Mobile Robot Control 2020 Group 7: Difference between revisions

| Line 6: | Line 6: | ||

= Group Members = | = Group Members = | ||

{| class="TablePager" style="width: 500px; min-width: | {| class="TablePager" style="width: 500px; min-width: 400px; margin-center: 2em; color: black;" | ||

|- | |- | ||

! scope="col" | ''' ''' | ! scope="col" | ''' ''' | ||

Revision as of 22:32, 30 May 2020

Group Members

| Name | Student Number | |

|---|---|---|

| 1 | Mick Decates | 0957870 |

| 2 | Steven Eisinger | 1449273 |

| 3 | Gerben Erens | 0997906 |

| 4 | Roohi Jain | 1475061 |

| 5 | Mengqi Wang | 1449435 |

| 6 | Goos Wetzer | 0902160 |

Introduction

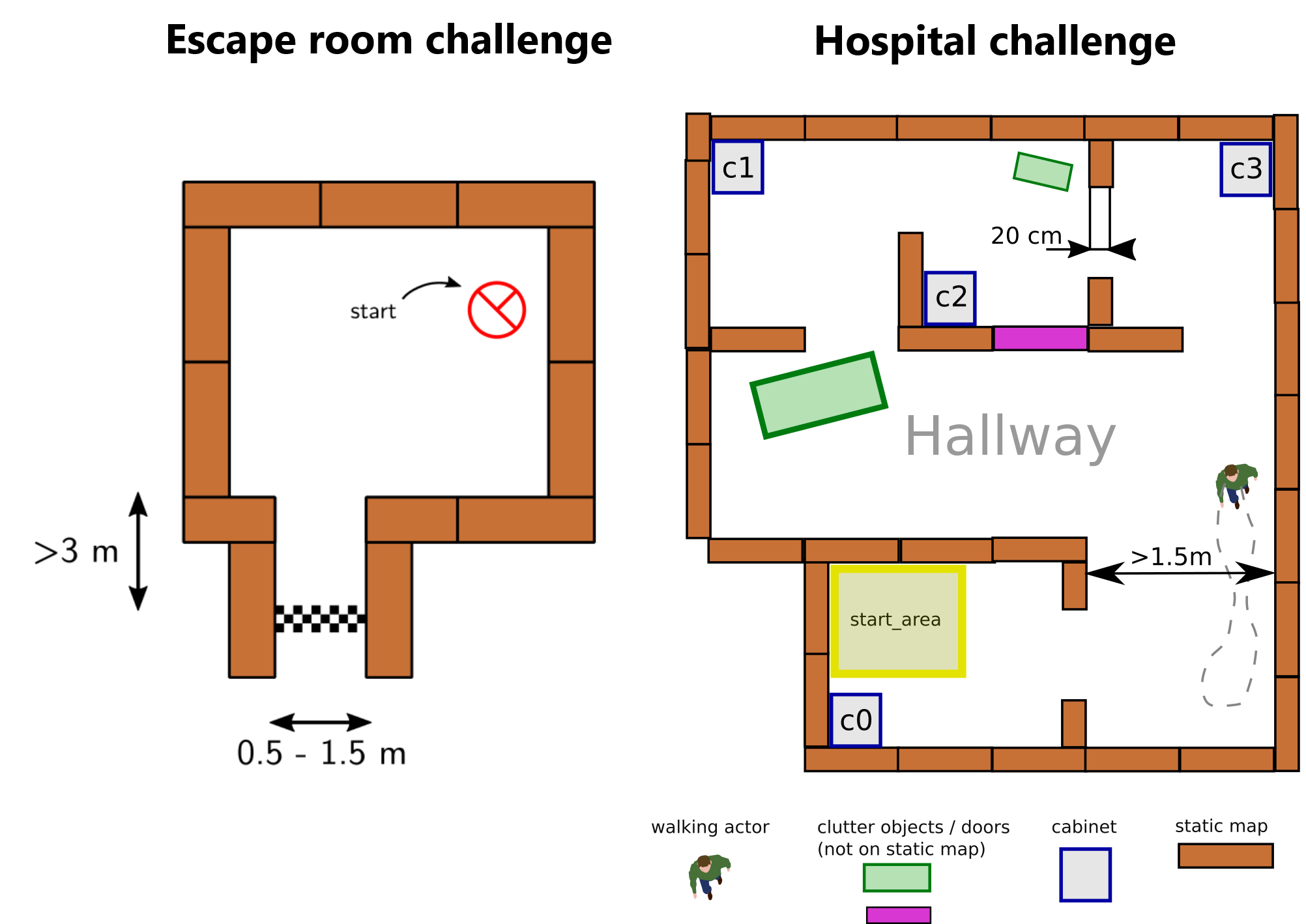

Welcome to the wiki of group 7 of the 2020 Mobile Robot Control Control course. During this course the group designed and implemented their own software which allows a PICO robot to complete two different challenges autonomously. The first challenge is the "Escape room challenge" where the PICO robot must drive out of the room from a given initial position inside the room. In the second challenge called the "Hospital challenge" the goal is to visit an unknown number of cabinets in a specific order, placed in different rooms. For both challenges the group designed one generic software structure that is capable of completing both challenges without changing the complete structure of the program. The example maps of both challenges are shown in Figure 1 to give a general idea about the challenges. The full details of both challenges are given on the general wiki page of the 2020 Mobile Robot Control course (link).

Escape room challenge

The main goal of the challenge was to exit the room as fast as possible, given an arbitrary initial position and orientation of PICO. The robot will encounter various constraints such as the length of the finish line from the door, width of the hall way, time constraints and accuracy. The PICO robot was first placed in a rectangular room with unknown dimensions and one door/opening towards the corridor. The corridor was perpendicular to the room with an opening on its far end as well. The initial position and orientation of the PICO robot was completely arbitrary. PICO was supposed to cross the finish line placed at a distance greater than or equal to 3 metres from the door of the corridor. The walls of the room were also not straight which posed a challenge during the mapping of the room from the laser data. The challenge is discussed in much detail about the algorithms used, implementation, program flow and results of the challenge in the following sections.

Hospital challenge

The main goal of this challenge was to visit the cabinets in a particular order given by the user as fast as possible. The global map consisting of rooms and cabinets and the starting room of PICO were mentioned beforehand. The hospital challenge contained multiple rooms with doors which can be open or closed. It tested the ability of PICO to avoid static/dynamic objects and plan an optimal path dynamically. The static objects included clutter objects/doors and the dynamic objects included human beings moving in the room while PICO was performing its task which were not specified on the given global map. Lastly, PICO was asked to visit the list of cabinets to visit in a specified order given by the user before the start of the challenge. The challenge is discussed in much detail in the following sections. The algorithms used are explained, how they are implemented is shown, the program flow is discussed, and the results of the challenge are told.

ESCAPE ROOM CHALLENGE

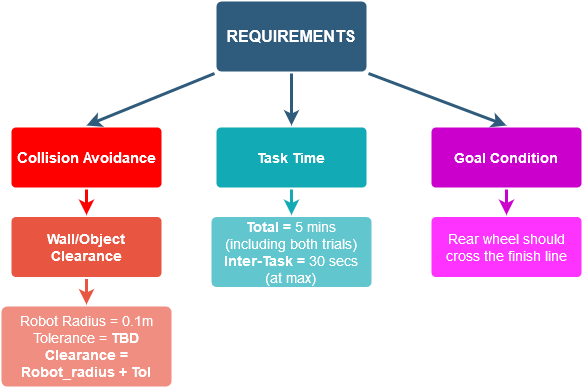

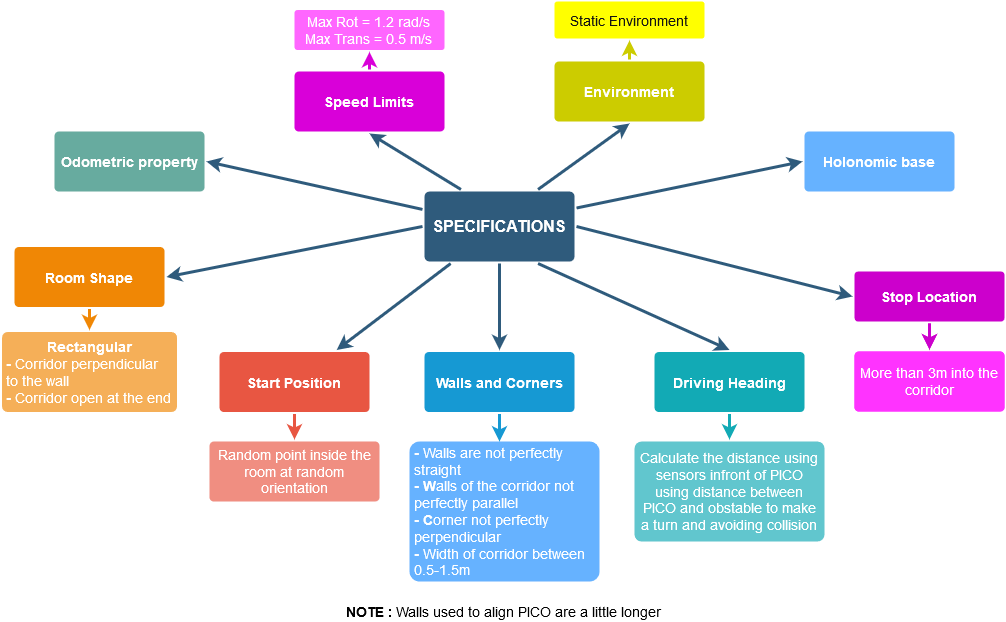

Requirements & Specifications

The requirements and specifications for the challenge are shown in figure. The primary requirement is safety that we need to fulfill by avoiding collision. All other requirements shall be treated equally.

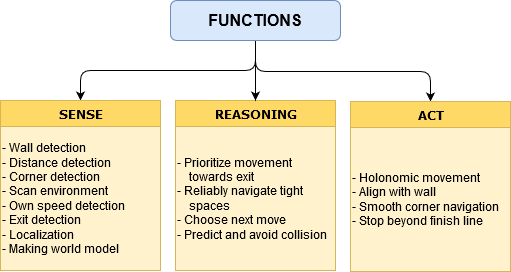

Functions

Once the robot is deployed in the room, it should sense around the room and try to find the exit corridor. If it cannot find the corridor, it should move around the room in an attempt to find it. Once the corridor is found it should position itself in front of the corridor and proceed through it until crossing the finish line.The functions that the robot needs to perform these tasks are described in Figure 2.1. These functions are divided into three main components: Sense, which allows the robot to perceive and quantify its world; Reasoning, where the robot makes a decision based on its perception; and Act, which determines what action the robot performs based on its reasoning information.

Hardware Components

Sensors - Laser Range Finder

The laser range finder measures the distance from the robot to the closest obstacle for a range of angles around the direction the robot is facing. The sensor data is stored in a structure called LaserData, which is described in table 3.1. There are 1000 measurements in total.

| Property | Description |

|---|---|

| range_max | The maximum range that can be measured is 10 meters |

| range_min | The minimum range that can be measured is 0.01 meters |

| angle_max | 2 radians from the direction straight ahead |

| angle_min | -2 radians from the direction straight ahead |

| angle_increment | Each angle is 0.004004 radians away from the next one |

| timestamp | Timestamp of the measurement in UNIX |

Sensors - Odometry

The odometry data measures the distance the robot has traveled in all 3 degrees of freedom in the horizontal plane.This data is obtained through encoders on the wheels of the holonomic base, which are stored in a structure called OdometryData, described in table 3.2. Small errors could accumulate over time due to measurement errors and wheel slip. To combat this, the positional data of the robot will be updated using the difference between the current and previous odometry measurement. This data is then corrected with the use of the world model and the data obtained from the laser range finder.

| Property | Description |

|---|---|

| x | distance travelled in horizonal direction since start of measurement |

| y | distance travelled in vertical direction since start of measurement |

| a | angle rotation since start of measurement |

| timestamp | Timestamp of the measurement in UNIX |

Actuators

The robot is built on a holonomic base, which means that it has three degrees of freedom in its horizontal plane: twotranslational, and one rotational. The robot is able to move in these ways using its omni-directional wheels, which are placed in a triangular formation on the base. Besides being able to provide a force in the driving direction,unlike normal wheels, the omni-directional wheels also do not constrain movement in the direction orthogonal tothe driving direction. Because of this, the robot is able to move with a given max velocity in all possible directions of the horizontal plane.

Software Infrastructure

The software will be divided into components, which are connected through certain interfaces. Major components are seen in Figure 5, and their interfaces are specified with the arrows. Perception is the component where the PICO uses sensor data from LaserData and OdometryData to get an idea of it’s current location. This data is interfaced with the World Model, which stores map and localization data, including the exit location once found. The Planning component takes care of decision making and control planning, including path finding and obstacle avoidance. The actuation component will actuate the holonomic base in order to carry out the movement plan.

Implementation

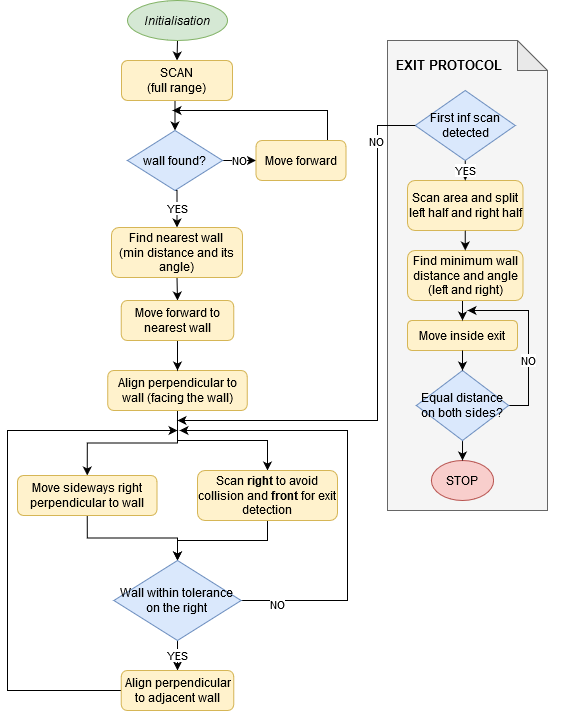

The overall software behavior is divided in five clearly distinguished phases. During each phase all actions lead to one specific goal and when that goal is reached, a transition is made towards the next phase. The overall program logic can be seen in Figure 6.

Initialization

This is the first phase of the robot as soon as the software is run. All the inputs and outputs of the robot are initialized and checked, during this phase. Moreover, all the required variables in the software are set to their correct values. At the end of the initialization phase the software is set and ready to perform the desired tasks. The first task of the robot is to find the wall and align with it.

Find wall and align with wall

When the robot is initialized in its environment, the first thing that the robot will do is find the wall that is the closest to him. The way that this has been implemented is by first scanning all the distances over a certain angle using the LRF. During this scan, the robot will store the value that has the shortest distance, along with the corresponding angle. These two values are returned, and the robot will check whether this value is in front of him or not. If the shortest distance is not in front of him, then the robot will rotate over the shortest angle, until it faces the shortest distance between him and the wall. Once the robot is facing the shortest distance, it will start moving towards it until the shortest distance value passes a given minimum value. This is so that the robot does not collide with the object in front of him. During this procedure, the robot is constantly updating its laser data in order to obtain the most recent version of its surroundings and checking whether it is still approaching the direction of the shortest distance. This could be used for example later in the project, when dealing with dynamic objects. If it happens that the robot does not see any objects around him, i.e., all registered distances are equal, the robot will start moving forward, until it registers a different minimum distance, through which it will start the procedure of moving towards this direction. In the end, the robot will be a certain distance away from the wall and facing it. From this state, it moves to the next state.

Follow the wall and lookout for corners

After the robot has aligned itself perpendicular to the wall, it follows the follow the wall routine. The robot moves right while facing the wall and keeping a minimum threshold to the wall. If the the robot is at a distance less than minimum threshold range value, it moves backwards till it reaches is in acceptable bounds while moving right. If the robot is at a distance more than the maximum threshold range value, it moves a little forward while following the wall. The robot while doing this also keeps a check on its right for detection of a corner. The corner is detected if the the right laser beam detects an obstruction at a distance of the threshold. If corner detected, the robot stops and rotates clockwise till it aligns itself perpendicular to the next wall. One aligned, it follows the routine till exit is detected.

Exit detection

As stated above, the robot will maintain its forward distance to the wall to be between two limits. To detect the exit, a similar principle is used. If the robot finds its forward distance to be somewhat greater than the upper threshold, it will drive forward to compensate. However, if it detects its forward distance to suddenly be vastly greater than the upper threshold (by having crossed a second, greater threshold), it knows it has detected an exit.

Exit Alignment

@Gerben add your part here

Move in corridor

After aligning to the corridor, the robot will find one of the walls of the corridor and move along it.

Back-up

A back-up version of the robot controller has also been made. This back-up operates on the same principle (drive to the right until the exit is reached), but works in a much more simple fashion. Most of the states of the controller have been removed. Most notably, the robot can no longer "know" it has reached the exit. Instead, the robot has been given the option to self-align: if the closest distance to the wall is not directly in front of the robot (within a small tolerance), the robot will rotate until the wall is in front again. This principle also applies to corners, and as a consequence, the robot is able to turn around outward-facing corners. This is sufficient to carry the robot out of the escape room.

Execution

HOSPITAL CHALLENGE

Requirements and Specifications