PRE2017 3 Groep10: Difference between revisions

| Line 764: | Line 764: | ||

Mass = 2.8*kg; % Total mass of the aircraft | Mass = 2.8*kg; % Total mass of the aircraft | ||

S = 0.28*m^2; % Wing area (Through fuselage as well)) | S = 0.28*m^2; % Wing area (Through fuselage as well)) | ||

b = 0.9*m; % Span of the wing (through the fuselage) | b = 0.9*m; % Span of the wing (through the fuselage) | ||

Swep_deg = 15; % Sweep angle of the wing [degrees] | Swep_deg = 15; % Sweep angle of the wing [degrees] | ||

S_ref = S; % Reference area = wing area | S_ref = S; % Reference area = wing area | ||

S_wet_fus = 0.65*m^2; % Wetted area of the fuselage (Including nose) | S_wet_fus = 0.65*m^2; % Wetted area of the fuselage (Including nose) | ||

S_wet_wing = 2.04*S*m^2; % Wetted area of the wing | S_wet_wing = 2.04*S*m^2; % Wetted area of the wing | ||

L_fus = 0.6*m; % length fuselage (Including nose part) | L_fus = 0.6*m; % length fuselage (Including nose part) | ||

A_max = 0.07*m^2; % Max fuselage cross sectional area | A_max = 0.07*m^2; % Max fuselage cross sectional area | ||

t_average = 0.1*m; % Average airfoil thickness of the wing | t_average = 0.1*m; % Average airfoil thickness of the wing | ||

c_average = 0.28*m; % Average airfoil chord length | c_average = 0.28*m; % Average airfoil chord length | ||

Revision as of 09:05, 22 March 2018

Introduction

Online shopping is becoming increaslingly popular [2], and since articles bought online have to be delivered to the requested address, parcel delivery is becoming more and more important in daily life. In 2010 already 90 million packages were deliverd, in 2014 this number more than doubled to 190 million[3]. If the increasing trend continues, then in 2020 there will be 280 million packages to be delivered. To keep up with this increase, delivery companies are coming up with more and more creative ways of delivering packages, such as bicycles. Another method which is being investigated is the use of drones in parcel delivery.

Nowadays parcels are delivered one by one by people, however, with drones becoming more sophisticated, drones might be able to improve this process in multiple ways. One of these methods is by using warehouses which house drones, these drones then do the parcel delivery directly from the warehouse to the buyer. Another method is to drive a truck to a certain location, from where the drones will deliver the parcels to the buyer. Yet another way is to have a 'flying warehouse', for instance a zeppelin, hang in the air, from where the drones can deliver parcels to the buyer.

All these methods have their own advantages and disadvantages, these need to be investigated and compared to the current parcel delivery method. Also the users should be incorporated, their needs and desires are vital in deciding if and how drones should be implemented in parcel delivery.

Problem statement and objectives

Problem statement

As discussed in the introduction, parcel delivery by means of drones can be implemented in several ways, to determine how these methods compare to the current method each of these methods needs to be investigated thoroughly. Next to that the users, society and enterprise need to be incorporated in determining if and, if indeed necessary, how drones should be implemented in parcel delivery. The problem tackled in this project is the problem of if and how drones should be implemented in parcel delivery. This leads to the research question:

How does parcel delivery by means of drones compare to the current way of delivery?

Objectives

The objective of this project is to make an analysis of the current parcel delivery method and several new methods of parcel delivery using drones. The analyses of the delivery methods using drones to the current method are then compared to see what the advantages and disadvantages of each method is. With the results of these comparisons and the results of the survey it can be determined if and how drones should be implemented in parcel delivery.

Stakeholders

Users

Buyers

The user of this system is the buyer of online products, the buyers are interested in a system which gives them fast and cheap delivery. They also want their package to be safe and undamaged during delivery. Next to that users do not want to have to be at home at a specific time to get their package.

Drones could provide for these wishes, they do not need a salary, which could save money for the seller of products, and thus also for the user. Drones could also provide undamaged delivery, as drones only carry one package at a time, so damage during transport is unlikely. Next to that drones can be used at any time of the day, so timing the delivery becomes easier.

However drones also have disadvantages for the buyers, for instance drones have to be able to see where they are going, so they may need cameras installed on them. Buyers will likely oppose camera images of their homes to be saved and stored. Also drones are often remotely accessable, so they may be hacked and taken over by others.

Society

Neighbourhoods

For neighbourhoods in general using drones mainly has disadvantages, the use of many drones by different companies could lead to noise disturbances in densely populated areas because of large numbers of drones flying around. This would be especially bad at later times of the day, since drones can fly almost 24/7 packages can be delivered at any time of the day. This could mean that at night many drones still fly around delivering packages when people want to sleep.

Also privacy is an important factor here, because drones need vision, camera images of neighbourhoods may be recorded. If these images are stored instead of deleted, people will likely oppose the use of drones.

Government

For the government the use of drones means a whole new set of laws which have to be formulated. These laws mainly have to do with the privacy issues and noise disturbances. The government needs to enforce laws to protect the privacy of their inhabitants, in that way people will feel reassured and safe, this could greatly help the use of drones. Also if the government makes clear airspace regulations the noise disturbance experienced by neighbourhoods could dramatically decrease.

Enterprise

Supplier

The enterprises which are affected by the implementation of drones are the parcel delivery services. For these companies it is important that deliveries are quick, so that they can deliver more packages per day. Next to that cheap delivery is important while still keeping the packages safe and undamaged.

Using the current delivery methods (trucks, bicycles etc.) companies cannot keep up with the amount of packages which have to be delivered on a daily basis [4]. Drones could provide a new way of parcel delivery, which can help companies like PostNL deliver their packages faster and cheaper.

Approach, milestones and deliverables

Approach

For this project the work was split in three parts, the literature study, the survey and the models.

The literature study was performed to learn more about the state of the art of drones. This gave us a good basis from which we could start our analysis.

The survey was done to find out how users think about the current parcel delivery system, where they would like to see improvements and which parts of the delivery system are annoying to them. This helped us in determining which parts of the delivery system as currently used can be improved upon.

The different delivery methods were modeled to get a good impression of the advantages and disadvantages of these systems. By then comparing these (dis)advantages with the preferences of the users the best solution was determined.

Milestones

Several milestones were defined to measure our progress during the project.

For the literature, the goal is to have at least 25 articles studied and summarised.

For the survey the goal is to have at least 75 surveys filled out.

For the models, the goal is to be able to have absolute numbers for amongst others the time-gain and costs.

The final milestone is to make a relevant comparison between the results of the survey and the outcome of the model.

Deliverable

Our deliverable is a report in which all our findings can be found, as well as the results from the survey and the models.

Who’s doing what?

- Pam: responsible for the survey and the model of the Zeppelin warehouse

- Thibeau: responsible for model of truck-drone delivery

- Marc: responsible for model of beehive system

- Nol: responsible for analysis of current system

- David: responsible for the wiki

Assumptions

Backed up assumptions Group 10

Delivery methods

An attempt to improve the current parcel-delivery system by the use of drones can possibly be done in different ways. During this project, the main focus is on three methods that have been researched by Amazon.com already. These three methods are: 1) Distribution centres (aka Beehives) that send out drones. 2) Truck-drone combinations for 'last-mile-delivery'. 3) Zeppelin as distribution centre using drones.

All three methods are explained in detail, also the comparison is made between each method and the current delivery approach.

Delivery Drones

Single rotor

The look of a drone that only has a single rotor is most easily described as a normal helicopter containing a pilot. This implementation uses one big rotor to travel vertically and also horizontally. The use of only one rotor will impact its power and maneuverability since there is only one rotor that needs to do all the work. Therefor this implementation will only be able to lift relatively light loads and the battery life will be low. Another downside of a single rotor is that the rotor needs to be pretty big which makes it mobility very low and not suitable for landing near a house on the street. The price of a professional single rotor helicopter is near €600,-[5]

Multi rotor

The most well-known drone for hobbyist and people with a little bit general aviation knowledge. Multi rotor drones are known for their stability and safety. The multiple rotors make it possible to keep the drone very stable and with the smaller blades and often applied “mudguards “ makes it also very safe for the customers and people around the delivery point. A down side of multiple rotors that have a relatively small diameter also drain a lot of battery if you want to enable a sufficient large working area for the drone. The costs of a Multirotor will be around €3000,- [6] [7]

Fixed Wing/Glider

Fixed wing gliders are more known for its application in the military due to his very high distance range and low energy use but it can still have its place in the parcel delivery industry. Another few advantages of a glider drone is that it travels faster than the multirotor drone variations where the rotors are direction vertically. Hobby remote controlled airplanes can already reach speeds of around 140 km/h. It is however limited by the package size and mass since the size of the package will determine the shape of the plane and maybe make it less aerodynamic. This can be remedied by placing the package internal in the drone. In comparison with vertical multirotor drones, are fixed wing drones capable in less weather situations(manned helicopters are capable to fly with wind power 11 [8]). And because it can glide more to lift off are possible for the drone such as catapulting. The reason that is a plus point is because it will save a lot of battery if the drone won’t have to use power to lift from the ground. The biggest problem with glider drones is that they can’t fly straight vertically to land. This makes it harder to implement a glider drone for parcel delivery tasks in busy city’s. Also the safety of these kind of drones will be a problem. With speeds of 140 km/h the plane can cause serious damage to humans, cars and buildings which makes this type of drone very dangerous. The costs of an Fixed wing drone will be around a professional well known RC Cessna 150 of €530,- [9]

Fixed wing hybrids

This type of drone is already in a very high stage of development by several companies including Amazon. This type of drone mixes the best of multiple worlds. It can glide in the sky and its lift off can be aided by a catapult which will guarantee better battery life and speed. It can also float in the air stationary which makes it much more applicable for delivering parcels. The speed will be comparable to the glider drone when it flies horizontally. The load will be sufficient enough, knowing that Amazon is already marketing it for the use of 5 pound parcels. Its ability to switch to “helicopter” mode makes it also a lot safer and when looking at the design Amazon already uses it can be stated that the rotors won’t cause harm.

Costs about this drone are unknown but it is very certain that this type will be the most expensive of all types.

Zeppelins

Current Delivery system

For the current delivery systems the trivial method of parcel delivery trucks is used. These trucks start from distribution centers that are currently scattered by PostNL. The locations are according to the website of PostNL[11] placed in or near the cities:

- Amsterdam (postcodegebied 1000-2199) PostNL Sorteercentrum, Liniepad, Halfweg. This is very west from Amsterdam close to Harlem

- Den Haag (postcodegebied 2200-2899) Forepark

- Nieuwegein (postcodegebied 3400-4299 & 6500-6999) Grote Wade 80, 3439 NS Nieuwegein

- Rotterdam (postcodegebied 2900-3399 & 4300-4999) Terbregseweg 300

- Den Bosch (postcodegebied 5000-6499)De Steenbok 2, 5215 ME

- Zwolle (postcodegebied 7000-9999)Anthony Fokkerstraat 2, 8013 NS

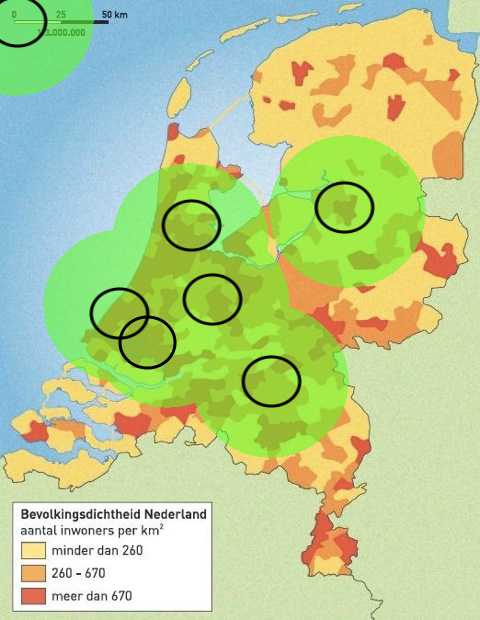

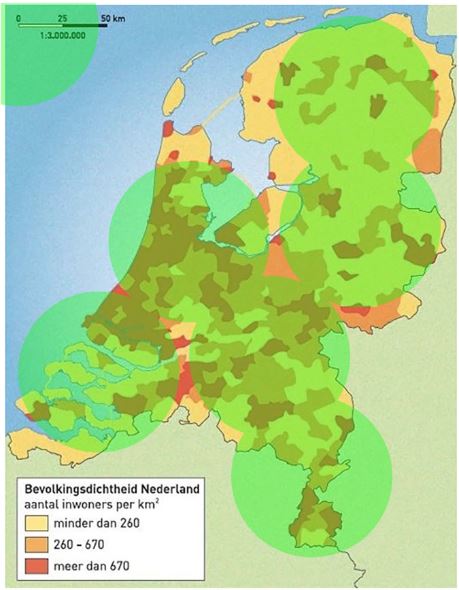

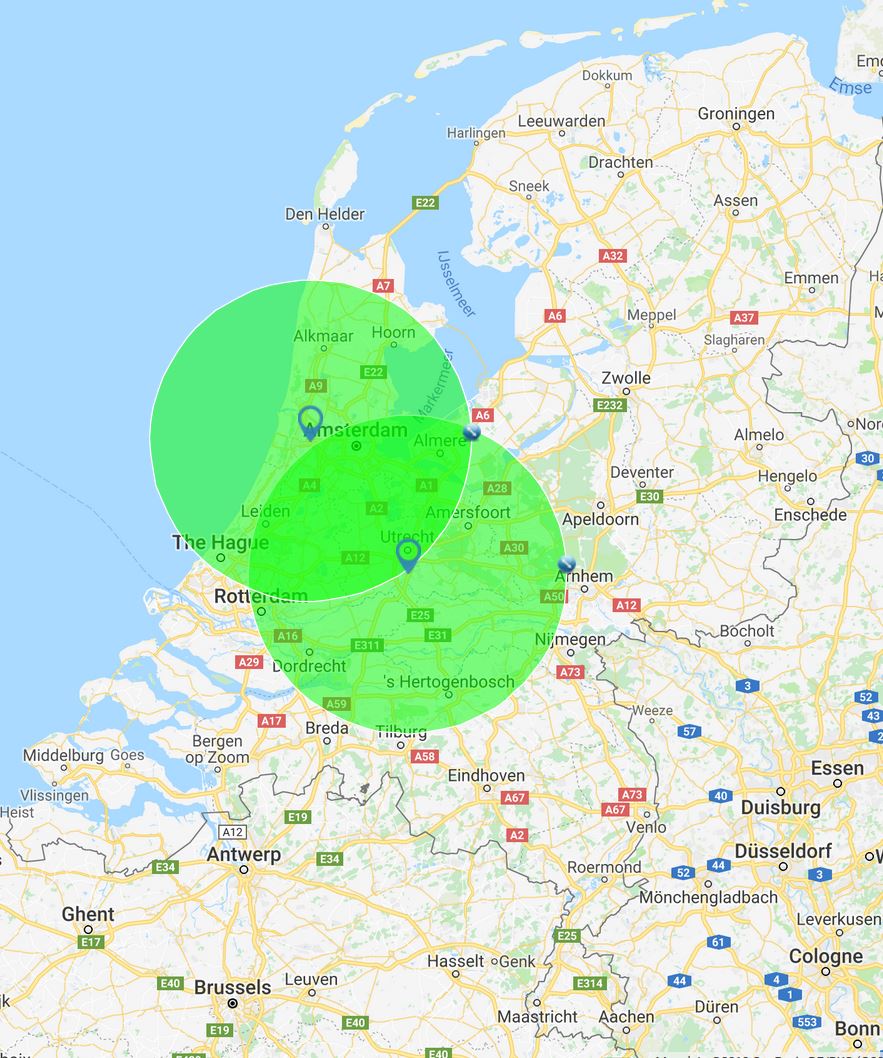

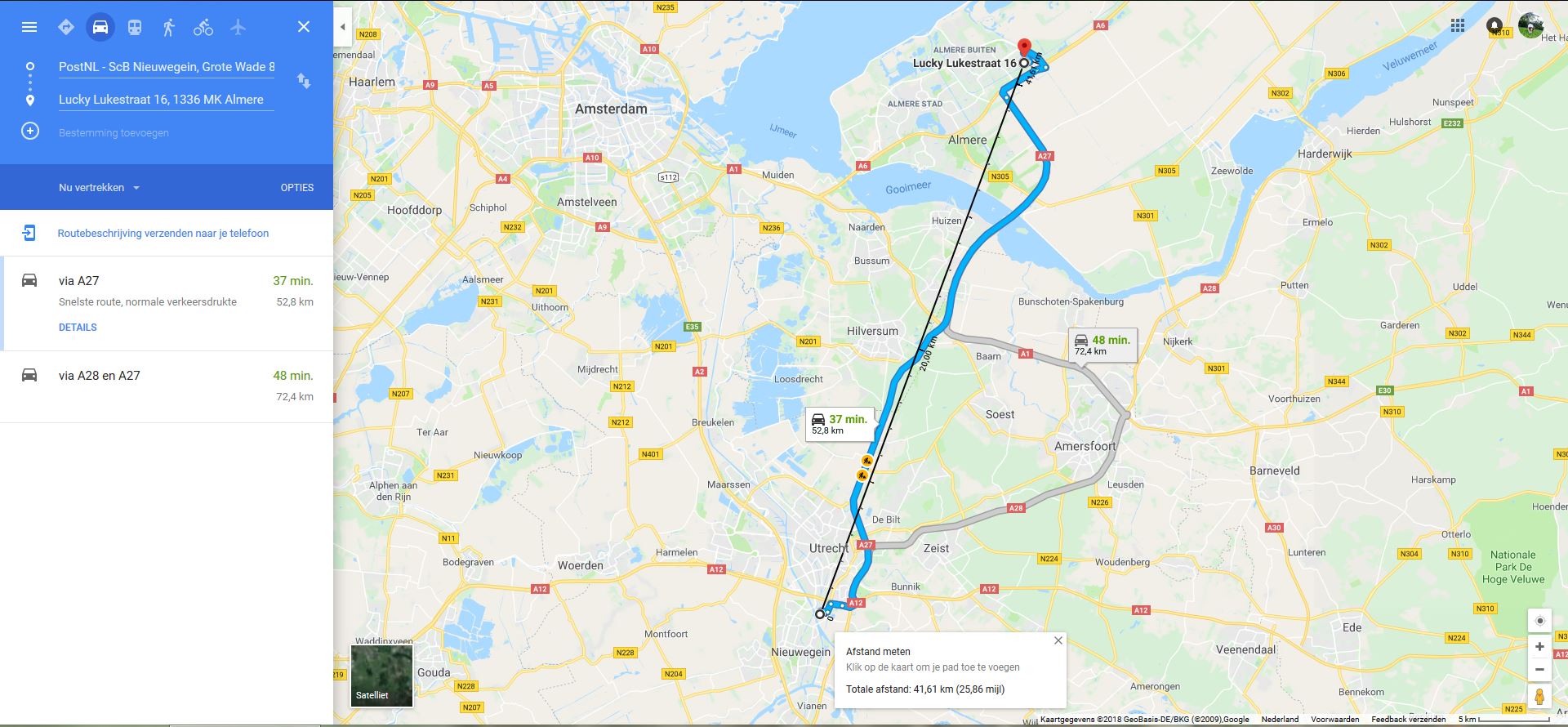

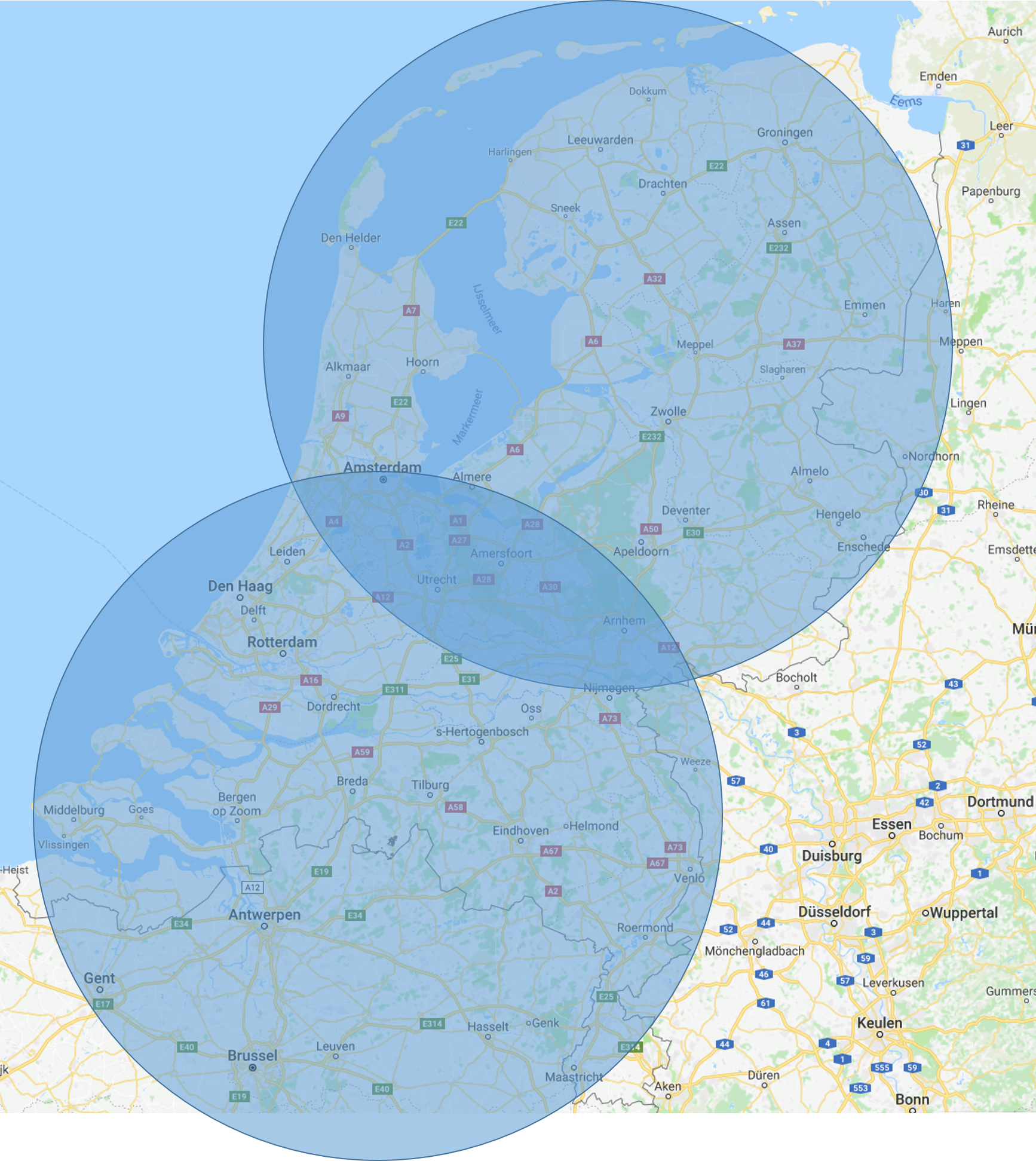

In order the get a analysis on how much time a parcel delivery truck takes when delivering a package, a time delivery interval should be derived showing both extremes in time. This way a quantitative conclusion can be drawn on the time efficiency of delivery trucks From the assumption that the delivery drones will have a radius of 48 Km it can be calculated what the time efficiency of the current delivery system is by checking the travel time of 2 cities of extremes. To see which city is the busiest and which is the least busiest, the following 2 maps show the traffic in the rush hours.

|

|

From these maps it can be easily concluded that Zwolle is the least busiest traffic city. For the busiest cities it is a little bit harder to point out the busiest city but it looks like Rotterdam is the busiest when morning and evening rush hour are both taken into consideration. From Rotterdam a circle of approximately 48 can be drawn and from that a location can be chosen where the parcel delivery truck has to deliver. From the traffic rush hour maps it seems that in the direction of Utrecht the most traffic jams takes place. Selecting a location in that direction will lead to the extreme where the delivery truck needs the most time.

Before proceeding the analysis, a few important notices should be made. The first notice is that the delivery centers are placed very concentrated in area's where a lot of traffic jams take place. This is a very strategically way to deal with the demands in very population dense area's. A second notice is that Bol.com and PostNL will not give information about the division of parcel delivery's per distribution center so an educated guess should be made determining which distribution center delivers where. The third notice is that because the distribution centers are placed in the strategic way it is done now, analyzing an extreme where the truck has to delivery a package exactly 48 km in the direction of a high potential traffic jam is not possible. The reason for this is that the location from a distribution center can be done by an other distribution center. So choosing Rotterdam as leaving point for a delivery in the direction of the Randstad will probably will not be the best choice for analysation. Hence another reasoning for a different city should be made. And a fourth notice is that Google maps doesn't include the average of traffic jams but instead takes the current traffic jam situation. Therefore two options can be taken; one is just taking "snapshot" of the travel distance Google maps gives or two, take a constant delay time that is incorporated in the travel time to a location. This delay time can be modeled by setting the average time over the whole travel distance to a constant. This time constant can be approximated by taking in account the average speed a truck drives in cities, suburbs, the country, village streets and the highways. It can be stated that on the types: city, suburbs, country and village streets the average speed a truck drives is 50 km/h which keeps in mind that these types are built-up area. For the highways the maximum speed of 130 km/h can be used but during traffic jams then it comes down to 50km/h.[12] It depends highly on the distance on what the average speed should be since if the road contains mostly high ways the average would be higher than a road that goes through the city most of the time.

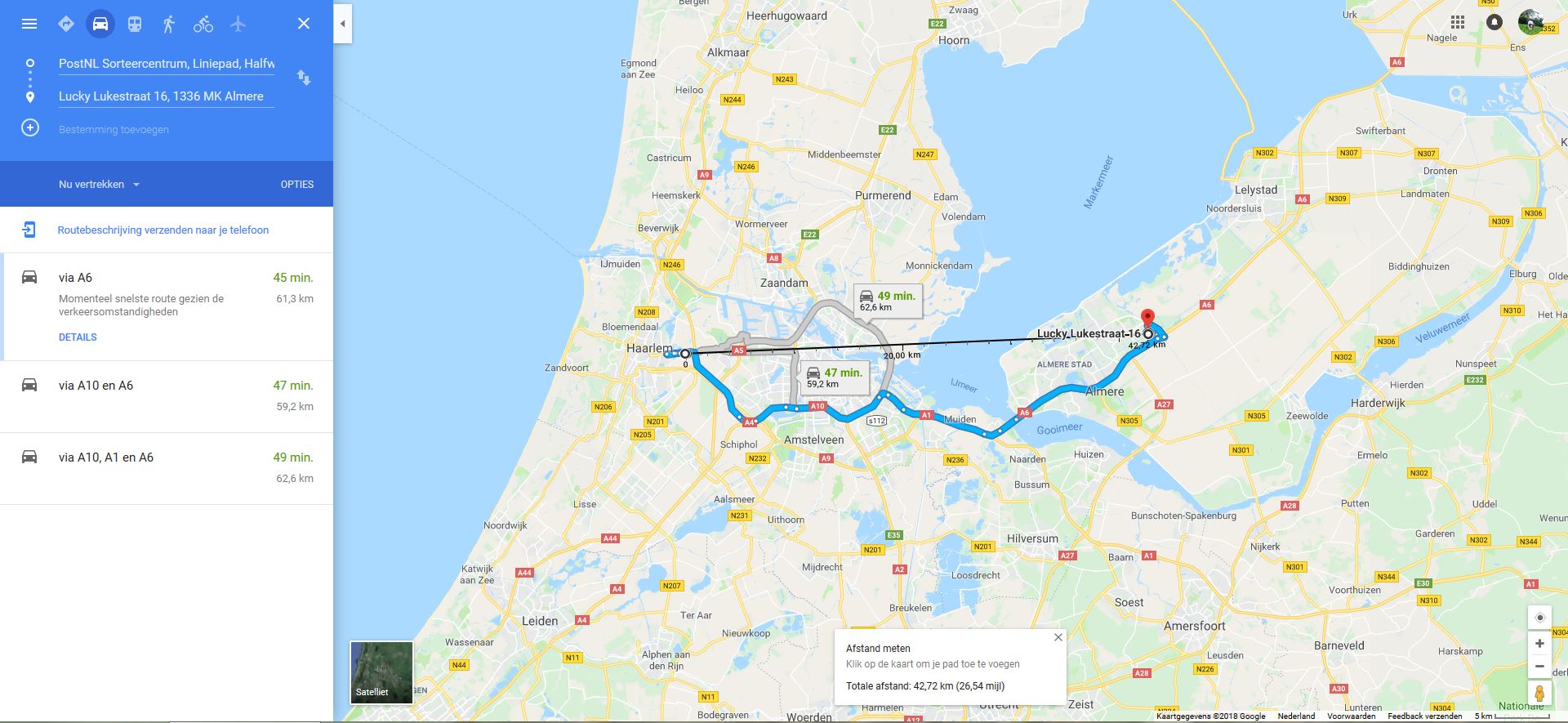

The best choice for getting a result where the an extreme can be derived is when the distribution center in Nieuwegein delivers a parcel to a location near Almere. The reason for this is as follow: If busiest city Rotterdam was chosen and the truck needed to deliver in Utrecht it will not give a reliable travel time since the delivery also could have been made by approximately 4 other distribution centers; Amsterdam, Den Haag, Nieuwegein and even Den Bosch. Its seems assumable that a parcel delivery suffers the most from traffic jams if the delivery location is in the north east direction with respect to Amsterdam, Den Haag, Rotterdam and nieuwegein together. The reason for north east is because towards the south the traffic jams are less long and concentrated or it is unclear which distribution center should do the delivery. Therefore it seems reasonable to disregard Rotterdam and Den haag as potential example for a worst case delivery scenario and thus Amsterdam and Nieuwegein Remain.

In the maps below circle are drawn that are exactly 48 km To select a delivery location that is exactly 48km crow flies is hard so we approximate by selecting a street that is near the edge of the 48 km circle. From this map it seems more reasonable that PostNL chooses Nieuwegein as distribution center that needs to deliver at Almere since the road seems more as the crow flies and Amsterdam is at its own a very busy city where the traffic is horrible so if the distribution center of Amsterdam needs to deliver to a location near Almere it will probably be very ineffective.

|

|

Comparing a drone with a truck in Google maps is shown in the two images above. The left one shows the substantiated case where the truck leaves from Nieuwegein and the right one is to show the disadvantage of letting the truck leave from Amsterdam where not only the road is meandering but it also have to go through the busy streets of Amsterdam, And it is also approximately 10km longer in terms of the travel road but also 1 km longer in a straight line. So in that case it can be concluded that the extreme we chose to compare is suitable. The pictures are taken during non rush hours so to incorporate the traffic jams the average is taken of the travel time calculated by Google Maps and the travel time if the whole road was driven with a speed of 50 km/h. With that the following data is received.

| Truck | Drone | |||

|---|---|---|---|---|

| Travel time when

traffic jam is accounted for |

50.18 | 31.2 | ||

| Travel time calculated

by Google Maps |

37 | 31.2 |

The beehive

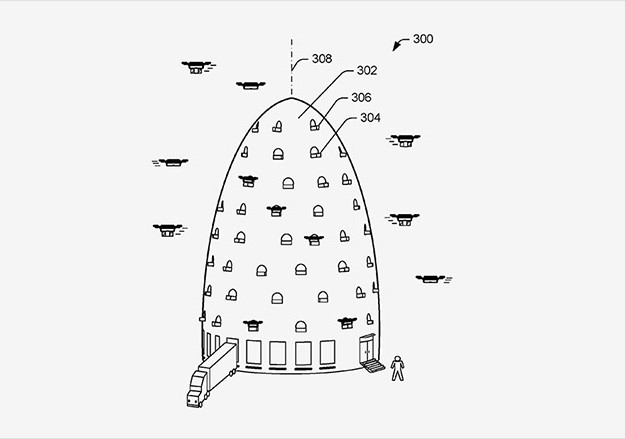

To be able to deploy delivery drones from distribution centres and warehouses, one must come with a smart design so drone deployment and truck deliveries don’t interfere. Today’s distribution centres and warehouses are typically large-volume single-floor buildings, located at the outer parts of the mayor cities [13]. But since drones are not restricted to the ground floor, it could efficiently fly from higher levels. Combining this possibility with the distribution centres results in the beehive.

The beehive is a distribution centre for the delivery drones to take off and land. [14] The beehive facilities would be built vertically so truck deliveries can be deployed from the ground floor while the drones can be deployed from higher levels. In this way the drones are already at a higher level in the sky and therefor restrict the danger of contact with pedestrians. [15] Inside the beehive robots move goods around and conduct maintenance on the drones. And since the facilities are so high, the delivery drones could fly inside as well. And by taking off from such a high level saves time and energy for the drones since it doesn’t need to ascend much, making it possible to fly further and faster. Another advantage of the multi-level facility is that the drone activities largely take place on the upper levels, therefor minimizing the noise for surrounding areas [16]. Since the building has multiple levels, it could have a considerably smaller footprint, therefor allowing the beehive to be build closer to city centres. Building the beehives closer to the cities results into items that may be delivered more quickly to the growing population of people that live in the cities, as well as the growing number of people who work in the cities [17].

The beehives could facilitate a large volume of drones that continually fly in and out to deliver the packages and recharge at site. Those drones could fulfil thousands of orders a day, depending on the number of drones being used. And to be able to control and oversee the flight operations of the drones the beehive could facilitate a command centre, comparable with a flight control tower at the airport. With the use of this command centre no drone delivery flies unseen or unmanned while the drones itself is autonomous.

Limitations of the drone’s flying radius

To understand the use and implementation of the beehive, it is important to look into the possibilities of the delivery drones. To be able to analyse the situation, the Amazon prima air delivery drone is used. In their current research status, these drones can cover a total distance of 32 kilometres. This means that the drones can fly within a radius of 16 km from the distribution centre on a full battery. Therefor one beehive can cover up a surface of (π * r2=) 803.84 km2. To cover up the entire Netherlands its surface (42.000 km2), this results in a demand of over 52 distribution centres. Comparing this to the current number of distribution centres of PostNL which is 6 centres through the entire Netherlands[[18]], a proposed increase of 875% on distribution centres is necessary. This would be the only way to deliver a package on the maximum distance of 16 km within 30 min. And for every delivery one drone is occupied for a maximum of 90 minutes, taking into account that recharging takes half an hour.

A possible solution for this would be to install wireless charging pads throughout the Netherlands, for example on lampposts. This would increase the distance one drone can cover with 200% since the first time the drone can fly straight for 32 km, before fully charging and then cover another 16km so it can still return to the charging pad. This would mean one distribution centre can cover up a radius of 48 km and therefor a surface of 7234 km2. This would mean that about 6 distribution centres could cover up the entire Netherlands, if ideally distributed over the country. In this case a drone maximally takes about 75 minutes for one delivery and another 75 minutes to return and another 30 min to recharge again, resulting in a total time of 180 minutes. It is a possibility to change the battery of the drone once it is back to the beehive, which can save up the last 30 min with just one action.

However, the Netherlands is not a perfect shape so the surfaces will not align with 6 beehives. Furthermore the distribution centres out optimally over the Netherlands. Currently the furthest distance to the closest distribution centre in the north is about 140 km. A clear overview of the centres of PostNL throughout the Netherlands can be seen in the figure above. The figure aside of it shows a favourable distribution of the beehives with respect to covering the most area. Currently, the centre of the Netherlands can be reached quite well with sometimes more than one distribution centre in range. The outer parts of the Netherlands are actually out of reach, even with the solution of wireless charging pads. Even when applying a second charge moment in the flight, extending the range with another 32 km, not every part of the Netherlands can be reached. And due to this extra charge the total flying time increased with 90 minutes and the delivery time is extended to 135 minutes, causing one drone to be occupied for about 5 hours before be ready for the next delivery.

It can be concluded that spreading out 6 beehives throughout the Netherlands is not going to be enough to deliver packages with drones throughout the entire Netherlands within a profitable time. A better implementation for the placements of the beehives would be to look into the population density. To see if PostNL has its distribution centres on favourable places, its warehouses are compared to the population density in the Netherlands. And around these distribution centres, the radius of the drone’s flying distance is drawn, as seen the figure below. The figure aside of it shows a favourable distribution of the beehives throughout with respect to the population density. A few notions can be made when comparing the distribution of distribution centres of PostNL compared to the distribution with respect to population density:

- Currently the distribution centres seem to mainly cover the most densely populated areas. Therefor leaving out a big part of the Netherlands.

- The map that respects the population density still doesn't cover the entire area of the Netherlands

- There shouldn't be a reason for PostNL not to place distribution centres in the northern part of the Netherlands existing of Friesland, Groningen and Drenthe.

Implementation of the beehives

To analyse the all the advantages of the beehive, it has to be analysed in a real situation. For this analysis it is chosen to compare a normal distribution centre on the outskirts of a big city to the beehive build almost in the city itself. And what better city to analyse than Amsterdam.

First of all, Amsterdam currently has a delivery of over 40.000 packages a day. And with the current grow of online purchases it is expected to grow over 100.000 packages a day within 10 years. [19] But according to the Amsterdam, the dense populated city can’t facilitate that amount of packages with the already their overcrowd traffic. Currently almost all packages are delivered with a van and a small amount is delivered with motorbikes or bicycles.

So let’s compare the possibilities with a normal distribution centre and the beehive. PostNL has its current distribution centre placed at Australiëhavenweg 100, Amsterdam. This location is indicated in the figure aside, as starting point of the route, encircled in black. Even though the Beehive could be placed quite a bit closer to the city itself, it is placed at the same location for the first comparison.

To start off, one package has to be delivered directly from the distribution centre to Agnietenkapel, located at Oudezijds Voorburgwal 231, close in the city itself. First of all, the package could be delivered with a van, having two options. First, driving through the city and taking a route of 11.2 km that takes up to 36 minutes or drive around the city taking a route of 20.3 km that takes up to 26 minutes. When delivered with motorbike it takes the route of 11.1 km and about 31 minutes. When delivered with bicycle it takes the route of 10.0 km that takes up to 35 minutes. But when delivering with a drone, it could fly in a straight line, taking a route of 7.2 km. Taken into account that it flies with an average speed of 60 km/h, it takes less than 8 minutes to deliver by drone.

But to get a proper comparison between the different transport systems more locations have to be added. There is chosen for a total of 6 locations, randomly chosen among Amsterdam. In the comparison the van is shown as a car, there is the bike, the bicycle and the drone. All cariers can take 6 packages with them, except for the drone. This results in the fact that the drone has to fly back to the distribution centre after every delivery to pick-up a new package. For this action 90 seconds have been added, each time. Also since the drone is not flying on ground level it has to ascend and land every time, each action taking 30 seconds into account. With this extra restrictions the model is believed to be more reliable and less in favour of the drone delivery.

To calculate the time necessary to deliver packages in Amsterdam, google maps is used. The final route for the car is shown in the figure aside, highlighted in blue. The final route for the bicycle is shown in red. The bike mostly rides on the bicycle lanes but sometimes has to drive on the main road, taking more time and some more distance. The drone flies into a straight line each time, with an average flying speed of 60 km/h. The table shows the distance (km) and time (min) covered up until reaching that location. In the end the total covered distance and time are shown as well as the average speed. Take into account that no extra time is charged for the car, bike and bicycle to actually deliver the packages. And even without this extra event the drone is almost 50% faster than the van. And below the top four calculation an implantation of more drones is shown. As seen in the table the total time consumed when using three drones is only 21.5 minutes for 6 deliveries, not taking the last return flight into account. Compared with the truck, this is an improvement of over 500%. Compared to the bike it improves with 475% and with the bicycle 630%.

As stated before, currently the model is running from the distribution centre location of Amsterdam as it is currently located. However, with the implementation of the beehive, the distribution centre could be placed even more central in the city being able to deliver packages all over Amsterdam and surrounding within 30 minutes. And this implementation is not only available for Amsterdam but for all major cities. With the use of the beehive, every big city in the Netherlands will be able to order packages that can be delivered within 30 minutes on the exact location necessary. With the transformation of the current distribution centres into beehives almost all big cities fall within the 16 km range. And with only a couple of extra beehives all major cities will be able to order packages with a delivery time below the 30 minutes.

| Delivery destinations | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Advantages and disadvantages of the beehive

Now that the main idea is of the beehive is clear and a comparison is made between the current methods and the method of the beehive, the advantages can be enlisted versus the disadvantages.

Advantages

Let’s look into the advantages at first. To implement the beehive, a distribution centre has to be transformed. The footprint will become smaller and the building will become a multi-level fulfilment centre. In this way it can be located closer or even within the major cities, since the space taken is much smaller. Another advantage is that the current methods doesn’t have to be changed completely, it is just altered. Drones are added for fast deliveries, but have to stay within range, while truck can still be deployed from the beehive to deliver outside this range. Due to the height of the beehive, the drones can fly away from a sufficient altitude preventing noise disruption and dangerous encountering with pedestrians on the ground floor. And since it has so much space on the higher levels, lots of drones can be stored that are either idle or charging.

Furthermore, the traffic jam within the city will decrease since less vans are necessary to deliver the packages. The packages can be delivered within 30 min in a 16 km radius of the beehive, any location necessary. This results in the fact that buyers don’t have to be home but can use GPS to uplink their current location so the drone can deliver at that specific location. The time profit made is between 300% and 600%, depending on the number of deliveries and the number of drones used. And keep in mind that a van would not depart to deliver one packages, while a drone flies straight away. Beside the fact that the deliveries a much quicker, they are also cheaper. A PostNL parcel delivery costs the user about €3.80 [20] and a PostNL deliverer costs about €8.57 [21]. A drone has a one-time investment cost and afterwards only makes costs with charging. Resulting in lower costs for the company and therefor a decrease in the price for the buyer which will probably be about €1 per parcel.

- Smaller footprint for distribution centre

- Closer to the city

- Less traffic jams

- Quick deliveries in overpopulated areas

- A time profit between 300 – 600% on deliveries

- Possibility to deliver within 30 minutes

- Cheaper for the buyer

- On time, more profit for the supplier

Disadvantages

Although the beehive offers a lot of promising advantages, there are also some downsides. First of all, to be able to deliver packages within 30 minutes to the 10 major cities of the Netherlands, every city needs its own beehive. These cities have been drawn on the figure aside [22]. Taking in account that currently, only 4 of the 10 cities have a distribution centre nearby, 6 completely new distribution centres have to be built. Building such project close-by or within those major cities brings along quite some trouble as well as costs. And all the drones delivering from the beehives have to be accounted for. As stated in the assumptions, 172.000 deliveries have to be made daily with drones. Assuming 67% is ordered in the major cities, about 115.000 deliveries have to be made with only 10 beehive. Assuming one drone can deliver about 4 packages an hour, recharging time takin into account, and the drones fly for about 10 hours a day, so 40 packages a day can be delivered by each drone. This results in a supply of around 3.000 drones in 10 beehives, so 300 per beehive. And since each drone costs €3500, a total of €10.5 million euros has to be invested.

Beside the fact that the implementation of the beehives need a big start-up, the beehive might not be the most attractive building to have around. It is quite high so it can clearly be seen over a large range and it has lots of activity, resulting in distractions and irritations for people in the surroundings. Not even starting about all the flying drones in the air which people might get frustrated about, especially the ones working in high business-towers. And the fauna environment around the beehive might also be supressed by all the flying drones.

- Limited within a range of 16 km

- Large start-up costs

- Building projects bring along trouble

- Distraction for fauna environment

- Distraction for surrounding people

Truck-drone combination

A truck-drone combination is another possible solution. The main idea of this concept is to deploy a number of drones from a stationary truck. By using a strategic position for the placement of the truck, the distance covered by the drones is minimized, hence the delivery time can be reduced. Implementing this method creates a number of difficulties that have to be tackled. First, the capacity of a truck has to be approximated. The amount of drones per truck and the amount of packets per truck have to be determined. This is done by making assumptions, this way a truck contains at least 10 packets and 2 drones. To investigate the efficiency, the calculations can be repeated for different numbers of drones and packets per truck.

Static deployment

Another important problem is that of the placement of the truck. In this delivery method it is assumed that 1 truck is placed in Eindhoven for all the deliveries at that time. To optimize this placement, different techniques can be used.[23] The two most appealing are:

1) Determine the geographic midpoint.

2) Determine the centre of minimum connecting distance (aka Steiner point).

For the first, the benefit is that the maximal distance from the truck to a destination is minimal. This way it can be prevented that an empty truck is extensively delayed by a single drone that is still enroute to/from the furthest delivery destination. This method is optimal when the number of drones is significant compared to the amount of packets to be delivered. For the second, the benefit is that the total distance travelled by the drones is minimized. Therefore when the number of drones is very small compared to the amount of packets, the total time can also be optimized.

To compare this method with a traditional parcel delivery, an example scenario is worked out.

The distribution company has 10 packets that they have to deliver in the city of Eindhoven.

The locations at which they have to deliver are (random locations) shown in Table I.

Calculating the geographic midpoint results in: 51.448193, 5.464556

Calculating the centre of minimum distance results in: 51.443398, 5.465531

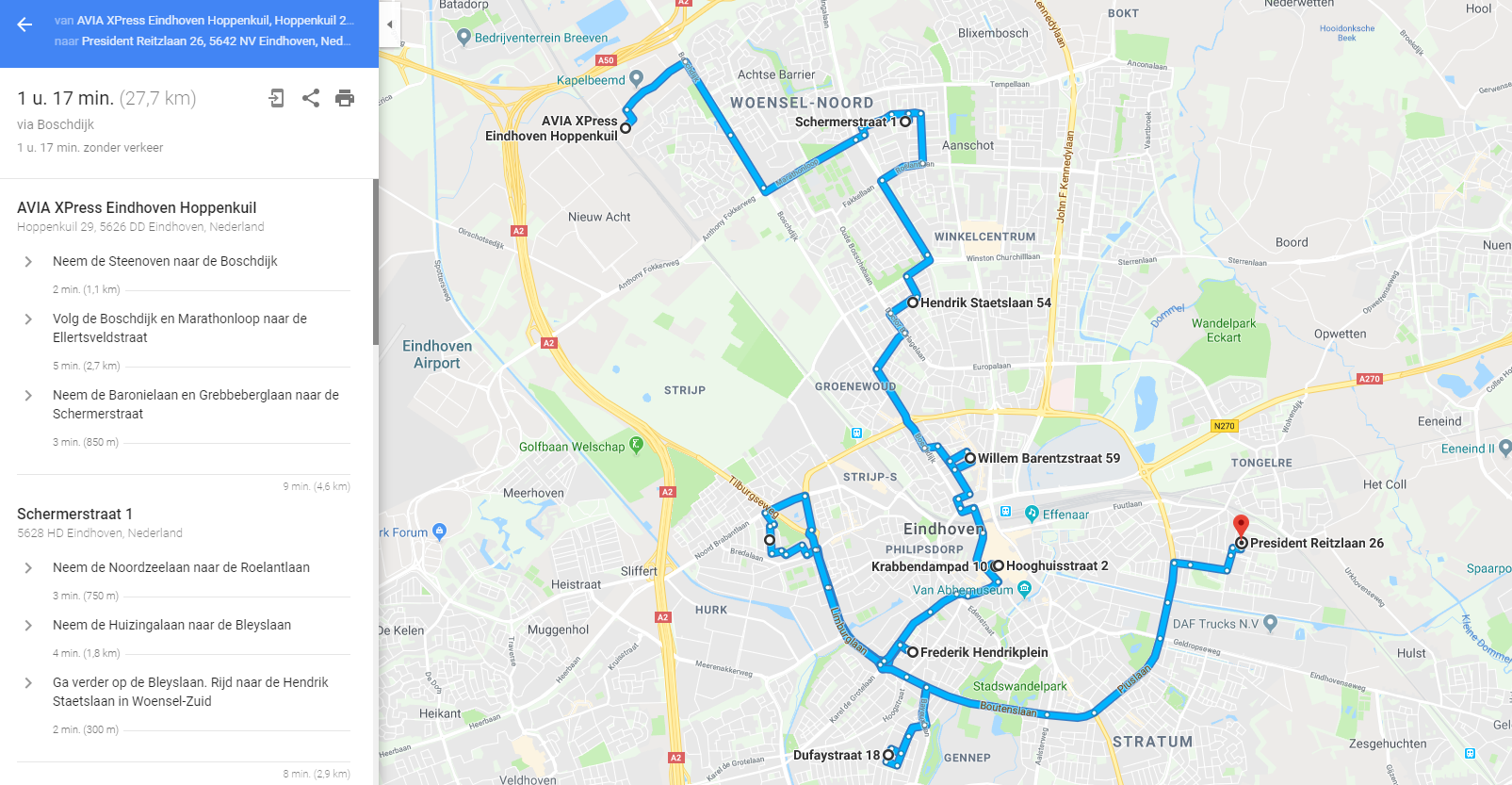

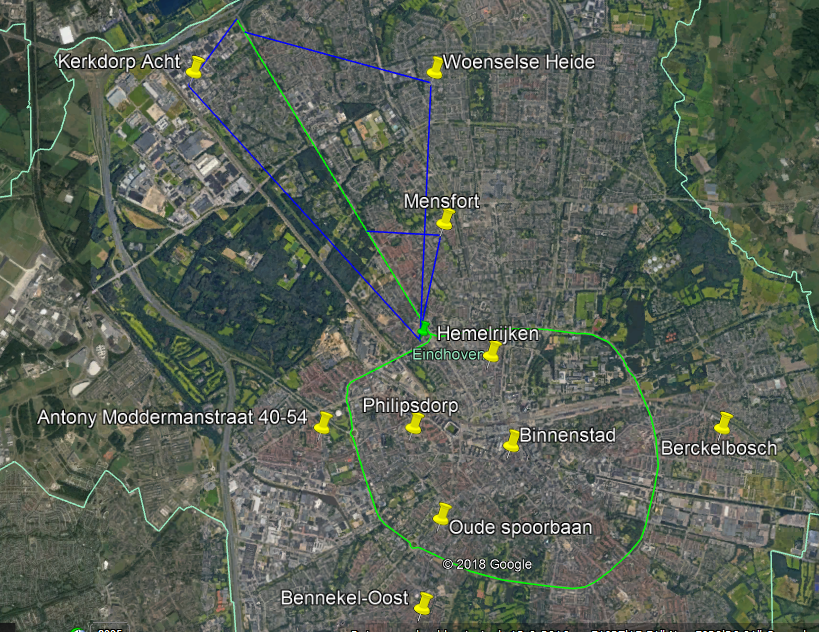

The comparison between the traditional delivery system and the truck-drone is computed. Since the distribution centre closest to Eindhoven is located at De Herven in Den Bosch, this means that the vehicle will be approaching from the North. With this in mind, the shortest route for the traditional delivery can be planned, starting at Kerkdorp Acht. The travel time from the distribution centre to Kerkdorp Acht is approximately 25 mins. The delivery route followed from there on to the 9 other destinations is shown in the figure on the right.

This accounts for an additional 1h 17mins for the delivery of all 10 packages. In total this results in a delivery-travel time, for the last package, of 1h 42mins.

Now this can be compared with the truck-drone method.

First of all, the truck has to drive from the distribution centre to the geographic midpoint, this takes approximately 30 mins.

From there, the drones will be deployed.

A deployment strategy for the drones is crucial to optimally use both the resources and the time available.

By measuring the total distance from the geographic midpoint to the delivery destinations, we can compute the minimal number of drones required to deliver the 10 packets without recharging.

The distances towards each point are shown in Table I.

| Delivery destinations | |||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Now with a total flight distance of 47410m it is known that a minimum of 2 drones is required to deliver all packets without recharging (assuming a total range of 32km for each drone).

Table II shows the order of delivery and the (cumulative) time it takes for each delivery. As can be seen, the order of deliveries is based on a decreasing distance towards the destination. In other words, the furthest delivery point will be the destination for the first drone, the second drone will fly towards the second furthest delivery point and so on. The cumulative time is used to determine which drone goes to what location. However, important to note is that the cumulative time is not the same as the delivery time, this is because the cumulative time is the time that corresponds with the moment where the drone arrives back at the truck. In other words, the delivery moment is equal to the cumulative time minus the time it took the drone to fly from the destination back to the truck. The maximal final delivery times for the locations are respectively: 1828.8s, 1230.96s, 901.84s, 687.44s, 598.8s, 384.4s and 380.08s.This way it can be seen that a decreasing maximal delivery time is achieved for an increasing number of drones deployed.

| Delivery destinations ordered | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

| Summary | ||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

It can be concluded that a lot of time can be gained by making use of this truck-drone combination. Increasing the amount of drones results in an increase in time gain, however a maximal time gain is reached at 8 drones (in this specific scenario), at this point the max travel time for the group of drones is equal to travel time of the drone that has to fly to the furthest destination.

Dynamic deployment

Even though using a static truck with multiple drones for parcel delivery offers a great gain in time efficiency compared to the traditional method, this still can be enhanced by optimizing the method. One way of doing this is, as shown in the tables above, by increasing the number of drones per truck. Another possible point of optimization is the truck placement. Instead of using a single position for the truck, a dynamic approach in which the truck is also moving while deployment is ongoing is probably even more efficient for time gain.

This dynamic approach creates a few extra difficulties. The first one is that of the deployment itself, certain questions need to be answered to verify the possibility of application. Can a drone be deployed while a truck is driving? What is the optimal route for the truck? Since the solutions to these questions are way more complex compared to the static approach, a basic solution is given that still has a lot of room for improvement.

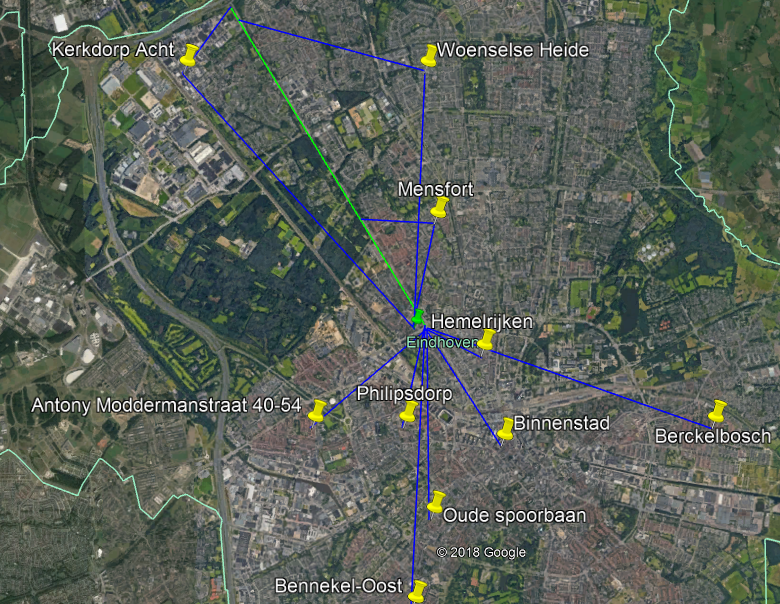

Using the same example scenario as for the static deployment, the dynamic approach is shown and simulated delivery times are calculated. Since the truck doesn't deploy at the geomidpoint anymore, new locations for deployment should be appointed. Based on the results of the static approach, it is known that for sufficient amount of drones, the main factor that constrains the max delivery time is the max distance from the truck to the furthest destination. So the aim of the dynamic approach will be to route the truck to minimize this distance.

|

|

So the figure on the left shows a possible solution for the dynamic approach. However in this specific situation, it is not an optimal solution. This is due to the fact that the truck has a low average speed in these parts of the city. The figure on the right aims to solve this, by limiting the amount of travel time for the truck by deploying all drones earlier. Since the dynamic aspect allowed the first three destinations to be reached by the drones before the truck comes to its final hold, enough drones are available (since a total of 8 is assumed to compare with static deployment) to reach the remaining 7 delivery locations. The travel times are represented in Table IV.

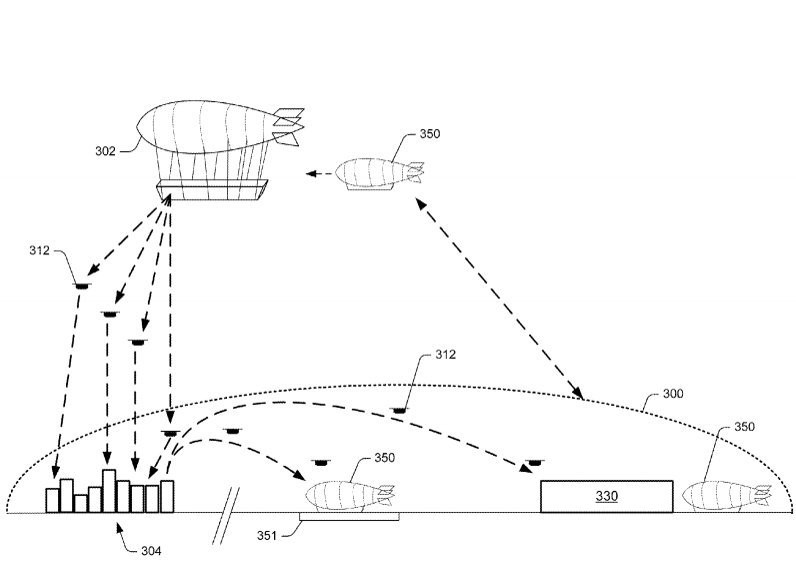

The Zeppelin warehouse

The last option which we consider as a delivery method with drones for packages is the zeppelin warehouse. For this idea Amazon has been awarded a patent. The idea of this delivery method is basically a giant flying drone mothership zeppelin warehouse, better known as the airborne fulfillment center (AFC) at high altitudes of around 45.000 feet in the air. This AFC contains lots of products and unmanned aerial vehicles (UAV/drones) which are used for the delivery of these products. The UAV will leave the AFC to deliver the product when the customer places an order. An advantage of this delivery method is the fact that the UAV’s will be able to have a much wider delivery range while consuming less power as they would be gliding down to deliver packages instead of having to take off and land. To maintain the functionality of the zeppelin warehouse there are used some smaller airships to return the UAV’s back to the AFC, to resupply the mothership with more inventory and fuel and shuttle workers to the flying factory. Another advantage is there is the possibility to deliver items within minutes. The mobile nature of the warehouses would allow Amazon greater flexibility in managing inventory in the face of changing demand. For example, the patent offers a hypothetical case of deploying a AFC near a sport stadium to allow for immediate delivery of team merchandise and snacks during a game. Also the drones would be able to communicate with each other via a mesh network to give information such as weather and route. UAVs could also recharge on the airship. For a visualization of this idea see the image below.

|

Implementation of the Zeppelin Warehouse

To make a success of the Zeppelin Warehouses and to realize the higher delivery ranges for packages, drones which can glide down effectively has to be implemented. When flown at a constant speed in still air a glider moves forwards a certain distance for a certain distance downwards. The ratio of the distance forwards to downwards is called the glide ratio (L/D ratio); this has to be highest as possible for this case:

[math]\displaystyle{ (L/D)=(\Delta s/\Delta h)=(V_{forward}/V_{down}) }[/math]

A glider's glide ratio varies with airspeed, but there is a maximum value which is frequently quoted. Glide ratio usually varies little with vehicle loading; a heavier vehicle glides faster, but nearly maintains its glide ratio.[20] For a few examples of glide ratio’s, see the following link: https://en.wikipedia.org/wiki/Gliding_flight Unfortunately the glide ratio for drones is unknown so there still has to be made an assumption for this (taking into account the known values). It is assumed that the Zeppelin Warehouse is located at 45.000 feet (=13,716 km) in the air. This will result in a delivery radius of 205.74 km. To this the radius of 32 km, covered due to the battery of the drone, can be added which results in a total delivery range of 237.74 km (see the illustration below).

|

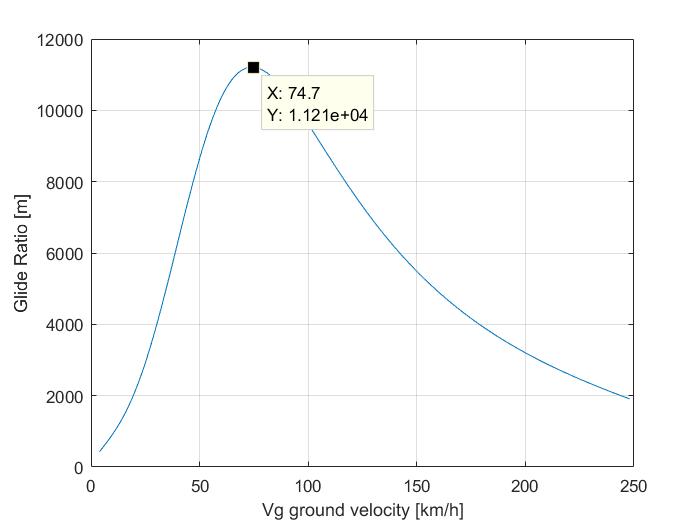

This results in a situation where only one Zeppelin warehouse can provide packages with drones in the Netherlands, Belgium, Luxembourg and a part of Germany. But can this situation be called effective? When there is only one Zeppelin, how long does it take before my package is delivered? To answer this question the speed of the drone has to be known. This can be calculated with the glide polar, which details the glider’s still air sink rate at airspeeds within its flight envelope, using the following formula: Glide ratio=(Airspeed/Sink rate). Unfortunately the glide polar for drones is unknown so an approach has to be made for this. To realize this, first the following specifications have been made for the delivery drones:

Mass = 2.8*kg; % Total mass of the aircraft S = 0.28*m^2; % Wing area (Through fuselage as well)) b = 0.9*m; % Span of the wing (through the fuselage) Swep_deg = 15; % Sweep angle of the wing [degrees] S_ref = S; % Reference area = wing area S_wet_fus = 0.65*m^2; % Wetted area of the fuselage (Including nose) S_wet_wing = 2.04*S*m^2; % Wetted area of the wing L_fus = 0.6*m; % length fuselage (Including nose part) A_max = 0.07*m^2; % Max fuselage cross sectional area t_average = 0.1*m; % Average airfoil thickness of the wing c_average = 0.28*m; % Average airfoil chord length

From the data above the glide polar can be made:

|

Here the y-axis is the horizontal flight range in [m] when the drone is at 1000m altitude, compared to the flight speed on the x-axis in [km/h].

Coaching Questions

State of the art

Questionnaire

1. Ben je een man of vrouw?

2. Hoe oud ben je? (categorieen geven)

3. Hoogst voltooide opleiding? (basisschool, MAVO,HAVO,VWO,MBO,HBO,WO, anders:..)

4. In wat voor soort omgeving woon je? (stad, dorp, platteland)

5. In welk type huis woon je? (flat, vrijstaand huis, twee onder een kap, rijtjeshuis)

6. Maak je gebruik van de mogelijkheid om online pakketten te bestellen? Zo niet, ga door naar vraag 4. Zo ja, ga door naar vraag 5.

7. Waarom maak je geen gebruik van deze dienst? (meerdere opties kunnen geven)

• de leveringssnelheid van het pakket is niet hoog genoeg

• wil het product liever in de werkelijkheid kunnen beoordelen/zien/aanraken

• niet betrouwbaar

• teveel bezorgkosten

• hinderlijk dat je thuis moet zijn op het moment van bezorgen

• hinderlijk dat je het pakket moet ophalen bij een pick up point

• de Track & Trace van het pakket is niet accuraat genoeg

• het is moeilijk en tijdrovend om een pakket te retourneren of te ruilen

• ik ben bang dat mijn persoonlijke gegevens voor andere doeleinden worden gebruikt

• het voelt als privacy schending dat mensen weten wat ik bestel

• de klantenservice is slecht

• ik kan geen specifieke vragen stellen over het product als ik dit online bestel

• het onjuiste product kan worden opgestuurd

• ik ben bang dat mijn pakket op de verkeerde locatie wordt afgeleverd

• ik vind het personeel onvriendelijk

• ik weet het niet

• anders namelijk:

8. Ben je tevreden over de huidige bezorgmethode? (helemaal niet tevreden, niet tevreden, neutraal, tevreden, heel tevreden)

9. Hoe vaak bestel je gemiddeld een pakketje op jaarbasis (meerdere opties geven)? (0-5,5-10,10-15,15-20,20-25,25-30, meer dan 30)

10. Welke dag bestel je meestal? (werkdag, zaterdag of zondag)

11. Op welk deel van de dag bestel je meestal? (ochtend (6:00-12:00), middag(12:00-18:00), avond (18:00-23:59), nacht (0:00-6:00))

12. Geef met cijfers van 0 t/m 10 aan hoe groot je irritatie is bij de volgende gevallen (van geen tot veel irritatie):

• De leveringssnelheid van het pakket is niet hoog genoeg

• Ik kan het product niet in de werkelijkheid beoordelen/zien/aanraken

• Online bestellen is voor mijn gevoel niet altijd betrouwbaar

• De bezorgkosten van de pakketten zijn te hoog

• Het voelt als privacy schending dat de medewerkers kunnen zien wat ik bestel

• De klantenservice is slecht

• Ik kan geen specifieke vragen stellen over het product als ik dit online bestel

• Het onjuiste product wordt opgestuurd

• Mijn pakket wordt op de verkeerde locatie afgeleverd

• Het personeel is onvriendelijk

• Het is moeilijk en tijdrovend om een pakket te retourneren of te ruilen

• Mijn persoonlijke gegevens zijn bij het bestellen van een pakket voor andere doeleinden worden gebruikt

• Thuis moeten zijn om een pakket te kunnen ontvangen

• Wanneer je niet thuis bent op het moment van bezorgen, moet je het pakket ophalen bij de buren of een pick up point

• Wanneer je thuis bent en het pakket geleverd wordt, is contact met de bezorger onvermijdelijk (bijvoorbeeld wanneer je in je in je pyjama zit, op de wc zit of net de douche in wilt stappen)

• Het tijdsinterval waarop mijn pakket geleverd kan worden is te groot

• De locatie van mijn pakket, die ik via Track & Trace kan volgen, is niet nauwkeurig genoeg.

13. Heb je er problemen mee wanneer je pakketten voortaan door een drone geleverd worden in plaats van door een menselijke bezorger? (ja/nee, waarom:..) (antwoord=nee -> ga naar vraag 10, dan naar 12)(antwoord=ja -> ga naar vraag 10,11,12)

14. Het bezorgen van pakketten met drones kan mogelijk veel voordelen leveren. Geef bij iedere stelling aan of dit voor jou een toegevoegde waarde zou zijn:

• Mijn pakket kan sneller worden geleverd

• Het pakket kan worden geleverd op de locatie waar ik op dat moment ben

• De bezorgkosten van het pakket kunnen verlaagd worden

• Er is meer privacy omdat de bezorger is vervangen door een drone

• Het pakket kan niet meer op de verkeerde locatie worden geleverd

• Er is geen contact met de bezorger meer omdat deze is vervangen door een drone

• Het is makkelijker en sneller om een pakket te retourneren of te ruilen

• Het tijdsstip, waarop mijn pakket wordt geleverd, kan exacter worden aangegeven

• Je kan live zien waar je pakket zich bevindt, dus de Track & Trace verbeterd

15. Stel dat het bezorgen van pakketten met drones de vaste bezorgmethode wordt, zou je dan extra geld betalen voor een menselijke bezorger?