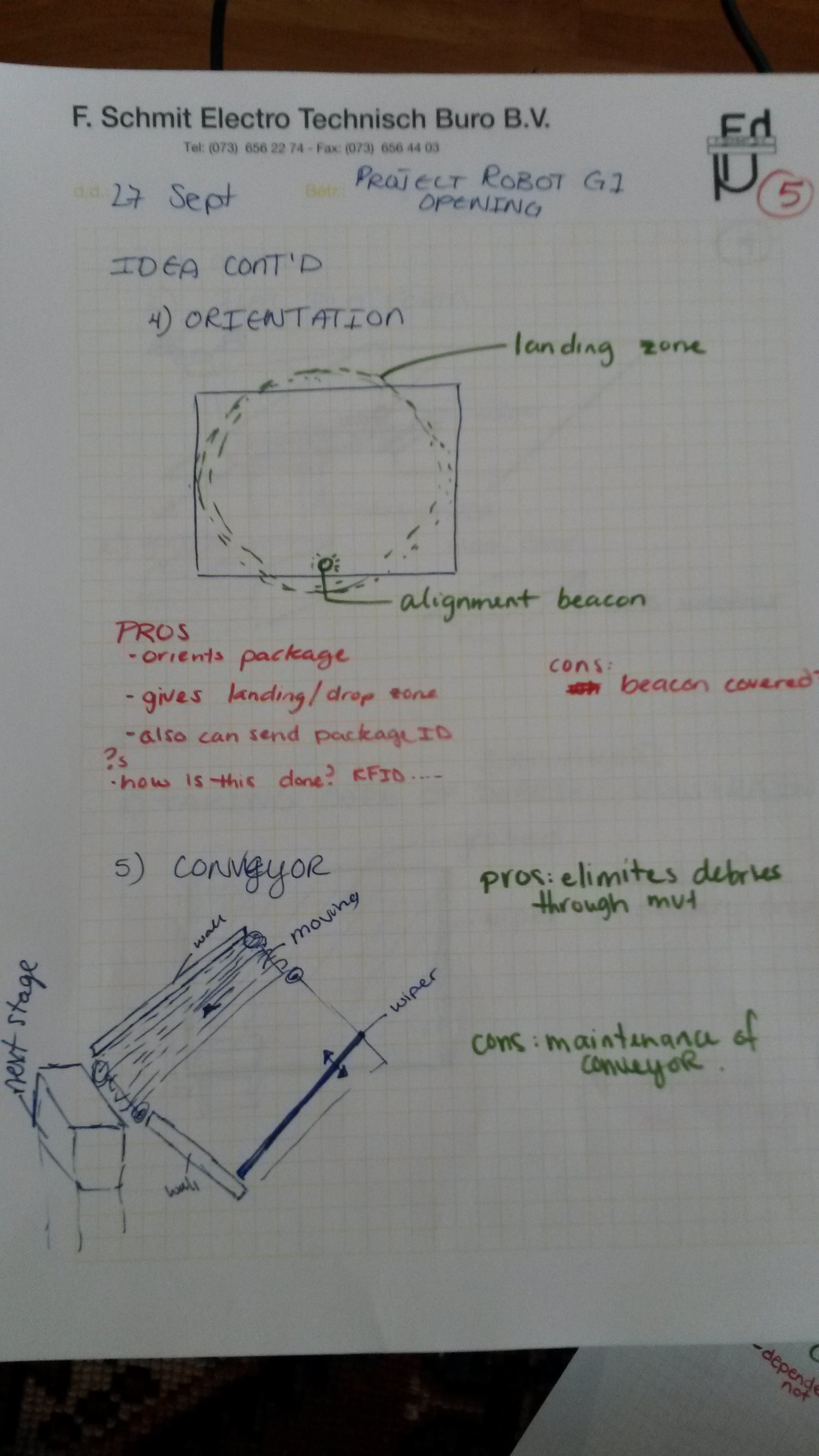

KS-OpeningP5-27-09

Orientation Idea & Conveyor Idea -

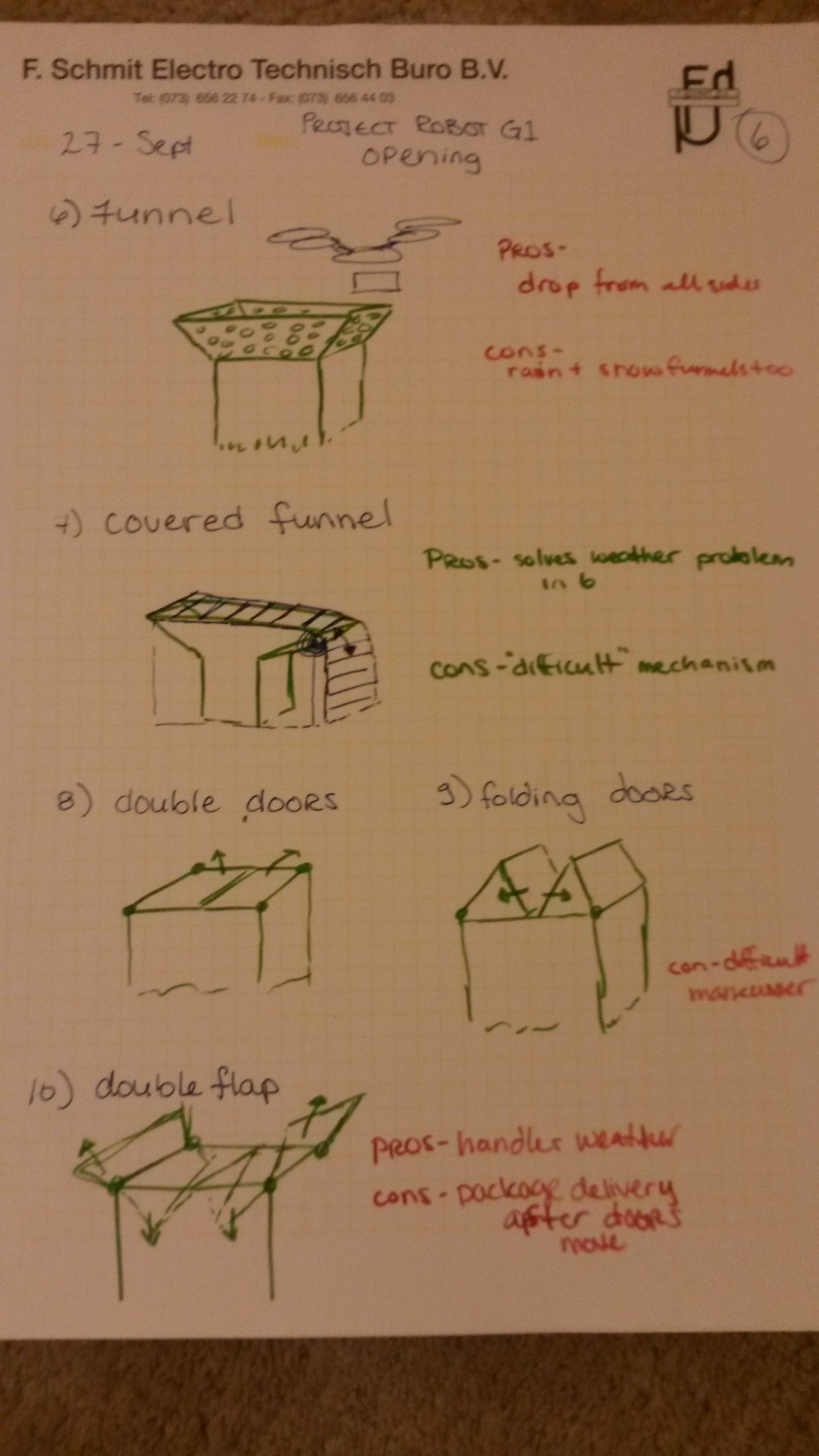

KS-OpeningP6-27-09

Funnel & Door Ideas

Drone Drop Zone

Sloped Platform

Labels: Drone Drop Zone

See page3 in gallery above for sketch.

| How it Works | Pros | Cons |

|---|---|---|

| As the name suggests, this set-up has a platform that is sloped with alignment to the roof. The slope allows for the package to be dropped and travel down with gravity towards the opening of the chimney. Also this system has a wiper which pushes the package in alignment after dropping. To make sure the package does not fall off the platform, there are guides. | Wiper can be used to clean off debris & snow. | Drone flight path slightly obstructed due to wiper & guides |

| Allows wide land/drop zone for the drone. | May look odd on buildings with flat roofs | |

| Drone can be oriented, but is not necessarily required b/c system aligns package after drop |

- See door mechanisms that could couple to this component to bring package into the system

- See orientation mechanisms that could couple to align package

Flat Platform

Labels: Drone Drop Zone

See page4 in gallery above for sketch.

| How it Works | Pros | Cons |

|---|---|---|

| This set-up has a platform that is flat and makes the use of two wipers. One in the x direction and one in the y direction, which will be used t align the package accordingly with the opening of the chimney. Guides prevents the package from falling off the platform. | Gets package oriented and to location | Flat less effective than slanted |

| Allows for big area land/drop zone | Drone flight path slightly obstructed by wipers & guides | |

- See door mechanisms that could couple to this component to bring package into the system

- See orientation mechanisms that could couple to align package

Conveyor

Labels: Drone Drop Zone See page5 in gallery above for sketch.

| How it Works | Pros | Cons |

|---|---|---|

| Similar to the other two platforms above. This idea has a large landing platform but has a continual moving conveyor located on one side. A wiper pushes the package onto the grated conveyor which leads the package to the chimney. | Continual movement of conveyor limits debris and snow accumulation | Maintenance very important |

| Possible noise issues? | ||

- See door mechanisms that could couple to this component to bring package into the system

- See orientation mechanisms that could couple to align package

Funnel

Labels: Drone Drop Zone

See page6 in gallery above for sketch.

| How it Works | Pros | Cons |

|---|---|---|

| Pro here | ||

| Pro here | ||

| Pro here |

Covered Funnel

Labels: Drone Drop Zone with Door Mechanism

See page6 in gallery above for sketch.

| How it Works | Pros | Cons |

|---|---|---|

| Pro here | ||

| Pro here | ||

| Pro here |

Door Mechanisms

Garage Door

Labels: Door Mechanism

See page4 in gallery above for sketch.

| How it Works | Pros | Cons |

|---|---|---|

| Pro here | ||

| Pro here | ||

| Pro here |

Double Doors

Labels: Door Mechanism

See page6 in gallery above for sketch.

| How it Works | Pros | Cons |

|---|---|---|

| Pro here | ||

| Pro here | ||

| Pro here |

Folding Doors

Labels: Door Mechanism

See page6 in gallery above for sketch.

| How it Works | Pros | Cons |

|---|---|---|

| Pro here | ||

| Pro here | ||

| Pro here |

Double Flap

Labels: Door Mechanism

See page6 in gallery above for sketch.

| How it Works | Pros | Cons |

|---|---|---|

| Pro here | ||

| Pro here | ||

| Pro here |

Orientation

RFID & Beacon

Labels: Orientation

See page5 in gallery above for sketch.

| How it Works | Pros | Cons |

|---|---|---|

| This is a possible solution for orientation & identification of the package. Through a radio frequency ID (RFID) a drone can signal to the delivery system that it is in range (or vice versa). Over this RFID information can be sent about the size and location of the drone drop zone so that the drone can find it. Once hovering over it, the drone can then align itself with a light beacon located at a point on the platform. | Can transfer information about the package over the RFID as well | Beacon can be blocked by environmental obstacles |

| Allows specification of drone platform location and size of drone zone | Possible hacking? | |

Contrast Symbol

Labels: Orientation

See page5 in gallery above for sketch.

| How it Works | Pros | Cons |

|---|---|---|

| This is a possible solution for orientation & identification of the package. Through a symbol painted on the drone zone platform, the drone can perceive the contrast and orient itself accordingly to the symbol. | Simple Solution of painting a symbol | Paint can fade |

| Allows specification of drone platform size on basis of symbol | Not a method to help find the platform | |

Requirements

| Functional | Product | Process | External |

|---|---|---|---|