PRE2016 3 Groep15

Group Members

| Name | Student ID |

| Martijn de Boer | 0907480 |

| Josja Geijsberts | 0896965 |

| Gijs Herings | 0953862 |

| Martin van Leeuwen | 0901497 |

| Max van Meer | 0951669 |

| Bart Tulkens | 0956335 |

Introduction

In the construction sector, building is still largely manual labor or aided by tools, but not automated. Some companies have tried to automate building construction by 3D printing layers of cement. This however, is not the only or the best solution. Pouring cement in this way generally leads to it not being reinforced concrete. If prefab components are grabbed and stacked to build a construction, electronics and piping can be built into the construction easily.

In this wiki page, a solution for an automated construction robot which places prefab building blocks, its advantages and disadvantages and how this can be achieved will be explained. Initially, a prototype of a simplified version was to be made using Duplo blocks to autonomously build a construction. However, after thorough planning and analysis, this plan was discontinued. The main reason was that this solution would be too time consuming and the other aspects of this project would receive too little attention. A new plan was developed, with a new goal. The new goal is to develop a functioning simulation with a user-friendly interface. Alongside the simulation, a detailed model will also be made. To achieve this goal, a couple experts in construction discipline will be contacted.

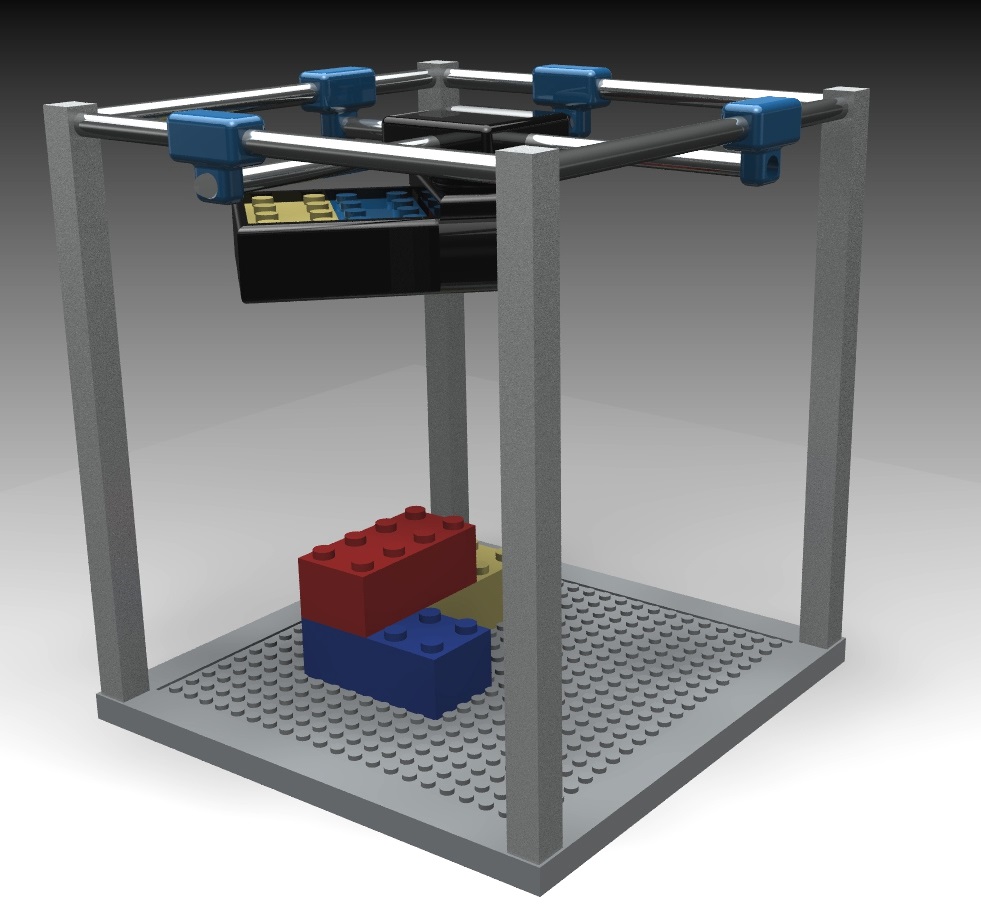

Initial Plan: Prototype

Initially, the goal was to develop a functioning, small-scale prototype. This prototype was to pick up and stack Duplo blocks basen on a given building plan as input. A 3D-model of this concept can be found in Figure 2. However, after thorough investigation, it was found that the achievability of this prototype was too low. A lot of small scale problems would have to be solved whilst there would not be enough time to discover and analyse the full-scale problems. It was therefore decided to discontinue the development and research into the prototype.

Renewed Plan: Simulation and Model

The new goal is to develop a functioning simulation with a user-friendly interface. Alongside the simulation, a detailed model will also be made. The simulation should be able to, on user input, provide the path that the printerhead should follow in order to build the desired building. This user input is yet to be determined, though, preferably, the input will be the output of a commonly used program for the designing of buildings. In this manner, the designer is not flooded with extra tasks. The interface should thereby also be self-explanatory and easy to use. The model will show a detailed concept of what the construction robot is expected to look like. The model will likely also lead to various designing issues that will be addressed in the upcoming weeks.

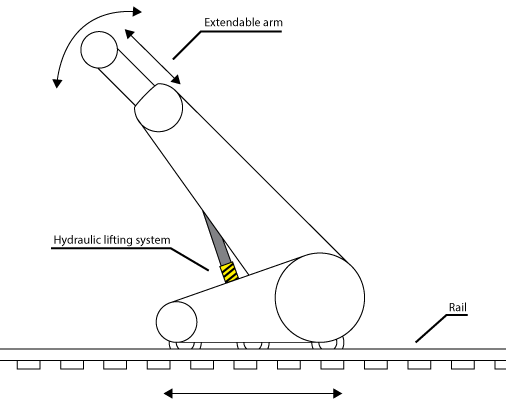

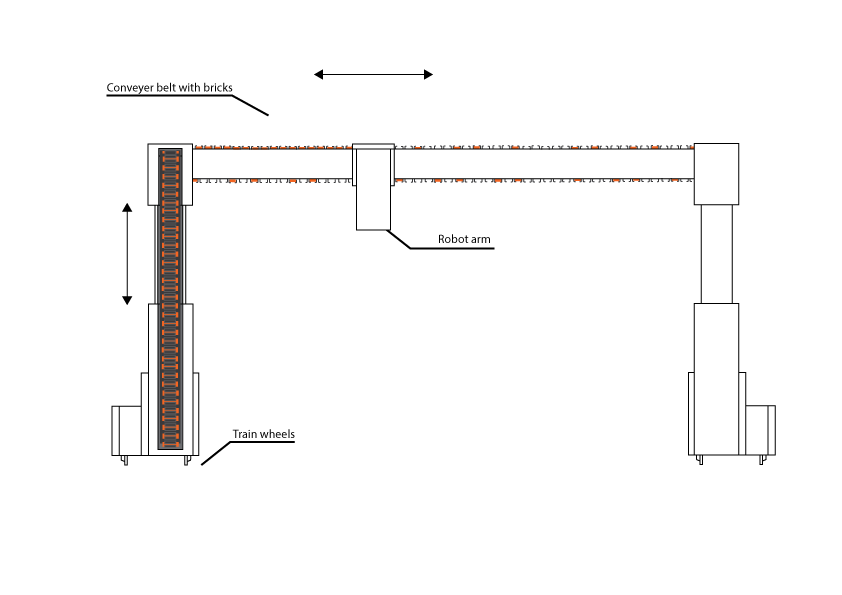

The side view of the final design can be seen in figure 1, while the front-view can be seen in figure 3. In figure 1, you can see the possible movements of the construction robot and the most special parts. The design is based on a concept of [Behrokh Khoshnevis] In figure 3, a brick providing solution is implemented in the design. The orange blocks represent bricks, while the gray part represents a conveyor belt.

USE Aspects

Below, a short overview of USE aspects is given.

User

- The construction robot will reduce the workload of the construction workers.

- The construction robot will reduce the amount of danger construction workers are exposed to.

- The construction robot will lead to a quicker realization time of the building, which in turn leads to quicker accessibility for potential future residents.

- The construction robot will enable more possibility for personalized designs

Society

- The quicker realization time of buildings the construction robot provides, will lead to a more efficient construction sector, which in turn leads to:

- The construction sector being more able to keep up with society’s demand for more living room.

- Possibly lower house costs due to reduced construction costs. This makes owner-occupied houses more accessible to a bigger audience.

- The construction robot could be used for building aid in third world countries.

Enterprise

- The quicker realization time of buildings can save construction companies a lot of money due to being able to do more projects in less time.

- The construction robot can save construction companies money on wages for construction workers

- The construction robot can help construction companies compete better on the market.

Potential Users

Larger scale

When looked at form a large perspective, mainly the construction robot will be important for construction companies. A construction robot will have a lot of benefits for these companies such as decreased building time. It will envigorate the market encouraging competition. Possibly being a major factor in the succes of certain construction companies.

Third world charity

The construction robot could also possibly be is used in development projects in third word countries. The fast building robot could make simple houses for people in the slums of big cities for example. This would be fast and very efficient since the homes would not have to be complicated with all kinds of personal wishes from the people who would be going to live there.

Smaller scale

When looked at more in detail the direct users of the robot will be construction workers. Their daily work pattern will be impacted heavily. More use of controls and repairing will be needed and less actual building. Possibly different kinds of people will be needed at a construction site because of that.

Private use?

When look at private users there is not any significant value in a construction robot. Maybe a smaller model as big as the prototype could be interesting as a hobby project, but most people won't be able to control the robot. Therefore the robot is mostly suited for professional or charity use.

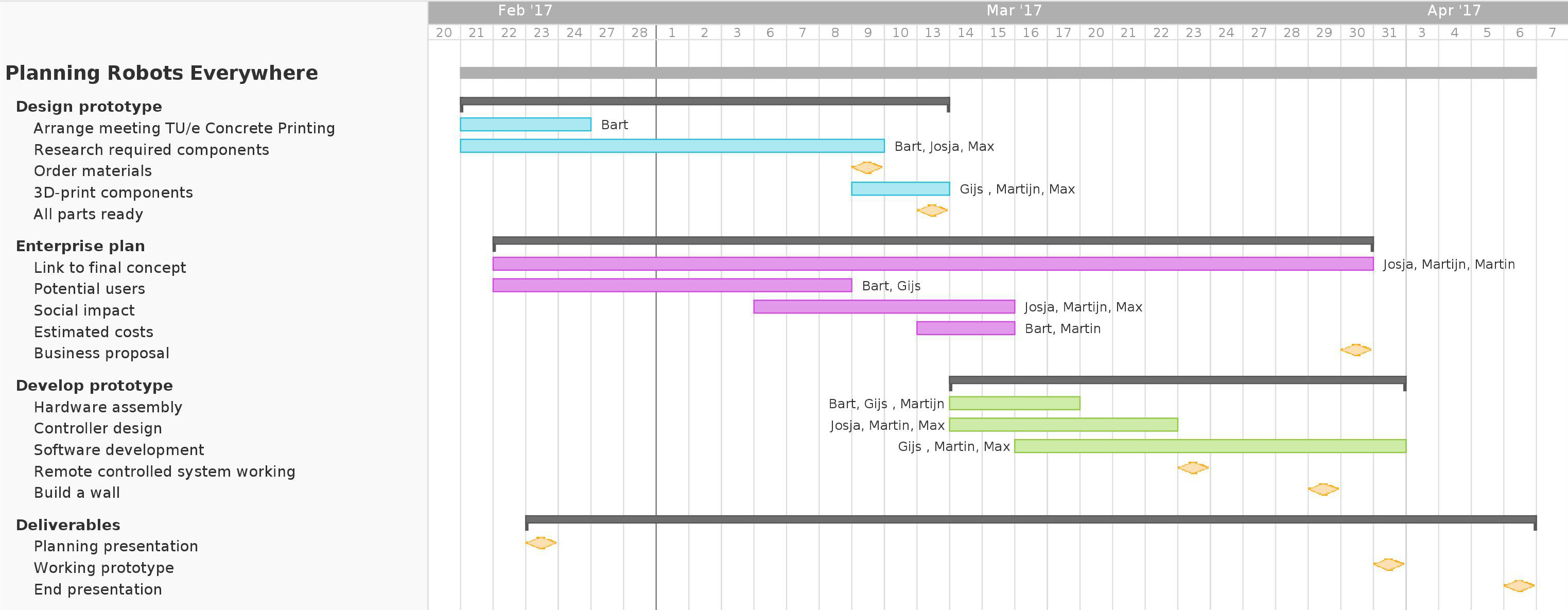

General planning

The general planning is displayed in a GANT chart, which can be seen in figure 2. In the GANT-chart activities, the work distribution and milestones can be seen. The planning will be adjusted if necessary.

week 1

- Deciding on the subject of the project

- Preparing the presentation about the concept.

week 2

- Concept Presentation

- Preparing the second presentation about the planning.

- Start working on wiki, explaining the concept and the deliverables

week 3

- Planning Presentation

- Rework project based on feedback

- Arrange meeting with TU/e Concrete Printing

- Start creating a list of required components for the deliverable

- Start working on the enterprise plan: Potential Users

- Update wiki

week 4

- Milestone: Order components for the deliverable

- Start desiging and printing components for the deliverable

- Finish Potential Users

- Start working on the enterprise plan: Social impact

- Update wiki

week 5

- Milestone: All components have arrived or printed

- Assembling all hardware

- Start designing controller and software

- Start working on the enterprise plan: Estimated costs

- Finish Social impact

- Update wiki

week 6

- Finish Estimated costs

- Start working on the enterprise plan: Business proposal

- Milestone: Remote control system working

- Update wiki

week 7

- Finish Enterprise plan

- Milestone: Business proposal

- Milestone: Build a wall

- Finish software development

- Milestone: Working Prototype

- Update wiki

week 8

- Buffer week

- Prepare final presentation

- Update wiki

Action plan

The initial step in the assembly of the robot is to get the green light for its creation. To ensure that the scope of the project is indeed properly defined. Once the theoretical background is sufficiently explored the construction of the robot can start. The construction can be divided in a few segments.

- Acquiring the required components

- Physical assembly

- Calibration

- Software implementation

- General Debugging