PRE2018 3 Group16: Difference between revisions

| Line 447: | Line 447: | ||

[[File:Irrigation_costs_combined_table.png|900px|thumb|left|table 5]] | [[File:Irrigation_costs_combined_table.png|900px|thumb|left|table 5]] | ||

== Soil measurement devices == | == Soil measurement devices == | ||

Revision as of 12:15, 27 March 2019

Group members

| Edwin Steenkamer | 1006712 |

| Sjir Schielen | 1024154 |

| Thijs Conner | 1011148 |

| Tobin van den Hurk | 1009573 |

| Tom Verberk | 1016472 |

Introduction

The environmental challenges in Africa, which are only increasing in difficulty due to, among other factors, the consequences of global warming, are a real concern for the food production in this area. As a consequence, independent and poor small-scale farmers and small villages living of agriculture across Africa may struggle to sustain themselves. The agricultural sector in Sub-Saharan Africa is dealt a bad hand, considering the suboptimal conditions they have to deal with in this arid and drought-prone land. Since the agricultral sector makes up a large part of the Sub-Saharan labor market, every improvement made in this area will benefit a substantial part of the African population. However, the lack of proper education and the misuse of technology in these agricultural areas hinders the development of efficient food production. This problem knows many sides and solving all of these in one solution is virtually impossible.

Problem specification

While researching the exact problems, it has become apparent that the lack of water is a clear limiting factor in agriculture. Even though this does not come completely out of the blue, only after some research it became apparent that there is still a lot of room for improvement regarding water usage, especially for small-scale farmers. Therefore, we will focus on these kind of farmers. Since the climate varies heavily across the enormous continent which is Africa, the solution presented on this wiki focuses primarily on the country Botswana, a country in which a large section of farmers is small-scale and irrigation is a not well known technology. In Botswana the dry season and rainy season are lengthy and significant. This allows for collecting water when rain is abundant, and storing it untill it is needed in the more dry parts of the year. This in turn would decrease the amount of failed harvest caused by drought, allow for a greater variety in crops, and shift the farmers' focus from trying to survive even if a harvest fails to maximizing harvest all year long instead.

Approach

For this project, an initial literature study is required. By exploring the subject in a top-down fashion, the main focus of the project can be adjusted. In other words, gathering information on the broad topic of farming in sub-optimal conditions in general, allows for the project to delve deeper into the aspects of farming deemed most important. Using this method instead of starting with a focus on a specific problem regarding farming, eliminates the threat of discovering this specific problem is not as interesting or important as expected. Another benefit of starting with an extensive research on the state-of-the-art, is that the amount of assumptions is expected to be limited. This allows for more grounded arguments and reasoning as to why certain aspects are deemed more important.

This led to the opinion that the most effective way of improving agricultural gains is by conquering extended periods of drought. Transporting water from more humid areas is a possibility, but unfavorable due to transportation costs and limited availlability of water even in those more humid parts. Therefore, a means to improve the usage of the already availlable water during the rain seasons is more desirable.

The process of increasing water efficiency has 3 distinctive steps, which all need to be looked at individually first: collection, storage and distribution. Then, these parts need to be combined into one construction, centered around the user.

Deliverables

This project will ultimately consist of 3 deliverables, a literature study, a system design and a model. The project’s literature study will focus on the following topics: Sub-Saharan african agriculture, agriculture in Botswana, farmers in Botswana, existing alternative solutions to our problem and the individual components of our system.

Furthermore, a system will be designed to solve the problem given in our approach. This system will consist of three parts: a water catchment part, a water storage part and an irrigation part. Finally, a model will be made to verify the effectiveness of our system.

State-of-the-art

Agriculture is one of the biggest sectors we have in this world. Without food, we would not be able to live on this planet. Since this project focuses on small-scale farmers, the research is divided into different subjects deemed most important in getting a better picture of how small-scale farmers could be assisted. The first section will briefly touch on some of the core aspects of Sub-Saharan agriculture, after which a more in-depth state of the art will be presented on drought prevention techniques such as water collection, irrigation, and water storage.

Sub-Saharan African agriculture

The best ways to provide energy to systems implemented on a farm.

Energy production is vital to the development of Africa. Currently only an estimated 31% of the whole population in Sub-Saharan Africa has access to electricity, whereas about 80% of the energy consumption is still accounted for by traditional biomass energy. An increase in energy consumption is needed for Sub-Saharan Africa to develop. Climate changes poses a threat to the already vulnerable agricultural sector of Sub-Saharan Africa. Energy sources other than biomass with low carbon emissions are needed to improve the agriculture in these fragile environments. The lack of funding is the major problem and as the globe warms, time is of the essence [15]. Sub-Saharan Africa offers conditions that may be beneficial for energy production. The area receives solar radiation with an intensity that is among the highest on the planet. The now commercially available technology concentrating solar power (CSP) is a candidate technology which, with the right investments, can generate a lot of power in North Africa [32]. There are possibilities for large scale energy production in this area, which may benefit other parts of the world as well, but the main problem remains funding.

How does livestock and vegetation affect (and benefit) each other.

There are theoretical benefits to the interaction between crops and livestock. Livestock can be used for physical labour on the land and manure can fertilize the soil. In Sub-Saharan Africa, however, this concept is not well integrated. The concept is not applied through the availability of information, but through environmental differences [25]. Another theory suggests that households in Sub-Saharan Africa use livestock as a buffer stock to insulate their consumption from income fluctuations. As the problems of engaging in rainfed agriculture are inevitable in a drought-prone area, it is often assumed that livestock form a buffer for the dry season. Results indicate that livestock transactions play less of a consumption smoothing role than often assumed. One can conclude that there are better ways to manage agriculture [13]. Another problem is that most livestock was introduced to Africa through trade with Europe and the Middle-East, hence the animals are less adapted to the extreme conditions [19]. The use of different animals as livestock may benefit the harsh areas. It is, however, important to analyze how effective species are with water. A way to do this is by the concept of livestock water productivity (LWP) [10]. LWP is defined as the ratio between the sum of all net livestock products and services and the sum of all depleted/ degraded water. It assigns a numerical value with the unit dollar per cubic meter of water. By using this concept a numerical problem can be formulated that allows optimization. This approach does, however, rely on available information and it is estimate based.

Methods of Soil sampling and analysis.

Soil consists of many different kind of elements which can have an effect on the crop growth. To measure these elements soil sampling and analysis has to be done. Different analysis methods are needed for different elements such as chemical, biological, organic matter, physical and water analyses [6] [17] [24]. The effectiveness of these tests, for a low budget and uneducated farmer, are dependant on the ease of use and low-cost equipment. Investigating new and improved ideas of how to measure specific elements may help in choosing the right tests [33] [35] [20]. In case of putting these sensors on a robot an assessment also has to be made about the effectiveness of different kind of agricultural robots [26].

Soil analysis and degradation.

Not just the drought, but rather soil degradation combined with the rapid increase in population in developing areas such as Sub-Saharan Africa, will pose a major threat for food production in the near future[31]. To combat this degradation, adequate measures should be applied. Measuring the soil composition at different locations in a single field, will give more insight in the so-called micro-variabilities[5]. These measurements can be used to more efficiently water, manure, and weed crops, which has proven to be more effective than simply introducing new techniques or machinery[4].

Obstacles for small scale farmers in poor countries.

The demand for food products for export markets is increasing severely in developing countries . But most of the small-scale farmers in those countries have difficulties profiting from this increasing demand. This article[12] gives a few problems small-scale farmers are having including pesticide use and poor storage facilities. To improve these farmers need technology, but to choose which technology is needed and then actually integrate this technology is easier said than done[14]. The conclusion is that a combination of lack of knowledge, resources, and technology is the reason small-scale farmers are having trouble to increase their production and make their farm more efficient[9].

Technology that is used in agriculture in industrialized countries.

Nowadays technology is having a massive impact on agriculture, especially in industrialized countries. A great example of this is precision farming. This type of farming uses wireless network systems (WNSs) to make sure every plant or animal gets a very precise treatment[7]. Other examples of smart farming is given in these articles[16][18]. The first article describes a system that can measure physical parameters of the soil that play a vital role in farming activities and the second article describes a system that can reduce the amount of water used by implementing a soil moisture sensor to automate the water sprinkler.

A more directed focus

The problems that Sub-Saharan Africa faces in the sector of agriculture are too broad to be solved in one solution. In an attempt to solve a smaller aspect of the problem, the following specifications are made. The focus lies on small-scale farmers in Botswana. Botswana is a country that lies in Sub-Saharan Africa. The system that will be designed is aimed to help water management for small-scal farmers in Botswana. To sketch the specific situation the state of the art below is focussed on Botswana.

Drought

Drought is considered to be one of the most complex natural hazards, as it affects more people than any other natural hazard, yet for all the damage it causes it receives relatively little attention. Of all natural hazards, it is the most difficult to predict and it can last longer than any other. Currently, there are many factors that cause a lack in preparedness by people living in drought-prone areas. One of these factors is the lack of a universally accepted definition of the word drought. Various scientific disciplines, such as meteorology, agriculture, hydrology and socio-economy, have different definitions. Here, the focus lies on the agricultural definition and the meteorological definition. The agricultural definition refers to a period of time in which the amount of water in the soil no longer meets the requirements of the crop. Meteorological drought is defined as the amount of precipitation being a certain percentage lower than usual for a prolonged period of time[9].

The Botswanan situation

Precipitation

Botswana is a typical semi-arid country: average annual evapotranspiration (sum of evaporation and transpiration by vegetation) exceeds the annual rainfall by a factor 3-4 in the north-east to 8-10 in the south-west. Seasonal rainfall and its distribution are very irregular and dry periods of more than one month are common. The country’s agricultural sector is built around the rainy season. The figure below shows the average rainfall from recorded data between 1925 and 1984, the average Penman potential evapotranspiration (PET) and theoretical day length for Gaborone[42].

What stands out is that rainfall is less than PET all year round. This means that the shortage of water is a problem not only in the dry season but also in the wet season. Keep in mind that the figure shows average data. The fluctuations in precipitation are unpredictable and it is not uncommon for a dry month to appear in the rainy season.

To manage agriculture, the rainy season is divided in three periods which roughly coincide the farming cycle. The early rainy season spans from October to December and is meant for soil preparation, planting and the first stages of crop development. The mid rainy season lasts from January to February. This period contains fast vegetative growth and has the highest water requirements. The late rainy season concludes the rainy season in the months March and April. In the late rainy season, the final stages of crop development occur and the water requirement declines[42] [43].

In practice, the farmers face challenges. First of all, the PET is higher than the amount of rainfall all year round. This means that even in the rainy season there is not enough water to support all biomass. Second, the fluctuations in arbitrary dry periods in the rainy season cause unpredictable risks in the cycle. The farmer needs enough time for his crops to grow while there is water available. Yet, if a dry month occurs it can cause the harvest to fail without enough time left in the rainy season for the farmer to replant. Even if the crops survive, the lack of water will cause less biomass to be produced.

A system that collects, stores and smartly irrigates water can be a solution. Since annual evapotranspiration exceeds annual rainfall, a smart way of collecting, storing and using the water is necessary. By collecting more water, a part of the water that would otherwise evaporate can be used. By improved storage, the farmer has a water supply that can act as a buffer in potential arbitrary dry months. If the water is used in a more effective way, which is aimed to be optimized by the use of technology, less water is lost in watering crops.

Alternative water sources

Less than 0.01% of agricultural land is artificially irrigated[66]. That means that 99,99% of the land relies solely on precipitation for watering the crops. The table below shows that Botswana has a low need for water for irrigation purposes (implying a higher need for precipitation) compared to other Southern African countries, stressing again why Botswana could be a prime benefactor of rainwater irrigation.

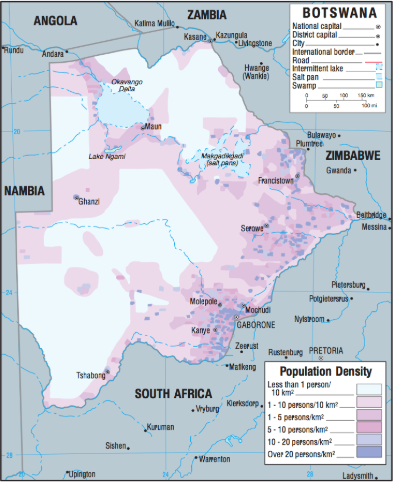

The reason behind the rarity of artificial irrigation, can be explained by the lack of availlable surface water[67]. The most obvious culprit is of course the dry climate, causing most of the surface water to evaporate. Another problem is Botswana's low and erratic run-off. This means that the excess precipitation will unpredictably make its way over the surface, preventing rivers or lakes from forming. This has a direct result on the availlability of dam sites. The poor run-off and therefore lack of lakes, rule out dams as a viable option to hold the freshwater. Important sources of surface water, are the Okavango river basin, located in North-West Botswana, and the Limpopo river basin on the far east. A drawback of these basins, is that all of their rivers are ephemeral, meaning they only last for a short time after rainfall and then disappear again. This means that the water in these basins has to be accessed directly, posing a problem for Botswanan population not living in close proximity to the basins. Another complication, is that all basins and their rivers have to be shared between neighbourig countries. The rivers run through multiple countries, which all depend heavily on the water from these rivers[67].

On the population map on the right, a large portion the Okavango river basin and the rivers from the Limpodo river basin can be clearly identified by the high population density. Note that the Makgadikgadi Pans is not a lake, but a wetland. This means that periodically, most often during the rain season, this area is swamp-like untill it dries up again[67].

In the present, Botswana has resorted to frequenter use of groundwater, surface water's more reliable counterpart. The foremost reason against the use of groundwater, is the expensive extraction costs. On the long term, however, a more problematic issue arises. At the current extraction rate, groundwater exceeds its replenish rate, which is often referred to as 'groundwater mining'[67]. Another problem with ground water in Botswana, is that Botswanan ground water is high in salinity. These high levels of salt make the water undesirable for crop growth. Maïze in particular is vulnerable to salt[70].

Cereal harvest

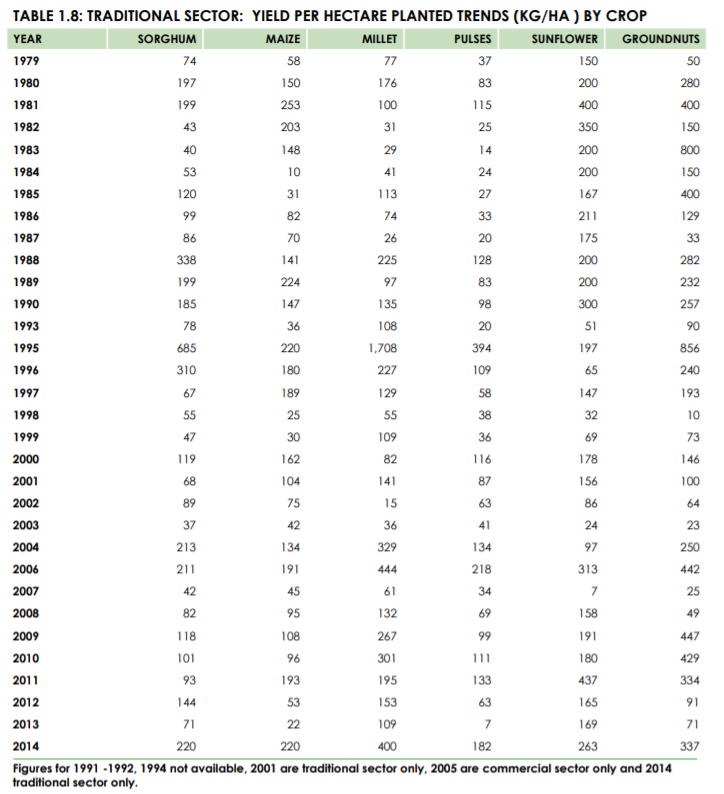

In general, cereal yield includes wheat, rice, maize, barley, oats, rye, millet, sorghum, buckwheat, and mixed grains. Different sources report average yields between 200[60] and 450[61] kilograms per hectare in 2014. This wide range of results can be accredited to the vast difference in efficiency between traditional farms and commercial farms, local differences and a margin of error. Yield can differ greatly from year to year, causing even more complexity when trying to compute an all-time average. On traditional farms, 2014 resulted in 260% more yield than 2013, causing both 2014 and 2013 to be on either end of the production spectrum for traditional farming, with 2014 on the high end and 2013 on the low end[62]. All these factors considered, an average yield of 200kg/ha per year will be adopted throughout this paper.

Using the fact that the average farmer in Botswana owns 0.1806 hectares of arable land[63], an estimate to average production can me made. As cereal and groundnuts account for almost all crops farmed in Botswana, the 200kg/ha per year derived earlier will be used here. This concludes that on average a farmer produces 36,12kg of cereals per year. Something worth mentioning, is that the local yield only accounts for 10% of Botswana's required cereals, as 90% of cereals used for domestic use are imported[64].

Farmer's current efforts of dealing with existing drought

Drought can be divided into two parts: predictable drought and unpredictable drought. As described in the section ‘The Botswanan situation’, there is a rainy season and a dry season. Predictable drought is the dry season. Unpredictable droughts are droughts that occur in the rainy season or predictable droughts that last longer than usual. Predictable droughts that last longer than usual can be specified as prolonged dry seasons.

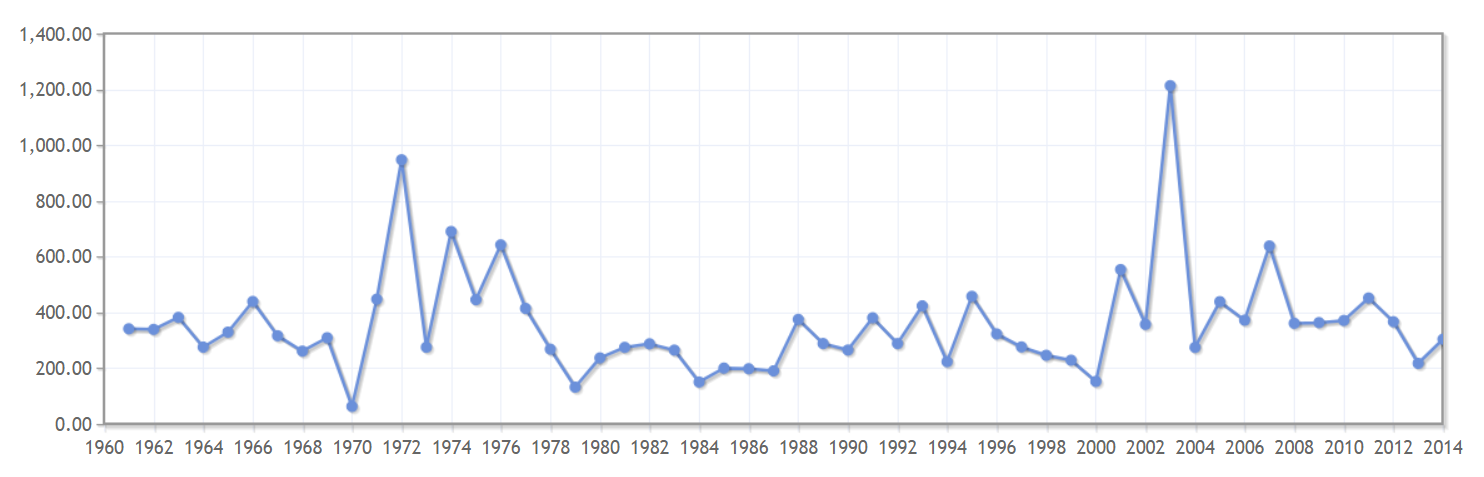

Farmers in Botswana use the farming cycle and the division of the rainy season into the early, mid and late sections as a way of dealing with the predictable droughts. These droughts are still a problem, as it pressures the agricultural sector into a critical period in which it must produce. Predictable droughts, however, form less of a problem than unpredictable droughts, as data shows that years, in which there was no unpredictable drought in the rainy season, produce a decent harvest. Data published by Botswana’s Ministry of Agriculture Department of Research, Statistics and Policy Development [45] show the crop yield in kilogram per hectare per year as can be seen in the figure below.

The Seven Year-Drought consisted of a prolonged dry season and dry months in the rainy season[46]. The Seven Year-Drought started in 1981 and ended in 1987. As the data below shows, there is a steady decline in crop yields after 1981 as it reaches an all time low in 1984. After the drought, in 1988, the food production is back to average. Normal years, or years with a predictable drought, have an average food production, hence the problem lies in unpredictable droughts.

Unpredictable droughts, such as the Seven Year-Drought, are the major problem. As the figure shows, after 1981 crop yields steadily decreased. Due to government effort and water reserves that are used in case of drought, the crop yields did not plummet in one year, but they decreased steadily. The water reserves are used for large scale farmers to assure a maximum crop yield given the circumstances. This means that small scale independent farmers are the real victims of a drought. It rarely is the case that a small scale independent farmer has access to water reserves or is supplied with water by the government. As of now, their best efforts are in managing the water they have as effective as they can. Though, if there is not enough, there is nothing they can do.

Opportunities in Botswana

Botswana is in many ways seen as a success story in Africa. As a developing country it has had the highest economic growth in the world. Now, the country is ranked fifth in the list of GDP per capita of African countries. In 2013, Fosu argued that after gaining independence from the British Empire in 1966, it was one of the poorest countries in the world (pp. 187-189)[12]. The country found great economic growth due to the following reasons. The country has known free and fair democratic elections ever since its independence. “Botswana has had no coups, no political instability, no civil wars, no threats of secession and excellent, dedicated, uncorrupt leadership” (pp. 188). Another driver of the economy is the country’s mining activities. Approximately 90 percent of Botswana’s export products are categorized under gems and precious metals. Botswana also invested in tourism as a sustainable source of income.

Although it may seem like Botswana is a country that does not need help, the country still faces the same problems as other poor Sub-Saharan African countries. “There is a great deal of poverty in rural areas, inequality is high (though falling), the economy has been unable to diversify, and more important there is a huge rate of HIV infection that the government is now fighting” (pp. 188)[47]. Small scale independent farmers are still struggling to make a living. When harvests fail, Botswana has the money to import food from other countries (mainly South Africa), but small scale independent farmers in poor rural areas are left with nothing.

There may lie an opportunity here, as the country still faces the problem of food production in droughts and poverty still exists in rural areas. If an automated system can improve the country’s food production, it will yield great benefits for Botswana. Through investing in a system that collects, stores and irrigates water automatically, small scale farmers have more certainty in their food production. This ultimately leads to a decrease in the inequality between the poor and the rich and it makes Botswana less dependable on food imports.

Users

The users of the technology can be divided into primary, secondary and tertiary users. The primary users are small based farmers that live in conditions which are suboptimal for agriculture. These conditions are mainly found in drought-prone areas of Africa, such as the areas in or around deserts. A country which stood out, was Botswana. Botswana has relatively long rain and (predicted) dry seasons, making it vulnerable to unexpected droughts. When researching the primary user group, smallscale farmers in Botswana, a surprising discovery was made. The percentage of young farmers, here categorized as being between 15 and 39, is only 10.2%. Another 38.3% was between 40 and 60 years old, with an impressive 51.0% of farmers being over 60 years of age. These percentages have been manually calculated using the data presented in Botswana’s annual agricultural survey report 2014[69], since the conclusions accompanying this data appear to be incorrectly stated in the report. Being primary users, the artifact or technology is directly aimed to be of use to this group.

Secondary users are the people in nearby villages that do not directly make use of the artifcat, but rather benefit from a more consistent food supply from the farmers that do. They benefit from the availlable food through the farmer's use of the artifact. Bigger farmer organizations (or collectives/unions) are also considered secondary users, as they benefit from higher production caused by the farmer's use of the artifact. Larger scale farmers may also use the technology, although it was intended for small scale farmers. Larger scale farmers are therefore considered secondary users.

The tertiary user is society as a whole. If food production increases it will benefit society. Society as a whole is not using the artifact, but it benefits from a more efficient use in water for agriculture through the increased production. As the artifact is aimed to increase the efficiency in the use of water, it is projected that more food becomes available. This is likely to cause economic growth in these developing areas, which makes it attractive to investors. Therefore, investors can also be seen as a tertiary user.

User Requirements

The technology requires a source of energy. As the energy infrastructure in Africa is underdeveloped to non-existent in certain areas, this forms a problem. In, for example, Sub-Saharan Africa, only an estimated 31% of all inhabitants have access to electricity [15]. Access to electricity is usually in towns or cities, which is not where the farmer has his piece of land. This means that the users require the technology to generate its own needed energy or to work on fuel.

The scarcity of water is the main reason behind this artifact. Water is very valuable in areas prone to drought and the sad reality is that it literally is a matter of life and death. Therefore the artifact must be efficient with water. This means that it should catch as much water as possible and store it while keeping losses at a minimum.

Although the technology is primarily aimed to be used for crops, it is unlikely that it will be the only use. If drought strikes and there is water available in the storage tank, people will use it for consumption. Even if it is explicitly clarified that it is no drinking water, to the people it is still better than no water at all. Therefore it is required that the storage tank keeps the water clean to a certain degree. This induces more difficulty in the design of the artifact which was not projected at first, but it does make the artifact more user oriented.

Former automation solutions have failed due to the weak state of the economy in these developing countries. Farmers live off the harvest rather than the profit they receive from selling their crops. This means that no jobs should be replaced by the artifact, which is vital for it to be adopted in the first place. The farmers will not use technology that replaces their jobs, therefore it is important that the artifact performs a task that no farmer can do. The system collects, stores and irrigates water, which are tasks that farmers cannot do themselves.

The artifact is aimed to help the farmer with water management. It is projected to perform this task autonomously, but in the end the farmer should have full control. In the case of a severe drought, if the water is required for drinking, the farmer should have access to the storage tank. Therefore the farmer should be able to intervene with the autonomous way of operation on request. The farmer should be able to understand how to interact with the artifact in the desired way. Therefore, it should be understandable. When specifying the system requirements, it should be taken into account that illiteracy rates are globally the highest in the underdeveloped parts of Africa, which is the same area in which the artifact is projected to operate.

A requirement that is applicable to all users and non-users of the artifact, is that the artifact’s greenhouse gas emissions should be as low as possible. This requirement becomes more and more important as the effects of climate change begin to show. It is especially important for the farmers in drought-prone areas as they live in areas which are expected to be heavily affected by climate change.

Assesment of possible design choices

Water collection

There are multiple possible way to gather water, some of these are better suited for the situation than others. Below the possible solutions are listed, the solutions are graded based on:

- Feasibility

- costs

- Revenue

- Space needed

- weather dependency

Below are the different criteria explained.

Feasibility

When looking at the feasibility of a solution we look at the practical and technical feasibility, in this technology invented yet and how do you transport all the needed material with bad infrastructure are questions asked when looking at the feasibility.

Cost

The costs can be seperated into two mayor categories short term costs and long term cost. Short time costs are the cost needed to buy the required materials to build the artifact, long term costs are the fixed costs that comes with the artifact.

Revenue

Revenue is measured by how much water the artifact will collect on average.

Space needed

Small based farmers often don’t have a lot of free space which is not used for farming or living. Our artifact therefore has to be space effective.

Weather dependency

As the weather is not something that can be regulated some artifacts might not work with negative weather.

Dig a Well

The first proposed solution is the simple solution of digging a well. If you have a well present at your farm, you are close to water everytime.

Feasibility

As has been shown before LINK a well can be dug in Africa and is a good way to get some water, Wells are however highly greographicly dependent, Wells only work when there is a reservoir in the ground. These reservoir however are very rare. Meaning that a well cannot be build at any place.

Cost

The cost of digging a well are only short term, the only costs is building the well, besides the material for the well the digging of the hole has to be financed as well. digging a hole will have a cost ranging from 2.000 to 500.000 usd depending on the depth of the well. [57]

Revenue

The revenue of the well in depth dependent. With an average bucket of 10 liter and after installing a system which gets the water up at a speed of 1 m/s. The well will get at max capacity a yield of 36.000 liters / meter per hour. However one must be careful not to dry the well.

Required space

The well itself doesn’t take up a lot of space, only problem is that there has to be a suited space to dig the well. Meaning there has to be a reservoir present and the location has to be somewhat level.

Weather dependency

The well is only weather dependent if there are long droughts which will make the well empty.

Conclusion

If we look at the above mentioned advantages and disadvantages we clearly see that the main advantages are that it is obvious, it has been done before and it will get enough revenue too water the farm. However the main disadvantage is that a well cannot be build at any place, it has to be build above a reservoir. Also a well cannot be improved a lot. Given these two disadvantages we think that a well is not the best solution.

Automated pump

Instead of building a well we can also dig an automated pump, the pump will be smaller than a well, but more efficient.

Feasibility

As stated by the well, an automated pump will be geographically dependent. Another disadvantage with regards to the will is that a automated well needs more sophisticated equipments, which means that getting the right machines there might be a problem.

Cost

The average cost of building a automated well will lie around 8000 usd. Which is way less than the average well costs. [58]

Revenue

The average revenue is about 5 gallons per minute for 2 hours. This to make sure the well doesn’t dry [59]

Required space

A pump doesn’t need any space, but the position the pump will be places must depend on the terrain.

Weather dependency

The pump is only weather dependent during long droughts.

Conclusion

The main advantages of a automated pump are the relative cheap building and the relative big revenue. Big disadvantages however are that there is not a lot of technical advancement possible and that a automated pump cannot be build anywhere. Since our group of users is every small based farmer. We think this is not the best solution.

Rooftop water harvesting systems

The general idea of a rooftop water harvesting system is that all the water that falls on your rooftop will be collected and transported via pipes to water tanks. This method has reseanably low effort since most of the things needed for this system are already present.

Feasibility

This method is reasonably feasable, the farmers already have houses and there are no technical solutions needed. The only problem would be the material of the houses (the house has to have a good roof).

Cost

The only things that would cost money with this idea is a huge tank, pipes to transport the water to the tank and some sort of material to improve the roof if needed. The overal cost would therefore highly depend on the amount of water that can fit into the tank. Prices can vary from 100 euro (100 liter) till 360 euro (1000 liter).

Revenue

The revenue of the system is primarily based on the surface of the roof. Therefore we don’t expect this solution to have the revenue to support an entire farm, given the small amount of rainfall.

Required space

For this artifact is only space needed for the watering tank.

Weather dependency

This artifact is highly weather dependent, if the weather is bad, this artifact will have a lower revenue than expected, when the weather is good the revenue will increase.

Conclusion

The main advantages of this system is that it relatively low cost. Since the only extra things needed are some pipes and a tank. Another benefit is that it is easy to setup. However the main advantage is that the revenue most likely will not be enough for the entire farm. Therefore we don't think this is the best solution.

Government-built water infrastructure

Another possibility would be for the government of the country to make a countrywide water network. This would not solve the water problem for one single farmer, but for farmers across the country.

Feasibility

Although this solution seems by far like the best one. The project is not really feasible. Some farms are a long distance separated from each other. Besides that, the land is not always suited to lay pipelines and most countries lack the technical support and knowledge to pull of such a big project.

Cost

the costs of this project would quickly go up into the billions. Although precise calculations have never been made, many expect the costs to far outweigh the benefits that will be gained from such a system.

Revenue

The revenue of this project would be better than all the other artifacts. This project would solve all the watering problems as water can get easily transported from areas where there is water.

Required space

The space needed at the farm is close to none, since all the pipes would most likely be beneath the ground. If this is not the case than the pipes will take up quite a lot of space.

Weather dependency

This artifact is no weather dependent as water can get shipped from other places.

Conclusion

The main advantage of this system is it's revenue, when such a system is in place there will most likely never be any water problems anymore. Huge disadvantage however is the huge costs that come with this project. Therefore we don't think this is the solution.

Water gathering robots

As the normal way for farmers at this moment is to walk to a well and get water, we could automate this process by making a robot who gets water out of a well on its own.

Feasibility

Technically speaking there are already robots who can travel a certain route. There is also enough ways for the robot to get the certain energy and the robot wouldn't be big. So getting the robot there also wouldn't be a big problem.

Cost

The cost of this would only be the installation the robot, after that the costs would be the power the robot uses, but this can be helped if the robot would get a solar power supply.

Revenue

The revenue of this artifact would be the same as it is now for a human to get water. It would therefore not increase the revenue, it would however relieve the farmer of this hazardous job.

Required space

The only space needed for this artifact is space to store the robot.

Weather dependency

This artifact doesn't have a lot of weather dependency. However when wells are dried this artifact might need reprogramming.

Conclusion

The main advantage of a water gathering robot is that it does the work cheap and good. However we plan to increase the amount of water of the farmer, not the way he gets his water, therefore this artifact is not suited for our idea.

Collection canvas

Feasibility

A construction to keep the sheet in place is required. This is easily achieved by connecting the sheet to wooden poles, where the height of these poles is variable

Cost

A 10m x 12m sheet costs between 60 and 80 euros, depending on the thickness of the sheet chosen. If the sheet is placed over the crops as described in the ‘space needed’ section, a mechanism should be created to roll the sheet in and out. When decided that the farmer can make use of a semi-automatic, manual mechanism, costs are expected to remain low when using a pulley system. An automated sheet, however, can become rather expensive. As an example, fully automatic pool covers for small pools cost around 2500USD. A benefit of the fully automatic method is the option to add a rain sensor for opening and closing based on weather conditions.

Revenue

The revenue of this method depends heavily on precipitation. If the construction of the sheet is sufficiently stable, it would be able to collect most if not all rainfall in the area covered by the sheet. No water should remain on the sheet, as this water would evaporate and go to waste.

Required space

2 different methods of placing the sheet are possible. The first method is placing the sheet on unused areas, allowing for the sheet to be close to the ground. The second, more efficient method would be to place the sail over the crops, and create a mechanism that can roll out the sheet when it rains and roll it back in as it clears up.

Weather dependency

The sheet collects water only when it precipitates, which varies heavily across Africa Northern Africa remains dry for most of the year, except for the coastal areas which see the most rain between November and March. Southern Africa has half a year of drought, from April to October, and half a year of rain, November to March. In particular, Botswana seems to have these clear distinctions.

Conclusion

Although this solution seems to have it's disadvantages at the start, it looks like this is the best solution for your everyday smallbased farmer in botswana

Water storage

Preserving water

A large array of water storage options is already used in Africa, some of these systems are integrated with the water catchment system such as the rock catchment system, the Sand or sub-surface dams or groundwater storage. Other storage options are open reservoirs such as ponds or dams, underground tanks or above ground tanks.

The commonly used traditional open rainwater ponds (or other open air water storage systems) have a short lifespan after the rainy seasons, as the water is lost via seepage and evaporation. Seepage is a major problem in water storage in earthen reservoirs, accounting for losses up to 69% of the harvested water [52].

Unlike the traditional open ponds, the recently developed cisterns in different parts of SSA are covered to reduce evaporation losses, and their walls are plastered to avoid seepage losses. The most important materials for construction and covering of these types of rainwater storage tank include cement, clay, clay–cement, lime–clay or lime–cement and polythene sheets. The cost of these materials makes macro-catchment rainwater harvesting systems relatively expensive and poor farmers are discouraged from investing in them [51].

Underground or above-ground tanks are often used in combination with rooftop collected rainwater in sub saharan africa [50]. Some of these tanks have the advantage that they are closed. This prevents both evaporation of the water inside the tank and helps prevent water caused diseases such as malaria to develop [48]. In the rush to develop water harvesting and storage for climate change adaptation, too little thought is given to the possible public health implications. Poorly planned and managed water storage will have adverse implications for public health, which can undermine the sustainability of the interventions [49].

Stagnant VS. Moving

It has been shown that mismanagement of irrigation resulting in the formation of stagnant pools lead to the transmission of water-related diseases such as schistosomiasis, malaria and typhoid fever [36]. Moreover, under the condition of stagnant water, cyanotoxins can reach high concentrations in water and might represent health and ecological risks [37]. Furthermore, stagnant water has a decreased oxygen content which is disadvantageous for crop growth. It has been found that aeration of crops can increase the yield by up to 96% [38] [39] [40]

Irrigation

Defining suitable irrigation

In irrigation, the notion of ‘more equals better’ is everything but true. Irrigation requires careful use of water, as opposed to as much water as possible. It should be obvious that using too little water is an absolute waste, as the crop still consumes this water until it dries out before reaching the harvestable stage. Flooding the crops with water, however, is even more harmful. High amounts of water prevent aeration, leach important nutrients from the soil and increase salinization. Additionally, more water evaporates as the crops are unable to absorb the water in time. This project requires a form of irrigation which will keep the ground moisture enough to prevent water stress, but also prevent the moisture from being too high and causing oxygen stress at all times. The moisture level should therefore be as continuous as possible.

For maize specifically, we are looking at an average root depth of about 50 centimeters. In the picture below we can see that 70% of the extracted water, is extracted from the 25 centimeters closest to the surface. It is therefore important to use a method of irrigation which effectively waters these parts of the root.

Types of Irrigation

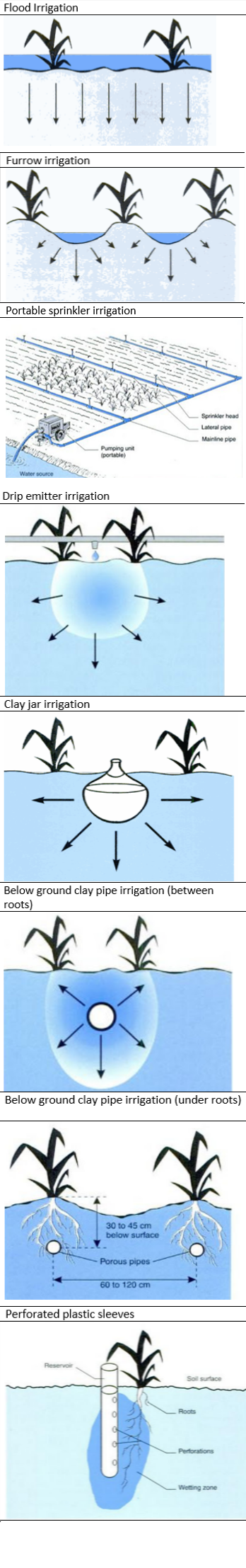

Different types of irrigation exist, to pick best type of irrigation for our user group these irrigation types will be compared. In the figure below some of these irrigation types are shown, to give a better understanding of these irrigation sorts. These irrigation types can be classified in four distinct groups: flood irrigation, sprinkle irrigation, drip irrigation and subsurface irrigation. The latter poses some alternative options for some of the other groups. All these groups have their advantages and disadvantages. To compare these irrigation systems to the requirements of our users, each of these irrigation systems will be evaluated to choose the most effective one for our users.

Flood irrigation

Flood irrigation is a classical method of irrigation, which consists of flooding the land to some depth with a large volume of water so as to saturate the soil completely, then waiting some days or weeks until the moisture stored in the soil is nearly depleted before flooding the land once again. This type of irrigation requires a soil with a high moisture storage capacity to store the water. If water is plenty this is one of the easiest ways of irrigating the farmable land, but it does come with some downsides. The excessive amount of water on the plants can cause oxygen stress and the optimization of soil moisture is difficult to achieve. Furthermore, it results in considerable runoff and evaporation. An improved version of flood irrigation is furrow irrigation, here channels are made between the rows of crops to improve the water management. This has the benefit of not “drowning” the plant which causes a lower oxygen stress and having a lower runoff.

Sprinkle irrigation

This method is based on spraying water into the air and allowing it to fall on to the plants and soil as simulated rainfall. For soils with a low moisture storage capacity or in arid climates with high evaporation this type of irrigation is better suited than flood irrigation. However, it also has some downsides, the water which is not directly absorbed by the soil or plant, has a high chance of evaporating in arid climates. Salt-scorching may be a consequence of this water evaporation. When there is a high evaporation the salt which is not evaporated stays on the surface and can cause a high soil salinity, if there is not enough water to wash this salt away. For crops like maize which are moderately sensitive to salinity this can have quite a large negative consequences to the crop yield.

Drip irrigation

Drip irrigation is based on dripping water on to a fraction of the ground surface so as to infiltrate it into the root zone. As the name suggests, drip irrigation is irrigating a field by having water fall drop by drop onto the surface to be irrigated. This method of irrigation avoids some of the issues present in other on-surface techniques if implemented correctly. So long as the rate of application of water on the soil, or in other terms the drip rate of the water, does not exceed the soil’s potential intake, no water will remain on the surface. This greatly reduces loss of water due to evaporation or and prevents water from flowing over the surface to other plants or away from the field entirely.

This type of irrigation works by making use of the high level of friction of water attempting to pass through a narrow opening. The tubing through which the water flows contains orifices, called emitters,cause the water to drip out of the tubing at a continuous rate at a low pressure, as opposed to the jets of water caused by sprinkle irrigation. Commercial emitters have a discharge rate of either 2, 4 or 8 litres per hour. To manage the timing of the drip irrigation, valves are used. These can either be manually operated, or set to automatically shut or open based on the volume of water that needs to be discharged.

An important drawback of drip irrigation is that once installed it needs constant supervision, as the tubes and emitters are prone to clogging or mechanical damage. Spare parts need to be at the ready at all times, and some expertise on the system is required to perform maintenance on it. Although drip irrigation is not yet adopted by many, a few farmers who have, have expressed their concerns with drip irrigation[41] which may explain as to way drip irrigation is not adopted more widespread. They have made it clear that if this form of irrigation is to benefit them, attention must be paid to educating the farmers on how to perform maintenance and how to make repairs to the system. Additionally, farmers also inquired the use of complementary technologies alongside drip irrigation, which makes it a great candidate for this current project.

The lateral tubes, the tubing that contain the emitters, can be spaced arbitrarily from each other. If crops are grown in rows within close proximity of one another, costs can be reduced by skipping every other row of crops or by placing the tube in the middle between rows, as to irrigate two rows with a single lateral tube.

The capital investment cost of drip irrigation systems are relatively high because large quantities of pipes, tubes emitters and ancillary devices are necessary to control the precise delivery of water to specific sites in the field. Moreover, since standard drip-emitter orifices are narrow, expensive filtration equipment is necessary to prevent clogging. Hence drip systems tend to be more expensive, at least initially, than surface irrigation. Drip systems may prove to be economically justifiable in the long run if they can indeed prevent the waste of water and the degradation of land that is so frequent under traditional irrigation.

Subsurface irrigation

This last method is a way to introduce the water directly into the root zone by means of porous receptacles or by subsurface drip irrigation. One of the oldest irrigation methods is clay jar irrigation. This method consists of placing porous clay jars in shallow pits. Water is poured into jars either by hand or by hose and slowly passes through the clay. A newer version of this technique is the below ground clay pipe, designed to spread water along a continuous pipe in the soil, rather than at discrete locations using pots. This pipe can be placed between rows of plants if these are close to each other or directly under the roots if they are further apart. The perforated plastic sleeve method is an interesting variant on the subsurface clay irrigation, where a perforated plastic sheet is used to irrigate the root zone. This has the advantage that it is very low in cost. However, if a soft plastic is used, it cannot maintain its shape and has to be filled with sand, which lowers the volume of water it can hold. Subsurface drip irrigation is a more sophisticated way of irrigating. This type of irrigation uses plastic perforated tubes below ground to deliver the water directly into the root zone. The amount of water which is delivered to the root zone can be controlled by the changing the pressure in the plastic tubing. This has the advantage that the water will not evaporate on the surface and that the amount of water feeded to the root zone can be controlled precisely. However, maintenance is a big issue for this kind of system since the pipes are not easily accessible.

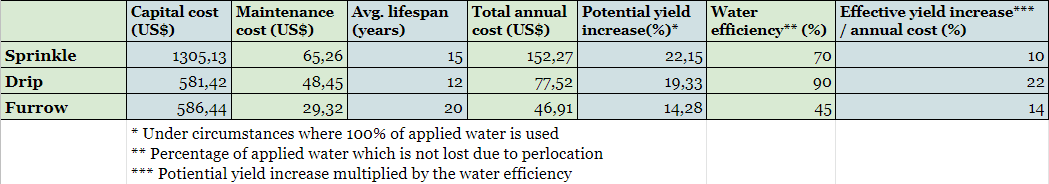

Cost efficiency analysis

Below is a table which contains the three most common types of irrigation: Sprinkler irrigation, furrow irrigation, and drip irrigation. This table lists an overview of mean values on various topics, which all contribute to a concluding effectiveness. The capital cost is divided by the life expectency of the system and then summed with the maintenance cost to picture the annual expense. The total efficiency of the system is determined by the efficiency of water usage and the expected yield increase. Note that the water efficiency is only based upon the perlocation of water, which is difficult to estimate and has a large error margin. This potential inaccuracy will be compensated by the loss of water due to evaporation, which in the table below is not taken into account. Even without the consideration of evaporation, which will be a huge contributing factor in Botswana, drip irrigation proves to be the most cost effective in the long term, as can be seen in the final column of the table.

Existing Solutions

Irrigation

Many different types of irrigation exist, all these types can be divided into four different kind of categories: Rainfed farming, gravity-flow irrigation, small-manual-pump irrigation and small-motor-pump irrigation [54]. All of these kind of irrigation have their own advantages and disadvantages. In table 4 these irrigation systems are explained in some more detail.

The bucket kit is a small-scale irrigation system that is used in Kenya. The bucket is mounted on a stand, which holds it one meter above the ground. The drip lines are supplied in lengths of 15m, and for, best result, they are laid on level ground. If the drip lines go up a small slope, the bucket or drum should be placed on the highest side. The lines are laid with the emitters facing up to reduce the problem of sediment setting on the emitters [73].

There are many suppliers of different commercial drip systems in Kenya. The majority of existing drip lines are designed for high-pressure systems. There are a few specifically designed low-head drip lines. Two common problems experienced by farmers using low-head drip systems are uneven water distribution, especially on sloping land, which can drastically affect yields due to under-irrigation of some plants and over-irrigation of others; and the tendency of emitters to clog [73].

The cost of these systems differ per supplier and can be as cheap ($0.18) per meter. More information on the cost and different kind of drip kits can be found in the following table.

(Subsurface) drip irrigation can reliably provide an increased yield and water use efficiency. Some difficulties in adopting this technology have been expressed by the few farmers who adopted it in sub saharan africa. The main recommendations for being able to have a successful adoption of this technology is, according to the farmers: (1) Redesign drip system to help prevent common problems (2) Invest in clear education for adopter, focusing on maintenance and repairs. (3) Encourage the adoption of complementary technologies to support the function of drip systems, such as water storage, purification and delivery systems[41].

Many different types of irrigation exist, all these types can be divided into four different kind of categories: Rainfed farming, gravity-flow irrigation, small-manual-pump irrigation and small-motor-pump irrigation [54]. All of these kind of irrigation have their own advantages and disadvantages. In table 4 these irrigation systems are explained in some more detail.

The cost of irrigation systems can differs quite dramatically per project and region, in the following table a summary of the costs of irrigation projects for SSA and other regions are summarized [55]. For our research only the data from sub saharan africa is needed, which can be seen in bold. This has also been divided into the ‘’success’’ projects and the ‘’failed’’ projects. From this data it seems that the cost of these irrigation projects is highly dependant on if the project is going to succeed or not.

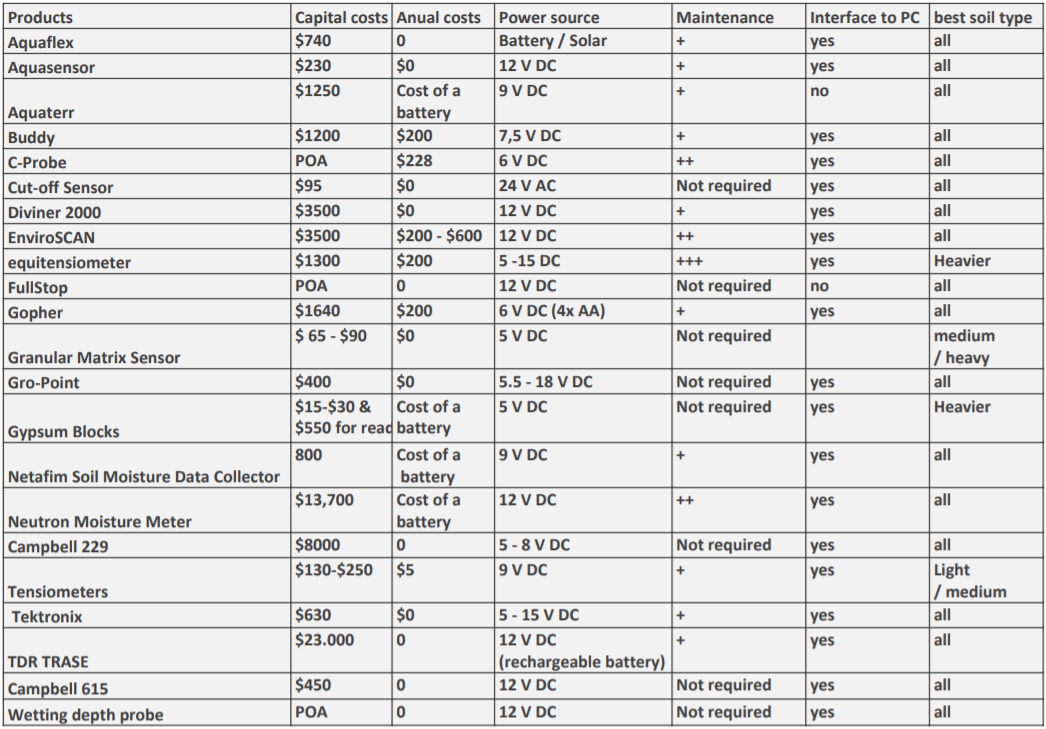

Soil measurement devices

There are many different techniques to measure the soil moisture levels. To make a better choice which one to pick, the different techniques will be compared to each other with regard to the user requirements. This is listed in the table below.

As can be seen in the table, devices may differ quite dramatically per category. To ultimately decide which device will be put in our system, these devices will be compared to our system and user requirements. The first requirement which will be looked at, is that the system should be cost effective. Some of these devices with a high capital cost (>$1000) or high annual cost ($>100) will therefore not be taken into consideration. Furthermore, the measurement device has to be able to interface to a computer, since this is necessary to make an automated system. Additionally, the measurement device should require as little maintenance as possible, since maintenance of the sensor may be difficult for the farmers. Since most of the farmland in Botswana consists of a lighter sandy soil, measurement devices that only work on medium/heavy soil are also unwanted. This list of requirements only leaves three measurement devices from the table, namely the cut-off sensor, the Gro-point and the Campbell 615.

To assess which one of these sensors would be best for our system, these sensors will be compared.

Cut-off sensor: “The cut-off sensor is a rectangular plastic card 20 x 10 cm that is covered in geotextile. Two parallel copper rods are glued to the face of the card and are connected by cables to an electronic controller. The controller is fitted in the power line to the solenoid valve. When the wetting front arrives at the cut-off sensor, the geotextile becomes wet and the electrical resistance between the two rods decreases. This change is detected by the electronics, and the power to the valve is turned off. As the soil dries the resistance increases and the sensor is reset [56].” The soil sensing volume of this sensor will thus be around the size of the sensor itself [34]. Furthermore, no calibration is necessary for this type of sensor.

Campbell 615:

“The campbell 615 consists of a 30-cm wave guide with the measurement electronics built into the probe head. the signal return from the guides causes a circuit (a bistable multivibrator) to change states between two discrete values. The output of the sensor is a frequency that reflects the number of state changes per second (or Hz). A wetter soil will cause a longer signal-return time, and will cause the 615 circuit to vibrate at a lower frequency. The wave guides can be buried for in situ readings or used as a portable probe [56].”

Furthermore, “calibration relates the output signal frequency to the volumetric water content. A calibration equation has been developed for a loamy fine sand. It has an accuracy of ± 2%. The product literature states that the same equation has been used with a range of mineral soils with an accuracy of ± 2.5%. The 615 has the disadvantage of being affected by salinity in soils of salinity > 2 dS/m. Custom re-calibration is required to optimise accuracy[56].”

This type of sensor has a soil sensing volume radius around the sensor of about 1.2 inch [34].

Gro-Point: “The Gro-Point uses the time-delay transmission concept to measure the soil dielectric. it measures a larger soil volume (4 - 5 ft3 ). and is designed for greater accuracy in both high clay and high sand soils. The Gro-Point is buried at the required position in the root zone. Furthermore, no calibration is necessary for this type of sensor [56].” [34]

From this information it seems that the Gro-point will be the best choice for a system where money is no problem. It may be more expensive then the cut-off sensor but makes up for it since it has a large measurement volume, which means less of these sensors will have to be placed. It also has the advantage that it is not a discrete sensor. The Gro-Point can give a precise value for the amount of water in the soil and not just say if there is too much or too little.

System requirements

High Level system requirements

- The system should be able to generate its own power

- The system should contain a canvas that catches all the rain that falls on its surface

- The system should contain a water tank that can store the water surplus

- The system should contain an irrigation system that can provide the crops with water in an efficient way

- The system should contain tubes that connect the canvas to the water tank and irrigation system

- The system should contain valves in the tubes that can be controlled by a software system to choose if the water is led to the water tank or the irrigation system

- The system should contain sensors that can measure the humidity of the ground

System design

The system can be divided into four parts: catching, maintaining and distributing water and the connection and control of these parts.

The first part of the system, which is aimed to catch rainwater, will exist of a canvas. This canvas is elevated and inclined at an angle. The elevation and inclination angle are needed to create a height difference which allows gravity to guide the water down one side of the canvas. The canvas should not be shaped like a plane, but rather have a V shape, which guides the water towards the middle. This allows it to be collected in one central point rather than along the edge of the canvas. To make sure that the canvas is forced into the desired shape, a certain amount of tension is needed. The material of this canvas is also an important aspect. It is straightforward that it should not be water permeable. Furthermore, it is desired that the material is sustainable and robust to ensure low maintenance costs. It is also desirable for the material to be as cheap as possible.

The second task the system has to perform is storing the water. The water storage will be done by use of a water tank. This tank should store a sufficient amount of water. In order to ensure that the water is safe to use for crops as well as consumption, attention has to be paid to how the water is stored. It should be a closed tank to prevent mosquitos or other insects using it as a breeding place. In order to prevent the growth of bacteria, the water in the tanks has to be moved around per period of time. Other important aspects are the size and the material that will be used. The material is desired to be as cheap as possible and should not be permeable. The size should be big enough for it to sustain the water supply of the farmer for x days in a drought.

The third task the system has to perform is distributing the water. This will be done by the use of an irrigation system. To create an automated irrigation system, the following factors have to be taken into account. A decision has to be made on whether tubes are placed in the soil to transport water directly to the roots or tubes are placed above the ground that transport water to the location of the plants. In order to automate the system, it needs to have a controller and sensors and actuators. The irrigation system gets an input signal from the soil measurement sensors that are in the ground. The actuators are a pump and valves which control where the water will flow. To design a system as effectively as possible, requirements, desires and constraints should be specified.

The fourth part is the connections between and control of the first three parts. To connect the canvas to the water tank tubes will be used. To connect the water tank to the irrigation system tubes are used that contain controllable valves. To control these valves a microcontroller is needed. This control system will get input from sensors that measure the humidity of the ground and actuates the valves to deliver the amount of water accordingly. Depending on the need for pressure on the water, a pump can be an additional actuator. To power the system, a source of power is needed. This can be done by a solar panel.

Storage and evaporation

Theory behind evaporation

Depending on the temperature of the body of water, there is an average energy in the particles that make up this body. Since it is an average, some particles have energies higher or lower than the average. At the surface of the body of the liquid, due to higher energies some particles move fast enough to escape from the attractive forces between the particles. This process is called evaporation.

The now airborne particles are in no connection to the body of water and can move freely through a three dimensional space in the gaseous state. The airborne particle travels through the space above the surface of the body of water. There are two situations that can be distinguished. Either the body of water is open to the air, like surface water, or the water is in a closed container, like a storage tank.

In the case of surface water, the airborne particle is not likely to collide with anything that redirects its trajectory back to the body of water. In this way, the particle is ‘lost’. This process will repeat for eventually all particles, hence all the water will evaporate.

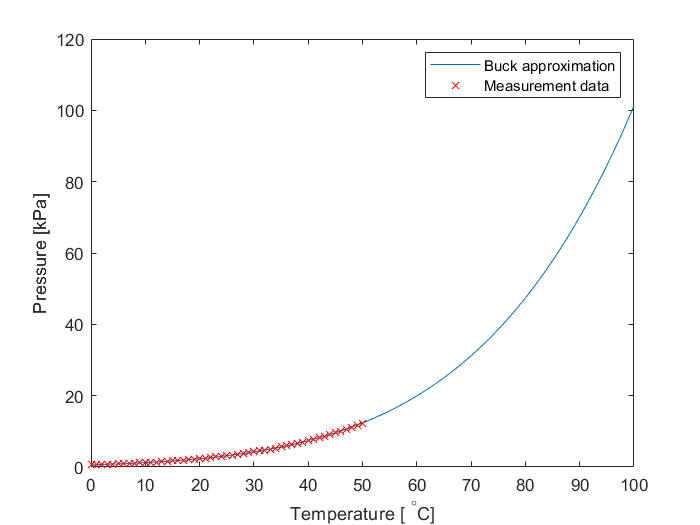

In the case of a closed container, the airborne particle can bounce off of the ceiling and walls until it eventually reaches the surface of the water again or it condensates on the walls or ceiling. As particles return to the surface, other particles are ejected again which forms an equilibrium in which the amount of returning particles is equal to the amount of ejected particles. This implies that there is a fixed number of particles in the gaseous state, which depends on the temperature. The particles in gaseous state bounce off of the walls and ceiling of the container exerting a pressure. This pressure is called the saturated vapour pressure. As shown in the figure below, the saturated vapour pressure depends on temperature[71].

Approximation

In 1981, Buck made an approximation for the saturated vapour pressure by fitting curves on the data of measured saturated vapor pressures per temperature [72]. In this equation, the pressure in kPa, Ps(T), is given by

[math]\displaystyle{ P_s(T) = 0.61121 e^{( 18.678 - \frac{T}{234.5} )( \frac{T}{257.14 + T})} }[/math],

where T is the temperature in degrees celsius. In the temperature ranges between 0-50 degrees celsius, the Buck approximation has a lower average error than other approximations, hence it will be used here. The maximum error in this temperature range is 0.04%. The figure below shows a Matlab plot of both the approximation and known pressure per temperature measurements. One can observe that the approximation is rather accurate in the temperature range that the storage tank is likely to be in.

The molecular weight of water is 18,01528 g/mol. By taking the density to be approximately equal to 1, one can freely interchange between milliliters and grams of water. The volume of water in milliliters that is evaporated can then be calculated by the amount of particles in gaseous phase and divide that by the amount of particles in a mol (6.02214e23 Avogadro’s number) and then multiply this number by the molecular weight. In equation form:

[math]\displaystyle{ V_{evap} = 18.01528 \frac{a_{gp}}{6.02214e23} }[/math],

where Vevap is the evaporated volume of water in milliliters and agp the amount of particles in gaseous phase.

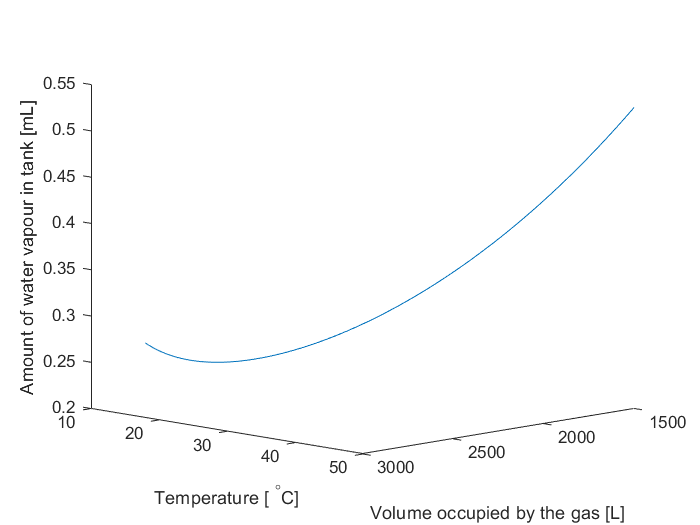

By using the ideal gas law, the amount of mol can be calculated. The ideal gas law is given by PV = nRT, where P is the pressure in atmosphere, V is the volume which the gas occupies in litres, n is the amount of mol, R is the gas constant and T is the temperature in Kelvin. The variable in this case is the temperature and the pressure can be approximated by Buck’s equation as a function of temperature. The gas constant for water vapour is 250.899 atm L mol-1 K-1. The volume which the gas occupies depends on the size of the tank and the amount of water in it. The volume is the total volume of the tank minus the volume of the water in it. The figure below shows the amount of water vapour in the tank in equivalent volume of liquid water. There are two variables in this case, the temperature and tank size. The tank size is still to be determined.

By opening the tank, the water which is in water vapour can be lost and the change in equilibrium causes more water to evaporate. If the tank has no holes or is not left opened, then the amount of water lost by evaporation is small.

Consecutive drought & crop yield losses

To estimate the return value of conquering unexpected periods of drought, it is important to determine the loss in production as a result of said drought. A generalized study which did not focus on the different stages of growth, but rather looked at the results of reducing the water supply during the full 130 day growth cycle, found that a water reduction of 40% correlates to a 39% decrease in yield [74]. One could use this finding to assume that the reduction of water relates to reduction in yield on a 1 to 1 ratio. This means that a quick and most likely inaccurate estimation of crop yield can be made by expressing the total precipitation as a percentage of the optimal quantity of water for maize.

However, the impact of drought varies greatly depending on the stage of growth the maize is currently undergoing and on the length for which the drought persists. For that reason, the different stages of growth will be considered below, each with their estimated production loss as a result of drought.

Growth stage. [Days 0 - 60]

First, consider the early growth stages. During this period the maximum yield is determined, which relies on the amount of kernel rows, the amount of kernels per row, and the kernel size. In the growing stages, the first symptom of water stress can be observed, the curling up of the leaves. This curling can already be observed on the first day of insufficient water. The longer the drought persists, the more the leaves will curl up. Maize can recover from a lack of water, as long as the missing water is supplied within four days. After four consecutive days of drought, crop yield will start to diminish[75]. Then, four to six weeks after sprouting, in the 6th leaf stage (V6), the amount of rows of kernels is determined. The next few weeks, up until the VT stage, is mostly just growth of both roots and leafs.

For the growth stage, up until week 9, the assumption is made that after 4 consecutive days of drought, it has been found that the yield is reduced by between 1% and 3%

Pollination stage [Days 60 - 80]

Nine weeks after sprouting, during the VT stage, the maximum amount of kernels per row is set. This takes one week on average. After the VT stage the R1 stage starts, lasting two weeks, during which the actual amount of kernels that will start growing is set. From this moment onward, water stress will cause kernels to abort their growth. [76][77]

The 3 weeks in which pollination and reproduction stages take place, called the VT stage and R1 stages respectively, are the most important weeks and the maximal yield is mostly determined in this stage. This time period encaptures the 1 week before pollination and the 2 weeks after pollination. During this period, an average of 8mm - 9mm of water is required daily. In phases VT and R1, which from now on will be referred to as the pollination phase, drought has the most severe consequences. This is due to the fact that losses caused by pollination failure can not be recovered. Every day of drought irreversibly reduces the yield by between 3% and 8%. After four consecutive days of insufficient watering, the duration of the so called anthesis-silking interval is increased, which causes a detrimental 40-50% loss of total yield.[78]

Kernel production stage [Days 70 - 130]

The kernel production, which starts in the R1 stage, makes up the last eight weeks of the crop growth. The first two weeks of this period have been covered in the pollination stage. For the remaining six and a half weeks of the kernel production, the loss in yield is initially 2.5% per day and scales up to 5.8% per day of drought, depending on the duration of the drought. Since our model is built on weekly sections rather than daily sections, this would translate to a rounded average of 30% yield loss per week.[78]

Model

To reason with more precision about the size of the canvas or the volume of the tank, a model is made. The model consist of three parts. The first part is setting up the model, inserting values in the model, recalculating some values to work for a time period of 10 days and some more setup related methods. The second part of the model are the simulations. The simulation runs 10 different scenarios. These scenarios will try to represented the droughts that the country might have, some drought will spread for several months, some droughts will be short but severe. For every scenario different sizes of canvas and different volumes of the water tank are tested. The different outcomes will be saved and added up. The last part of the model consist of portraying the outcomes of the scenario’s. All the outcomes of the model will be displayed in a table, where the most wanted scenarios will be highlighted and examined in more detail. We will discuss the different steps of the model in more detail below.

Setup

The setup consists of initializing some well defined variables, initializing the rainfall and initializing the water needed to hydrade the plants. Before any calculations can be made, assumptions must be made. The following variables are used within the model;

- StartingMonth: being the month in which the simulations starts.

- sizeOfField: being the size of the field over which we apply calculations, this field is around the average of small-based farmers.

- nrSimulations: The amount of simulations you perform, being 10 in our case.

- plantsPerHectare: The amount of plants that grow on one hectare.

- minTotalStorage: The least volume that will be tested

- maxTotalStorage: The maximum volume that will be tested

- stepTotalStorage: The increment for the storage space that will be used.

- minSizeOfCanvas: The minumum size of the canvas

- maxSizeOfCanvas: the maximum size of the canvas

- stepSizeOfCanvas: The increment for the canvas size that will be used.

Next to those variables we have a couple of methods to determine the rainfall. First we have a method that simply adds all the rainfall in a month to an array. The next method we use is the calculateTo10dayly method, this method recalculates the rain that falls from rain per month to rain per week. Between these method is also a method available to add some drought, this was for the initial estimations for the drought. The last thing that will be done in the setup is calculate how much rain

Simulations

For the simulations we run 10 different simulations. Within all the simulation the weather will be changed from the agregated rainfall. This is done to simulate real weather in these countries. For every scenario different sizes of canvas will be tested. For every size of canvas different sizes of the tank will be tested. The canvasses tested range from a size of 0 square meter till 100 square meter. The volume of the tank ranges from 500 Liter till 10000 Liter. The incrementation of the canvas is 2 meter per step. The incrementation is 500 Liter per step. This was done to optimize the result as much as possible.

Scenario

To make the simulation more real life we decided to implement some diffent scenario’s and test the different sizes and volumes in the diffent scenario. The scenario’s are partly based on real life data, partially based on our own intuition. The scenario’s will be discussed below.

simulation of drought

As described in the state of the art, drought is a loosely defined term. By the meteorological definition of the word, drought is a lower amount of precipitation than usual for a prolonged period of time. Since simulation by a mathematical model requires exact inputs, the period of time and the degree to which it is lower than usual have to be expressed in numerical values.

The standardized precipitation index (SPI) expresses the deviation from the average amount of precipitation in an amount of standard deviations. It basically is an application of the standard score from probability theory, which is given by the equation

[math]\displaystyle{ Z = \frac{x - \mu}{\sigma} }[/math],

where Z is the standard score, x is the random variable or sample, μ is the mean of the samples and σ is the standard deviation. By filling this formula in with meteorological terms, one finds the SPI:

[math]\displaystyle{ SPI = \frac{x_i - \mu}{\sigma} }[/math],

where xi is the sampled periodic precipitation, μ is the periodic mean and σ is the standard deviation calculated from samples compared to the periodic mean [79].

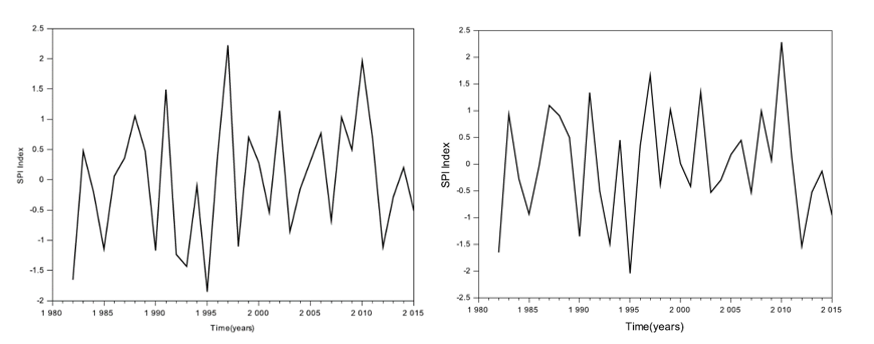

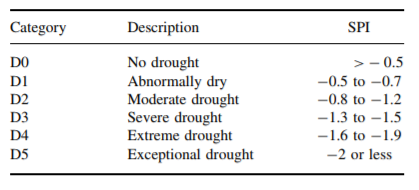

The SPI indexes were calculated for the same place (Kang, Botswana) for several periods of time (Keitumetse, 2016). In the figure below, the SPI index is shown for a period of 3 months on the left and 6 months on the right [79].

What stands out is that although the graphs tend to have the same shape, they differ slightly. This is expected, as drought is unpredictable so there is no correlation between the first 3 and the last 3 months of sampling. Since the data is presented with a period in which samples are taken of at least 3 months, for the inputs of our model it is assumed that the 3 month data also applies to a period of 1 month. This means that the slight differences between the 3 month and the 6 month period SPIs are also expected when using the 3 month data to model a period of at most 1 month. These discrepancies fall under the estimation error.

As shown in the table below, there are different categories of drought based on the SPI [80]. For a periodic moisture deficit to be considered a drought, an SPI of at most -0.8 is needed.

Now the droughts can be modeled by multiplying the SPI index from data collected from the past with the standard deviation. The standard deviation is calculated by using rainfall data for the random variable X and applying the equation:

[math]\displaystyle{ \sigma = \sqrt{\frac{1}{N} \sum_{i=1}^{N}(x_i - \mu)^2 } }[/math],

where N is the number of data inputs and μ is calculated by

[math]\displaystyle{ \mu = \frac{1}{N} \sum_{i=1}^{N}x_i }[/math].

By applying this method, the mean is found to be 52.57 and the standard deviation 23.63, both expressed in millimeters of precipitation. This is based on monthly precipitation amounts of 23, 40, 48, 79, 73, 82, 23, for the months october until april respectively [86].

Portraying