PRE2023 3 Group3: Difference between revisions

| Line 1,206: | Line 1,206: | ||

| rowspan="6" |Week 9 | | rowspan="6" |Week 9 | ||

|Patryk Stefanski | |Patryk Stefanski | ||

|Work on polishing up the interview section of the wiki (2h), Format wiki sections (0.5h), NetLogo last minute quality of life updates (1h), Mapping section of the wiki (2h), Sensor part updates (1h), NetLogo simulation explanation and wiki (5h) | |Work on polishing up the interview section of the wiki (2h), Format wiki sections (0.5h), NetLogo last minute quality of life updates (1h), Mapping section of the wiki (2h), Sensor part updates (1h), NetLogo simulation explanation and wiki (5h), Proof reading and general imporvements (2h) | ||

| | |13.5 | ||

|- | |- | ||

|Raul Sanchez Flores | |Raul Sanchez Flores | ||

Revision as of 22:27, 11 April 2024

This project was guided from start to finish by Dr. Ir. René van de Molengraft and Dr. Elena Torta.

Group members

| Name | Student ID | Current Study Programme |

|---|---|---|

| Patryk Stefanski | 1830872 | CSE |

| Raul Sanchez Flores | 1844512 | CSE |

| Briana Isaila | 1785923 | CSE |

| Raul Hernandez Lopez | 1833197 | CSE |

| Ilie Rareş Alexandru | 1805975 | CSE |

| Ania Barbulescu | 1823612 | CSE |

Problem statement

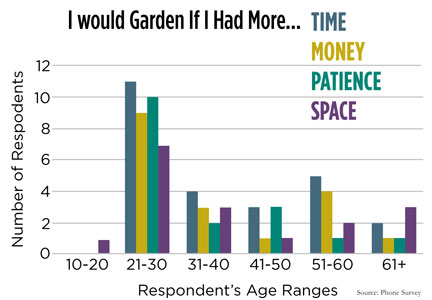

In western society, having a family, a house, and a good job is what many people aspire to have. As people strive to achieve such aspirations, their spending power increases, which allows them to be able to afford to buy a nice home for their future family, with a nice garden for the kids and pets. However, as with many things, in our capitalist world, this usually comes at a sacrifice: free time. According to a study conducted by a student team at Manchester University[1], the three main reasons why people don't garden which made up 60% of the survey responses included time constraints, lack of knowledge/information, and space restraints. Gardening should be encouraged, due to its environmental benefits and many other advantages[2].

In the past decade, robotics has been advancing across multiple fields rapidly as tedious and difficult tasks become increasingly automated [3], this is not any different in the field of agriculture and gardening [4]. In recent years, many robots have become available that aid farmers in important aspects such as irrigation, plantation, and weeding. These robots are large mechanical structures sold at a very high price meaning their only true usage is in large-scale farming operations. Unfortunately, one common user group has been left behind and not considered when developing many features of this new technology in gardening and agriculture; the amateur gardener. Amateur gardeners, often lacking in-depth knowledge about plants and gardening practices, face challenges in maintaining their gardens. Identifying issues with specific plants, understanding their individual needs, and implementing corrective measures can be overwhelming for their limited expertise. It is not surprising that traditional gardening tools and resources often fall short of providing the necessary guidance for optimal plant care, so another solution must be found. This is the problem that our team's robot will be the solution to. We cannot help the fact that some people do not have a space to garden, but we can address the two other common problems. So, the questions we asked ourselves were:

"How do we make gardening more accessible for the amateur gardeners?"

"How do we provide the necessary guidance and information?"

"How can we make our product aid time efficiency?"

Objectives

The objectives for the project deliverables that we hope to accomplish in the next 8 weeks can be represented as MoSCoW requirements. To determine the importance of each requirement we will be sorting them into 4 categories of priority. These 4 categories of priority are: Must, Should, Could and Would. Normally, for “MoSCoW” Won’t is used for ‘W’. However, for most projects it is not really needed to make clear what we won’t be doing, therefore, it is better to use a fourth category of priority instead; Would. Since for this project we want to definitely complete most of the requirements that we set out, we define most requirements as Must's.

| Requirement ID | Requirement | Priority |

| The Robot | ||

| R001 | The robot shall cut the grass while traversing the environment. | M |

| R002 | The robot shall map the garden and store it in its memory. | M |

| R003 | The robot shall traverse the garden avoiding any obstacles on its way. | M |

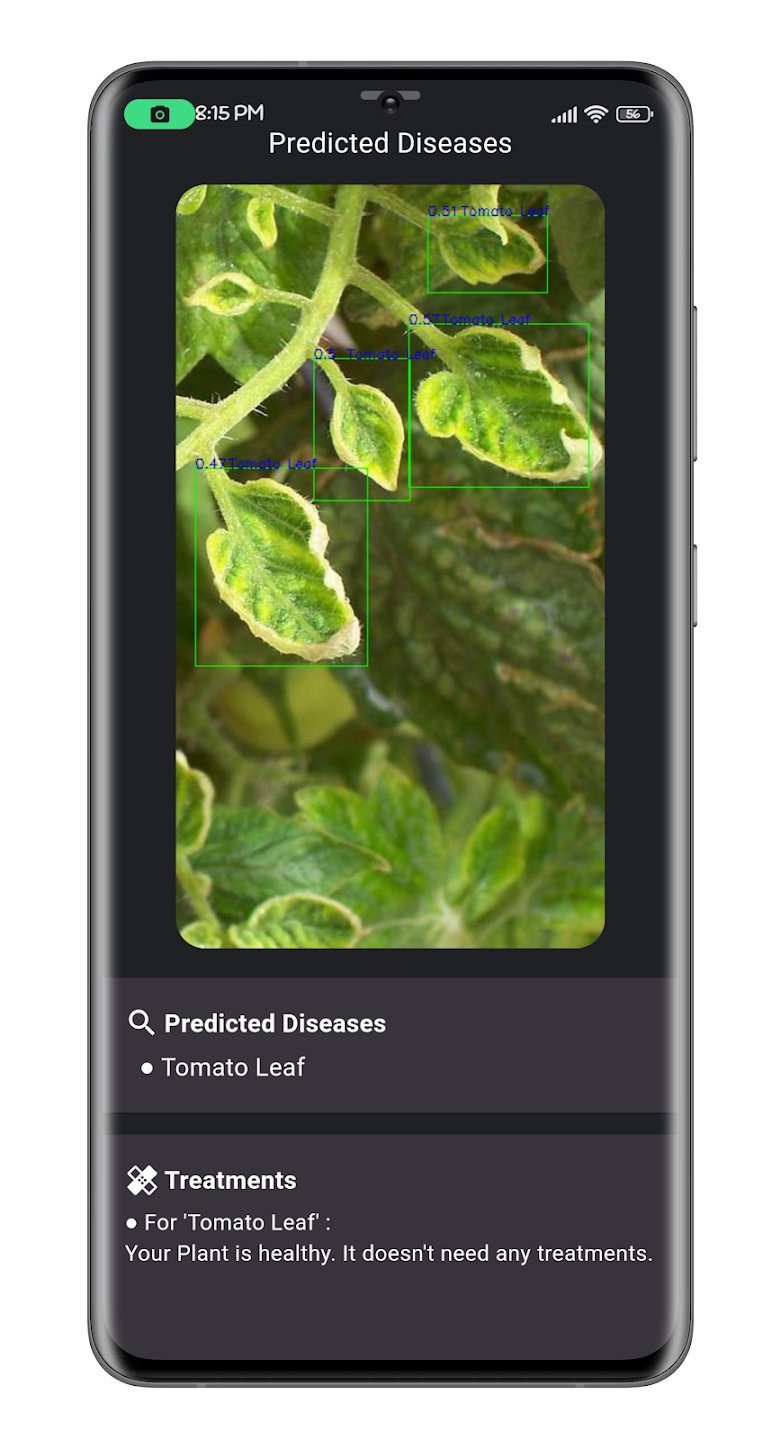

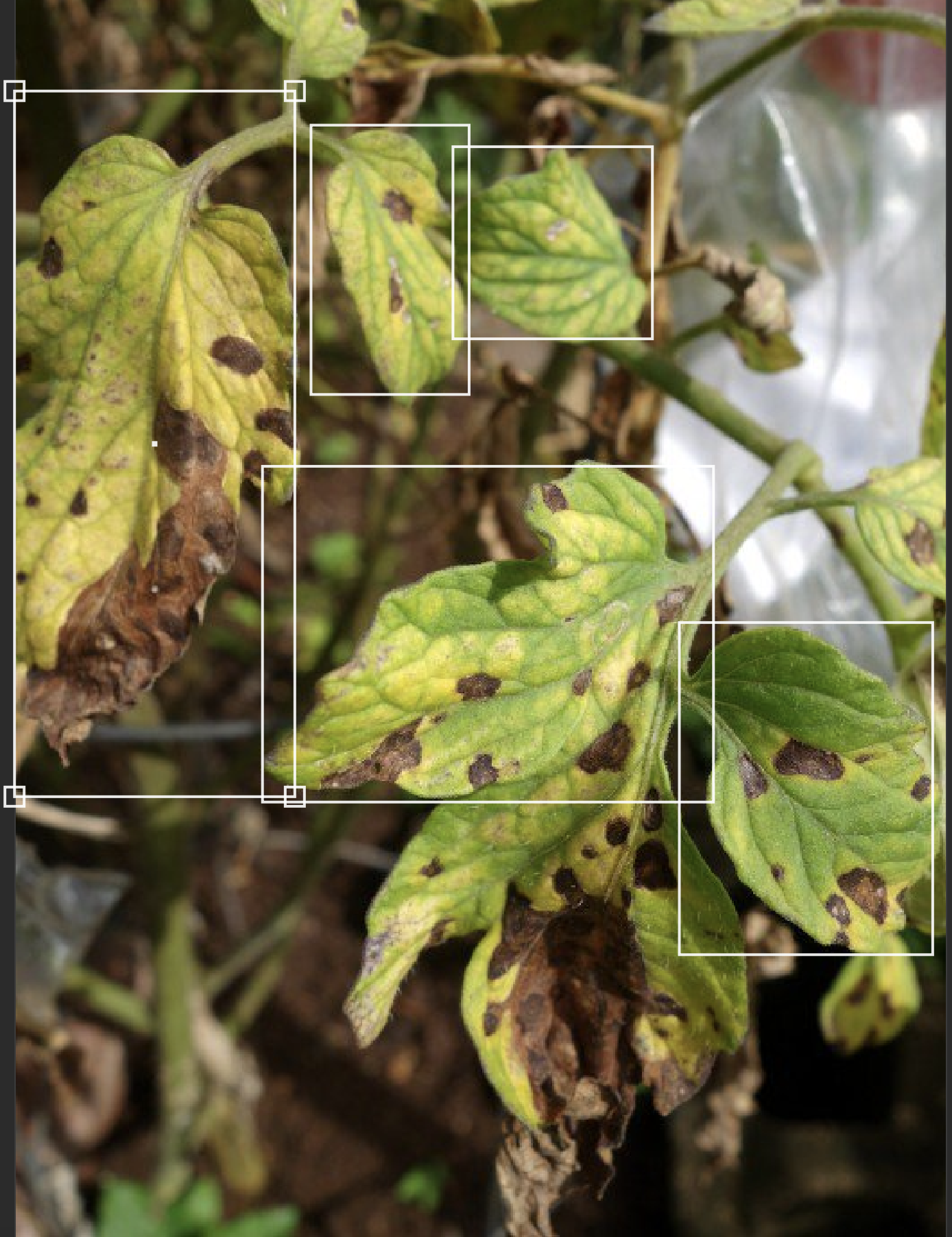

| R004 | The robot shall detect different types of plant diseases and their location through the use of cameras and sensors. | M |

| R005 | The robot shall know its GPS/RTK location at all times. | M |

| R006 | The robot shall send a signal to the mobile application when it detects a diseased plant. | M |

| R007 | The robot shall make a noise when the user wishes to find the robot through the app. | S |

| The App | ||

| R101 | The app shall provide a button to start the robot. | M |

| R102 | The app shall provide a button to stop the robot. | M |

| R103 | The app shall display a notification to the user when a plant disease is detected in a specific region. | M |

| R104 | The app shall display the location of the robot on the map at all times. | M |

| R105 | The app shall present the user with an option to schedule the operation times of the robot. | M |

| R106 | Upon disease detection, the app shall provide the user with necessary information to aid the affected plant. | M |

| R107 | The app shall display the location of the unhealthy plant on the map when a user clicks on a specific notification. | M |

Users

Who are the users?

The users of the product are garden-owners who need assistance in monitoring and maintaining their garden. This could be due to the fact that the users do not have the necessary knowledge to properly maintain all different types of plants in their garden, or would prefer a quick and easy set of instructions of what to do with each unhealthy plant and where that plant is located. This would optimise the users routine of gardening without taking away the joy and passion that inspired the user to invest into the plants in their garden in the first place.

What do the users require?

The users require a robot which is easy to operate and does not need unnecessary maintenance and setup. The robot should be easily controllable through a user interface that is tailored to the users needs and that displays all required information to the user in a clear and concise way. The user also requires that the robot may effectively map their garden and identify where a certain plant is located. Lastly, the user requires that the robot is able to accurately describe what actions must be taken, if any are necessary, for a specific plant at a specific location in the garden.

Deliverables

- Research into AI plant detection, mapping a garden and best ways of manoeuvring through it.

- Research into AI identifying plant diseases and infestations.

- Survey confirming and asking about further functions of the robot.

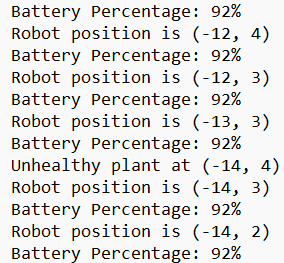

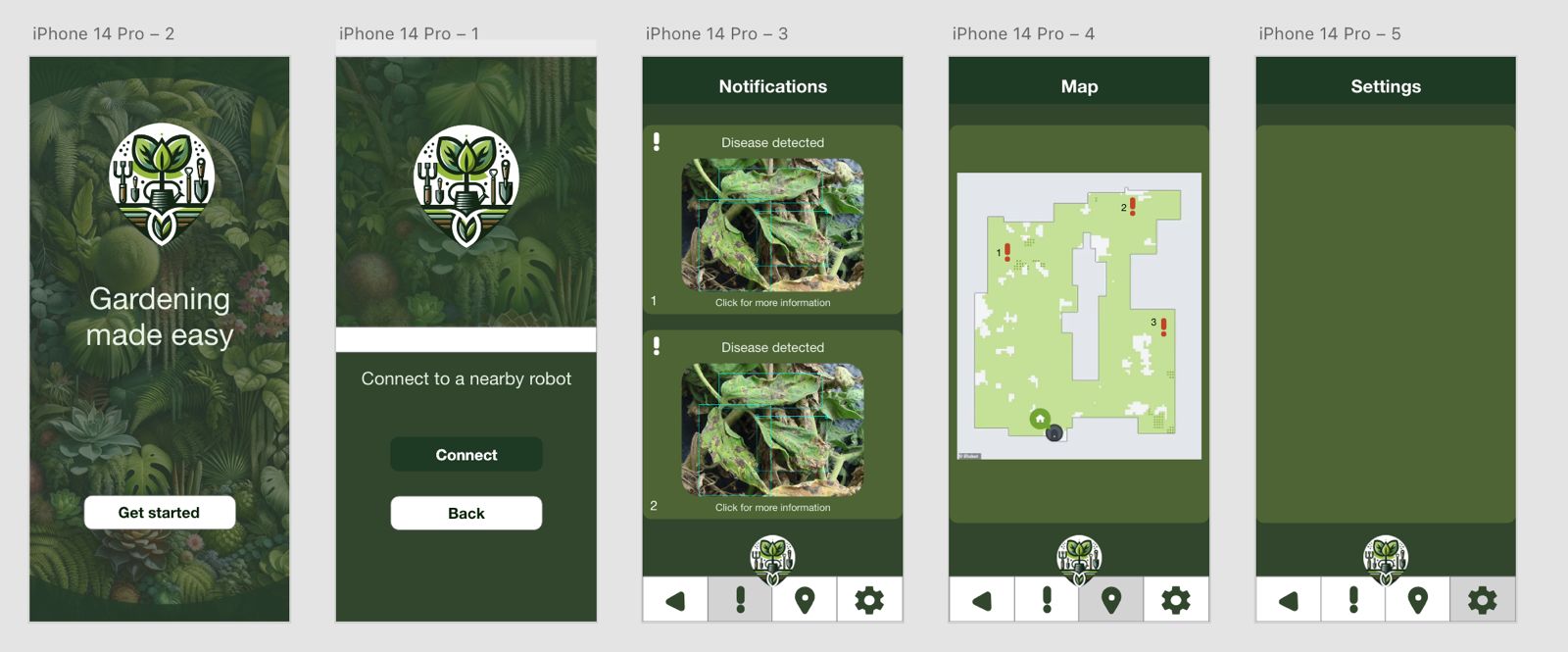

- Interactive UI of an app that will allow the user to control the robot remotely, which implements the user requirements that we will obtain from the survey. The UI will be able to be run on a phone and all of its features will be able to be accessed through a mobile application.

- This wiki page which will document the progress of the group's work, decisions that have been made, and results we obtained.

- A simulation in NetLogo that shows the operation/movement of the robot in the environment.

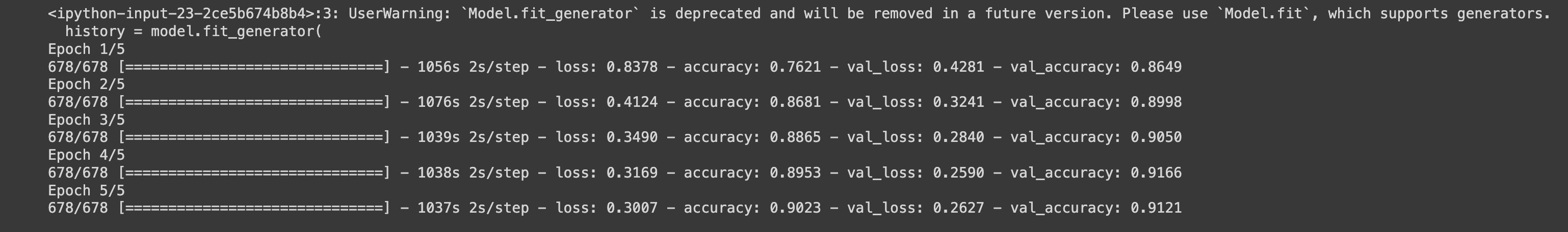

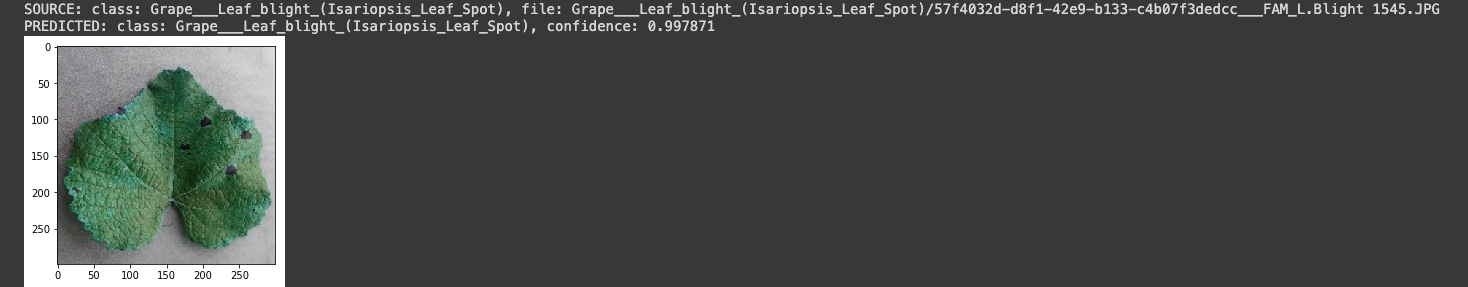

- A trained model for recognising plant diseases.

- Final design of the envisioned robot.

Through these deliverables, we aim to showcase the design of our robot and the user experience. These deliverables are nicely tied together. The research that we do stands at the core of our other deliverables, in particular, it aids the training of the plant recognition model and that of the final design. The survey that will be sent out, will help us design the user interface of our mobile application and confirm some of our literature and features. The trained model will show that it is feasible to have reliable plant detection when it comes to the designed robot, and will set the foundation for an extensive plant disease recognition model. The simulation in NetLogo shows how the robot will navigate the field and some of the information from this deliverable is sent to the mobile application, exactly as the robot would if it had already be manufactured. Finally, everything related to these deliverables and their progress is shown on this wiki page.

State of Art

Our robot idea can be separated into multiple functionalities: automated grass cutting, disease detection in plants and an app to control your automated robot. The combination of all of these features in a gardening robot targeted to amateur users is currently non-existent, however these individual features have already been implemented in more specialised robots. Therefore, it is very useful to explore the current state of the art of all of these distinct features individually, with the end goal of then using state of the art to avoid creating existing technology from scratch for our final robot. Moreover, it allows us to identify whether such a market for these technologies exists, and to understand what our target costumers will prefer.

Automated Gardening Robots

TrimBot2020

The TrimBot2020 was the first concept for an automated gardening robot for bush trimming and rose pruning. It began as a collaboration project between multiple universities, including ETH Zurich, University of Groningen and University of Amsterdam. Trimbot2020 was designed to autonomously navigate through garden spaces, maneuvering around obstacles and identifying optimal paths to reach target plants for trimming, which was done with a robot arm with a blade extension.

EcoFlow Blade

Standing at nearly 2600€, the EcoFlow Blade is an automated grass trimming robot, meant to reduce the time needed to maintain the user’s garden. At first use after purchase, the user will use a built-in application on their smartphone to direct the robot, tracing the edges of their garden. This feature saves the user the need to add barriers to their garden, allowing a more straightforward interaction with the user. Once done, the robot will have a map of where to cut, for it to work automatically. TMoreover, the robot comes with x-vision technology designed to avoid obstacles in real time, ensuring that it doesn't break and that it won't destroy objects or hurt people.

Greenworks Pro Optimow 50H Robotic Lawn Mower

Standing at 1600€, the Greenworks gardening robot also focuses on mowing gardens. Greenworks has made multiple versions for different garden sizes, spanning from 450-1500m2. The Pro Optimow’s features are also integrated with their own app, which allow the user to schedule and track the robot, as well as specifying any areas that need to be managed more carefully, like areas that are more prone to flooding. The boundaries of the garden are set with a wire, and the robot navigates the garden with random patterns, cutting small amounts at a time.

Husqvarna Automower 435X AWD

Finally, the Husqvarna Automower is designed for large, hilly landscapes, capable of mowing up to 3500m2 of lawn, as well as having great manoeuvrability and grip for rough and slanted terrains. This robot again has an integrated app, which works with the robot’s built-in GPS to create a virtual map of the user’s lawn. Moreover, the app allows the user to customise the robot’s behaviour in different areas, whether it be cutting heights, zones to avoid, etc. The Husqvarna gardening robot also uses ultrasonic sensors to detect objects and avoid them. The robot also requires the user to set up boundary wires to map out the garden. Finally, the Husqvarna is integrated with voice controls such as Amazon Alexa and Google Home, allowing the user to command the robot easily.

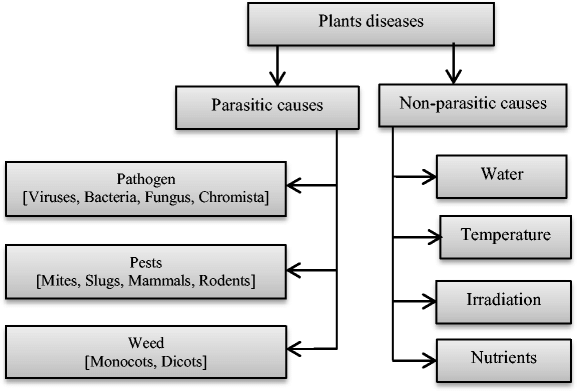

Plant (Disease) Detection Systems

LeafSnap

LeafSnap is an app on iOS and Android that claims to have plant identification and disease identification built in, by scanning images through the camera. They claim to have an accuracy rate of 95% at identifying the species of the plant, as well as having instructions for how to care for each specific species. Moreover, it sends reminders to the user to water, fertilise and prune their plants. LeafSnap is able to identify plants thanks to a database with more than 30000 species.

PlantMD

PlantMD is an application that employs machine learning to detect plant diseases. More specifically, they used TensorFlow, an open-source software library for machine learning developed by Google, focused on neural networks. The development of PlantMD was inspired by PlantVillage, a dataset from Penn State University, which created Nuru, an app aimed at helping farmers improve cassava cultivation in Africa.

Agrio

The app allows farmers to utilise machine learning algorithms for diagnosing crop issues and determining treatment needs. Users can snap photos of their plants to receive diagnosis and treatment recommendations. Additionally, the app features AI algorithms capable of rapid learning to identify new diseases and pests in various crops, enabling less experienced workers to actively participate in plant protection efforts. Geotagged images help predict future problems, while supervisors can build image libraries for comparison and diagnosis. Users can edit treatment recommendations and add specific agriculture input products tailored to crop type, pathology, and geographic location. Treatment outcomes are monitored using remote sensing data, including multispectral imaging for various resolutions and visit frequencies. The app provides hyper-local weather forecasts, crucial for predicting insect migration, egg hatching, fungal spore development, and more. Inspectors can upload images during field inspections, with algorithms providing alerts before symptoms are visible.

Inspection Robots in Agriculture

Tortuga AgTech[12]

The winners of Agricultural Robot of the Year 2024 award, Tortuga AgTech revolutionised the field of automated harvesting robots. The Tortuga Harvesting Robot are autonomous robots designed for harvesting strawberries and grapes, using two robotic arms that “identify, pick and handle fruit gently”. To do this, each arm has a camera at its end, and the AI algorithms identify the stem of the fruit, and command its two fingers to remove the fruit from the stem. Moreover, the AI has the ability to “differentiate between ripe and unripe fruit”, to ensure that fruit is picked only when it should be. After picking a fruit, it will place them in one of the many containers it has in its body, having the ability to pick “tens of thousands of berries every day”.

VegeBot[14]

Designed at the University of Cambridge, the VegeBot is a robot made for harvesting iceberg lettuce, a crop that is particularly difficult to harvest with robots, due to its fragility and growing “relatively flat to the ground”. This makes it more prone to damage the soil or other lettuces that are in the robots surroundings. The VegeBot has a built-in camera, which is used to identify the iceberg lettuce, and to check its condition, including its maturity and health. From there, its machine learning algorithm decides whether to pick it off, and if so, cuts the lettuce off the ground, and gently picks it up and places it on its body.

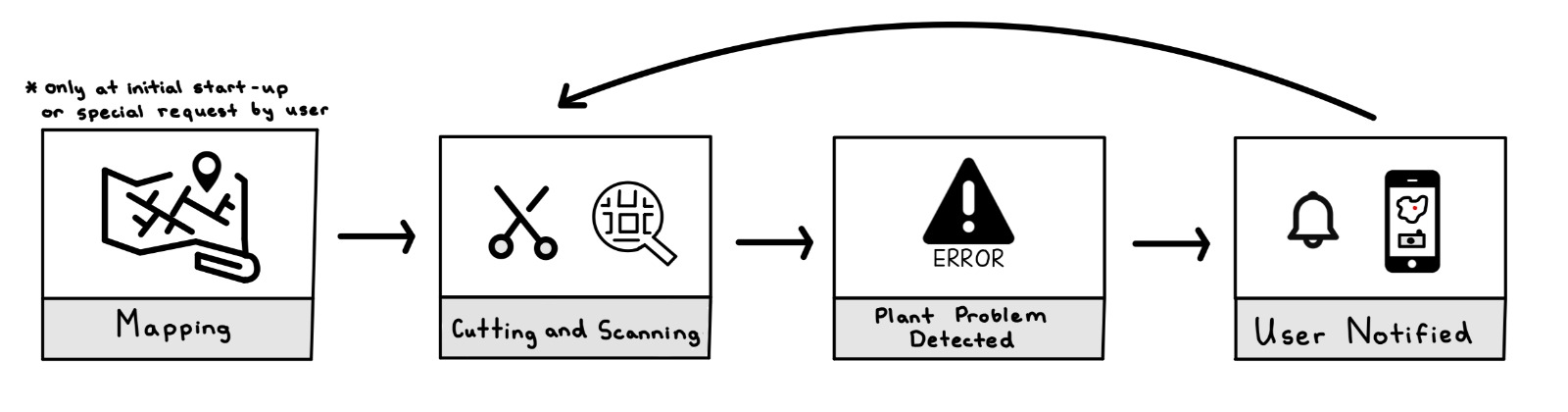

Regular Robot Operation

As with any piece of technology it is important that the users are aware of its proper operation method and how the robot functions in general terms. It is important that this is clear for our robot as well. Upon the robot's first use in a new garden or when the garden owner has made some changes to the garden layout, the mapping process must be instantiated in the app. This mapping will be a 2D map of the garden which will then later allow the robot to efficiently traverse the entire garden during its regular operation without leaving any part of the garden unvisited. In order to better understand this feature one, can compare it to the iRobot Roomba. After the initial setup phase has been completed the robot will be able to begin its normal operation. Normal operation includes the robot being let out into the garden from its charging station and traversing through the garden cutting grass while its camera scans the plants in its surroundings. Whenever the robot detects an irregularity in one of the plants, it will notify the user through the usage of the app, where the robot will send over a picture of the plant with an issue as well as its location on the map of the garden. The user will then be able to navigate in the app to view all plants that need to be taken care of in their garden. This means that not only will the user have a lawn which is well kept but also be aware of all unhealthy plants keeping the user's garden in optimal condition at all times.

Maneuvering

Movement

One of the most important design decisions when creating a robot or machine with some form of mobility is deciding what mechanism the robot will use to traverse its operational environment. This decision is not always easy as many options exist which have their unique pros and cons. Therefore is is important to consider the pros and cons of all methods and then decide which method is most appropriate for a given scenario. In the following section I will explore these different methods and see which are expected to work the best in the task environment our robot will be required to function in.

Wheeled Robots

It may be no surprise that the most popular method for movement within the robot industry is still a robot with circular wheels. This is due to the fact that robots with wheels are simply much easier to design and model[16]. They do not require complex mechanism of flexing or rotating an actuator but can be fully functional by simply altering rotating a motor in one of two directions. Essentially they allow the engineer to focus on the main functionality of the robot without having to worry about the many complexities that could arise with other movement mechanisms when that is not necessary. Wheeled robots are also convenient in design as they rarely take up a lot of space in the robot. Furthermore, as stated by Zedde and Yao from the University of Wagenigen, these types of robots are most often used in industry due to their simple operation and simple design[17]. Although wheeled robots seem as a single simple category there are a few subcategories of this movement mechanism that are important to distinguish as they each have their benefits and issues they face.

Differential Drive

Differential drive focuses on independent rotation of all wheels on the robot. Essentially one could say that each wheel has its own functionality and operates independently of the other wheels present on the robot. Although rotation is independent it is important to note that all wheels on the robot work as one unit to optimize turning and movement. The robot does this by varying the relative speed of rotation of its wheels which allow the robot to move in any direction without an additional steering mechanism[19]. In order to better illustrate this idea consider the following scenario - suppose a robot wants to turn sharp left, the left wheels would become idle and the right wheel would rotate at maximum speed. As can be seen both wheels are rotating independently but are doing so to reach the same movement goal.

| Pros | Cons |

|---|---|

| Easy to design | Difficulty with straight line motion on uneven terrains |

| Cost-effective | Wheel skidding can completely mess up algorithm and confuse the robot of its location |

| Easy manoeuvrability | Sensitive to weight distribution - big issue with moving water in container |

| Robust - less prone to mechanical failures | |

| Easy control |

Omni Directional Wheels

Omni-directional wheels are a specialized type of wheel designed with rollers or casters set at angles around their circumference. This specific configuration allows a robot which has these wheels to easily move in any direction, whether this is lateral, diagonal, or rotational motion[21]. By allowing each wheel to rotate independently and move at any angle, these wheels provide great agility and precision, which makes this method ideal for applications which require navigation and precise positioning. The main difference between this method and differential drive is the fact that omni directional wheels are able to move in any direction easily and do not require turning of the whole robot when that is not necessary due to their specially designed roller on each wheel.

| Pros | Cons |

|---|---|

| Allows complex movement patterns | Complex design and implementation |

| Superior manoeuvrability in any direction | Limited load-bearing capacity |

| Efficient rotation and lateral movement | Higher manufacturing costs |

| Ideal for tight spaces and precision tasks | Reduced traction on uneven terrains |

| Enhanced agility and flexibility | Susceptible to damage in rugged environments |

Legged Robots

Over millions of year organisms have evolved in thousands of different ways, giving rise to many different methods of brain functioning, how an organisms perceives the world and what is important in our current discussion, movement. It is no coincidence that many land animals have evolved to have some form of legs to traverse their habitats, it is simply a very effective method which allows a lot of versatility and adaptability to any obstacle or problem an animal might face[23]. This is no different when discussing the use of legged robots, legs provide superior functionality to many other movement mechanisms due to the fact that they are able to rotate and operate freely in all axis. However, with great mobility comes the great cost of their very difficult design, a design with which top institutions and companies struggle with to this day[24].

| Pros | Cons |

|---|---|

| Versatility in Terrain | Complexity in Design |

| Obstacle Negotiation | Power Consumption |

| Stability on Uneven Ground | Sensitivity to Environmental Changes |

| Human-Like Interaction | Limited Speed |

| Efficiency in Locomotion | Maintenance Challenges |

Tracked Robots

Tracked robots, which can be characterized by their continuous track systems, offer a dependable method of traversing a terrain that can be found in applications across various industries. The continuous tracks, consisting of connected links, are looped around wheels or sprockets, providing a continuous band that allows for effective and reliable movement on many different surfaces, terrains and obstacles[26]. It is therefore no surprise that their most well known usages include vehicles which operate in uneven and unpredictable, such as tanks. Since tracks are flexible it is even common that such robots can simply avoid small obstacles by driving over them without experiencing any issues. This is particularly favorable for the robot we are designing as naturally gardens are never perfectly flat surfaces often littered by many natural obstacles such as stone, dents in the surface or even possibly branches that have fallen on the ground due to rough wind.

| Pros of Tracked Robots | Cons of Tracked Robots |

|---|---|

| Superior Stability | Complex Mechanical Design |

| Effective Traction | Limited Manoeuvrability |

| Versatility in Terrain | Terrain Alteration |

| High Payload Capacity | Increased Power Consumption |

| Efficient Over Obstacles | |

| Consistent Speed |

Hovering/Flying Robots

Hovering/Flying robots provide, without a doubt, the most unique way of movement from the previously listed. This method unlocks a whole new wide range of possibilities as the robot no longer has to consider on-ground obstacles; whether that is rocks or uneven terrain. The robot is able to view and monitor a very large terrain from one position due to its ability to position itself at a high altitude and quickly detect major problems in a very large area. This method also unlocks the possibility of the robot to optimize its movement distance as it is able to move from point A to point B directly in a straight line saving energy and time. However, as is the case with any solution, flying/hovering has its major problems. It is by far the most expensive method, as flying apparatus is far more costly and high maintenance than any other solution. This makes this unreliable and likely a method far out of the technological needs and requirements of our gardening robot. Furthermore, its operation is best in large open fields which perfectly suits the large farms of the agriculture industry, however, this is not the aim of the robot we are designing. Most private gardens are of a small size, meaning its main strength could not be used. Additionally, it is likely that a robot which has aerial abilities would find difficulty in maneuvering through the tight spaces of a private garden and would have to avoid many low hanging branches or pushes ultimately making its operation unsafe.

| Pros | Cons |

|---|---|

| Versatile Aerial Mobility | Limited Payload Capacity |

| Rapid Deployment | Limited Endurance |

| Remote Sensing | Susceptibility to Weather |

| Reduced Ground Impact | Regulatory Restrictions |

| Dynamic Surveillance | Security and Privacy Concerns |

| Efficient Data Collection | Initial Cost and Maintenance |

Sensors are a fundamental component of any robot that is required to interact with its environment, as they aim to replicate our sensory organs which allow us to perceive and better understand the environment around us[28]. However, unlike with living organisms, engineers are given the choice to decide what exact sensors their robot needs and must be careful with this decision in order to pick the sufficient options to be able to allow the robot to have its full functionality without picking any redundant options that will make the robot unnecessarily expensive. This decision is often based on researching and considering all possible sensors that are available on the market which are related to the problem the engineer is trying to solve and selecting the one which fulfils the requirements of the robot most accurately[29]. In this section we will specifically be looking into sensors which will aid our robot in traversing our environment, a garden. This means that we must consider the fact that the sensors we select must be able to work in environments where the lighting level is constantly changing as well as possible mis inputs due to high winds and/or uneven terrain. Additionally, it is important to note that unlike the discussion in the previous section, one type of sensor/system is rarely sufficient to fulfil the requirements and most robots must implement some form of sensor fusion in order to operate appropriately and this is no different in our robot[30].

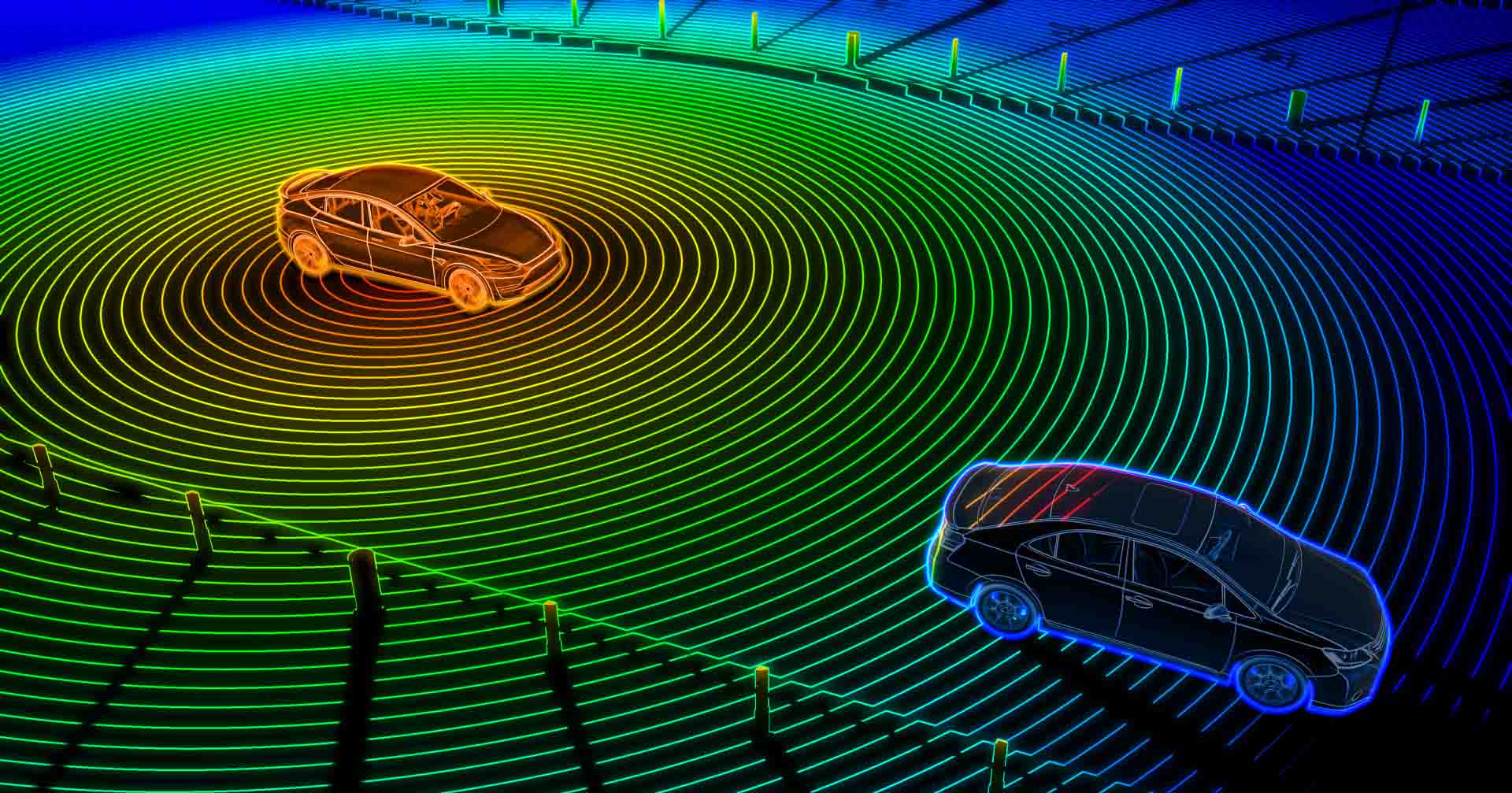

LIDAR sensors

LIDAR stands for Light Detection and Ranging. These types of sensors allow robots which utilize them to effectively navigate the environment they are placed in as they provide the robot with object perception, object identification and collision avoidance[32]. These sensors function through sending lasers into the environment and then calculating how long it takes the signals they send to return back to the receiver to determine the distance to the nearest objects and their shapes. As can be seen, LIDAR’s provide robots with a vast amount of crucial information and even allow them to see the world in a 3D perspective. This means that not only are robots able to see their closest object, but whenever faced with an obstacle they can instantaneously derive possible methods of avoidance and to traverse around it[33].

LIDAR’s are often the preferred option by engineers in robots that operate outdoors as they are minimally influenced by weather conditions[34]. Often sensors rely on visual imaging or sound sensors which both get heavily disturbed in more difficult weather conditions, whether that is rain on a camera lens or the sound of rain disturbing sound sensors, this is not the case with LIDAR's as their laser technology does not malfunction in these scenarios. However, an issue that our robot is likely to face when utilizing a LIDAR sensor is that of sunlight contamination[35]. Sunlight contamination is the effect the sun has on generating noise in the sensor’s data during the daytime and therefore possibly introducing errors within it. Since our robot needs to work optimally during the daytime it is crucial that this is considered. However, the LIDAR possesses many additionally positive aspects that would be truly beneficial to our robot such as the ability to function in complete darkness and immediate data retrieval. This would allow the users of our robot to turn on the robot before they go to sleep at night and wake up to a complete report of their garden status. Furthermore, these features are necessary for the robot as they would allow it to work in a dynamic and constantly changing environment, which is of high importance to as our robot is to operate in a garden. The outdoors can never be a fully controlled environment and that has to be considered into the design of the robot.

As it can be seen, the LIDAR sensor has many excellent features that our robot will likely require, therefore it is a very important candidate when making our next design decisions.

Boundary Wire

A boundary wire is likely the most cost efficient and commonly implemented technique in state-of-the-art garden robots that are on the private consumer market today. It is not a complicated technology but still a very effective one when it comes to robot navigation. A boundary wire in the garden acts as a virtual barrier that the robot cannot cross, similar to a geo-cage in drone operation[37]. In order to begin utilizing it, the robot user must first lay out the wire on the boundaries of their garden and then dig them approximately 10 cm below the ground's surface, so that the wire is safe from any external factors. This is a tedious task for the user but has to only be completed once and the robot is now fully operational and will never leave the boundaries set by the user. It is important for the user to take their time in the first setup as any change they will want to make will require digging up many meters of wire and once again putting it in the ground after relocation.

The boundary wire communicates with the robot by emitting a low voltage, around 24V, signal which is picked up by a sensor on the robot[38]. This means that when the robot detects the signal it knows that the wire is underneath it and it should not to continue moving in its direction. As is displayed above, the boundary wire is a very simple technology, which with a slight amount of effort of the user can perform the basic navigability tasks. However, its functionality is fairly limited, it cannot detect any objects within the area of its operation and therefore avoid them meaning that its environment has to be maintained and clear throughout its operation.

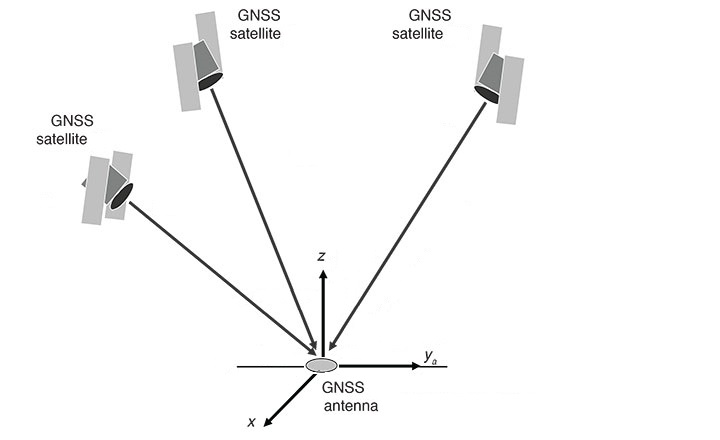

GPS/GNSS

GPS/GNSS are groups of satellites deployed in space that allow robots and devices to receive signals from them, which aid them in positioning. Over the past few years these systems have gotten extremely accurate and can position devices to the nearest meter[40]. This happens through a process called triangulation, where multiple satellites calculate their distance to a device and establish its location[41]. The usage of this sensor in our robot is very encouraging as it has been proven to be effective in the large scale gardening industry for many years, more specifically the precision farming domain[42]. An important distinction to note is that of GPS and GNSS. Although GPS is likely the term many are more familiar with from navigation applications they have used in the past, it is really just a subpart of GNSS which represents all Constellation Satellite Systems and GPS is simply one of them. If it is equipped with a sensor that can communicate with satellites and fetch its location at all times, our robot will be able to precisely ping the location it has found sick plants or any plants that need care and send that information to the users device. Once again promising to be a very key component in our robot design.

Bump Sensors

Bump sensors, commonly referred to as collision or impact sensors, are sensors designed to detect physical contact or force, a robot could encounter while traversing its environment[44]. These sensors can be seen being utilized across various industries in robotics in order to increase the safety and allow for greater automation of the robots they are integrated into. Additionally, these devices are crucial in robotics and many different types of vehicles as they allow the robot to replicate the human ability of touch and have a tactile interface with the environment.

In order to have this feature, bump sensors are typically composed of accelerometers, devices that are able to detect and measure a change in acceleration forces, or simply a switch which gets pressed as soon as the robot applies pressure on it from factors in its environment[45]. In its many applications the contact the robot experiences is with larger objects, so the sensor must not be extremely sensitive. This could not be the case in our gardening robot, as the robot would have to consider smaller and more fragile objects, requiring the sensor to have a much higher sensitivity. Bump sensors are most commonly used to make sure a robot does not drive into and collide with large objects, it allows the robot to detect that a change of direction in its motion must occur before continuing its operation. Although in many industries bump sensors are a last resort form of defense against the robot breaking or destroying important elements in our environment, in the robot we are designing it is a lot less of an issue if the robot were to detect an object through this sensor[46]. The robot would have to signal contact that it has collided with an object and change its direction of motion without further applications. However, this should still be unlikely to happen as in our robot the LIDAR sensor should have detected the problem beforehand and dealt with it. Nevertheless, technology is not always reliable and having a backup system ensures the robot experiences fewer errors in its operation, especially with the possibility of faults of the LIDAR due to sun contamination.

Ultrasonic sensors

Ultrasonic sensors, or put in more simple terms, sound sensors, are another type of sensor which allows a robot to measure distances between objects in its environment and its current position. These sensors also find widespread applications in robotics whether that is liquid level detection, wire break detection or even counting the number of people in an area. Their strength is that they allow robot that have them to replicate human depth perception in a method similar to that of a dolphin[48].

Ultrasonic sensors function by emitting high-frequency sound waves through its transmitters and measuring the time it takes for the waves to bounce back and be received by its receivers. This data allows the robot to calculate the distance to the object, enabling precise navigation and obstacle detection. Although this once again is similar to the function of a LIDAR sensor, it allows the robot to work in a frequently changing environment without the use of state-of-the-art and expensive technology. One thing that must be considered in the usage of this sensor is that it tends to perform worse when attempting to detect softer materials which our team will have to take into account and make sure the sensor is able to detect the plants it is approaching[49].

In our gardening robot, ultrasonic sensors could once again play an important role in supplementing the functionality of more advanced sensors like the LIDAR. Through its simple and reliable solution, ultrasonic sensors provide essential functionality, improving the robot's operational reliability in a very wide range of gardens it could encounter in its deployment.

Gyroscopes

Gyroscopes are essential components in the field of robotics that help in providing stability and precise orientation control in a wide range of industrial areas. These devices use the principles of angular momentum to constantly maintain the same reference direction, in order to not change its current orientation[51]. This allows robots to improve their stability and therefore enhance their operational abilities.

In order to perform their functionality, gyroscopes consist of a spinning mass, mounted on a set of gimbals. When the orientation of the gyroscope changes, its mechanism of conserving angular momentum means that it will apply counteracting force essentially keeping it in the same orientation. This feature is very important in the field of robotics as it allows the robot to know its current angle with regards to the ground and when that gets too large the gyroscope helps the robot to not flip over or fall during its operation.

Since thousands of relevant sensors exist, we can only discuss the most important ones. Sensors such as lift sensors, incline sensors and camera systems can also be included in the robot for navigation purposes, however in the design of our robot they are either too complex or unnecessary.

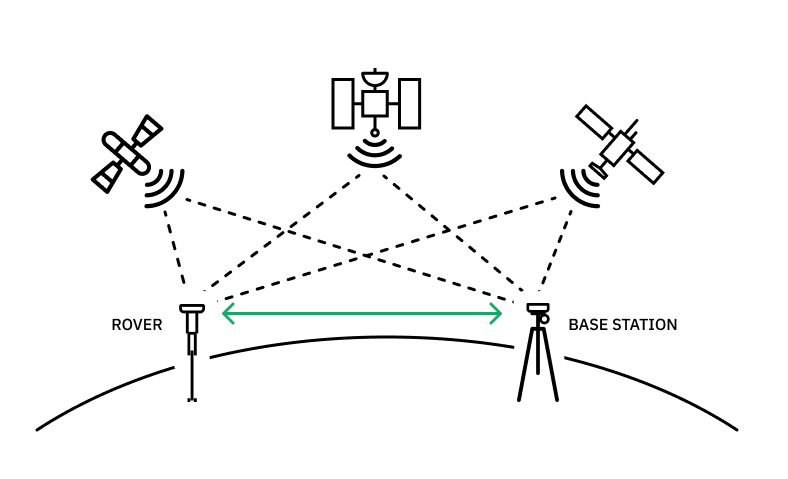

RTK sensor

RTK, or Real-Time Kinematic, is a really advanced positioning technology that allows for positioning of devices that is extremely precise.[52] This precision being able to only have an error of 0.025m.[53] Therefore it is no surprise that this technology can be seen in various applications such as in agriculture and construction.[54] At its core, an RTK system utilizes a combination of GPS (Global Positioning System) satellites and ground-based reference stations which aid in positioning a robot. Unlike traditional GPS systems that offer accuracy within several meters, RTK improves this precision significantly, making it very necessary for tasks that require precision such as our plant identification robot which needs to be able to send the location of an unhealthy plant to the user with centimeter precision.

The key component of an RTK system is the RTK receiver, which is installed within the robot itself. This receiver communicates with GPS satellites to determine its position, but what makes this system unique from all others is its ability to also receive corrections from nearby reference stations.[56] These reference stations are able to precisely measure their own positions and then broadcast correction signals to the RTK receiver that is mounted on the robot. Essentially, this means that the robot knows its slightly inaccurate location obtained from just the GPS signal but due to the fact that it also receives a signal from a reference station it can correct its GPS reading by comparing them with the ones received from the reference station allowing the robot to achieve centimeter-level accuracy.

Although at first the idea may seem complex, the main idea of the operation of an RTK system is called carrier phase measurement. Unlike regular GPS systems, which rely on pseudorange measurements to determine the position of its user, RTK receivers use carrier phase measurements.[57] This process involves measuring the phase of the GPS carrier signal, allowing for highly accurate positioning. However, carrier phase measurements alone are subject to errors due to atmospheric conditions and other factors.[58] This is where the corrections from the reference stations come into play, enabling the RTK receiver to mitigate these errors and achieve centimeter-level accuracy in real-time.

To make communication between the reference stations and the RTK receiver possible, methods such as radio links, cellular networks, or satellite-based communication systems are needed.[59] Regardless of the communication method used, the goal is to ensure that the RTK receiver receives timely and accurate correction data to correct its current position.

As can be seen this technology solves a major issue our robot was facing that was kindly pointed out to us by one of our tutors, Dr. Torta. This issue being the fact that the robot can not simply use the GPS to send the location of the plant to the user as its accuracy is of a couple meters. This would mean that if the user were to have multiple plants within a 2-3 meter radius, even if provided with an image of the plant the user would have a difficult time finding the plant that is unhealthy.

Mapping

Introduction

Mapping will be one of the most important features of our robot as it will be the very first thing the robot performs after being taken out of its box by the user and will rely on the quality of this process for the rest of its operation. Mapping is the idea of letting the robot familiarize itself with its operational environment by traversing it freely without performing any of its regular operations and simply analyzing where the boundaries of the environment are and how it is roughly shaped. This allows the robot to gain the required knowledge so that during its normal operation throughout its lifecycle it is aware of its positioning in the garden, areas it has visited in the current job and areas it still must visit. Essentially it turns the robot from a simple-reflex-agent to a robot which has knowledge stored in its database and can access it to make better informed decisions for more efficient operation. Mapping can be done both in 3D and in 2D depending on the needs of the robot and user. Initially, we considered 3D mapping in this project, enabling the robot to also memorize plant locations in the garden for easier access in the future, however since plants grow very rapidly, the environment would change quickly and the mapping process would have to be repeated on a daily basis, leading to a very inefficient process. Now that the decision was made to implement 2D mapping, similar to that of the Roomba vacuum cleaning robots, the purpose of the map would be to learn the dimensions and shape of the garden. It may come at no surprise, but as is the case in most design problems, there is rarely one solution and that is no different in the case of mapping. Nonetheless, the most optimal method for our robot is using the already existing method developed by Husqvarna AIM (Automower Intelligent Mapping) technology.

Husqvarna AIM technology[60]

Husqvarna Automower's intelligent mapping system operates through taking advantage of multiple cutting-edge technologies, allowing gardeners to maintain their gardens even easier than they previously could. At the core of its functionality the technology uses a combination of GPS, onboard sensors, and intelligent algorithms. The process begins when the robot is first taken out of its packaging and turned on. The robot straight away begins exploring the garden by first moving randomly through it as it initially has no information to reference. As discussed in the course Rational Agents we could say that the robots knowledge base is initially empty. However, as the robot is exploring, simultaneously, GPS technology aids in mapping the layout of the lawn, providing precise coordinates to guide the robot's movements. Through GPS, the robot establishes a blueprint of the terrain similar to that of the well known and loved Roomba, enabling it to navigate efficiently and cover every patch of grass.

Once the GPS mapping is complete, the robot that has this technology is able to traverse the garden with great precision. Although mapping is very reliable, it is important that the robot is equipped with onboard sensors, including collision sensors and object detection technology, so the robot can detect obstacles in its path and adjust its movement. This ensures that no matter what, the safety of the robot will be maintained and other objects such as plants in the vicinity will not be harmed. Moreover, the intelligent mapping system enables the robot to adapt to changes in terrain and navigate complex landscapes effortlessly. This means that even if the robot is faced with slopes, tight corners, or irregularly shaped lawns, the AIM technology’s algorithms can find the best way the robot shall proceed at all points.

Furthermore, Husqvarna Automower's intelligent mapping system incorporates features that enhance user experience and customization. Users can designate specific areas within the lawn for prioritized mowing or exclude certain zones altogether. This level of customization allows for tailored lawn care according to individual preferences and requirements. Additionally, the robot’s connectivity features enable remote control and monitoring via smartphone applications, providing users with real-time updates on mowing progress and allowing them to adjust settings as needed. Although not really relevant with our project, the robot using this technology may connect to many smart home devices such as the Google Home or Amazon Alexa.

Another feature of Husqvarna Automower's intelligent mapping system is its ability to customize the robots mowing schedules based on current weather conditions, and energy efficiency. Although this seems almost impossible, the robot can do this by analyzing data gathered from its onboard sensors and weather forecasts that it can connect to. This approach to lawn maintenance saves a vast amount of time and effort for users, but also a lot of electricity, which does not have to be used when the robot decides it is unnecessary.

In conclusion, we can confidently say that Husqvarna Automower's intelligent mapping system is truly a groundbreaking advancement in robotic lawn care technology. Through utilization of the GPS and RTK sensors, and intelligent algorithms, the robot which utilizes this technology is able to successfully and efficiently navigate any garden it is utilized in. This is crucial for our plant identification robot as it will allow us to not worry about the navigation of the robot and we can be ensured that the robot's navigation will be efficient and let the robot visit every location in the garden without a problem allowing it to detect all sick plants that need care.

Hardware

Our goal for this project is to have a rough design of our robot concept, that is, a design that can be given to a manufacturer to finalise and analyze. In order to do this, we need to have a more concrete understanding of our robot’s capabilities and features. Therefore, we thought it was necessary to research the most important hardware components of our robot, the lawn mowing mechanism and the camera, as they are the main selling points of our robot concept. For the lawn mowing mechanism, we'll need to determine the cutting style (rotary, reel, etc.), based on their strengths and weaknesses, and how their goals align with our robot. Additionally, we should consider features like adjustable cutting height and the collection of grass. For the camera, we'll need to choose between existing camera models based on the resolution, field of view, and processing power required to achieve our desired functionalities. By defining these aspects in detail, we can ensure both mechanisms are optimised for efficient lawn mowing and reliable obstacle detection, ultimately creating a great product for our target market.

Lawn Mowing Mechanism

Rotary Lawn Mowers

Rotary lawn mowers are the most common lawn mowers. They have 1 or 2 steel blades spinning at around 3000 rpm horizontally near the surface(1). Because the blades cut a specific height of grass, grass that is not sitting straight up won’t be cut well, and thus they sometimes don’t cut short grass evenly (2). Rotary lawn mowers usually have a cover over the blades, ensuring the safety of any people or animals that get close to the lawn mower, as well as ensuring that the grass doesn’t fly everywhere, potentially staining the user’s clothes (1). These types of lawn mowers usually have internal combustion engines, however many are powered using electricity, through either a cord, or a rechargeable battery such as lithium-ion batteries (1).

| Pros | Cons |

|---|---|

| Compact | Not the best at cutting low grass |

| Simple | Noisy |

Reel Lawn Mowers

The reel lawn mower is a type of lawn mower that is most commonly manual, that is, the user walks it around and it has no engine to spin the blades(1). Specifically, as the reel lawn mower is moved along the grass, the central axis of the cylinder rotates, causing the blades to rotate with it(1). This type of lawn mower is great for cutting low grass, as the blades “create an updraft that makes the grass stand up so it can be cut”(1). However, it is not great at cutting tall or moist grass, as its blades can get stuck and not cut properly(2). Manual reel lawn mowers tend to be much cheaper than rotary lawn mowers, however, motorized ones can be just as expensive(2).

| Pros | Cons |

|---|---|

| Great at cutting low grass evenly | Not the best at cutting high grass |

| Doesn’t make any noise | Mechanism is very separate from engine, can be more bulky |

| Bad with damp grass |

Cameras

Terms and Definitions

- Horizontal/Vertical Field of View: Field of View (FOV) refers to the area that a camera can capture. Field of view can be broken down into two components, horizontal FOV, which refers to the width of the scene that can be captured, and the vertical FOV, which defines the height of the scene. This is important to consider, as our robot needs to cover all of its surroundings to ensure that all plants are detected and disease detection is consistent.

- Global Shutter: With this type of shutter, the camera sensor shuts off the light exposure to all pixels simultaneously, essentially creating a ‘screen capture’ effect. This implies that camera motion is not an issue to take a picture with high quality, as the camera doesn’t get the chance to move before the shutters are closed. However, as all pixels are captured at the same time, this means that more memory is required to store the information from the pixels, and thus cameras with global shutters tend to be more expensive.

- Rolling Shutter: Rolling shutters, as opposed to global shutters, shut the exposure to light off row by row, which makes the camera need less memory, as it only needs to store 1 row of pixels at a time, so they are cheaper and thus more common. However, if the camera is moving while the picture is being taken, this will lead to distortion of the image, as the information captured from each row of pixels is obtained at different time intervals.

- Maximum Exposure Time: This refers to the maximum amount of time that the camera’s image sensor is exposed to light while capturing an image. In layman’s terms, it refers to how long the camera’s shutters can be open in a continuous duration.

- Sensor Resolution: Measured in megapixels (MP), sensor resolution refers to the total number of pixels on the camera sensor. Higher resolution translates to sharper images with finer details, potentially allowing for more precise plant (disease) identification. However, it needs more processing power and more storage space for captured images from the robot, as each pixel is extra information that needs to be processed and stored.

- Frame rate: When referring to video capture, frame rate refers to the number of still images (frames) a camera can capture in one second. Higher frame rates are essential for smooth, high-quality video, especially for capturing fast-moving objects or the robot's own movement for plant detection and disease identification.

Camera Modules

The choice between the cameras is a difficult one, as each camera has its upsides and requires a unique strategy to be implemented. Therefore, while comparing the cameras, we will also compare the different strategies in our camera, that is considering all specifications defined above.

Raspberry Pi Cameras

Raspberry Pi cameras are very popular and affordable cameras specifically designed for the Raspberry Pi single-board computer. They are generally also quite light, which increases the versatility of their usage, and allows us to put more on our robot without putting too much weight on the robot. Out of all of the models, we considered the following: Module 3 and Module 3 Wide which cost 25€ and 35€ respectively. As can be inferred from the Module 3 Wide, its field of view is larger than the Module 3, having a horizontal FOV of 102 degrees compared to the 66 degrees of the Module 3. Both use rolling shutters, so both cameras will struggle detecting plants if the robot is moving very quickly or in bumpy territory. However, since both can record video at about 30fps, and have a maximum exposure time of 110 seconds, recording is a viable option. Moreover, both have an image sensor resolution of 11.9MP, which is very high quality and enough for our usage.

ArduCamOV2643

The ArduCam OV2643 are cheap cameras specifically designed for arduino boards, standing at 20-30€. They have a horizontal field of view of 60 degrees, quite a lot less than the previous RPi cameras. It also uses rolling shutters, and hence usage with the robot will be limited, just like the RPi cameras. Moreover, the camera’s sensory resolution is 2MP.

Insta360 One X2

The Insta360 One X2 is a high end camera capable of 360 degree vision, meaning that only one of these cameras would be needed to cover the entirety of the robot’s surroundings. As mentioned before though, it is expensive, standing at around 315€, which is over 10 times more expensive than previous cameras. Moreover, it uses rolling shutters, which may lead us to think that it might struggle like the previous cameras in plant identification. However, with a resolution of 18MP, this camera has been designed to be used for video recordings with a lot of motion, which means that it can be used for our robot’s plant identification feature.

Interview With Grass-Trimming Robot Owner

Introduction

In order to confirm our decisions and ask for clarifications and recommendations on features that our user group truly desires, we performed an interview. The interview will be completed with the owner of two different private gardens in Poland. The interviewee also owns two grass trimming robots, one produced by Bosch and the other by Gardena, which he utilizes in both gardens. We believe his expertise and hands on experiences with similar state-of-the-art robots will allow us to solidify our requirements and improve our product as a whole. The interview will be performed in Polish as the interviewee is not fluent in English and will be translated into English on the wiki. One of his gardens can be seen in the image on the right. The interviewee has one robot which cuts the triangle shaped part of the garden on the left which has "islands" of various flowers and bushes and the other robot cuts the rest of the garden (the right side). Before conducting the interview, the interviewee was handed an informed consent form to make him aware of how the interview will be conducted and how the results from it will be used. After analysing the document the interviewee agreed to proceed with the interview. A screenshot of the cover page of the document can be seen to the right and it can accessed fully through the following link: Interview Consent Form.The interview was performed on a video-call on Whatsapp due to the fact that the circumstances did not allow any group members to travel to Poland to conduct it in person.

Questions Asked and Answers Provided

Below is the rough transcription of the interview translated into English. Each question has a number besides it and the answer that follows to it is preceded by an indented bullet point.

- What is the current navigation system your robot uses?

- My current robot navigates by randomly walking around the garden within the limits I set by cables that I dug into the ground that came with the robot. This means that the robot is able to move freely, however when it reaches a boundary cable it stops and turns around making sure it does not go past it.

- What issues do you see with it that you would like improved?

- I mean the obvious thing would be, I guess, if it's less random it might take a quicker time to finish cutting the grass but honestly I do not really see an issue in that as it does not affect my time as I do not have to monitor the robot anyway. Furthermore, it would be nice to have the robot connected to some application as right now everything has to be setup from the robot's interface.

- What is the way in which you would currently charge your robot and how would you like to charge and store the plant identification robot?

- Currently my robot has a charging station to which it returns to charge after it has completed cutting grass, if something similar could be made for the plant identification robot I would be very satisfied.

- Would you like the robot to map out your garden before its first usage to set its boundaries or would you like that to be done by the boundary wires your current robot uses?

- I feel my case is a bit special as I have already done the work of digging the boundary cables into the ground so I would not have to do anything again so it would really not matter to me if the plant identification robot would use the same system. However as I understand, this product is also likely for new customers and if I was a new customer I feel like the mapping feature would be better as I would not have to set up the whole boundary cable system which was tiring and time consuming for me.

- Would you like the robot to map out your garden in order to pinpoint problems in your garden and display them on your phone or would you just like to receive the GPS coordinate of the issue and why?

- I feel like seeing the map of my garden on the app will always make my life simpler however, if I simply get the GPS location which then I can paste into google maps or some application and see its location that would also be more than fine. As long as I know where the sick plant is I will be happy with it.

- Are there any problems with movement that your current robots are facing with regards to using wheels? (getting stuck somewhere, etc.)

- Generally I would say no. There are times, however, where the robot has to go over a brick path running through my garden and sometimes it struggles to get up on the ledge, however eventually it always manages to find a more even place to cross and it crosses it.

- Are there any hardware features that you believe would benefit your current robot?

- I wouldn't say there is anything that the robot is missing in its core functionality, however I recently installed solar panels on my house and they help me save on electricity so maybe if the robot also had some small solar panel it would use less electricity as well, but besides that I am not sure.

- How satisfied are you with the precision and uniformity of grass cutting achieved by the robot's mowing mechanism?

- I am very satisfied, although I remember the store employee telling me that it evenly cuts the grass even with random movement. I did not believe him but I can truly say I guess over the time it operates it manages to cut the grass everywhere within its area.

- Have you noticed any issues or areas for improvement regarding the battery performance or power management features?

- Not really, my robot works in a way that it operates until the battery drains and it returns to its charging station to charge. Once its done charging it resumes its operation so I do not really see any issues with its battery and especially since it works the whole day I don’t see any problems with it charging and returning to work.

- How well has the automated grass cutting robot endured exposure to various weather conditions, such as rain, heat, or cold?

- I cannot run the robot in the rain and it really is not recommended either, so when it starts raining I just tell the robot to got back to its station. Regarding heat and cold, I've not seen any issues, obviously it hasn't had any significant running in cold temperatures as I don't use it during the winter as there is snow and no need for grass cutting.

- Have you observed any signs of wear or deterioration related to weather exposure on the robot's components or construction?

- No, not at all. The robot is still in a very good condition after some years now. I have seen that you can buy some replacement parts if something breaks, but I have not had the need to.

- What plant species do you currently own?

- Too many to name if I’m being honest, and also I'm not sure if I could name what a lot of them are (chuckle) but many flowers, bushes and trees.

- Have you always gravitated towards these species, or did you grow different species in the past?

- When we first bought the house with my wife around 2004 we just had a gardener and some friends/family help us decide how to decorate the garden with plants and when plants die, the gardener who comes each spring helps us decide whether to replace it with something new or the same one again.

- What health problems do your plants typically encounter?

- Probably the most important issues are drying out during the summer as I often forget how much water each plant needs when the temperature is high. At some point a few years ago I also had some bug outbreak which spread and forced me to dig up many flowers.

- Is there anything that you find confusing about the design of modern apps, and, if so, what?

- Obviously I am getting quite old and not so good with new technology so what I love about apps that I use is that they have their main features on the home page and are easily accessible, I have a hard time finding things if I have to navigate through many pages to find it.

- What is the current navigation system your robot uses?

Conclusion

In the end, we were very pleased with the input that our interviewee provided and we are very thankful for his time and thought that was put into answering each question. The interviewee also displayed a lot of interest in the project and insisted that we get back to him with the progress we made at the project's conclusion. Furthermore, the most important thing that the interview provided us with is clarification of a lot of points of discussion we had and he paved a clear direction that the project should head towards. The interview allowed us to solidify many of the main features and although not all requests, such as the solar panels on the robot, can be completed, we have been given a lot of information that we can work with and continue developing now knowing that we have backing from a potential user. As this section is not fit to discuss how the interview will contribute to the final design of the robot, all changes and decisions that were made that can be traced back to this interview will be discussed in the Final Design section of this wiki.

Survey

Having done all the necessary research on existing technologies that could be implemented by our robot, we wanted to narrow down all possible functionalities into the few necessary ones that would be preferred by possible users. To that end, we conducted a survey amongst peers, family and through open group chats, allowing user-led information to guide us into designing our robot, and especially the app that controls it. We asked 11 multiple choice/multiple answer questions to the users, 6 questions about the User Interface of the app, e.g menus, buttons and tabs, and 3 about functionalities of our robot, e.g operation of robot and locating plants. We got a total of 39 responses, most of which were family members who had lawns, however some were friends and colleagues who did not necessarily own a garden. While they may not be the most accurate representation of our potential users, their perspective and opinions are still valuable, as they offer fresh perspectives on the usability and appeal of our robot and its app beyond the traditional gardening demographic. Additionally, their input allows us to anticipate and address the needs of users who may not have prior gardening experience but are interested in adopting technologies that facilitate plant care and maintenance. Therefore, incorporating their perspectives enables us to create a more inclusive and user-friendly product that caters to a wider audience.

Survey Results

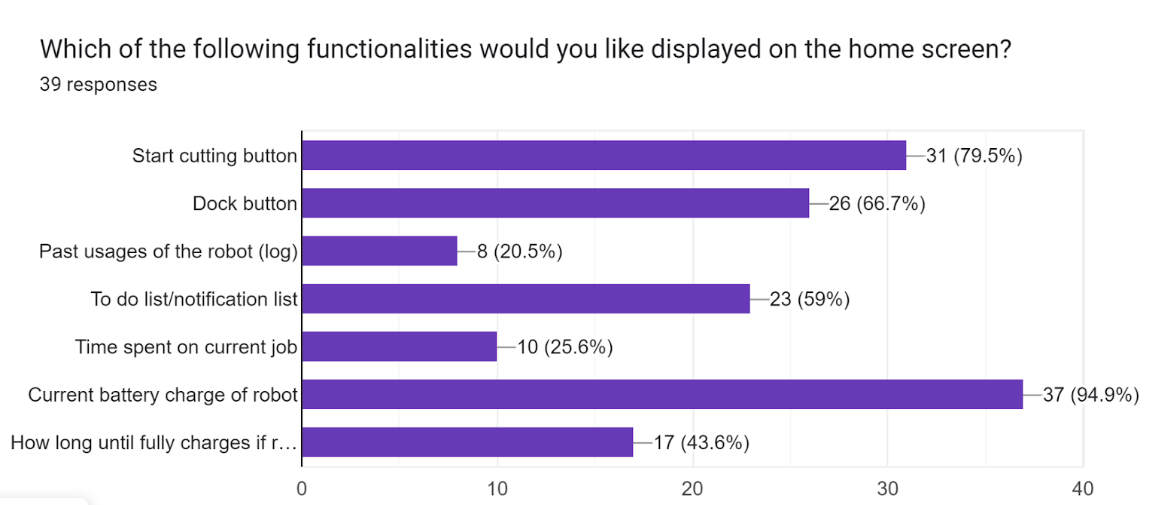

As stated before, we used the following survey results to make some design choices with regard to our app and our robot. For all questions in the survey, if the question was a multiple choice (Pie chart), the option with the highest percentage was chosen for our design. However, if it was a multiple answer question (Bar chart), then we included all options that had at least a 66% (⅔) rate of being chosen by our users. This is because if a sufficiently large number of possible users want this feature, we should include it to ensure that our users are satisfied.

User Interface

The following questions are there to finalize the UI design of our app. We wanted to ask our users what would be most helpful for them, in terms of notifications, home screen, and button placements. For example, in the first question we queried further what functionality they would like to see on the home screen, as the home screen should have the most important functionality, to make the app straightforward and easy to use.

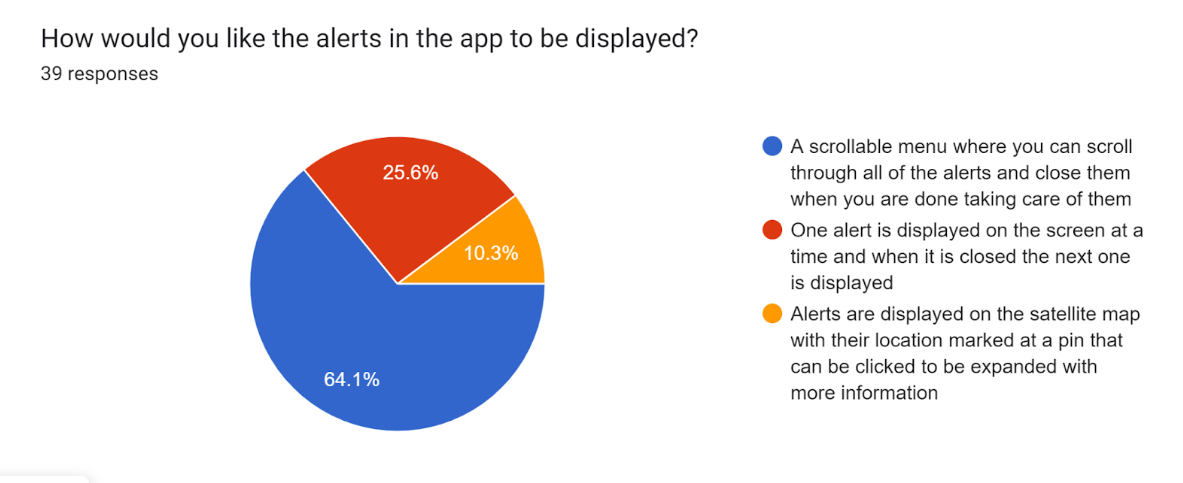

- We asked the following question because we weren't sure how to display alerts on our app, as a scrollable menu might be more overwhelming, but might also tell users exactly how many notifications they have. From the results of our survey, a scrollable menu was chosen, as it had the highest popularity. Moreover, even though only 10.3% chose the satellite alerts, we decided to add a fluctuating light on the map to let people where the plants was.

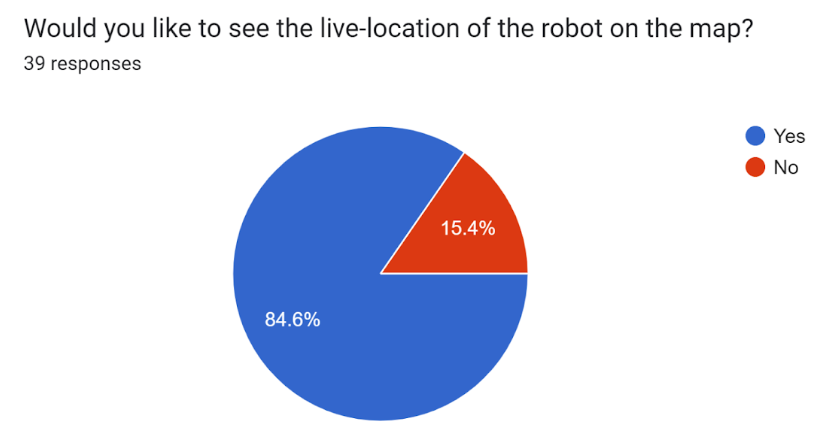

- We weren't sure whether the live location of the robot was necessary, as it might make the map more crowded and distract the user from the main goal of our app, which is the detection of plant diseases. However, as the users told us that they preferred to have the live location, we included the live version of the NetLogo environment on the app as well, to showcase the robot's location and their progression in cutting the grass.

- The app's home screen is where the most important functionalities should be, which is why we asked our users to choose between 7 functionalities. In the end, the start cutting button, dock button and current battery charge of the robot were added to the home screen, as the majority of those surveyed chose them. Unfortunately, considering these 3 buttons, we weren't able to add a to-do list, as it would take too much space and would make the home screen too crowded.

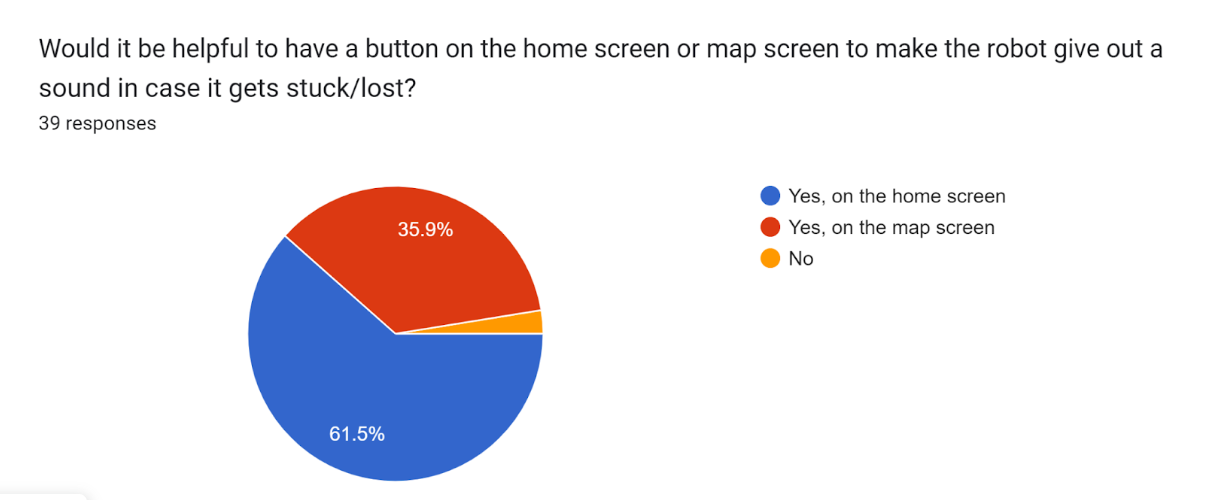

- We were not sure whether a button was needed to give out a sound in case the robot was lost, as our robot was going to be big enough to be visible, and we didn't want an unnecessary button on the home screen or the map screen. However, the reached consensus was that the button was very much necessary, and that users preferred it on the home screen, so that is what we chose.

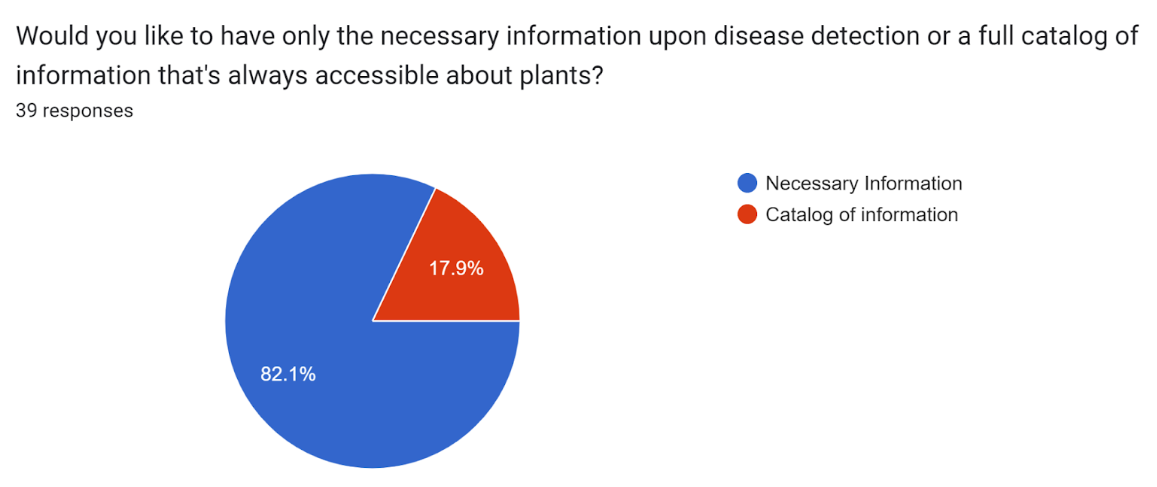

- Our goal for our robot and app is to make gardening easier for our users by automating the most tedious part of gardening. Moreover, we were also targetting inexperienced users who might not know much about how to take care of plants, and so we wanted to ask them how much information they actually wanted. Unsurprisingly, most only wanted the necessary information upon disease detection.

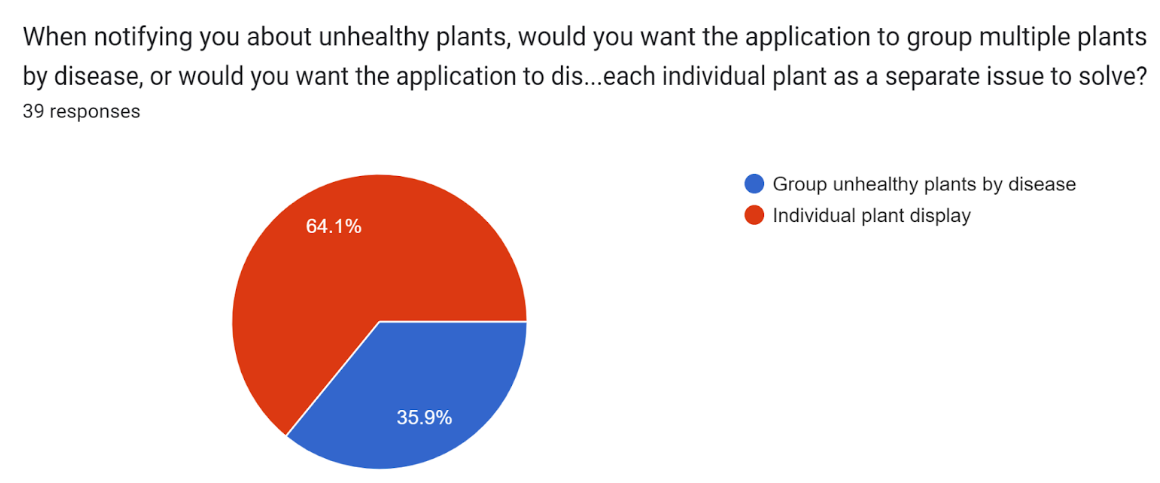

- The grouping of unhealthy plants came up during one of the meetings with the tutors, which lead us to think of the different ways users might want to get notifications and see plants on the map. Grouping plants by disease might help the user treat all the plants with the same disease at the same time, but it also might be very inefficient, as the user would have to treat 1 illness at a time, passing by ill plants that would not be treated in that round. The alternative was to just notify the user for each plant, which allowed the user to choose which plants they wanted to treat first, and it turned out to be the preferred choice.

Functionality of Robot

The following questions ask further about the functionality of the robot. We wanted to ask further about not only how automated they would want the robot to be, but also give us insight and anticipate difficulties that the users might have while interacting with the robot. For example, it occurred to us that users might have a hard time finding an identified plant using just the GPS location, so we gave them extra options like images or paint drops to help them locate the plant.

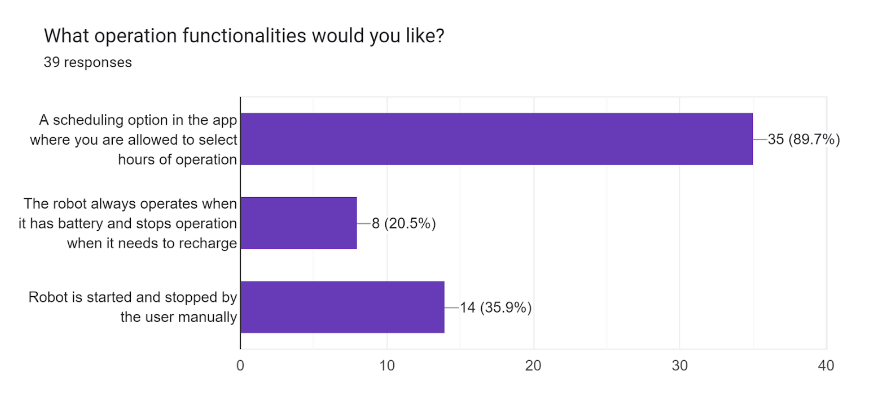

- The functionalities of the robot itself could have been included in the question about functionalities in the home page, however we want to know specifically how automated the users wanted the robot to be. Effectively, the possible answers are semi-automated, automated and manual, in that order. Unsurprisingly, people preferred the semi automated version, however we were surprised at the fact that only 36% of people wanted to be able to start and stop manually, considering that in question 1, people wanted a start and dock button. However, this is probably the case because people didn't want the start and stop exclusively, and wanted to specify how important scheduling was for them.

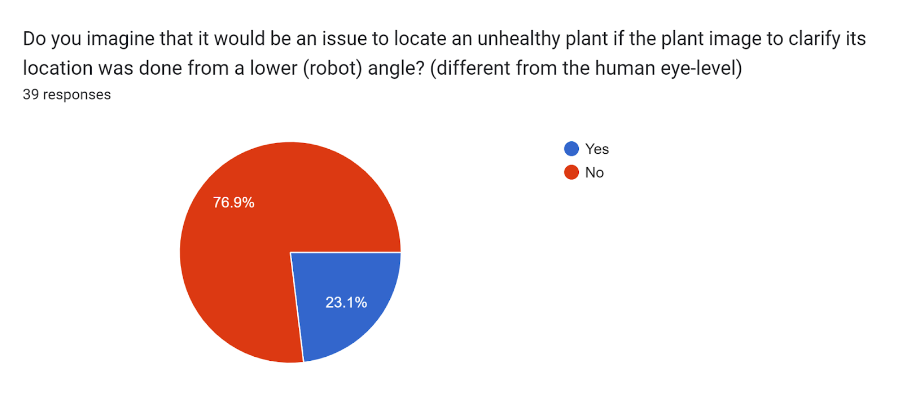

- Another problem that came up in the meetings with the tutors is the location of unhealthy plants, as the camera angle would be quite a lot lower than the human eye angle, and therefore humans might have difficulties locating plants by only using a GPS location and an image. However, we confirmed the fact that this was not an issue, having shown in the survey an example of an image from the view of the robot.

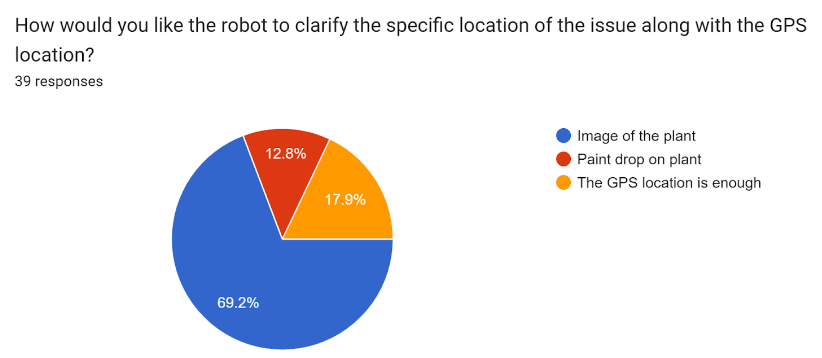

- Finally, to ensure that users were able to find marked plants, we asked them of different ways that might help them locate this plant along with the GPS. As acknlowedged by the previous question, an image of the plant, regardless of the angle, would be useful for the user to locate the unhealthy plant. Very few people only wanted the GPS, which is probably because there can be multiple plants nearby that may not have the same disease, and identifying based exclusively on location might have been tough.

Conclusion

This survey was very helpful to clarify some doubts we had about the UI and functionalities. There are infinite possibilities as to what to include in the UI, so having the user preferences was very helpful to reach a final design of the app. Moreover, some features require extra effort from us, so choosing the necessary features and excluding the unnecessary features was very useful, not only to ensure that the user only has what they prefer, but also to ensure that our time is not wasted. For example, we weren’t sure what functionalities to display on the home screen, and after the survey, we were able to choose the 3 most important functionalities, such that those functionalities are what a user sees immediately after opening the app. There were also some worries about the functionality of our robot, e.g. the user having difficulty finding a specific diseased plant. This is because our robot would take pictures from a different angle than human's eye view, which might impede them from finding the plant matching the picture, even if they have a GPS location. However, we were reassured by the survey results, which stated that it wasn’t a big issue. We do have to take into consideration the fact that the user is answering a hypothetical, but the positive response from users tells us that having this feature would not be a turnoff to any potential customers.

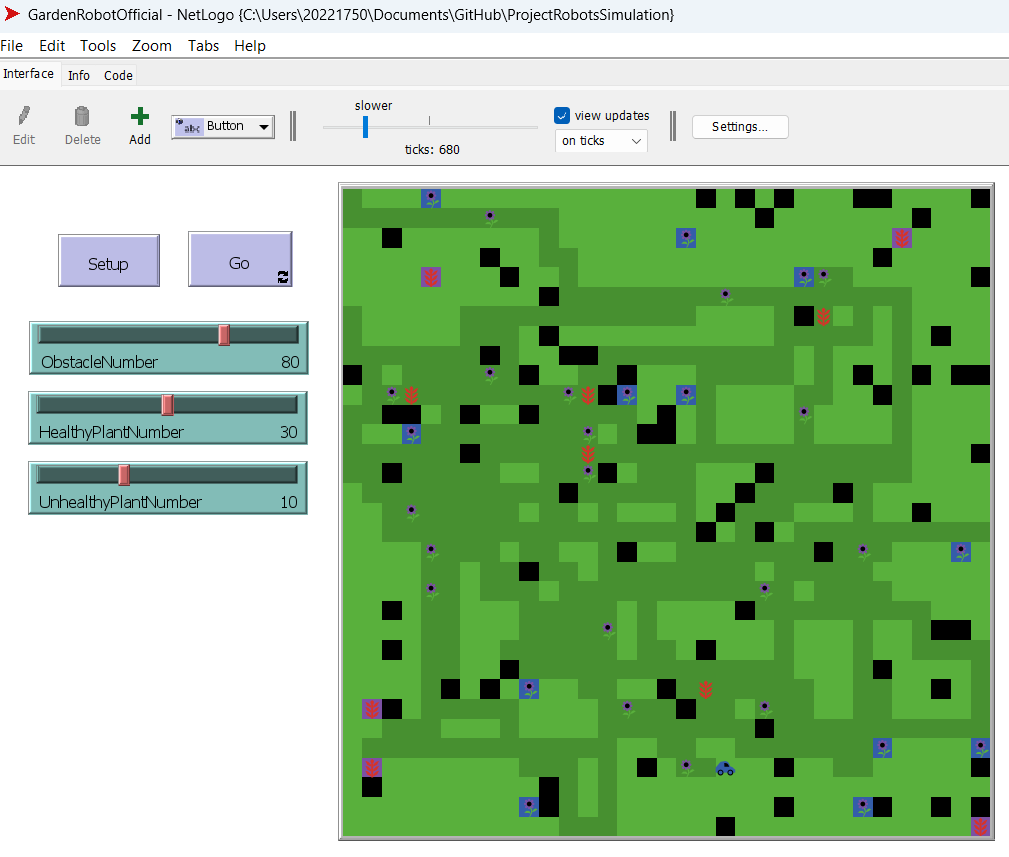

NetLogo Simulation

Introduction

Our NetLogo deliverable aims to simulate and display how the functioning of the robot will look visually as well as how the robot will communicate and interact with the app. The simulation will display the robot throughout the process of a regular operation, traversing the mapped garden, trimming grass and scanning for plants which are sick. In the simulation when a robot detects a sick plant it will drive up as close as possible to its location and send the coordinates of the sick plant to the application. Currently, this is also done for healthy plants, in order to not limit the possible features of the robot at this prototype stage. For example, in the future it could be possible for manufacturers and designers to want to incorporate the locations of healthy plants into their robots in some way, so we want to make that a possibility from the start. After detection, the application will then be able to receive this information and display it graphically for the user to observe, access and analyze.

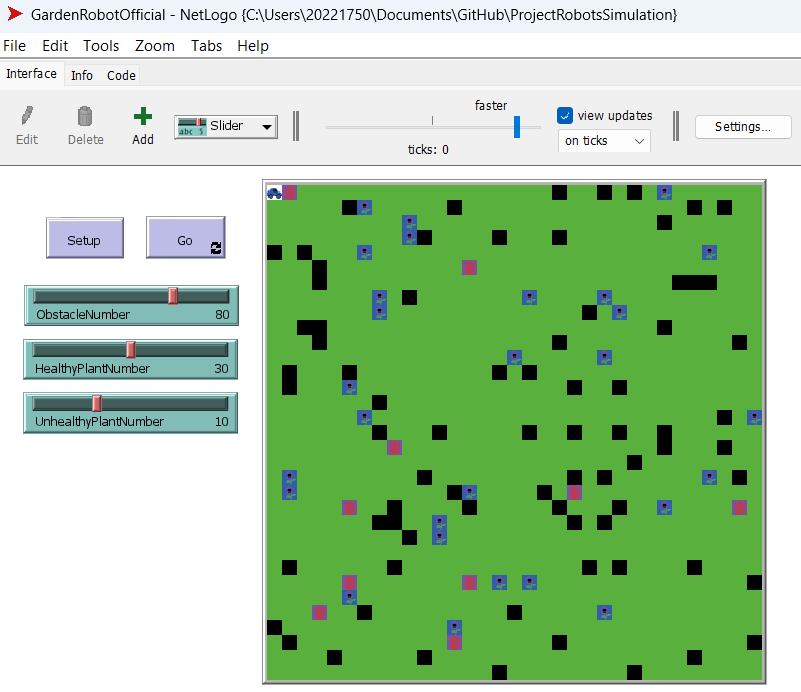

Creating the Environment

The first step in making the simulation was at first to create its environment, essentially the locations the robot will be able to traverse through. It was important for the environment to include certain important features which if not implemented would make the simulation lose its true functionality. However, before getting into the core of the environment as is the case for all NetLogo simulations we had to decide the size of the grid of the simulation and where to place the Setup and Go buttons. After some experimenting, and taking into consideration the time it would take to demo the simulation we decided that the size of the environment should be a 16 by 16 grid. Furthermore, we decided to place both the Setup and Go buttons in an easy accessible location on the top left of the screen.

Moving onto the actual patches and how they were designed it is evident that firstly the environment must include the robot's charging station which will be the location where the robot will begin its operation every time the simulation is initialized and run. In the simulation, the charging station was picked to be represented by a white patch. Furthermore, it was important to make the garden realistic. This meant that the environment had to include some form of obstacles or areas that the robot could not drive across as can be seen in real life gardens by rocks, tree roots, sheds and any other large obstacles. Therefore, obstacles were added into the simulation as black patches. Additionally, the environment had to include some standard or default patch of grass on which the robot can move freely and not have any responsibilities or tasks. As is the case in real gardens most patches in the simulation were of this specific kind and were represented by light green patches. Finally, possibly the most important patches in the simulation were patches which contained the actual plants in the garden. These patches were separated into two kinds; healthy plants and unhealthy plants. Healthy plants were represented by patches with a purple background and unhealthy plants were represented by patches with a red background. Although in the initial version of the simulation these patches did not include any icons, we decided that it would be easier to understand and view if the patches also included icons. Therefore, adding onto simply the background color, healthy plants had an icon of a flower on them and unhealthy plants had an icon of a weed on them. In the first version of the simulation the number of each patches was hard-coded meaning the user of the simulation could not change their value. However to increase the interactivity of the simulation we added sliders that can allow the user to customize the number of each type of patch, this obviously does not include the charging patch as there cannot be more than one. All sliders are placed below the previously mentioned Setup and Go buttons.

Creating the robot

The creation of the robot and its algorithm was by far the most challenging step in creating the simulation. Unlike the environment and its patches, the robot performs an action at each time unit which in NetLogo is a tick. In NetLogo, the robot was made using an element called a turtle. Turtles are able to move around the environment and interact with objects making them far more complex than patches and suitable to represent our robot.

Initially we believed the most optimal way to design our robot was to make it have random movement which included boundary wires. This meant that at each tick, the robot had to pick a random direction and move 1 step in that direction. Although this algorithm seemed quite simple to design as it required the robot to pick one of 4 options non-deterministically, we quickly found out that many problems were present that we initially had not considered. Firstly, it was not possible for the robot to walk over an obstacle, which we previously defined to be a black patch, this meant that when making the non-deterministic choice of direction the robot had to consider the fact that a black patch could be present one step away from it. When that problem was fixed, the robot also had to be aware of the boundaries of the simulation, which essentially are the boundaries of our garden. Although NetLogo does allow the robot to wrap around boundaries meaning that if it exits through the right side of the environment it just reappears on the very left side we felt this was not appropriate as it was unrealistic in comparison to the real world. In reality it is trivial that doing that is impossible so in order for the simulation to reflect reality that was not an option. In order to deal with this issue we had to make the robot treat the boundaries of the simulation as if they were a black obstacle patch which proved to be more difficult than expected, however in the end it was completed.