PRE2024 3 Group13

In the last few years, the Moon has seen renewed interest from space agencies, notably with NASA’s Artemis mission aiming to reestablish human presence on the Moon for the first time since the 1970s. The mission's goal is to have a settlement on the moon as a stepping stone for a settlement on mars[1]. Of course, any advanced operations require infrastructure, and transporting the necessary materials from Earth is prohibitively costly. Therefore, inquiries are being made into using the resources available indigenously on the Moon. One specific problem, for a small settlement on the moon, is the amount of water it needs per crew member. Sending water from earth to the moon is very expensive, $2,000 to $20,000 per kg[2], so it is more economical to harvest ice on the moon's surface. According to Nasa's Human Integrated Design Manual estimates a 118 Liter of water is needed to support a crew of 18 people with regenerative live support. This means that the system needs 6.47 kg per crew member per day[3]. To meet this quota, ice has to be extracted from the surface of the moon by robots. This ice does not lay as snow or big chunks on top of the regolith, but as grains of ice between the grains of regolith. There are various ways of capturing these grains of ice, such as sieving, thermal extraction and grinding.

The objective of this project is to develop a solution for meeting the quota of 118 liters of water per day with the three different extraction methods. We will look at which method is the most energy efficient; which is the most time efficient and which is the most mass efficient. With mass efficiency, we mean that as much ice as possible is extracted and the least amount of ice as possible is lost.

Our target user is Nasa, since it wants to launch its Artemis mission.

Group members

| Name | Student ID | Email address |

|---|---|---|

| Bas Coppus | 1706160 | b.coppus@student.tue.nl |

| Mikolaj Pujanek | 1732595 | m.p.pujanek@student.tue.nl |

| Maksim Fisekovic | 1889524 | m.fisekovic@student.tue.nl |

| Ingmar Verweij | 1629433 | i.verweij@student.tue.nl |

| Thomas Passon | 1890190 | t.passon@student.tue.nl |

Ice location on the moon

here the location on the moon will be described

Ice location on the moon

[1] https://science.nasa.gov/solar-system/moon/nasas-lro-lunar-ice-deposits-are-widespread/#:~:text=Prior%20studies%20found%20signs%20of,Haworth%2C%20Shoemaker%20and%20Faustini%20craters. (cited) [2] https://doi.org/10.3847/PSJ/ad5b55 [3] https://nssdc.gsfc.nasa.gov/planetary/ice/ice_moon.html (cited)

[1,2] Found lunar ice in the PSRs (permanently shadowed regions) of the moon like lunar craters near the south pole (77 degrees south). Examples of such locations are some regions of the craters Cabeus, Haworth, Shoemaker and Faustini. [3] Describes how ice detection is done using a neutron spectrometer. Thermal and epithermal (slow and intermediate) neutrons result from collisions of normal (fast) neutrons with hydrogen atoms. A lot of hydrogen atoms would indicate water. Both the north and south pole contain ice.

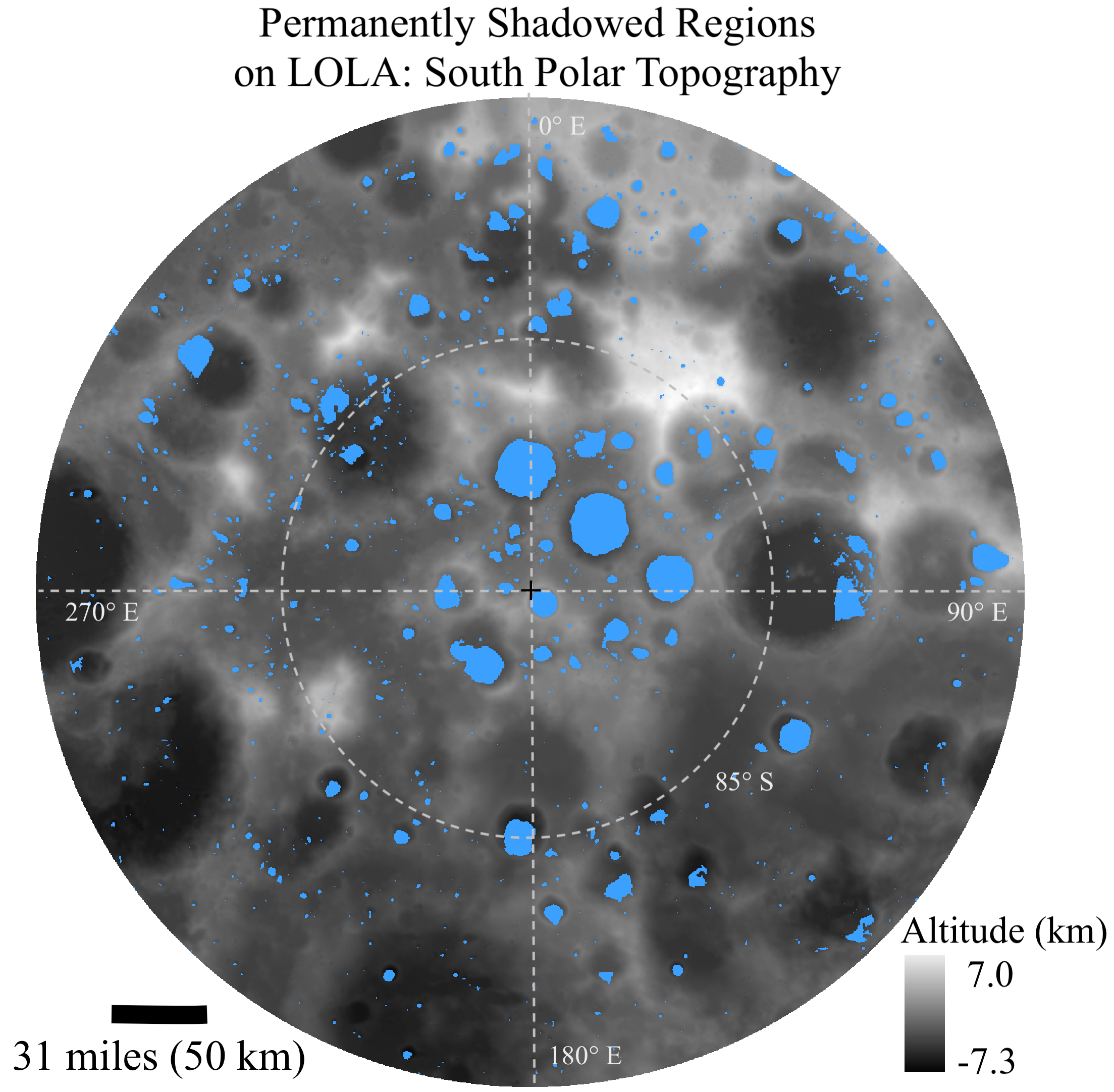

Ice is located in deposits in lunar dust and rock, which is known as regolith. Nasa's Lunar Reconnaissance Orbiter (LRO) mission showed where ice is likely or less likely to find on the moon. Previous studies found that ice is located in the larger permanently shadowed regions (PSRs) near the lunar south pole. Some known areas are the Cabeus, Haworth, Shoemaker and Faustini craters. According to Dr. Timothy P. McClanahan: "We find that there is widespread evidence of water ice within PSRs outside the South Pole, towards at least 77 degrees south latitude”, see figure 1 [4]. According to McClanahan's model and analysis, it is shown that the greatest ice concentrations are expected to near the PSRs' coldest locations, which are below 75 K or -198°C and near the base of the PSRs' poleward facing slopes. They can not determine if the PSRs' ice deposits are buried under a dry layer of regolith. It is expected that for each square meter, at a deposit, there should be five more liters of ice within the surface top one meter, compared to the surrounding areas.

Ice formation

Thermal extraction

Crushing

Sieving

Literature review

Massdrivers

The paper: "Lunar based massdriver applications" [5] describes that there are two types of mass drivers a Gauss or a coilgun and a Lorentz Rail Accelerator (LRA). Due to the simplistic design of the components and the developed railgun technology, the work in this paper will be considered with the LRA.

The LRA needs to be powered and the best way to do do this is by making PV-panels out of the minerals of the moon, which has an efficiency of 16%. These solar-panels do not track the sun, because they are robust and low in maintenance. This means that only 40% of the lunar revolution (27.3 Earth days) the massdriver can not operate.

A small vehicle is used to load the massdriver. This reduces the retention time within the first acceleration modules. A vehicle with a load is sliding down a ramp in which the barrel of the LRA is at equal height of the payload such that the vehicle and load can detach with each other. In this case a velocity of 1 m/s is used. This way of loading or injecting is needed, otherwise the heat load and friction would damage the modules of the payload. To monitor the launch, a control center is needed with a sufficient height to oversee the launching and if needed breakoff the launch. This breakoff can be done by extending the barrel and do the reverse of the injection process.

The best way to build the massdriver is to use the minerals of the moon. The rails will be made by aluminum due to the higher conductivity per kilogram ratio as copper for example. Oxygen is a by product from a lot of refining metals.

The velocity of the payload increases the barrel quadratically but the acceleration decreases the barrel linearly. So the launch velocity has to be minimized to keep the total acceleration short. A maximum acceleration of 20g is permitted for comparable payload launches at Earth. The payload can directly shoot to Earth via elliptic trajectories. These shots are called Earthshots. The most efficient launch opportunity is at the lunar apogee, but only once shot per lunar orbit can be achieved. So, for frequent launches, an optimized sit is chosen between the perigee and mean lunar distance for balancing energy efficiency and launch frequency. This is feasible when the launch velocity is between 2.1-2.5 km/s and the barrel is between 15-16km long. The best position is at Oceanus Procellarum; Encke and kapler craters and Reiner-Gamma lunar swirl.For large scale projects, a mass of 10 metric tons of payload is needed. This can not be launched in one shot due to technical limitations(the rails would melt due to the high currents). So a stacking concept of multiple LRA's are used. The simplest way is stacking in the width. The gap width between the rails is 200mm, with this geometry, the highest force density can be achieved. To shot the a payload of 10 ton with 20g a current of 560kA is needed and a launch time of 12.5 s can be achieved. The acceleration modules have a length of 1 m, so only the first module has a heating load of 1 s, which will be designed to cope with this. If the massdriver operates continuously, a power of 8.63 GW is needed.

It is also possible to shot these payloads into the lunar orbit for constructing space stations or space crafts. With precise calculation, ships can gather these payloads. These payloads can also be gathered by guiding systems inside the payload.

In the paper "Mission and System Analysis for Lunar Massdriver Applications" [6], only the relevant chapters will be summarized, since it is a thesis of 200 pages. The chapter 5.7.5 Energy production and 5.7.6 Energy Storage will be summarized because as seen from the paper "Lunar based massdriver applications", it takes a lot of energy to operate the massdriver.

According to this paper, if a tracking solar-panel is used, a power of 1210 W per m2 can be harvest from the sun. However, the goal is to use materials from the moon to create low efficiency solar panels, since it is assumed that there are no nuclear or chemical sources are on the moon. These low efficient solar-panels can be made in huge amounts.

Another way of producing power is by using concentrated solar radiation. The complex mirror shapes can easily be produced by rapid prototyping techniques for base structure and coated by highly reflective materials such as aluminum. However, this is not very effective since you need motors which are hard to make with the materials on the moon and the moon has a 2 week cold or dark period so the slat inside the tower will cool down. So the best way of generating power is by stationary solar panels.

Energy storage is also important since that the moon will have no light for 2 weeks. One way is with gravity potential; a second idea is via kinetic energy; a third way is via thermic energy; a forth way via chemical potential and the last idea is via a direct electric storage.

The gravity potential energy storage is based on increasing the height of a certain mass when there is a lot of energy available and lowering the mass when there is no energy available on the moon's grid. The increase and decrease of the height can be done by pumped hydroelectricity plants. But due to the low gravitational force ( 1/6 of the Earth's gravity). Fluid based systems have an efficiency of 80%. This fluid will be liquid oxygen. An more efficient way is via electromotors. They have an efficiency of 94%. Here you only need an electromotor and a lifting mechanism. the masses can be made of regolith blocks.

Kinetic energy storage is based on a big fly wheel that rotes with a large mass. If there is plenty of energy the kinetic energy can be increased and decreased when there is a shortage. Due to near perfect vacuum environment, losses are suspended. Large quantities of energy can be stored in here.

Thermal energy can also be stored in containers of molten regolith. These containers can stay warm during a Lunar night. These high temperatures heat up a gas for example oxygen which goes to a turbine. The efficiency is 62.8%. Another approach is using a phase change of oxygen but it has an efficiency of 7%.

A chemical potential can also be used by reversing the refining process. A lot of oxygen is produced and a chemical reaction like combustion of metals will produce a lot of energy. However, the efficiency is very low and not suitable.

The last way of storing energy is via a direct electrical storage. However, a capacitor is not suitable due to the electrons leakage between the plates. Another way is via a superconducting material. When a current is applied, the current will indefinite time without loss. The conductor has to be thermally insulated and monitored to maintain its temperature below the critical temperature. If superconductors have to be supplied from Earth it is not feasible.

Helium-3 mining

Mikolaj:

For different modes of transportation on the Moon, two main approaches are proposed in literature: a lunar railroad[7], or traditional wheeled rovers[8]. Aerial transport is not possible due to the lack of an atmosphere, and of course for large numbers of autonomous robots, wheeled transport is preferred for its versatility and autonomy. However, if our solution has for example one central hub location with the mass driver, human base etc. and multiple refineries/mining stations, then setting up a railroad may be more efficient in the long run. This depends heavily on the specifics of the resources being mined and the characteristics of their deposits.

There have been studies of the economic and technological feasibility of extracting Helium-3 from regolith on the Moon. They suggest that extracting 100kg of Helium-3 (enough to produce 1GW of fusion power for a year, and approximately the entire supply currently available on Earth) would require processing about 100 million tons of regolith[9], or an area of 2 square kilometers to a depth of 3 meters. The authors cite this as feasible, compared to a typical terrestrial oil mine processing 150 million tons of oil sand in a year. The study is from 2014, and at that time they estimated that the cost of setting up a mine that produces one ton of Helium-3 per year would cost about 17 billion USD, while the estimated value of the produced fuel is 3.7 billion USD, making the project economically viable in the medium term (assuming fusion is solved). With recent breakthroughs in spaceflight cost-efficiency on the back of reusable rockets, such as SpaceX's Starship[10] (already contracted by NASA to help with the Artemis project), the cost of setting up such a mine might be even lower than that.

One proposed method of processing lunar regolith to extract Helium-3 was proposed by Gajda in 2006[11]. It features a large standalone rover that takes care of the entire extraction and refinement process: it uses a bucket wheel to scoop up regolith, isolates the smallest grains containing the Helium-3 using sieves and electrostatic separation, and then heats up the grains to release the Helium-3 along with other volatiles. This approach still needs a dedicated facility for separating the gases present in the obtained mixture. One downside of this approach is that the rover weighs 18 tons and has lots of moving parts, making it difficult and costly to deliver to the Moon, and possibly requiring a lot of maintenance. Our approach using many smaller, specialized robots could improve on this area.

Swarm control

Maksim:

Quick summary of each article: the article: "Time-Efficient Mars Exploration of Simultaneous Coverage and Charging with Multiple Drones "[12] describes a build idea for a robot swarm that would be operational on Mars. This robot swarm would consist of robots of constant speed, operated through an autonomous control principle. By making use of the CACER-II algorithm for pathfinding, as well as layered information maps for gathering data. The article "The Design Challenges of Drone Swarm Control" [13] describes the difference between direct and indirect control, and looks at several possible control scheme implementations. Chapter 4 of the book: "Robot Swarms: Dynamics and Control "[14] goes into depth about the behavior of swarms and how that can be translated into control schemes for swarm robotics. The book offers information about swarm robotics as a whole, instead of focusing only on space applications. The blog: "Robotic swarm swarm intelligence for Lunar exploration"[15] is an extremely well-written summary on existing swarm robotics and goes into depth on exactly swarm robotics in space. A myriad of examples on swarm robotics in space are given, as well as shown in several YouTube videos. While not describing swarm control in great detail, this blog gives many practical examples and implementations of swarms in space, which could form the basis for our control system. The article: "Collective control of spacecraft swarms for space exploration"[16] explains the rules necessary for controlling spacecraft swarms. This is slightly different than our desired project, as this article mainly mentions satellites and swarms travelling through space. However, the rules about swarm control should be applicable to most control systems.

What is the best way to design the swarm control? It is hard to tell, however, using autonomous or semi-autonomous control seems necessary. It is borderline impossible for humans to remotely control the swarm from earth. An information map could be implemented to avoid obstacles and perceive the environment. The robot design meant for Mars uses the CACER - II algorithm for pathfinding. Something perhaps more achievable is a semi-autonomous system for multiple robots as presented in "The Design Challenges of Drone Swarm Control"[13]. In this system, the robots are hardcoded to act based on a set of rules, depending on the position of the so called leader robot. This leader robot is remotely controlled by humans. This implementation seems feasible, as article: "Robotic swarm swarm intelligence for Lunar exploration"[15] claims that a study has been conducted on swarm navigation on planets, where researchers propose communication between units through time-division multiple access (TDMA), which would enable all units to constantly be aware of the position of the other units.

Locations of Helium-3 on the moon

Ingmar: [1] http://www.lpi.usra.edu/meetings/lpsc2007/pdf/2175.pdf [2] https://doi.org/10.1016%2Fj.icarus.2009.12.032 [3] https://doi.org/10.1007/s11434-010-4198-9 [4] https://doi.org/10.1007/s11433-011-4561-0 [5] https://doi.org/10.1006/icar.2000.6545 [6] https://doi.org/10.1016/j.icarus.2009.11.034 [7] https://doi.org/10.1006/icar.2000.6545 [8] https://www.space.com/28189-moon-mining-economic-feasibility.html [9] https://doi.org/10.1177/1946756714536142 (I could not get full access to this citation, but the abstract is promising) [10] Matar, S. (2021). Energy analysis of extracting helium-3 from the Moon (Doctoral dissertation, Politecnico di Torino).

Summary: From the paper "The estimation of helium-3 probable reserves in Lunar regolith"[17] it was found that He-3 is implanted into the lunar surface by the solar wind. The problem is not the implantation, however, but the retention of the He-3 within the lunar surface. The retention of He-3 depends on the grain size of the lunar regolith[17] [1] (<50 micron seems to hold the most helium-3), the electroconductivity of the lunar regolith (TiO2 was mentioned)[18] [3] and it also seems to depend on the solar exposure[19] [2], meaning less sunlight is better able to retain the He-3. This would mean that craters at the lunar poles seem to be the best option [2]. The Chang-E-1 mission was able to measure the thickness of the regolith layer by measuring the thermal radiation of the lunar regolith[20][21][22] [4][5][6] (I don't fully understand this yet). Another method was found in the paper " Regolith Layer Thickness Mapping of the Moon by Radar and Optical Data "[23] [7] by using radar waves (at 70cm) and measuring the thickness by using scattering from the underlying substrate. There have also been other materials on the surface of the moon, mainly uranium, thorium and platinum-group elements that could be exploited as well[24] [8]. It was estimated that a mine that produces one ton of he3 would cost around 17 billion USD, while this one ton would give profits of around 3.7 billion USD, making it viable in the medium term[25] [9]. “Mare Tranquillitatis” and “South Pole Aitken” seem to provide the most helium-3[26] [10]. Also, energetically, the mining operation seems feasible, since the energy produced is roughly three times as much as the energy consumed in the entire chain of sending equipment to the moon; mining; refining; returning he3 to earth and using it in a reactor[26] [10].

Mining robots

Thomas:

[1] https://ntrs.nasa.gov/api/citations/20210022801/downloads/AIAA%20ASCEND%202021%20Paper_211018.pdf [2] https://ijcrt.org/papers/IJCRT2108016.pdf [3] https://www.mdpi.com/2075-1702/12/12/845 [4] https://www.mdpi.com/2076-3417/14/19/8876 [5] https://www.mdpi.com/2313-7673/9/11/680

Summary: Mining using robotics is advantageous, because [2] the of health and safety hazards and improved productivity[27]. The mining environment is always evolving, in the sense that the goal of mining is changing a lot, and the equipment are becoming more hydraulically operated and diesel driven. These challenges have meant that robotics has not been rapidly adopted by the mining industry to date, but it is clear that the mining industry will have to adopt more automation, and with robotics[28]. [3] Some possible evolutions of intelligent mining machines are the use of Artificial intelligence to improve the use of data and and deep reinforcement learning for controlling equipment . The use of swarm robotics in mining[29], [4] this article suggests different animal based models for different objectives, namely: the honey-bee model for high selectivity and precision, like extracting high-grade ores, the ant model, with its high reliability and task specialization, may be the most effective one for ore transportation. And finally the firefly model could be used in ore detection.

So far, there are multiple methods theorized for mining Helium-3 on the moon[30] [1]. Among these designs, there is the Mark series, which uses solar energy and heat to extract He-3. Another one of these methods is the spiral method, but this concept is not as far developed, even tough this design could improve flexibility and reduce to complexity and mass of each mining robot.

Mining on the moon using swarm robotics has also been theorized for mining water and ice[31] [5]. One of the limitations that is discussed is disrupted communications due to the lack of atmosphere on the moon. Extreme temperatures and fine, loose rock on the surface pose additional risks, such as traction loss and path deviations. These limitations underscore the need for an adaptable and robust framework when considering mining operations on the moon.

Extraction methods

Thermal extraction[32]

Thermal extraction can be done by heating the surface, or by the insertion of heated drills. Thermal extraction works by heating the soil so that the ice contained in the soil turns in to vapor. This vapor is then caught and refrozen for transportation.

Water extraction through heating is a power hungry process if it is not optimized. The configuration also depends on the ice content in the soil. The best of the two methods that were found was the surface heating method. This method had the highest extraction rate of all calculations done. The power needed to extract a significant amount of water starts at 1 kW. Before this amount of power the amount that was extracted was negligible, even if the method was used for a very long time. To extract a significant amount of water with a heating power of at least 1 kW, at least tens of hours are needed, with the extraction time for the highest efficiency calculated being around two days. Extraction efficiencies of the thermal extraction method are never close to 100%, with only the highest efficiency being above 50%. Increasing the heating power or density of the drills does not increase the amount of vapor that is extracted. This can be explained by refreezing of the water vapor inside or potentially outside of the heated region.

Planning

This planning is a rough estimate of what should be done. First I will write down what should be done then in what week something has to start and finish.

Week 2

Person 1 will start looking at the physical properties of the robots. What sensors do they need, how large the buckets and loading platforms are; operating time of the batteries; charge time; drive speed; what type of usurers are involved and energy usage. Go as detailed as possible.

Person 2 look at where the mines will be placed on the moon. This person also needs to find out how much can be mined and how many mines we need. First, find the top 5 important places then 5 additional or more places if possible. This needs to be done with urgency since we need these places and mines for simulations. try to find an actual map. Also find the quota needed to make this successful

Person 3 starts with simulating the mining robots in an arbitrary environment. The robot needs to dig, drive and recharge. Make some arbitrary points on the map where the robot can dig and recharge. This simulation can be done in NetLogo. Take into account the excavation time and unloading time. Also simulate the battery time and the driving from the digging site to the recharge station. This is called the simple excavating model. Also take the driving into account from the excavation site to the unloading side at the station or refinery

Person 4 looks at the program of the swarm robots. What type of behavior is needed and how to implement it in netlogo.

Person 5 looks at how to map the findings of person 2 into NetLogo including the mines, refineries, charging stations and the massdriver. Based on the findings of person 2, it will be determined if we make one big refinery or smaller ones. Here it is also important to know how much refining kg per material cost in terms of energy. If Person 1 is finished with his findings about the batteries, it can also be implemented in the map.

Week 3

Person 1 will continue the literature study about the robots. Try to find multiple designs and argue the pros and cons.

Person 2 continue the research about the best possibilities of mining areas. The quota needs to have defined

Person 3 will finish the simple excavating model and start at the advanced excavating model. This model entails that the mine can have a depth and that the findings of person 1 will be implemented. For example, if a square is with it is the surface, if it is light gray it is the first 10 meters, dark gray 20 meters deep and black 30 meters deep. Every square is a block of 10 cubic meters . The excavator can only move to a square with one lighter shade . So the robot can not move from a white to a dark gray square. The robot has also take into account to make the mine pit wider if it goes deeper. Keep track of energy usage and the amount of tons regolith or ice has been excavated

Person 4 still looking for multiple swarm strategies to test.

Person 5 finish the total map whit al the mines. start with implementing the robots of the simple excavation model for testing.

Week 4

Person 1 finish the literature study. Put this study in the Wiki

Person 2 finishing the places of the mine. Put these findings in the Wiki

Person 3 finishing the advanced excavating model and start the combined model by implementing the advanced truck driving model.

Person 4 finishing the advanced truck driving model and start the combined model by implementing the advanced excavating model.

Person 5 look if the simple model fits in the map and adjust the map or the models in all the 5 mines. Take track of how much energy the refineries use and how much of each material will be produced. Find out how many robots we need per mine.

Week 5

Person 1 makes minor changes if needed.

Person 2

Person 3 finish the combined model. Start implementing the total map. Here we have to make a code that does the logistics for example, if the driving time of the robot becomes longer due to de depth of the mine, new trucks have to be made to catch up. Maybe we can interchange robots from one mine to another.

Person 4 finish the combined model. Start implementing the total map. Help person 3 and otherwise start documenting on this simulation.

Person 5 finish the total map and start implementing the combined model. help person 3 and otherwise start documenting on this simulation.

Week 6

In this week the presentation will be made and finished at least at Friday. Everybody is responsible for their one work in the wiki and presentation. So the persons who worked on the model put their findings in the slides and Wiki, for example.

Week 7

In this week on Monday, the presentation will be held in the morning.

Week 8

Finishing the Wiki and documentation.

Individual effort

| Name | Total time | Progress and time |

|---|---|---|

| Bas Coppus | 18h | Making small basic sections in the wiki page and trying to understand how to edit the page works (1h). Finding a subject to research and how to implement this research into a program, prototype or a literature research and finding some papers (2h) . Lecture and meetings (4h), Summarizing papers (5h), finding papers (4h), Make a planning (3h) |

| Mikolaj Pujanek | 18h | Lecture and meetings (4h), researching what topic to use for the project (5h), finding and reading papers (6h), writing introduction for wiki page (1h), summarizing and extracting relevant insights from papers (2h) |

| Maksim Fisekovic | 15h | Lecture and meetings (4h), researching and deciding on a topic (3h), finding and reading papers about the topic (5h), summarizing papers (3h) |

| Ingmar Verweij | 17hr | Find a research subject (2h), Lecture and meetings (4hr), Finding literature paper (2hr), Reading literature (6hr), Summarizing literature (3hr) |

| Thomas Passon | 13 hr | Lecture and meetings (4h), Finding papers (2h), reading the papers (5h), summarizing papers (2h) |

| Name | Total time | Progress and time |

|---|---|---|

| Bas Coppus | 13h | Meetings (2h), reading papers(9h), structure the wiki and planning (2h) |

| Mikolaj Pujanek | 15h | Meetings (2h), studying Lunarminer paper (5h), researching improvements and other papers (8h) |

| Maksim Fisekovic | 15h | Meetings (2h), Reading papers (3h), Creating NetLogo simulation (10h) |

| Ingmar Verweij | 12h | Meetings (2h), reading paper (4h), researching ice locations on the moon (6h) |

| Thomas Passon |

| Name | Total time | Progress and time |

|---|---|---|

| Bas Coppus | Meetings (1h), organize the docu wiki (1h) | |

| Mikolaj Pujanek | ||

| Maksim Fisekovic | ||

| Ingmar Verweij | ||

| Thomas Passon |

| Name | Total time | Progress and time |

|---|---|---|

| Bas Coppus | ||

| Mikolaj Pujanek | ||

| Maksim Fisekovic | ||

| Ingmar Verweij | ||

| Thomas Passon |

| Name | Total time | Progress and time |

|---|---|---|

| Bas Coppus | ||

| Mikolaj Pujanek | ||

| Maksim Fisekovic | ||

| Ingmar Verweij | ||

| Thomas Passon |

| Name | Total time | Progress and time |

|---|---|---|

| Bas Coppus | ||

| Mikolaj Pujanek | ||

| Maksim Fisekovic | ||

| Ingmar Verweij | ||

| Thomas Passon |

| Name | Total time | Progress and time |

|---|---|---|

| Bas Coppus | ||

| Mikolaj Pujanek | ||

| Maksim Fisekovic | ||

| Ingmar Verweij | ||

| Thomas Passon |

Sources

- ↑ NASA. (2025, 11 februari). Artemis - NASA. https://www.nasa.gov/humans-in-space/artemis/

- ↑ Ice on the Moon. (z.d.). https://nssdc.gsfc.nasa.gov/planetary/ice/ice_moon.html

- ↑ Tan, J., Melkoumian, N., Harvey, D., & Akmeliawati, R. (2024c). Lunarminer Framework for Nature-Inspired Swarm Robotics in Lunar Water Ice Extraction. Biomimetics, 9(11), 680. https://doi.org/10.3390/biomimetics9110680

- ↑ 4.0 4.1 Wasteigerwald, & Wasteigerwald. (2024, 3 oktober). NASA’s LRO: Lunar Ice Deposits are Widespread - NASA Science. NASA Science. https://science.nasa.gov/solar-system/moon/nasas-lro-lunar-ice-deposits-are-widespread/#:~:text=Prior%20studies%20found%20signs%20of,Haworth%2C%20Shoemaker%20and%20Faustini%20craters

- ↑ Ehresmann, M., Gabrielli, R. A., Herdrich, G., & Laufer, R. (2017). Lunar based massdriver applications. Acta Astronautica, 134, 189–196. https://doi.org/10.1016/j.actaastro.2017.02.007

- ↑ Ehresmann, M., Institute of Space Systems, Herdrich, G., Laufer, R., & Gabrielli, R. (2016). Mission and system analysis for lunar massdriver applications (Door S. Fasoulas) [Master thesis IRS-16-035, University of Stuttgart]. https://doi.org/10.13140/RG.2.2.35323.52003

- ↑ Schrunk, D., Thangavelu, M., Cooper, B., & Sharpe, B. (1998). Physical Transportation on the Moon: The Lunar Railroad. Space 98. doi:10.1061/40339(206)41

- ↑ Baratta, M., Genta, G., Laurenzano, D., & Misul, D. (2018). Exploring the surface of the Moon and Mars: What kind of ground vehicles are required? Acta Astronautica. doi:10.1016/j.actaastro.2018.04.030

- ↑ Simko, T., & Gray, M. (2014). Lunar Helium-3 Fuel for Nuclear Fusion. World Futures Review, 6(2), 158–171. doi:10.1177/1946756714536142

- ↑ Chris Palmer. SpaceX Starship Lands on Earth, But Manned Missions to Mars Will Require More. Engineering, 2021, 7(10): 1345‒1347 https://doi.org/10.1016/j.eng.2021.08.005

- ↑ Gajda, M. E. (2006). A lunar volatiles miner (Doctoral dissertation, University of Wisconsin--Madison).

- ↑ Chang, Y., Yan, C., Liu, X., Wang, X., Zhou, H., Xiang, X., Tang, D., & National University of Defense Technology. (2020). Time-Efficient Mars Exploration of Simultaneous Coverage and Charging with Multiple Drones. In arXiv [Journal-article]. https://arxiv.org/abs/2011.07759v1

- ↑ 13.0 13.1 Saffre, F., Hildmann, H., Karvonen, H., VTT Technical Research Centre of Finland Ltd, & TNO - Netherlands Organisation for Applied Scientific Research. (2021). The Design Challenges of Drone Swarm Control. In Springer, Engineering Psychology and Cognitive Ergonomics, HCII 2021. https://doi.org/10.1007/978-3-030-77932-0_32

- ↑ Gazi, V., Fidan, B., Marques, L., & Ordonez, R. (2015). Robot Swarms: Dynamics and Control. In ASME Press eBooks (pp. 79–126). https://doi.org/10.1115/1.860526_ch4

- ↑ 15.0 15.1 Kaczmarek, S. (2021, 31 augustus). Robotic Swarm Intelligence for Lunar Exploration - Sylvester Kaczmarek. Sylvester Kaczmarek. https://sylvesterkaczmarek.com/blog/robotic-swarm-intelligence-for-lunar-exploration/

- ↑ Sabatini, M., & Palmerini, G. B. (2009). Collective control of spacecraft swarms for space exploration. Celestial Mechanics And Dynamical Astronomy, 105(1–3), 229–244. https://doi.org/10.1007/s10569-009-9183-8

- ↑ 17.0 17.1 Slyuta, E. N., Abdrakhimov, A. M., Galimov, E. M., & V.I. Vernadsky Institute of Geochemistry and Analytical Chemistry. (2007). THE ESTIMATION OF HELIUM-3 PROBABLE RESERVES IN LUNAR REGOLITH. Lunar And Planetary Science XXXVII. https://www.lpi.usra.edu/meetings/lpsc2007/pdf/2175.pdf

- ↑ Fa, W., & Jin, Y. (2010). Global inventory of Helium-3 in lunar regoliths estimated by a multi-channel microwave radiometer on the Chang-E 1 lunar satellite. Chinese Science Bulletin, 55(35), 4005–4009. https://doi.org/10.1007/s11434-010-4198-9

- ↑ Cocks, F. H. (2010). 3He in permanently shadowed lunar polar surfaces. Icarus, 206(2), 778–779. https://doi.org/10.1016/j.icarus.2009.12.032

- ↑ Ping, J., Su, X., Huang, Q., & Yan, J. (2011). The Chang’E-1 orbiter plays a distinctive role in China’s first successful selenodetic lunar mission. Science China Physics Mechanics And Astronomy, 54(12), 2130–2144. https://doi.org/10.1007/s11433-011-4561-0

- ↑ Shkuratov, Y. G., & Bondarenko, N. V. (2001). Regolith Layer Thickness Mapping of the Moon by Radar and Optical Data. Icarus, 149(2), 329–338. https://doi.org/10.1006/icar.2000.6545

- ↑ Fa, W., & Jin, Y. (2009). A primary analysis of microwave brightness temperature of lunar surface from Chang-E 1 multi-channel radiometer observation and inversion of regolith layer thickness. Icarus, 207(2), 605–615. https://doi.org/10.1016/j.icarus.2009.11.034

- ↑ Shkuratov, Y. G., & Bondarenko, N. V. (2001b). Regolith Layer Thickness Mapping of the Moon by Radar and Optical Data. Icarus, 149(2), 329–338. https://doi.org/10.1006/icar.2000.6545

- ↑ David, L. (2015, 7 januari). Is moon mining economically feasible? Space.com. https://www.space.com/28189-moon-mining-economic-feasibility.html

- ↑ Simko, T., & Gray, M. (2014). Lunar Helium-3 Fuel for Nuclear Fusion. World Futures Review, 6(2), 158–171. https://doi.org/10.1177/1946756714536142

- ↑ 26.0 26.1 Matar, S. (2021). Energy analysis of extracting helium-3 from the Moon (Doctoral dissertation, Politecnico di Torino)

- ↑ John, A., Krishna, M. S., Ali, A., Suku, A., & Kumar, S. (2021). APPLICATION OF ROBOTICS IN MINING- a REVIEW [Journal-article]. International Journal Of Creative Research Thoughts (IJCRT), 9(8), 105–106. https://ijcrt.org/papers/IJCRT2108016.pdf

- ↑ Kokkinis, A., Frantzis, T., Skordis, K., Nikolakopoulos, G., & Koustoumpardis, P. (2024). Review of Automated Operations in Drilling and Mining. Machines, 12(12), 845. https://doi.org/10.3390/machines12120845

- ↑ Tan, J., Melkoumian, N., Harvey, D., & Akmeliawati, R. (2024). Evaluating Swarm Robotics for Mining Environments: Insights into Model Performance and Application. Applied Sciences, 14(19), 8876. https://doi.org/10.3390/app14198876

- ↑ Olson, A. D. S., NASA Kennedy Space Center, Wisconsin Center for Space Automation and Robotics, University of Wisconsin’s Fusion Technology Institute, Wisconsin Center for Space Automation and Robotics, NASA Kennedy Space Center Swamp Works Electrostatics & Surface Physics Lab, & AIAA Member. (z.d.). Lunar Helium-3: Mining Concepts, Extraction Research, and Potential ISRU Synergies. NASA Kennedy Space Center, FL, 32899, U.S.A. https://ntrs.nasa.gov/api/citations/20210022801/downloads/AIAA%20ASCEND%202021%20Paper_211018.pdf

- ↑ Tan, J., Melkoumian, N., Harvey, D., & Akmeliawati, R. (2024b). Lunarminer Framework for Nature-Inspired Swarm Robotics in Lunar Water Ice Extraction. Biomimetics, 9(11), 680. https://doi.org/10.3390/biomimetics9110680

- ↑ Brisset, J., Miletich, T., Metzger, P.(2020). Thermal extraction of water ice from the lunar surface - A 3D numerical model. https://doi.org/10.1016/j.pss.2020.105082