PRE2018 3 Group13

Abstract

A robot which is able to read a book/form of text and is able to translate it into braille so that deaf-blind people can read it.

Problem statement

In this world, there is an estimate of around 356.000 deafblind people internationally. Only around 1% of all books are translated in braille which means that people who are deaf-blind have small amount of available reading material. Even the blind people will most often need to resort to audio books if they want to read a certain novel.

Objective

Make it possible for people whose only choice to read books is using braille to read books which are not translated in braille and give a choice to blind people who prefer to read in silence to do so.

Who are the users?

The users of our device will be people with visual and/or hearing impairments who know how to read braille. For the people with both visual and hearing impairments, they will use this product in order to read novels. For the people with just visual impairments, they will use the product incase they prefer to read in silence. Most visual impaired people have to resort to use audio books because of limited availability braille books.

What do they require?

A way to convert (digital) text to braille.

Solution:

Create a robot which is able to translate e-books into braille so that the users can read it. (with translate do not mean to write a new book with the translation but instead some other form of reusable interface.

Braille interface

Input

e-book / digital text

Output

physical braille letters

Prototype

Manual digital letter input for testing first, outputs a single braille letter. Multiple letter output can be considered afterwards.

Approach

If we build a prototype of the mechanical part: Firstly, we will research braille on which we can base our user requirements on. We then look for existing patents and their mechanics on a Braille output system and look for possible trade-offs. Once we have detailed insight on the possible solutions, we devise our own solution based on our design decisions that correspond to the user requirements. We make a concept to visualize our idea and eventually we will make a (physical) prototype that can be tested with our target users.

If we only focus on user-friendliness

Firstly, we will research braille on which we can base our user requirements on. We then look for the most user-friendly materials and user-interface so we can improve the user-friendliness of the machine.

Milestones

Have digital text be the input of a reusable interface where the text is converted to braille. The braille can be projected per word or group of words, depending on their length. Choose the research topic Summarize a State-of-the-Art by performing a literature study Find a contact person that fits our target user group to gather additional information regarding our case Create user requirements for the robot Validate the requirements with the contact person Design a concept build corresponding to the requirements Validate the concept with the contact person Build a prototype of our concept and test it with the contact person Produce a final presentation in which we discuss the process, design and prototype

Deliverables

Compact, user-friendly and cost-efficient physical braille interface. The Braille interface should accept digital text and convert it to several Braille characters at a time. User-friendliness consists of: Type of material to interact with Speed of the machine Possible physical interaction with buttons/triggers (functionality)

Possibly a working prototype of one or several letters, that can be reset and configures itself to a given input.

Who will do what

- Material choice

- Dennis

- User interface (layout, buttons etc.)

- Thomas

- Converting feedback of test person to useful information

- Luc

- Hardware internals stuff

- Luc

- Builder

- Simon

- Programmer if we build a 6-segment letter prototype

- Dirk

Planning

Week 2 (16 Dec - 22 Dec):

|

Task |

Person responsible |

Deadline |

Remarks |

Done |

|

Creating planning |

Everyone |

14-02-2019 |

||

|

Researching different materials: Making a overview of different materials based on multiple aspects such as cost, smoothness, stretchability or other factors which could be important. |

Dennis |

20-02-2019 |

Needs to add the references and finish small parts. Will be done before the tutor meeting |

|

|

Getting blind contacts, make appointment and creating a survey. |

Luc |

20-02-2019 |

Appointment date doesn’t have to be within the deadline |

Didn’t create survey |

|

Working out existing Braille mechanism solutions for six-dot cells and argue their (cost)effectiveness |

Thomas |

20-02-2019 |

Piezo-electro |

|

|

Creating system/process of taking .pdf text input and outputting Braille |

Dirk |

20-02-2019 |

Requires documentation First output to plain text and then to Braille |

|

|

Look for possibilities of creating Windows program that outputs to Arduino |

Simon |

20-02-2019 |

Requires documentation on choices made |

|

|

Discuss the survey contents |

Everyone |

20-02-2019 |

Content finished during meeting |

|

|

Put the planning in the wiki |

Simon |

20-02-2019 |

Will do today |

Week 3 (23 Dec - 29 Dec):

|

Task |

Person responsible |

Deadline |

Remarks |

done |

|

Word context to Braille shortcuts recognition |

Dirk |

27-02-2019 |

Optimization of .pdf to Braille system |

|

|

Finish survey layout and give it to our target group. |

Luc |

27-02-2019 |

Or interview them depending on the appointment |

|

|

Define the user requirements based on the results of the survey. |

Everyone |

27-02-2019 |

First iteration of the user requirements |

|

|

Defining the Braille mechanism |

Luc |

27-02-2019 |

Blueprint of how it should be constructed with calculations |

|

|

Specifying the parts and create circuit diagram |

Thomas |

27-02-2019 |

Includes calculations electricity usage and resistors |

|

|

Defining the output of Arduino to the Braille mechanism |

Simon |

27-02-2019 |

How to let the Arduino work correctly with the mechanism i.e. reversing polarity |

|

|

Creating user interface concept with the current user requirements |

Thomas |

04-03-2019 |

This date may change depending on the user requirements |

|

|

Choose and get the best material(s) and look into how to make a suitable dummy Braille. |

Dennis |

27-02-2019 |

Best materials will be based on the research and based of off multiple perspectives (such as cost, smoothness and stretchability) |

|

|

Buying the components |

Everyone |

27-02-2019 |

Will be done during the meeting |

Week 4 (29 Dec - 5 Jan):

|

Task |

Person responsible |

Deadline |

Remarks |

Done |

|

Inquire users on the new user requirements and test the material usability |

Luc |

Depends on appointment date estimate: 06-03-2019 |

Second iteration of user requirements Let users touch materials to see preferences |

|

|

Re-creating user interface concepts with new user requirements |

Thomas |

Depends on appointment date estimate: 06-03-2019 |

||

|

Testing the entire software with Arduino output |

Simon & Dirk |

06-02-2019 |

||

|

Creating different dummies to test usability without the material. |

Dennis, Luc & Thomas |

06-02-2019 |

The material should be able to be attachable to the dummy. |

Week 5 (5 Jan - 13 Jan):

|

Task |

Person responsible |

Deadline |

Remarks |

done |

|

Creating single cell prototype as a whole |

Simon |

13-02-2019 |

Finished software + Braille mechanism & Arduino |

|

|

Test dummy and prototype with the users and note feedback |

Luc |

13-02-2019 |

||

|

Discuss feedback on prototype and dummy material |

Everyone |

13-02-2019 |

||

|

Change requirements/usability where needed |

Thomas |

13-02-2019 |

Iterative improvement process |

|

|

Changing dummies based on the feedback |

Dennis, Luc & Thomas |

13-02-2019 |

Iterative improvement process |

Week 6 (5 Jan - 13 Jan):

|

Task |

Person responsible |

Deadline |

Remarks |

|

Iterate prototype and dummy test with users and note the feedback |

Luc |

20-02-2019 |

|

|

Change requirements/usability where needed |

Thomas |

20-02-2019 |

Iterative improvement process |

|

Discuss feedback from users |

Everyone |

20-02-2019 |

|

|

Changing dummies based on the feedback |

Dennis, Luc & Thomas |

20-02-2019 |

Iterative improvement process |

Week 7 (5 Jan - 13 Jan):

|

Task |

Person responsible |

Deadline |

Remarks |

|

Finalize corresponding wiki sections |

Everyone |

27-02-2019 |

|

|

Create final presentation |

Everyone |

27-02-2019 |

|

State-of-the-Art literature study

We have a seperate page for the literature study, which can be found here

Braille mechanism

The idea of a mechanism that dynamically creates Braille output has been worked out in all kinds of ways by existing patents over the years. We will be discussing some of the more common mechanisms and eventually decide on the one that fits our scenario the most by looking at the trade-offs.

Piezo-electric actuators

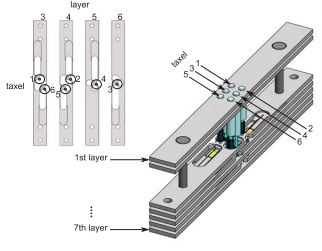

Piezo-electric actuators for the use of Braille displays were introduced in 1979 and still mostly constitute the operating principle of commercially available Braille displays [1]. In order to get a complete view on the implementation of this actuating mechanism, we take the TactoBook [2] system which presents the use of piezo-electric ultrasonic actuation. The dimensions they have taken for their Braille configuration is 2.54 mm spacing between pins and 0.7 mm vertical strokes.

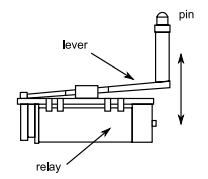

By using a relay-lever mechanism with the piezo-electric benders, we can move the pin up when voltage is supplied and move it down back to its original position when the power is off due to the self-weight of the lever mechanism. However, there is a design drawback with this mechanism as this implementation requires much space and may therefore make the entire product less portable.

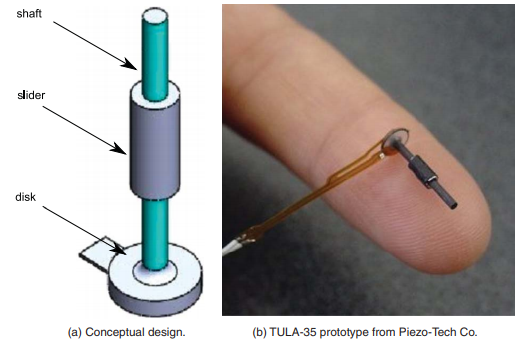

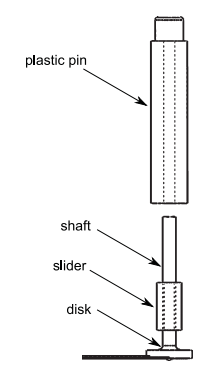

In order to overcome the compactness problem, the paper discusses the use of piezo-electric linear actuators instead. Here the actuator consists of a shaft, a moving slider and a piezo-electric ceramic disk. Its entirety is very small and lightweight as it is 2.4 mm diameter, 11.6 mm in length and 370 mg in mass. There are no burdensome relay levers that require the use of more space.

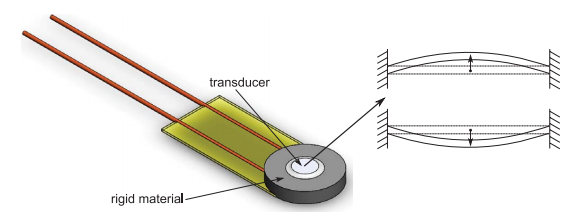

So the ceramic disk has a rigid case surrounding the transducer, which vibrates when voltage is applied. This creates vertical movement, allowing the slider and shaft to move up and downwards. The motion is based on the principle of inertia displacement by square wave electric potential [3]. Both the slider and shaft move upwards when the power is on, if it’s turned off then the shaft will be moving downwards while the slider remains at its global position due to its inertia. The power will be turned back on to move both the shaft and slider upwards and the power will be turned off again, which only moves the shaft downwards. Through this cycle we can move the slider and consequently move the pin up and down as the slider is attached to the plastic pin. The reverse motion can be achieved by simply inverting the cycle’s electric potential.

Here the assumption is made that the plastic pin is bi-stable. This means that we only require energy to changing one position from another. In order to acquire this, we assume that the friction between the slider and shaft is such that the slider retains its position without the use of power. To create an actual compact device with this mechanism, you would need the following design goals:

Each pin is independently addressed and their motion should not limit the motion of neighbouring pins

Each pin must be placed within a Braille cell and have convenient access to electricity without influencing other pins

Pins should be easily removable when necessary

The proposed design concept is to use multiple layers, where the first layer acts as the contact surface where pins will poke through and the second acts as a guiding structure for the pins. The consequent layers will have two pins each, while the bottom layer acts as a base of the cell.

As a result, a prototype of this concept would have the following performance:

108 mN pull force

5 Hz refreshable bandwidth

0.7 mm strokes

The product is available through manufacturer quotes and not to the general consumer, so there is a wide price range and model variety. As of now, the rough estimate is around $50 per actuator which is quite expensive.

1. Tetzlaff, J.F.: Patent US 4283 178 A (1981) 2. Veláquez R., Hernández H., Preza E. (2012), A portable piezoelectric tactile terminal for Braille readers, Applied Bionics and Biomechanics 9, pp 45-60. Available at: http://downloads.hindawi.com/journals/abb/2012/637851.pdf 3. H. Ko, S. Kim, S. Borodinas, P. Vasiljev, C. Kang and S. Yoon, A novel tiny ultrasonic linear motor using the radial mode of a bimorph, Sensors and Actuators A 125 (2006), 477–481.

Electro-magnet actuators

To discuss the viability of electro-magnet actuators, we have looked at various existing patents from the literature study that utilize this mechanism in order to consider understand the core workings.

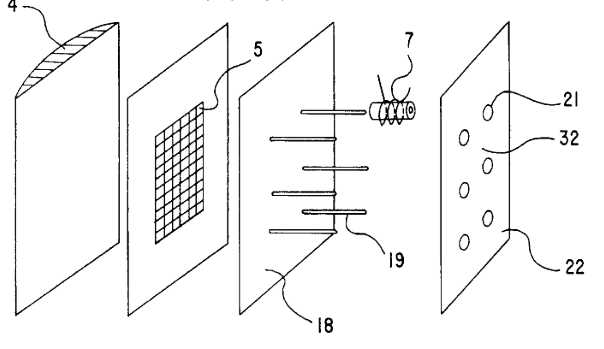

We see that the general use of electro-magnets is simple and take the portable reading device for the blind patent [1] as an example.

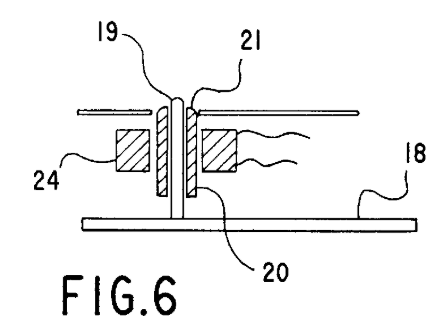

In the figure we see an expanded view of the housing concept for the Braille pins (19). These non-metallic pins (19) are attached to the plate (18) to keep them interdependent. The tips of the pins are always sticking through the holes (21) and form small dots. Large dots will be representing the actual Braille letters are moving cores (20) of micro-electromagnets (7) and its tip will be rounded. These moving cores (20) are hollow and crossed by the non-metallic pin (19), in order to allow the dots to remain protruding from the holes (21) when the mechanism is not actuated. When the micro-electromagnets are energized, the large dot made by the moving core (20) will protrude which causes the small dot to disappear. To reset the moving core back to the resting position when the micro-electromagnet is no longer energized, we can use a leaf spring that acts on a groove made in the moving core (20)

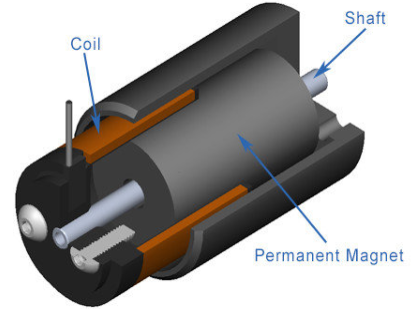

This actuator construction can be generalized as follows. The moving part is an axially magnetized cylindrical permanent magnet and there are two coils connected in series in such a way that they create magnetic flux of opposite directions in the region of the permanent magnet. Consequently, the permanent magnet will move either up or down depending on the polarity of the power supply. In order to move up, the coils should create flux in the air gap and to move down the polarity is simply reversed. This motion is transferred to the Braille dot using a non-metallic shaft to prevent magnetic interference.

1. Parienti R. (1999). U.S. Patent No. US6159013A. Available at: https://patents.google.com/patent/US6159013

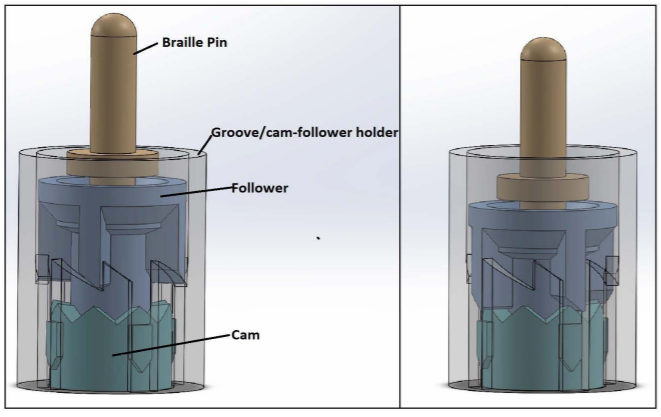

Cam follower actuator

The mechanical linear actuator is the simplest actuator that would fit as a Braille mechanism, as it creates motion in a straight line. These typically operate by converting rotational motion into linear motion by using screws or gears. We consider the cam and follower assembly which consists of five basic parts; the groove, cam, follower, spring and pin. Here we create a toggled system that only has two states, where the pin is either protruding or not. As shown in the figure [1], the groove holds all parts, while the cam pushes the follower to the state it is not in. The spring is used to ensure that the follower can transition states every time the cam is active.

With the mechanism, we can disregard concerns of keeping active protruding Braille dots in place when the user is pressing on them while reading. Since the follower is resting on the cam’s grooves, it is locked in place until it is pushed by the cam.

1. Mubvuma T.H., Molter L., Alternative Actuators for Braille Devices. Available at: https://scholarship.tricolib.brynmawr.edu/bitstream/handle/10066/14255/Mubvuma_thesis_2014.pdf?sequence=1&isAllowed=y

Comparison

Linear piezo-electric actuators are the most compact and lightweight, but their high costs make it unreasonably expensive for a full display Braille product so we will not opt for this actuator.

Micro-electromagnets and cam followers are more accessible to general consumers than linear piezo-electric actuators and they are also significantly cheaper as the prices are around $10 per actuator. They do however take relatively more space, but this varies per actual product.

The main advantage of the cam follower actuator is that the protruding Braille dot state is very robust, as the user cannot force the dot down due to the locked grooves of the cam part. However, this can also be negated in the use of micro-electromagnets by having sufficient magnetic force keeping the dot protruding.

We can assume that the mechanism will be used very often, so by keeping the degradation of the performance in mind we can make the decision. The cam follower actuator uses mechanical parts that can degrade after many uses and are more prone to hardware failure. Meanwhile, the micro-electromagnets mechanism’s moving part is only dependent of the permanent magnet and the coils. Magnets generally remain magnetic for hundreds of years and its most prominent performance degradation factor is due to the reduction of its volume, which is not of a concern if we have working design. Here we don’t have many risks of hardware failures even after long extended uses and from the user’s perspective it would be preferable to have a longer-lasting product that highly unlikely requires repair in the future. Hence, we shall opt for the micro-electromagnet actuators for our Braille robot mechanism.

Technical specification

As mentioned above, we will be making use of electromagnetic linear actuators but there are many different possible implementations with this mechanism. We will be considering the voice coil actuators and solenoids as they are both highly similar to the patent on micro-electromagnetic actuators for the braille display.

Voice coil actuators

Voice coil actuators or also known as non-commutated DC linear actuators consist of two assemblies. A permanent magnetic assembly, which contains the permanent magnets and ferrous steel and there is a coil assembly. As current flows through the coil assembly it will interact with the permanent magnetic field since it produces magnetic flux from the coil windings, which consequently generates a force vector perpendicular to the direction of the current based on the Lorentz force principle. This force vector can be reversed simply by changing the polarity of the current that flows through the coil. Either one of the assemblies can be used as the moving part in the voice coil actuator.

The amount of force generated can be expressed as F = kBLINwhere

F = force (Newton)

k = force constant

B = magnetic flux density (tesla)

L = wire length (meter)

I = current (Ampere)

N = number of conductors

With a given voice coil, all the parameters are fixed except the current. Therefore, we can see that the generated force is directly proportional to the input current. This actuator is typical for fixed-stroke applications with maximum strokes of approximately 15 cm. The generated force is constant throughout the stroke, with exceptions of the beginning and the end of the stroke.

The amount of force generated can be expressed as F = kBLINwhere

F = force (Newton)

k = force constant

B = magnetic flux density (tesla)

L = wire length (meter)

I = current (Ampere)

N = number of conductors

With a given voice coil, all the parameters are fixed except the current. Therefore, we can see that the generated force is directly proportional to the input current. This actuator is typical for fixed-stroke applications with maximum strokes of approximately 15 cm. The generated force is constant throughout the stroke, with exceptions of the beginning and the end of the stroke.

Material study

For materials we’ll first look into materials which can act as a cover over the pins of the robot. For this to be possible, the material would need to be sufficiently elastic. With this approach we aim to provide a good user experience which might be hindered by the spaces and inconsistencies that a non-elastic braille display would provide. This inconsistencies might be created because of faults in the connection between the braille display and the pins or unintended deformation of the braille display. Based on the feedback we’ll receive from our interviews, we might look into the non-elastic materials. Materials For the materials regarding the display of the article, we’ve done some research as to which materials would be useable. Since the exact requirements of the materials are not yet calculated, the requirements will mostly based on estimates. The requirements of the materials are that they are sufficiently elastic, easily deformable, durable and have a low friction coefficient. We distinguish between the following material types: Metals, Polymers, ceramics and textiles.[1] For each of these material types we’ll discuss what they include exactly and if applicable which materials could be useable . Since both deformability,durability and friction coefficient are not easily specified, we’ll focus on the elasticity.

Metals

Metals refers to a group of materials that that consists of elements that readily forms positive ions and has metallic bonds. In general, metals conduct electricity and heat relatively well and are overall a popular material type to use. Depending on the type of metal, they could be easily deformable and in our situation durable. The main problem with metals regarding our robot is that in general their elasticity is low. This means that if the material is deformed too much, it will not revert back to its original form. We assume our design would need a decently high elasticity and for these reasons we’ll look into the metals with the highest elasticity. We found the following metals:

Chromoly steel with Cr <= 9%

Chromoly steel is an alloy including both chromium and molybdenum. Chromoly is often used when the strength of mild carbon steel is not enough. You often see this material used in things such as bicycle tubes, molds, pins and chain links. Cost: $0.06 – 0.15 / kg Elasticity: 29.7* 10^6- 30.9 * 10^6 psi [2]

Carbon steel

Carbon steels refers to a steel which contains carbon elements up to 2.1% of its weight. Carbon steel has many different uses based on the percentage of carbon. The higher the percentage of carbon, the stronger the material is. Because of this carbon steels has a range of uses from constructing small things such as fences to construction of buildings and bridges. Cost: $0.86 – 1.03 / kg [4] Elasticity: 29.3* 10^6- 29.5 * 10^6 psi [2]

Polymers

A polymer refers to a type of material in which the material is made from long chains of molecules which may have cross linking bonds affecting flexibility and stiffness. Polymers can be categorized in three different categories. The first category is thermoplastics. Thermoplastics refers to a polymer which can only be flexible or moldable above certain temperature. The thermoplastic with the lowest moldable temperature is 60 °C. Since the temperature is too high for long term exposure to the skin, we can conclude that there are no thermoplastics which can be used for our robot. The second category is thermosetting polymers. Thermosetting polymers refers to polymer which is irreversibly hardened. Once hardened the thermosetting polymers cannot be changed in form. For this reason thermosetting polymers are not usable for our robot. The third is elastomer. Elastomer refers to polymers that are capable of recovering their original shape after being stretched or deformed to great extents. This polymer type can be used in our design because of its high elasticity. A good choice for the material for our design would be a certain type or rubber. Rubber is an easily obtainable material and because of its general high elasticity, it could be used in our robot. The main problem with using rubber is that rubber generally has a high friction. When the user would use our robot to read over the letters, the high friction will most likely cause a bad experience for the user. This could be solved by applying a low friction rubber coating to the robot to reduce the friction coefficient. Cost: $ 3.46 / kg

Ceramics

Ceramics are solid materials which are composed of inorganic compounds of metal, non-metal and covalent bonds. Ceramics are hard materials which are known to have an even lower elasticity at room temperature than most metals. Because of this, we will assume for now all ceramics will be unusable for our robot.

Textiles

Textiles are any material ,which can be used to create fabrics , cloth or the resulting material. An example of textiles are cotton or wool. There exists multiple kinds of textiles in which each of them has his own characteristics. Depending on how the materials are created, textiles could be elastic and thus be used in our robot.

A good candidate for our robot is the textile wool. Wool is a fibre formed of sheep fur which is both elastic and durable. Since wool made up of multiple threads, there could be some hindrance when reading the braille points. This is because threads will have to be spun and thus will not be a perfectly flat layer. This will have to be tested with the users in order to verify the viability of this material.

Braille to Arduino

We're using an Arduino Uno with 6 outputs which represents a braille character. For testing purposes, we'll be using LEDs for these 6 outputs. Serial Monitor is used for input. Enter the numbers of the LEDs you want to enable (eg. 1256). After you press “send” on the interface or “enter” on your keyboard, the lights corresponding to the number input will light up. We've also added a button and by pressing it, you can reset all lights (the Braille output).

converting a pdf file to braille code

Using http://braillebug.afb.org/braille_deciphering.asp for general braille rules.

We can describe a 6-pin braille symbol by the position of the ‘active’ pins. In order from top to bottom and then left to right. We can represent this as a boolean vector or equivalent binary number. The symbol ‘a’ for example becomes 100000.

Conversion rules:

- Each letter in the alphabet and some symbols are converted to the corresponding braille code. (using a table)

- A capital letter is made by adding 000001 in front of the normal code.

- A capitalised word is made by adding the 0000001 symbol twice before it. (what if the only non-capitalised symbols in a word are not letters?)

- A number is made by placing 001111 in front of the symbols for the letters that correspond to the digits. For example a=1,b=2 so 12 = 001111 100000 110000

- 000011 must be placed between a number and a letter if the letter directly follows the number

- Some groups of letters get contracted to a single symbol or multiple (but less) symbols. (using a table)

Currently we have written a program in java that accepts a pdf file and outputs a txt file with the text translated symbol by symbol to braille. The braille is encoded as described above.

TODO: Apply word context dependent rules including the number and letter prefixes. Add a way for the user to supply character translations so that things like language specific translation can be added when needed. Pass the translation to the arduino.

V2

DONE: Segregation into words. Word specific number and letter symbols. Contractions for full words, prefixes and suffixes. A full list of these is not implemented and has to be provided, what kind of contractions people want to read also differs from person to person (grade 2 and grade 3 braille).

PROBLEMS:

- Complicated grammar rules like mentioned in https://en.wikipedia.org/wiki/English_Braille :

“When there are several ways to write a word, the shortest one is chosen, and when they are of equal length, the one without (two-cell) abbreviations is chosen. So, thence is written th-ence (3 cells) rather than the-n-c-e (4 cells). However, with the sequences -anced, -ancer, -enced, -encer, the form with -ance/-ence is used even if not shorter.” “In general, these are acceptable as parts of longer words as long as they retain their pronunciation”

Some of these could be practically impossible to implement, for example when pronunciation is mentioned.

- Currently capitalized parts words are not contracted unless this part is also capitalised in the list of contractions used by the program. (this could actually be the desired behaviour)

- Contractions containing punctuations symbols cannot be recognized right now because they are not considered part of the word. (luckily I don't think these exist)

We are choosing to ignore the more complicated situations since we do not even know if most people can read these kind of contractions.

description of the algorithm

- The algorithm looks for the next word in the text. A word is a sequence of symbols which is between 2 symbols that are not alphanumeric (e.g. punctuation and whitespace)

- All symbols that are between this word and the previous word are translated to the corresponding braille symbol (punctuation and whitespace)

- A table is used to look for possible contractions for the whole word, a prefix or a suffix. The contracted part of the word is then removed an*d the contraction is saved.

- The rest of the word is translated symbol for symbol while also adding the symbols indicating capitalization and numbers.

Dummy

In the next section we’ll split the parts of the dummy into two categories.

The display

The first part is the braille display. The braille display refers to the way we’re going to display braille. This could be done with either providing a solid plate in which braille is already displayed and simply using that or a mechanisms which display’s the braille. This mechanism could for example be manually pushing the pins to create a braille display. Depending on the depth of which we want to test, there are multiple options to create the braille display.

The first option is to create a very basic braille display dummy. This dummy would be similar to a solid plate, which contains braille, and could be attached on top of the casing of the robot. This form of braille display will be relatively simply and will ignore the user preferences for material types or other preferences such as a button and focus more on main interactions. These interactions will be purely based on what they think of the idea and what they would improve. This option would be sufficient in case you want to verify the intent of your product. In case you want to test multiple things such as user preferences for example materials or buttons, this option might be insufficient. On another note, this option might be sufficient as a base dummy in which you can extent later on. For example it might be possible attach the materials which you wish to test into the basic braille display or to create buttons at the end of the display. However, depending on the design of the display, extensions might have a low quality.

The second option for the braille display would be to design a display similar to the previous one, but instead design it with these extensions already included. In other words, a braille display consisting of a to-be-tested material which contains braille which is changeable. This could be done in either two ways. The first one would be to create a display on which the materials can be attached upon in such a way that the readability of the display is sufficient. This method would allow for easier testing since both materials could easily be changed and it allows for reusability of the braille display. The main problem with this method would be the technical problem, in which you have to create a mechanism with a loosely coupled material who ensures sufficient readability. The main problem with the readability would be the that the material would simply be pushed up completely by the braille pins since it’s loosely attached. This problem would could be solved by making the material more attached to the braille display, however this method might then lose its purpose depending on how tight the attachment is.

The second method to achieve this option would be to create the multiple displays in which the to-be-tested material are integrated. In these displays, the materials would be strongly attached to the display. This method does not suffer from the problems that the previous method does. This method instead uses more materials, as multiple displays have to be created. Additionally, due to the aforementioned reasons, the reusability of the display is lower.

The casing

The second part of the dummy will be the casing. This casing refers to the outside of the dummy which is used to provide an estimate of the size of our robot and a base on which the other parts will be attached to. Since we focus more on the reading aspect, for the base a simple box would be sufficient. The dimensions of this box will most likely depend on the needed estimated space for the hardware and the size of the braille display. An important thing to take into consideration when creating the casing, will be to consider interaction between the braille display dummy and the casing itself. For example in case you want to change the letters of braille on the display, the casing should allow for a display to be removed and reattached.

Sources for materials

[1]https://www.the-warren.org/ALevelRevision/engineering/Materialclasses.html

[2]https://www.engineeringtoolbox.com/young-modulus-d_773.html

[3]http://burncentrecare.co.uk/about_burned_skin.html https://www.orfit.com/faq/what-are-low-temperature-thermoplastic-materials-lttps/

[4]https://agmetalminer.com/metal-prices/carbon-steel/

http://www.campaignforwool.org/about-wool/

http://bieap.gov.in/Pdf/CGTPaperII.pdf

https://global.kyocera.com/fcworld/charact/strong/rigidity.html

https://www.engineeringtoolbox.com/ceramics-properties-d_1227.html

http://www.dynacer.com/properties/

http://www.newworldencyclopedia.org/entry/Elastomer

https://www.britannica.com/science/elastomer

https://en.wikipedia.org/wiki/Thermosetting_polymer

https://en.wikipedia.org/wiki/Thermoplastic

https://www.onealsteel.com/carbon-and-alloy-steel.html

https://www.metalsupermarkets.com/what-is-chromoly/

https://www.economicshelp.org/blog/301/concepts/understanding-elasticity/