Viotar/ Ways To Exite The String

Ways to exite the stringExitation by ElectromagnetPrincipleAnother way to exite the string is by using an electromagnet force on the steel strings. This force is created by the flow of current through a coil wrapped around a magnetizable core, creating an electro magnet. The force can be controlled by changing the current that flows through the coil. Because current can be controlled by speeds in the order of several Gigahertz, the flow can be controlled very rapidly.

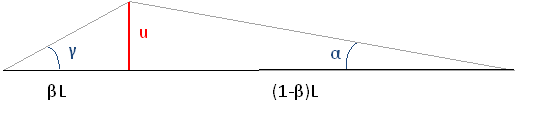

Estimation for the maximum bow force on the stringFigure x shows the string on the moment it's being exited by the violin bow. The displacement of the string is called 'u', creating two angles α and γ. The string will be exited on position βL.

The force in y-direction is calculated with: [math]\displaystyle{ F_y=sin(\gamma)A\sigma_{1}+sin(\alpha)A\sigma_{2} }[/math] [math]\displaystyle{ \sigma=E\varepsilon }[/math] [math]\displaystyle{ \varepsilon= {dL\over L_0 } }[/math] [math]\displaystyle{ F_y = AE \left (sin(\gamma){\sqrt{\beta^2 L^2+u^2}-\beta L \over \beta L} + sin(\alpha){\sqrt{(1-\beta)^2 L^2+u^2}-(1-\beta) L \over (1-\beta) L} \right) }[/math]

Estimation for the maximum dynamical force acting on the stringSince the string isn’t only exited statically but is being moved continuously, the static force calculated above isn’t the only force that has to be dealt with. The string should vibrate in a predefined pattern, and therefore big accelerations become important. The force needed to accelerate a certain mass m, is calculated using Newton’s second law of motion. This law states that this force is equal to acceleration times mass. Since the acceleration of the string varies linearly over the length of the string, the acceleration (and thus force) should be calculated separately for every small segment of the string. This gives rise to an integral over the whole string. In order to do this, the string is divided into two pieces, being the part βL and the part (1-β)L. This gives the following for the part βL: [math]\displaystyle{ F = {ma} }[/math] [math]\displaystyle{ F = \sum_{i=1}^{n}{m_ia_i} }[/math] [math]\displaystyle{ F_1 = \sum_{i=1}^{n}{m_i\left( {da \over dx} x_i \right)} = \sum_{i=1}^{n}{m_i\left( {a \over \beta L} x_i \right)} }[/math] [math]\displaystyle{ m_i = {\rho {\beta L \over n} A_{cross.sect.}} }[/math] [math]\displaystyle{ n = {x \over dx} = {\beta L \over dx} }[/math] [math]\displaystyle{ m_i = \rho A_{cross.sect.} dx }[/math] [math]\displaystyle{ F_1 = \int_0^{\beta L} {{a A_{cross.sect.} \rho} \over {\beta L}} x \;dx }[/math] [math]\displaystyle{ F_1 = {{a A_{cross.sect.} \rho} \over {\beta L}} \int_0^{\beta L} x \;dx }[/math] [math]\displaystyle{ F_1 = {{a A_{cross.sect.} \rho} \over {\beta L}} [ \frac{1}{2} x^2 ]_0^{\beta L} }[/math]

[math]\displaystyle{ F_2 = {{a A_{cross.sect.} \rho} \over {(1-\beta) L}} [ \frac{1}{2} x^2 ]_0^{(1-\beta) L} }[/math] Where: a = The acceleration of the string on position βL

[math]\displaystyle{ F_{tot} = F_1 + F_2 }[/math] [math]\displaystyle{ F_{tot} = {{a A_{cross.sect.} \rho} \over {\beta L}} [ \frac{1}{2} x^2 ]_0^{\beta L} + {{a A_{cross.sect.} \rho} \over {(1-\beta) L}} [ \frac{1}{2} x^2 ]_0^{(1-\beta) L} }[/math]

a = 500 m/s2 The maximum total force, which is the force needed to give the string the maximum acceleration at the maximum position, is given by the sum of Fy and Ftot. This means that the maximum magnetic force that is needed is about 50 N. FeasibilityThe calculation shows that a magnetic force of 50 N should be enough to exite the string in the desired pattern. Finding an electromagnet that generates this magnetic force is not a problem. However, the width of these electromagnets could be a problem, since there might not be enough space to place an electromagnet for each string separately. This problem could be solved by making the electromagnets on our own. The force that is generated in an electromagnet is only depending of the number of windings and the current through the coil. Since there is enough space underneath the strings, a long and tight electromagnet would work. Another point is that the magnet of one string might interfere with another and disturb it’s magnetic field. However, this problem would be quite easy to deal with as will since a screen could be placed in between the strings or the control device a magnet could compensate for disturbances from the others. DrawbacksDespite the theoretical possibility to use electromagnets for actuation, there are two very important drawbacks in this concept. Firstly, the instrument will no longer be bowed although it sounds as such. In fact the instrument then will no longer be a bowing instrument, which was one of the main requirements. But probably the biggest disadvantage of this concept, is the quite illogical way of synthesizing the sound. To get the string in the desired vibration, this vibration should be known in advance. Getting this vibration would be no problem, since we can get it out of the model or simply record it from a real bowing instrument. But once the vibration is known, it has to be exited on the string using electromagnets, recorded using a sensor and then amplified before it is played. This is very strange since we already had the desired vibration when we started, and thus were already able to play it. ConclusionThe conclusion about this concept is that it would work most likely and that every vibration pattern could be chosen. However, the big drawbacks that it is no longer a bowing instrument and that the synthesizing routine is very illogical, make the concept fail. Actuation by piëzo crystalsPrincipleA piezo actuator utilizes the phenomenon that crystals of certain substances expand when a voltage is applied on it or conversely, they give a voltage when pressure is exerted on the crystal. The name piezo is derived from the Greek word piezein, which means pressing. The concept for actuation by the piezo, is that the string is attached to a piezo element, which expands when a voltage is applied. The idea is that by varying the voltage, the movement of the string can be controlled, giving the desired vibration in the string FeasibilityIf the feasibility of this concept is considered, the combination of required force and deflection seems to be a problem. The reason is that piezo elements only enlarge a little, varying from a few micrometers to some tens of micrometers. There are piezo elements on the market that serve as a linear motor and have a maximum amplitude up to 100 mm, but again does not provide the required force. Another possibility is to use so-called piezo stacks. This a series of piezos allowing the maximum deflection to increase. However, this excursion is also just a little more than 1 mm for the required force, which is not enough. DrawbacksThe main disadvantage of piezo actuation is that the deflection they give is not large enough. This problem is partly dealt with using a stack, but even then the deflection is not large enough to make the string vibrate in the desired shape. Furthermore, in this design the instrument will no longer be a bowing instrument ConclusionFrom the foregoing it can be concluded that it is not possible to get the string in the desired vibration using piezoelectric actuators. Also the instrument would not be a bowing instrument anymore, which is an important factor in the design.

The bowing wheel   One straightforward way to excite the string electronically is by using a “bowing wheel”, which contacts the string as shown in Figure 1.1.

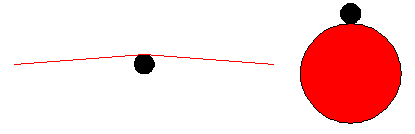

The bow’s stiffness in z-direction can be simulated using a bowing wheel by suspending the wheel in some way in z-direction. The bow’s stiffness in y-direction, coming from the longitudal stiffness of the bow’s hairs, corresponds with the rotational stiffness of the wheel in ϕ direction. The wheel can be suspended in this direction as well, so the bow’s stiffness in y-direction can be accounted for. The impulse responses in both y- and z-directions can be simulated in the control of the rotation of the wheel and the z-translation of the wheel, respectively. The surface properties can then theoretically match those of a mat of bow hairs when a mat of bow hairs is somehow applied to the outside of the wheel. This leaves only the property of the shape of the wheel to be compensated for. The wheel, as it is round, doesn’t have the same shape around the string as a bow. This is important because when the string transverses in y-direction (which will be the direction in which it will ideally vibrate), it keeps contact with a bow because a bow is almost straight, with the bow hairs actually tilting a bit towards the string around the bowing point, as in the left side of Figure 1.2. With a bowing wheel this is different, because it tilts away from the string around the bowing point, as shown in the right side of Figure 1.2.

This effect could hypothetically be prevented by the controller for the z-translation of the wheel. If the current friction force and normal force between the wheel and the string could be determined at every moment, the controller could “make sure” that these two stay at “natural” values (i.e. the same as when using a bow). This requires a constant reference for these both forces over the course of one vibration period, and a construction together with an actuator capable of following this reference with a total delay time including the sampling of the force measurements t_d that is much smaller than one vibration period, t_d≪T. This in addition with the sensors that are needed to measure the forces, makes bowing wheel a very unrealistic concept.

The Bowing BeltA more traditional way to vibrate a string is to hold a rotating belts against the strings. The big advantage of a belt is that it is as close to which has similar properties to a violin bow. Therefore it is most likely to have virtually all of the required properties, as noted previously in the piece written about the bowing wheel. Both the stiffness in z-direction and y-direction of horse hair can be achieved by constructing the bowing belt in such a way that the stiffness of the medium (for instance horse hair) dominates the stiffness of the other materials within the belt. By making sure the elastic properties of this materialmake it more elastic then horse hair. A great benefit of using a bowing belt with horse hair is that the surface properties of the medium are about the same as normal violin bow. With possible differences in the way the hair is attached on the belt compared to the the hairs on a bow which are strung. But that isn’t something which can’t be overcome by intelligent designing hopefully. One of the things caused by the usage of multiple hairs i that with higher presure the surface on the string increases, causing more stick Another benefit of using a bowing belt is of course that it’s length can be long enough to be able to contain enough rosin that it won’t wear of too quickly. Another factor There are several options to employ a bowing belt, but using one belt per string we found a design which is stiff and light enough. So that no doubts exist concerning the realization of a prototype. Making controlling the bowing pressure and speed better. In reference to the shape of the medium directly surrounding the point of contact with the string, it’s clear that it resembles a normal violin bow, only the material which keeps the hairs within the belt can interfere with that. So once again a material has to be found which has the required properties Alternative Bowing Belts, it temporary etc. |