PRE2019 3 Group13: Difference between revisions

| (341 intermediate revisions by 5 users not shown) | |||

| Line 39: | Line 39: | ||

|g.v.bakel@student.tue.nl | |g.v.bakel@student.tue.nl | ||

|} | |} | ||

== Peer review == | |||

[[Peer review ]] | |||

== Presentation == | |||

You can download the presentation here: https://we.tl/t-bdd7DOqQko . | |||

== Problem Statement == | == Problem Statement == | ||

Simple tasks like eating are not as | Simple tasks like eating are not as easy for everyone. For instance: people with a tremor, or who are suffering from Parkinson’s disease, have trouble with something as simple as bringing a spoon to their mouth. Their meals take a lot longer and they often have to be assisted while eating. There are several products available on the market, like self-stabilizing spoons and forks, but the disadvantage of these products is that they are quite expensive and big. With these existing solutions people are able to eat independently again, but they always have to take their own cutlery with them. | ||

== Objectives == | == Objectives == | ||

'''Independent use''' | '''Independent use -''' | ||

The user should be able to utilize this product independently to assist them while eating. This means that the device should be easy to turn on and be natural to use. This way, the user can do daily life tasks without needing help from caregivers, making them more independent. | The user should be able to utilize this product independently to assist them while eating. This means that the device should be easy to turn on and be natural to use. This way, the user can do daily life tasks without needing help from caregivers, and thus making them more independent. | ||

'''Cost efficient''' | '''Cost efficient -''' | ||

As people with Parkinson's disease often already have enough costs to care for their disability, it is important that the device | As people with Parkinson's disease often already have enough costs to care for their disability, it is important that the device is affordable (less than €100,-). This way, it can be available for way more users in need. Another point to keep in mind is safety. If this device is too expensive the user will be at risk of being robbed, which has to be considered as people with Parkinson's disease can be more vulnerable and an easy target to rob. | ||

'''Comfortable in use''' | '''Comfortable in use -''' | ||

The device should be comfortable in use for the target group. It should have a shape that is comfortable for the duration of a three-course meal. Using the device should not cause any pain or harm and users should have no negative feelings | The device should be comfortable in use for the target group. It should have a shape that is comfortable to hold for the duration of a three-course meal. Using the device should not cause any pain or harm and users should have no negative feelings when using it. These criteria will be verified through user tests. The user should be fully comfortable using the device within two weeks of getting used to it. | ||

'''Recognize nature of movement''' | '''Recognize nature of movement -''' | ||

The device should recognize unwanted vibrations that are, for instance, caused by a tremor or Parkinson’s disease. The unwanted vibrations should be distinguished from | The device should recognize unwanted vibrations that are, for instance, caused by a tremor or Parkinson’s disease. The unwanted vibrations should be distinguished from deliberate movement of the cutlery within one period of movement. The error in recognizing the nature of the movement should be less than 10%. | ||

'''Act on unwanted movement''' | '''Act on unwanted movement -''' | ||

When an unwanted movement is recognized, this should be compensated by keeping the piece of cutlery stable. The stabilizing should not take more than two periods of | When an unwanted movement is recognized, this should be compensated by keeping the piece of cutlery stable. The stabilizing should not take more than two periods of unwanted vibrations. The piece of cutlery should only be allowed to move in the direction of the deliberate movements. | ||

'''Modular''' | '''Modular -''' | ||

The device should be compatible with at least 90% of the cutlery that is used in restaurants. Therefore the part of the device that is connected to the cutlery must be adjustable in size and it should be able to attach and use the device within one minute. This means that the user can feel more comfortable when using the device, as the device can be | The device should be compatible with at least 90% of the cutlery that is used in restaurants. Therefore the part of the device that is connected to the cutlery must be adjustable in size and it should be able to attach and use the device within one minute. This means that the user can feel more comfortable when using the device, as the device can be attached to the cutlery other people are using for example. The device should be able to work for at least three hours without intermediate charging. This is for the comfort of the user, as they might want to use the spoon during the whole day without having to charge it. | ||

== Approach, Milestones Deliverables and Planning == | == Approach, Milestones, Deliverables and Planning == | ||

=== Approach === | === Approach === | ||

The aim of this project is to help people with nerve diseases | The aim of this project is to help people with nerve diseases that cause tremors to become more independent. We are going to do this by making a device that can be attached to any cutlery, which makes it possible to eat independently for the target group. We want to achieve this goal by doing extensive research and eventually delivering a simplified prototype including information about this prototype on the wiki page. The approach to reach these goals contains multiple steps. | ||

1. Research | 1. Research | ||

Firstly, we will be going through research papers and other sources which describe the state of art of such cutlery and its respective components. This allows our | Firstly, we will be going through research papers and other sources which describe the state of the art of such cutlery and its respective components. This allows our team to get a grasp of the current technology of such a system and introduce us to the new developments in this field. This helps to create a foundation for the project, which we can develop into. The state of art also gives valuable insight into possible solutions to solve our problem statement. The research has to be done with the use of literature, survey(s), personal interview(s), recent reports from research institutes and the media and analysing patents that are strongly connected to our project. | ||

2. USE aspects | 2. USE aspects | ||

Furthermore, we will continue to analyze the problem from a USE – user, society, enterprise – perspective. An important source of this analysis is the state of art research, where the | Furthermore, we will continue to analyze the problem from a USE – user, society, enterprise – perspective. An important source of this analysis is the state of the art research, where the impact of these cutlery systems in different stakeholders is discussed. The USE aspects will be of utmost importance for our project as every engineer should strive to develop new technologies for helping not only the users but also the society as a whole and to consider the possible consequences of the system they develop. This analysis will lead to a list of requirements for our design. We also set up a survey to find out any unknown requirements. This makes that the requirements are based on the USE analysis and the survey. | ||

3. Product shaping | 3. Product shaping | ||

When we finish these two steps, we will develop a prototype in which the product will be conceptualized and programmed. In this process, the RPC's are used to design the software, hardware and the appearance of the prototype. | |||

4. Documentation | 4. Documentation | ||

To finish, the wiki has to be updated and should contain the whole process of designing our prototype, as well as all of the research that is done to get there. To accomplish this, someone will be assigned to check and edit the page every week. Besides the wiki, a presentation has to be made in anticipation of the last few weeks. | |||

Listed below is a summary of the main steps in our approach of the project. | |||

*Doing research on our chosen project using SotA literature analysis | *Doing research on our chosen project using SotA literature analysis | ||

* | *Analysing the USE aspects and set up the survey to determine the requirements of our device | ||

*Choose the Hardware and Software for the prototype | *Choose the Hardware and Software for the prototype | ||

*Work on the prototype | *Work on the prototype | ||

| Line 98: | Line 110: | ||

* Week 1: The subject is chosen and also the Plan for the project has been made. | * Week 1: The subject is chosen and also the Plan for the project has been made. | ||

* Week 2: It is clear who the users are, the research is finished and also the requirements are | * Week 2: It is clear who the users are, the research (SotA) is finished and also the requirements are determined. | ||

* Week 3: Research into design prototype and costs + | * Week 3: Research into design prototype and costs + set up survey. | ||

* Week 4: Research into software prototype and a list of parts and estimation of costs is made | * Week 4: Research into software prototype and a list of parts and estimation of costs is made. | ||

* Week 5: Building prototype + information from | * Week 5: Building prototype + information from survey to improve the prototype. | ||

* Week 6: The prototype has been made. | * Week 6: The prototype has been made. | ||

* Week 7: The | * Week 7: The demo will be finished and ready to be presented. | ||

* Week 8: The wiki page is finished and updated with the results that were found from testing the prototype. Also, future developments are looked into and added to the wiki page. | * Week 8: The wiki page is finished and updated with the results that were found from testing the prototype. Also, future developments are looked into and added to the wiki page. | ||

| Line 111: | Line 123: | ||

*This wiki page, which contains all of our research and findings | *This wiki page, which contains all of our research and findings | ||

*A presentation, which is a summary of what was done and what our most important results are | *A presentation, which is a summary of what was done and what our most important results are | ||

*A prototype | *A prototype, due to the situation caused by COVID-19 this consists of two parts: the electronics and the 3D printed case which could not be put together. | ||

*A | *A demo, due to the situation caused by COVID-19 this is included in the presentation | ||

===Planning=== | ===Planning=== | ||

| Line 130: | Line 142: | ||

| style="text-align: center; font-style:italic; background-color:#deedfd;" | Research | | style="text-align: center; font-style:italic; background-color:#deedfd;" | Research | ||

| style="text-align: center; font-style:italic; background-color:#deedfd;" | RPC's and USE Analysis + start prototype research | | style="text-align: center; font-style:italic; background-color:#deedfd;" | RPC's and USE Analysis + start prototype research | ||

| style="text-align: center; font-style:italic; background-color:#deedfd;" | Hardware Design + | | style="text-align: center; font-style:italic; background-color:#deedfd;" | Hardware Design + Survey | ||

| style="text-align: center; font-style:italic; background-color:#deedfd;" | Software Design + | | style="text-align: center; font-style:italic; background-color:#deedfd;" | Software Design + Survey | ||

| style="text-align: center; font-style:italic; background-color:#deedfd;" | Prototype | | style="text-align: center; font-style:italic; background-color:#deedfd;" | Prototype | ||

| style="text-align: center; font-style:italic; background-color:#deedfd;" | Proof Reading | | style="text-align: center; font-style:italic; background-color:#deedfd;" | Proof Reading | ||

| style="text-align: center; font-style:italic; background-color:#deedfd;" | | | style="text-align: center; font-style:italic; background-color:#deedfd;" | Demo | ||

| style="text-align: center; font-style:italic; background-color:#deedfd;" | Conclusions | | style="text-align: center; font-style:italic; background-color:#deedfd;" | Conclusions + Future Developments | ||

|- | |- | ||

| rowspan="3" style="text-align: center;" | Heather Hanegraaf | | rowspan="3" style="text-align: center;" | Heather Hanegraaf | ||

| Line 147: | Line 159: | ||

| Wiki Page check | | Wiki Page check | ||

|- | |- | ||

| | | Brainstorm subject ideas | ||

| Requirements justification | | Requirements justification | ||

| Survey | | Survey | ||

| Line 154: | Line 166: | ||

| Survey ideas | | Survey ideas | ||

| Finish presentation | | Finish presentation | ||

| | | Finish presentation + audio | ||

|- | |- | ||

| Make the planning | | Make the planning | ||

| Line 163: | Line 175: | ||

| Efficiency of performance method | | Efficiency of performance method | ||

| Clean the wiki page | | Clean the wiki page | ||

| | | Clean the wiki page | ||

|- | |- | ||

| rowspan="3" style="text-align: center;" | Yara Daamen | | rowspan="3" style="text-align: center;" | Yara Daamen | ||

| Line 182: | Line 194: | ||

| | | | ||

| Finish chapter "holding spoon" | | Finish chapter "holding spoon" | ||

| | | Finish presentation + audio | ||

|- | |- | ||

| | | | ||

| Line 193: | Line 205: | ||

| | | | ||

|- | |- | ||

| rowspan=" | | rowspan="3" style="text-align: center;" | Mayke Scheffer | ||

| Write problem statement and objectives | | Write problem statement and objectives | ||

| Research Prototype | | Research Prototype | ||

| Line 210: | Line 222: | ||

| Prototype Justification | | Prototype Justification | ||

| | | | ||

| | | Finish prototype | ||

|- | |- | ||

| | | | ||

| Line 219: | Line 231: | ||

| | | | ||

| Edit BoM | | Edit BoM | ||

| | | Start testing prototype | ||

|- | |- | ||

| rowspan="3" style="text-align: center;" | Wouter Haneveer | | rowspan="3" style="text-align: center;" | Wouter Haneveer | ||

| Line 247: | Line 250: | ||

| Final 3D model printing | | Final 3D model printing | ||

| | | | ||

| | | Edit BoM | ||

|- | |- | ||

| | | | ||

| Line 256: | Line 259: | ||

| | | | ||

| Edit Wiki page | | Edit Wiki page | ||

| | | Clean wiki page | ||

|- | |- | ||

| rowspan=" | | rowspan="2" style="text-align: center;" | Gijs van Bakel | ||

| Write User part | | Write User part | ||

| Research Prototype | | Research Prototype | ||

| Line 272: | Line 275: | ||

| | | | ||

| Arduino code on wiki page | | Arduino code on wiki page | ||

| | | | ||

| | | | ||

| Write future improvements | | Write future improvements | ||

| | | Finish future improvements | ||

|- | |- | ||

| style="background-color:#3f96f1; color:#efefef;" | | | style="background-color:#3f96f1; color:#efefef;" | | ||

| Line 304: | Line 298: | ||

| Skype Meeting online | | Skype Meeting online | ||

| Skype Meeting 1 | | Skype Meeting 1 | ||

| | | Skype Meeting 1 | ||

|- | |- | ||

| Online meeting ( | | Online meeting (WhatsApp) about subject | ||

| | | | ||

| | | | ||

| Line 313: | Line 307: | ||

| | | | ||

| Skype Meeting 2 | | Skype Meeting 2 | ||

| | | Skype Meeting 2 | ||

|- | |- | ||

| | | | ||

| Line 322: | Line 316: | ||

| | | | ||

| | | | ||

| | | Skype meeting 3 | ||

|} | |} | ||

== State of the Art== | == State of the Art== | ||

Several papers have been collected on the topic of self-stabilizing | Several papers have been collected on the topic of self-stabilizing technologies, which are shown at the 'Literature study week 1' section near the end of the report, together with a short summary in one or two sentences. They are sorted into distinctive categories for clarity. The following section summarizes the most important findings of the collected literature for our project, together with additional research on other topics that have been done at a later time such as the section on mechanical stabilization. | ||

=== Similar products === | === Similar products === | ||

Active cancellation hardware is currently used in noise-canceling headphones | Active cancellation hardware is currently used in noise-canceling headphones and a similar method can be used for self-stabilizing spoons<ref>Thilmany, J. (2013). Stable spoon. Mechanical Engineering; New York, 135(5) </ref>. This method uses two DC motors connected with mechanical yokes that couple vertical and horizontal motion of the spoon. The sensor/controller system uses a tri-axial accelerometer embedded in the spoon base to sense the direction of tremor in the x and y directions and directs the spoon to move in the opposite direction. A bandpass filter is used to filter out noise, and acceleration data as a function of time is resolved into the frequency domain using Fourier transformation<ref name = "Pathak">Pathak, A., Redmond, J. A., Allen, M., & Chou, K. L. (2013). A noninvasive handheld assistive device to accommodate essential tremor: A pilot study. Movement Disorders, 29(6), 838–842. https://doi.org/10.1002/mds.25796 </ref>. | ||

Vibration isolation and a dynamic vibration absorber can be used to reduce the hand tremor with a semi-active device, which can not only reduce hand tremors but can also generate its needed electrical energy<ref> Abbasi, M., & Afsharfard, A. (2018). Modeling and experimental study of a hand tremor suppression system. Mechanism and Machine Theory, 126, 189–200. https://doi.org/10.1016/j.mechmachtheory.2018.04.009 </ref>. In this system, two clamped guided piezoelectric beams are used to hold the spoon and a clamped piezoelectric beam is used as a dynamic vibration absorber. | |||

A PID controller can be used to actively control the system. This type of controller continuously calculates an error value e(t) as the difference between the desired setpoint (SP) and a measured process variable (PV) and applies a correction based on proportional, integral, and derivative terms (denoted P, I and D respectively), hence the name. In the study “Design of a noninvasive and smart hand tremor attenuation system with active control: a simulation study” two motors are used that can rotate in perpendicular directions, which allow the mechanism tip to move horizontally and vertically<ref> Abbasi, M., Afsharfard, A., Arasteh, R., & Safaie, J. (2018). Design of a noninvasive and smart hand tremor attenuation system with active control: a simulation study. Medical & Biological Engineering & Computing, 56(7), 1315–1324 https://doi.org/10.1007/s11517-017-1769-9 </ref>. | |||

A PID controller can be used to actively control the system. This type of controller continuously calculates an error value e(t) as the difference between | |||

Another method uses Inertial | Another method uses Inertial Measurement Unit (IMU) sensors and actuators for stabilizing a cup while under severe hand vibration. It is like the Active force method in the sense that a microcontroller processes the feedback from the IMU, upon which it rotates the two motors in the opposite direction of hand movement in order to achieve proper stabilization. PI and PID controllers are also used for this self-stabilizing cup<ref> Vishnu, V., Prabaharan, P., Sujadevi, V.G., Meher, M.D.IMU sensor-based self-stabilizing cup for elderly and Parkinsonism (2017) 2017 International Conference on Advances in Computing, Communications and Informatics, ICACCI 2017, 2017-January, pp. 2264-2269. </ref>. | ||

Note on the frequency of tremors: Based on previous studies, it is concluded that the frequency of the hand tremor is different from the frequency of the voluntary movement. Accordingly, the frequency of the hand tremor in Parkinson’s disease is in range of 3–6 Hz and it is between 5 and 12 Hz in essential tremor disease Therefore, a low-pass filter, with a cut-off frequency of 3 Hz, can be used to distinguish the voluntary motion from tremor movement | Note on the frequency of tremors: Based on previous studies, it is concluded that the frequency of the hand tremor is different from the frequency of the voluntary movement. Accordingly, the frequency of the hand tremor in Parkinson’s disease is in the range of 3–6 Hz and it is between 5 and 12 Hz in essential tremor disease. Therefore, a low-pass filter, with a cut-off frequency of 3 Hz, can be used to distinguish the voluntary motion from tremor movement<ref> Bhidayasiri R (2005) Differential diagnosis of common tremor syndromes. Postgrad Med J 81(962):756–762. https://doi.org/10.1136/ </ref>. | ||

=== Solutions to reduce tremors === | === Solutions to reduce tremors === | ||

Next to self-stabilizing wearables we also did research on ways to reduce tremors, | Next to self-stabilizing wearables we also did research on ways to reduce tremors, the most important findings to reduce tremors are listed below. | ||

One could think about adding weight to the patient's wrist or use a heavier spoon, since then an equal amount of force would mean less movement since the mass is bigger <ref> McGruder, J., Cors, D., Tiernan, A. M., & Tomlin, G. (2003). Weighted Wrist Cuffs for Tremor Reduction During Eating in Adults With Static Brain Lesions. American Journal of Occupational Therapy, 57(5), 507–516. https://doi.org/10.5014/ajot.57.5.507 </ref> | One could think about adding weight to the patient's wrist or use a heavier spoon, since then an equal amount of force would mean less movement since the mass is bigger<ref> McGruder, J., Cors, D., Tiernan, A. M., & Tomlin, G. (2003). Weighted Wrist Cuffs for Tremor Reduction During Eating in Adults With Static Brain Lesions. American Journal of Occupational Therapy, 57(5), 507–516. https://doi.org/10.5014/ajot.57.5.507 </ref>. Although some research<ref> McGruder, J., Cors, D., Tiernan, A. M., & Tomlin, G. (2003). Weighted Wrist Cuffs for Tremor Reduction During Eating in Adults With Static Brain Lesions. American Journal of Occupational Therapy, 57(5), 507–516. https://doi.org/10.5014/ajot.57.5.507 </ref> does support this, there are also studies<ref> Meshack, R. P., & Norman, K. E. (2002). A randomized controlled trial of the effects of weights on amplitude and frequency of postural hand tremors in people with Parkinson’s disease. Clinical Rehabilitation, 16(5), 481–492. https://doi.org/10.1191/0269215502cr521oa </ref> that state that no significant changes can be seen by adding weight. | ||

Another | Another solution that could be applied to the spoon is to make the handle smaller. As research<ref> Ma, H.-I., Hwang, W.-J., Chen-Sea, M.-J., & Sheu, C.-F. (2008). Handle size as a task constraint in spoon-use movement in patients with Parkinson’s disease. Clinical Rehabilitation, 22(6), 520–528. https://doi.org/10.1177/0269215507086181 </ref> shows that a smaller handle makes people with Parkinson's disease move faster and smoother, possibly since they have more control over the spoon due to the shorter distance to it. | ||

An exoskeleton can also be used to suppress tremors <ref> Meshack, R. P., & Norman, K. E. (2002). A randomized controlled trial of the effects of weights on amplitude and frequency of postural hand | An exoskeleton can also be used to suppress tremors<ref> Meshack, R. P., & Norman, K. E. (2002). A randomized controlled trial of the effects of weights on amplitude and frequency of postural hand tremors in people with Parkinson’s disease. Clinical Rehabilitation, 16(5), 481–492. https://doi.org/10.1191/0269215502cr521oa </ref>. Here, an exoskeleton uses an electromyogram (EMG) signal, which is a biosignal which affects the activation of muscles, to measure whether the movement is voluntary or not. If the movement is voluntary the exoskeleton moves with the body, else it will not move and suppress the movement. However, exoskeletons can be used in other parts of the arm as well, like seen in research<ref>Hosseini, S.M., Al-Jumaily, A., Kalhori, H.Tremor suppression in wrist joint using active force control method(2017) 9th Australasian Congress on Applied Mechanics, ACAM 2017, 2017-November.</ref> much more complicated exoskeletons can be made. This one uses Active Force Control (AFC) based on piezoelectric actuators to reduce tremors in the wrist. | ||

Tremors could also be reduced by measuring distance to | Tremors could also be reduced by measuring the distance to an object and keeping this distance the same with the help of motors<ref> Song, C., Gehlbach, P. L., & Kang, J. U. (2012). Active tremor cancellation by a “Smart” handheld vitreoretinal microsurgical tool using swept-source optical coherence tomography. Optics Express, 20(21), 23414. https://doi.org/10.1364/oe.20.023414 </ref>. However, for our project this is not relevant since we want our tool to be usable in a dynamic environment and to pick up food, we need to go towards the food and this way would work against what we want to accomplish. | ||

With the use of accelerometers, actuators and position sensors, tremors could be seen and reduced by countering the force of the tremor with an equally big force | With the use of accelerometers, actuators and position sensors, tremors could be seen and reduced by countering the force of the tremor with an equally big force in the opposite direction, according to research<ref> Hamdy, A. (1999). Active damping of vibrations in elevator cars. Journal of Structural Control, 6(1), 53–100. https://doi.org/10.1002/stc.4300060105 </ref>. However, this system is designed for cars and is therefore too big and expensive to use for a spoon. If a way smaller and cheaper version could be made, it might be a good way to reduce tremors in a spoon but the problem is that it might be difficult to see whether a movement is from a tremor or a voluntary movement from the user itself. | ||

By rotating an unbalanced mass, one could counter and thus reduce a tremor <ref> Chuanasa, J., & Songschon, S. (2014). Essential tremor suppression by a novel self-balancing device. Prosthetics and Orthotics International, 39(3), 219–225. https://doi.org/10.1177/0309364614525185 </ref> . However, added on a spoon this would make the spoon heavy since we should add multiple masses to be | By rotating an unbalanced mass, one could counter and thus reduce a tremor<ref> Chuanasa, J., & Songschon, S. (2014). Essential tremor suppression by a novel self-balancing device. Prosthetics and Orthotics International, 39(3), 219–225. https://doi.org/10.1177/0309364614525185 </ref> . However, added on a spoon this would make the spoon too heavy since we should add multiple masses to be able to create a counterforce in every direction, thus making it not usable for cutlery. | ||

Using a coin type vibration motor and a | Using a coin type vibration motor and a microcontroller, it is possible to create random vibration patterns to distract the user from the bio-mechanical feedback loop with the hand and reduces the hand tremor and improving the ability to grip or hold an object<ref> Vidya, V., Poornachandran, P., Sujadevi, V.G., Dharmana, M.M.Suppressing Parkinson's diseases induced involuntary movements using wearables(2018) Proceedings of 2017 IEEE International Conference on Technological Advancements in Power and Energy: Exploring Energy Solutions for an Intelligent Power Grid, TAP Energy 2017, pp. 1-4. https://doi.org/10.1109/TAPENERGY.2017.8397267 </ref>. | ||

Lastly, we found that muscle co-contraction could be used to stabilize joints <ref> Gallego, J.A., Rocon, E., Belda-Lois, J.M., Pons, J.L. A neuroprosthesis for tremor management through the control of muscle co-contraction (2013) Journal of NeuroEngineering and Rehabilitation, 10 (1), art. no. 36. DOI: 10.1186/1743-0003-10-36 </ref> . When a tremor is measured, the muscles are electronically contracted to stabilize the joint, this reduces the tremors since your muscles are contracted and thus unable to create a tremor. | Lastly, we found that muscle co-contraction could be used to stabilize joints<ref> Gallego, J.A., Rocon, E., Belda-Lois, J.M., Pons, J.L. A neuroprosthesis for tremor management through the control of muscle co-contraction (2013) Journal of NeuroEngineering and Rehabilitation, 10 (1), art. no. 36. DOI: 10.1186/1743-0003-10-36 </ref>. When a tremor is measured, the muscles are electronically contracted to stabilize the joint, this reduces the tremors since your muscles are contracted and thus unable to create a tremor. | ||

=== Measuring tremors === | === Measuring tremors === | ||

We also did research on ways to measure tremors, here our findings of how to measure tremors. | We also did research on ways to measure tremors, here are our findings of how to measure tremors. | ||

One could measure tremors by using advanced mathematical methods of time series analysis as seen in <ref>Lauk, M., Timmer, J., Lücking, C. H., Honerkamp, J., & Deuschl, G. (1999). A software for recording and analysis of human tremor. Computer Methods and Programs in Biomedicine, 60(1), 65–77. https://doi.org/10.1016/s0169-2607(99)00012-7</ref>. Here an easy to use Microsoft windows application is built to investigate forms of tremors using advanced mathematical methods of time series analysis. | One could measure tremors by using advanced mathematical methods of time series analysis as seen in this research<ref>Lauk, M., Timmer, J., Lücking, C. H., Honerkamp, J., & Deuschl, G. (1999). A software for recording and analysis of human tremor. Computer Methods and Programs in Biomedicine, 60(1), 65–77. https://doi.org/10.1016/s0169-2607(99)00012-7</ref>. Here an easy to use Microsoft windows application is built to investigate forms of tremors using advanced mathematical methods of time series analysis. | ||

We also found a device using | We also found a device using four accelerometers and is capable to measure tremors, movement and accidental falls<ref>Gugliandolo G, Capra PP, Bramanti A, Di Lorenzo G, Campobello G, Donato N, Marino S (2019). A Movement-Tremors Recorder for Patients of Neurodegenerative Diseases. IEEE Transactions on Instrumentation and Measurement, 68(5), 1451-1457. | ||

https://doi.org/10.1109/TIM.2019.2900141</ref>. This device also has the possibility to connect | https://doi.org/10.1109/TIM.2019.2900141</ref>. This device also has the possibility to connect via Bluetooth, Wi-Fi and GSM to a remote supervisor. | ||

Another way to measure tremors is by combining accelerometers with gyroscopic transducers | Another way to measure tremors is by combining accelerometers with gyroscopic transducers. A device is made using three-axis accelerometer and three axis gyroscopic transducers embedded in one device called shimmer<ref>Reem Musab, Azizan As’arry, Khairil Anas Md Rezali, Nawal Aswan Abdul Jalil, Raja Mohd Kamil Raja Ahmad, Mohd Zarhamdy Md Zain (2019). Tremor Quantification and its Measurements Using Shimmer. Journal of Physics: Conference Series, 1262. https://dx.doi.org/10.1088/1742-6596/1262/1/012024</ref>. This device can measure the acceleration, velocity and displacement of a tremor. | ||

https://dx.doi.org/10.1088/1742-6596/1262/1/012024</ref>. This device can measure the acceleration, velocity and displacement of a tremor. | |||

=== | === Stabilization in other fields === | ||

So far all the sources that are found | So far all the sources that are found are directly related to our product, either with the active force method, a PID controller or some other electronic device. However we know that other methods of stabilizing, for instance mechanically, are also used in other fields. Since no sources have been found that directly use mechanical stabilization for stabilizing cutlery, some literature on self-stabilizing cameras has been found to see if we can draw any parallels. Mainly because we also wanted to see whether this could be applied to our problem statement. So to reach this goal, more literature research into stabilization in general has been done, with the results of this presented below. | ||

Some literature<ref> Rodriguez-Padilla, I., Castelle, B., Marieu, V., Morichon, D. A simple and efficient image stabilization method for coastal monitoring video systems (2020) Remote Sensing, 12 (1), art. no. 70. https://doi.org/10.3390/RS12010070 </ref> mentions how image stabilization is actually not done actively, but “edited in”. A template matching method is used that consists of selecting small high-contrast regions of an image and these are matched with a reference image to compute their displacement, which is then corrected<ref> Rodriguez-Padilla, I., Castelle, B., Marieu, V., Morichon, D. A simple and efficient image stabilization method for coastal monitoring video systems (2020) Remote Sensing, 12 (1), art. no. 70. https://doi.org/10.3390/RS12010070 </ref>. | |||

Another source of literature mentions a similar approach to the ones that have been found for stabilizing cutlery, using a PID controller with an inertial measurement unit (IMU) | Another source of literature mentions a similar approach to the ones that have been found for stabilizing cutlery, using a PID controller with an inertial measurement unit (IMU)<ref> Auysakul, J., Xu, H., Pooneeth, V. Video stabilization with a dual system based on an IMU sensor for the mobile robot (2019) Advances in Intelligent Systems and Computing, 856, pp. 618-626. https://doi.org/10.1007/978-3-030-00214-5_78 </ref>. The same method is used for cameras on UAVs (unmanned aerial vehicles)<ref> Franco, F.P.L., Loubach, D.S., Fioravanti, A.R. An embedded system design for a two-axis camera platform control used in unmanned aerial vehicles (2017) Proceedings - 2017 LARS 14th Latin American Robotics Symposium and 2017 5th SBR Brazilian Symposium on Robotics, LARS-SBR 2017 - Part of the Robotics Conference 2017, 2017-December, pp. 1-6. https://doi.org/10.1109/SBR-LARS-R.2017.8215289 </ref>. | ||

MEMS (micro-electromechanical system)-based gyroscopes and accelerometers are also used in order to stabilize cameras. These units are however specifically made for this purpose and would be too big to use in the area of self-stabilizing cutlery | MEMS (micro-electromechanical system)-based gyroscopes and accelerometers are also used in order to stabilize cameras. These units are however specifically made for this purpose and would be too big to use in the area of self-stabilizing cutlery<ref> Sofla, M.S., Parsa, M., Golshanian, H. Stabilizing a camera mount using MEMS gyroscope and accelerometer (2016) Transactions of the Institute of Measurement and Control, 38 (11), pp. 1345-1352. https://doi.org/10.1177/0142331215587339 </ref>. | ||

== USE Analysis == | == USE Analysis == | ||

It is good to first know who the users of the product are. Society and enterprise must also be taken into account before we start making the prototype. That is why a USE analysis is | It is good to first know who the users of the product are. Society and enterprise must also be taken into account before we start making the prototype. That is why a USE analysis is being carried out. The requirements will then be formed from this USE analysis after which we will us to develop the prototype. | ||

===User=== | |||

' | First, we take a look at the user aspect of our product. At the start of this project it was only clear that there would be a product for people with a tremor or a disorder in the nerves. First of all, research was done into which disorders where tremors occur, since people with those disorders are potential users of our product. It was interesting to conduct further research into the disorders MS, Parkinson's and essential tremors. Now, a short analysis will follow about these diseases and then a choice will be made for which patients our device will be developed. | ||

'''MS''' | |||

More than 2.3 million people are affected by MS worldwide. Most people living with MS are diagnosed between the ages of 20 and 50, with more than twice as many women as men being diagnosed with the disease. MS is an abbreviation for multiple sclerosis. It is an unpredictable, often disabling disease of the central nervous system, caused by the immune system which attacks the protective sheath (myelin) that covers nerve fibers and causes communication problems between your brain and the rest of your body. Eventually, the disease can cause permanent damage or deterioration of the nerves<ref>Mayo Clinic Staff. (2019, 19 April). Multiple sclerosis - Symptoms and causes. Retrieved from https://www.mayoclinic.org/diseases-conditions/multiple-sclerosis/symptoms-causes/syc-20350269</ref>. Symptoms range from numbness and tingling to blindness and paralysis. The disease varies greatly from person to person, and from time to time, for the same person. For instance, one person might experience abnormal fatigue, another might have severe vision problems, and another could develop attention and memory issues. Besides these symptoms, tremor, lack of coordination or unsteady gait can also be experienced. Even severe symptoms could disappear completely and the person could regain lost functions. However, in the worst cases, people can have partial or complete paralysis<ref> National MS Society. (z.d.). MS the Disease. Retrieved from https://www.nationalmssociety.org/About-the-Society/Press-Room/MS-the-Disease </ref>. | |||

'''Parkinson's disease''' | |||

Parkinson's disease is the second most common progressive brain disease with 7 million patients worldwide. Parkinson's disease is a brain disorder that leads to shaking, stiffness, and difficulty with walking, balance, and coordination. Parkinson's symptoms usually begin gradually and get worse over time. As the disease progresses, people may have difficulty walking and talking. They may also have mental and behavioral changes, sleep problems, depression, memory difficulties, and fatigue. One clear risk factor for Parkinson's is age, most people with Parkinson’s develop the disease at about age 60. Parkinson's disease signs and symptoms can be different for everyone. Early signs may be mild and go unnoticed. Symptoms often begin on one side of your body and usually remain worse on that side, even after symptoms begin to affect both sides. Parkinson's disease has four main symptoms: | |||

tremor (trembling) in hands, arms, legs, jaw, or head, stiffness of the limbs and trunk, slowness of movement and impaired balance and coordination, sometimes leading to falls<ref> National Institute of Aging. (2017, 16 May). Parkinson’s Disease. Retrieved from https://www.nia.nih.gov/health/parkinsons-disease </ref>. Another symptom is chewing and swallowing difficulties can occur, especially during the later stages of the disease. These can be due to changes in function either in the autonomic nervous system or the muscles in the throat, known as the pharyngeal muscles<ref>The MNT Editorial Team. (2018, 26 October). Parkinson’s disease complications. Retrieved from https://www.medicalnewstoday.com/articles/323399#chewing-and-swallowing</ref>. | |||

'''Essential tremors''' | |||

Essential tremor is a nervous system (neurological) disorder that causes involuntary and rhythmic shaking. It can affect almost any part of your body, but the trembling occurs most often in hands — especially when doing simple tasks, such as drinking from a glass or tying shoelaces. Essential tremor is usually not a dangerous condition, but it typically gets worse over time and can be severe for some people. Other conditions don't cause essential tremor, although essential tremor is sometimes confused with Parkinson's disease. Essential tremor can occur at any age but is most common in people aged 40 and older. The tremor signs and symptoms begin gradually, usually more prominently on one side of the body, worsen with movement, usually occur in the hands first, affecting one hand or both hands, it can include a "yes-yes" or "no-no" motion of the head and it may be aggravated by emotional stress, fatigue, caffeine or temperature extremes<ref>Mayo Clinic Staff. (2019, 23 January). Essential tremor - Symptoms and causes. Retrieved from https://www.mayoclinic.org/diseases-conditions/essential-tremor/symptoms-causes/syc-20350534 </ref>. | |||

'''Target group''' | |||

Our targeted users are people suffering from hand and arm tremors which are caused by the Parkinson’s disease but also people suffering from essential tremors. We have chosen both conditions as users, as this increases the number of people who are potential users. Furthermore, essential tremors and the tremors in Parkinson's disease are very similar, therefore the spoon can be used by both patients. | |||

To really focus on perfecting a product fitted to our targeted users, it is necessary to choose a specific topic. Therefore, we mainly focus on Parkinson's patients, as this is a much better known problem that needs to be addressed. These users, people with Parkinson’s disease, are in almost all cases elderly around or above 60. These people are often in need of a lot of care and can’t perform a variety of independent tasks on their own. Especially eating is a very frequent activity that has to be assisted minimally 3 times a day. For patients who are still mentally healthy it can be a very degrading feeling to have to be fed. A device that could help these patients could greatly improve their independence and feeling of self-worth. Although we focus on Parkinson, the spoon can thus still be used by both parties. | |||

===Society=== | |||

For the society, this device can make a small, but needed, change to the healthcare. As the population of elderly grows bigger and bigger so will the amount of patients with Parkinson’s disease. This will have a big impact on the society as they are in high need of caring. By using this device, the working load for the caretakers could be decreased, allowing them to have more time for other activities. Furthermore, it can greatly improve patients' independence and feeling of self-worth. This is also a benefit to society, as people may feel happier overall. | |||

===Enterprise=== | |||

The Enterprise stakeholder is about companies that have the same kind of idea to tackle this problem. It is clear that there is already a market for these products. We will now discuss some of those similar products. | |||

'''Flexible TPE and Lepel Torso Grip''' | |||

Our solution is aimed at robots and works through the use of electricity, but there are also companies that have come up with a much simpler solution. For example, a flexible silicone edge around the edge of the spoon. In this way, the food stays on the spoon better. This can indeed be a good solution for the problem, but the success rate of an electric spoon is higher than with this solution. | |||

Another simple solution is to make a better grip on the spoon. This way the spoon is easier to hold for people with Parkinson's disease. The handle of the spoon itself then becomes larger, which research shows that this has no positive effect on the use of the spoon. This research was conducted by Clinical Rehabilitation and their findings were as follows: "The movement of the participants with Parkinson's disease was faster (shorter movement time) and smoother (fewer movement units) when they used spoons with a small or medium-sized handle than when using a spoon With a large-sized handle. In contrast, the healthy controls showed no significant differences in movement kinematics between handle sizes. Moreover, the participants with Parkinson's disease had a significantly smaller hand aperture and used more fingers to hold the spoons than the controls did"<ref> Ma, H.-I., Hwang, W.-J., Chen-Sea, M.-J., & Sheu, C.-F. (2008). Handle size as a task constraint in spoon-use movement in patients with Parkinson’s disease. Clinical Rehabilitation, 22(6), 520–528. https://doi.org/10.1177/0269215507086181 </ref>. This shows that the handle should not be too large, but it should be big enough since patients with Parkinson's hold the spoon with more fingers. So, in our design we want a combination of good grip, big enough size for holding the spoon, but not too big because this would have a negative effect on the time to move and the smoothness to do so. | |||

'''Foodrobot''' | |||

A robotic arm is another solution to the problem. ZorgvanNu explains how it works: "Obi has two control buttons: one to choose which bowl to scoop from, and one to control the scooping movement. An arm with a spoon on it scoops up the food and brings it to the mouth. If you are going to use Obi, first set the correct position of the arm in relation to your mouth. You can always set it (or have it adjusted) in a different way, so that you do not always have to sit in the same way"<ref> Zorg van nu. (2020, 11 February). Hulp bij eten met een eetrobot. Retrieved from https://www.zorgvannu.nl/oplossingen/hulp-bij-eten-met-een-eetrobot</ref>. This can be an effective solution if the tremors become so bad that the patient can no longer hold the spoon. However, we have opted for a different solution, which is to be more mobile and not to have to carry a large device if the patient goes out for diner, for example. Another disadvantage of this solution is that the contact between human and robot must be very consciously taken into account. Because if the patient suffocates, the robot simply continues, which would not be user-friendly. It is a good solution, if people come in the next stage of Parkinson's and they have no other option left. However, our solution is for people who can still use a spoon themselves. | |||

'''Liftware, Gyenno and "Smart"-spoon''' | |||

There are also products that are very similar to what we want to produce. This is namely a spoon that measures the tremors and then tries to counteract it by making the opposite movement. Liftware, Gyenno and "Smart" spoon are examples of this. Although there are already working products on the market, we are convinced that we can improve the product. | |||

Those products are namely still expensive and the spoon is attached to the device. Our goal is to produce a simple and cheap working device that can be attached to any spoon to create a natural eating experience. | |||

[[File:Enterprisegood1.jpg|thumb|center|900px|''Figure 1: Other solutions for the same problem, Stakeholder Enterprise'']] | |||

== Survey == | |||

A survey has been set up to find out how the prototype can be better shaped and which requirements have to be met. This survey was sent to several Parkinson associations. The first association we chose to message was called Parkinson Vereniging. We chose to send it here, as it is the largest institution of Parkinson's disease in the Netherlands. It was decided to conduct a survey in the Netherlands, as those associations are best accessible and the quickest response to our survey. The e-mail address we sent it to is: info@parkinson-vereniging.nl<ref>Parkinson Vereniging. (z.d.). Contact - Parkinson Vereniging. Retrieved from https://www.parkinson-vereniging.nl/vereniging/over-ons/contact</ref>. The survey is addressed to the caregivers of patients with Parkinson's. Here's what the survey looks like. [https://docs.google.com/forms/d/e/1FAIpQLSfME0exoPSjNz4ReOvD5ulC4dInkMmjatNTKIomBhKOiNx2iQ/viewform?usp=sf_link Link Survey]. They responded by telling us the Parkinson Vereniging wasn't really meant for that. They did however link two other options to continue our research. The first link they sent was of parkinsonzorgzoeker.nl<ref>parkinsonzorgzoeker. (z.d.). Contact - parkinsonzorgzoeker. Retrieved from https://(www.parkinsonzorgzoeker.nl</ref>. However, this site is mostly meant for approaching individuals, whereas we needed to contact as many people as possible. We thus decided that this site was not useful for us. The next link they sent was also from Parkinson Vereniging, but this time meant especially for research requests<ref>Parkinson Vereniging. (z.d.). Contact - Parkinson Vereniging. Retrieved from https://www.parkinson-vereniging.nl/onderzoek/oproepen-onderzoek/oproepen</ref>. We also sent them a mail. However, they reacted saying that they were for research centred around the people who have Parkinson's disease, not the caretakers. We then chose to go for different associations. We found Brabantzorg<ref>Brabantzorg. (z.d.). Contact - Brabantzorg. Retrieved from https://www.brabantzorg.eu/contact/Paginas/default.aspx</ref>, but they told us they were too busy because of corona. This is also the case for an association called Careyn<ref>Careyn. (z.d.). Contact - Careyn. Retrieved from https://www.careyn.nl/contact-met-careyn/</ref>. They also informed us that they were too busy with corona. The last association we messaged was 24uurszorgsevice<ref>Brabantzorg. (z.d.). Contact - Brabantzorg. Retrieved from https://www.24uurszorgservice.nl/contact/</ref>. They haven't responded yet. | |||

In view of circumstances (the COVID-19 virus) we still send the survey to the caregivers, but bearing in mind that there was probably no response to this, because the caregivers have their hands full. Hoping that there would be a reaction, it was the intention that a thematic analysis<ref>VPPK. (2017 maart). Thematic Analysis. Retrieved from https://www.vppk.be/wp-content/uploads/2017/03/THEMATIC_ANALYSIS.pdf</ref> was carried out on the results. This allowed us to make our product even better for the users, but given that we unfortunately did not have any responses to the survey, the requirements that follow in the next section are only based on the USE analysis and thus on literature study. | |||

== Requirements == | == Requirements == | ||

The requirements follow from the user analysis. This is because the users are going to use the product and therefore the device must meet their requirements. | The requirements follow from the user analysis. This is because the users are going to use the product and therefore the device must meet their requirements. | ||

{| class="wikitable" | border="1" style="border-collapse:collapse" | {| class="wikitable" | border="1" style="border-collapse:collapse" | ||

| Line 459: | Line 457: | ||

|- | |- | ||

| R1 | | R1 | ||

| The | | The device must cancel out at least 60% -70% of a sudden movement caused by a tremor | ||

|- | |- | ||

| R2 | | R2 | ||

| The | | The device must be able to withstand heat flux | ||

|- | |- | ||

| R3 | | R3 | ||

| The | | The device must be able to withstand water or other liquid | ||

|- | |- | ||

| R4 | | R4 | ||

| Line 477: | Line 475: | ||

|- | |- | ||

| R6 | | R6 | ||

|The | | The device must ensure that a person with a disability in the nervous system can eat independently | ||

|- | |- | ||

| R7 | | R7 | ||

| Line 483: | Line 481: | ||

|- | |- | ||

| R8 | | R8 | ||

| The weight of the spoon must not be more than that | | The weight of the spoon must not be more than that of a normal spoon | ||

|- | |- | ||

| R9 | | R9 | ||

| The cost of the | | The cost of the device must not be higher than 100 euros | ||

|- | |- | ||

| R10 | | R10 | ||

| Line 492: | Line 490: | ||

|- | |- | ||

| R11 | | R11 | ||

| The device must work for | | The device must work for 3 hours without the need for replenishing batteries. | ||

|- | |- | ||

| R12 | | R12 | ||

| Line 498: | Line 496: | ||

|- | |- | ||

| R13 | | R13 | ||

|The device must be durable and able to withstand | |The device must be durable and able to withstand sustained use | ||

|- | |- | ||

| R14 | | R14 | ||

| Line 510: | Line 508: | ||

'''Technical Requirement Justification''' | '''Technical Requirement Justification''' | ||

It must be measurable whether the device works or not, which is why it has been stated in the requirements that the spoon must be able to | It must be measurable whether the device works or not, which is why it has been stated in the requirements that the spoon must be able to resolve 60% to 70% of all tremor movements. In this way, it is testable whether the spoon is indeed functioning properly. The percentages come from literature studies, from similar products. This study demonstrated a 71% to 76% reduction in tremor with the ACT device on<ref name="Pathak" />. Moreover, the classical Parkinson's tremor that occurs at rest is often asymmetrical and has a distal maximum and a typical frequency of 4–6 Hz<ref> Zach, H., Dirkx, M., Bloem, B. R., & Helmich, R. C. (2015). The Clinical Evaluation of Parkinson's Tremor. Journal of Parkinson's disease, 5(3), 471–474. retrieved from: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4923747/ https://doi.org/10.3233/JPD-150650 </ref>. So to meet the requirement of 60 to 70%, 2.6 - 3.9 Hz would have to be cancelled. | ||

The product must also be able to withstand heat flux and liquid. This is because it is used when eating | The product must also be able to withstand heat flux and liquid. This is because it is used when eating hot meals. For example, think of soup, which is both liquid and hot. | ||

Another standard but important requirement is the lowest possible | Another standard but important requirement is that the product should consume the lowest energy possible, which is self-explanatory. | ||

The last technical requirement is very important. As you can read in the USE Analysis section, there are similar products that also help people with tremors to eat independently. However, their product is a spoon, fork or knife that eliminates tremors. We want to make a product that can be attached separately to a spoon, fork or knife. In this way you only have to take the small device with you and not all the adjusted cutlery. | The last technical requirement is very important. As you can read in the USE Analysis section, there are similar products that also help people with tremors to eat independently. However, their product is a spoon, fork or knife that eliminates tremors. We want to make a product that is modular, so it can be attached separately to a spoon, fork or knife. In this way, you only have to take the small device with you and not all the adjusted cutlery. | ||

| Line 519: | Line 517: | ||

'''Functional Requirement Justification''' | '''Functional Requirement Justification''' | ||

The most important requirement is | Of course, The most important requirement is that the spoon must help the user to eat independently. Furthermore, there are also requirements for the weight and size of the device. This is because people with Parkinson's disease already have trouble eating, and therefore the size and weight must be kept as small and as light as possible, so as not to add any more obstacles. The price of the spoon is also important since comparable but very expensive products are already on the market. We want to develop a product that is affordable for everyone, so a requirement has been set for the price of the product. Furthermore, the device must have a constructive elegance, this requirement speaks for itself. It must look presentable, or nobody would want to use it. Another functional requirement is that the service life of the spoon should last approximately 3 hours. This is because the device must at least accompany a meal since people do not want to replace the batteries in the middle of the meal. | ||

The device should be natural to use because a lot of elderly (especially those who are not mentally healthy anymore) struggle to use new technologies. If the device is not natural and simple to use, the eating experience might only be more stressful than before. The device should be durable because it will be used multiple times per day and will be cleaned and moved all the time. Furthermore, people with tremors can accidentally drop this device on the ground and bump it around, so it should be sturdy enough to withstand all of | The device should be natural to use because a lot of elderly (especially those who are not mentally healthy anymore) struggle to use new technologies. If the device is not natural and simple to use, the eating experience might only be more stressful than before. The device should be durable because it will be used multiple times per day and will be cleaned and moved all the time. Furthermore, people with tremors can accidentally drop this device on the ground and bump it around, so it should be sturdy enough to withstand all of these incidents. As already stated before, the device must be separately attached to cutlery, but it is important that it is able to grab onto (almost) all cutlery and keep it secure. This makes our product stand out as it can be applied to the already provided cutlery. The last requirement, that the device must be compact and streamlines is also important. If there are loose parts or parts sticking out, they can get stuck to the environment which stops the user from eating. Especially due to the tremors the device will move around a lot and we do not want it to get stuck to anything. | ||

== | == Systems for holding spoon == | ||

From the USE analysis, the requirement emerged that our product must be a device that can be attached to the spoon (or other cutlery) and that it should be a separate device. This is because it then becomes much more portable. In this way, you only have to take the small device with you and not all the adjusted cutlery. However, this requires a system that ensures that the device can be attached to any spoon (or other cutlery), regardless of its size. Research has been done into which type of system would work best for this. In this section, you can read the results of the research. | |||

There are several ways to hold the spoon in place within the tool. It should be able to tightly hold on to almost any type of spoon and should thus be able to get a grip on different kinds of handles. Some of these systems offer a part of the solution or more. | |||

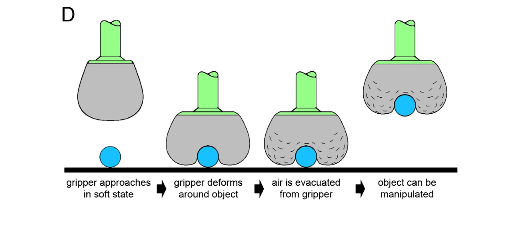

'''Gripper''' | |||

= | One of these systems is a gripper for small parts. These grippers are made to accommodate to different kinds of weights and shapes of small objects<ref> | ||

Camillo, J. (z.d.). Grippers for Small Parts. Geraadpleegd op 23 Maart 2020, van https://www.assemblymag.com/articles/94073-grippers-for-small-parts?iframe=1 | |||

</ref>. However, these grippers are mostly designed for small and delicate parts notes Costas Charalambous :“Grippers and vacuum cups always need a light tough to properly grab small parts because they’re delicate,”. Nonetheless, these grippers could be applied to our product even if they're originally made for more delicate parts. You can see such a gripper in Figure 2. | |||

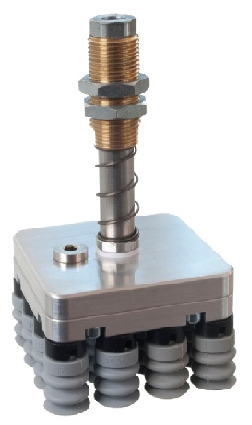

'''Vacuum Gripper with Fingers''' | |||

Another one of these systems is a vacuum gripper which you can see in Figure 3. These grippers are very useful for gripping any kind of workpieces regardless of size, material and surface. It is also very lightweight and would be ideal for our device. However, this product seems to be very expensive. As we want to develop a cheap solution we will not be able to use this system, as one of our requirements mentions that the costs should be as low as possible. | |||

'''Vacuum Gripper wrapped around''' | |||

The third system is similar to the vacuum system, but replaces the "fingers" with a material that wrappes around the object and holds it. It is demonstrated in Figure 4. This material can meld to any shape upon contact with the object<ref>Wevolver | Knowledge shared by technology developers and scientists. (z.d.). Retrieved from https://www.wevolver.com/wevolver.staff/universal.robotic.gripper/</ref>. This system reduces the amount of parts that have to be controlled and can thus be more reliable and cheap. | |||

<div style="display: inline; width:1200px; float: right;"> | |||

<div style="display: inline; width:400px; float: left;"> | |||

[[File:gripper.jpg|200px|thumb|''Figure 2: Gripper system for small parts'']] | |||

<div style=" | </div> | ||

[[File:gripper.jpg]] | <div style="display: inline; width:400px; float: right;">[[File:material.png|300px|thumb|left|''Figure 4: Material that wrapped around the object'']] | ||

< | |||

''Figure 4: | |||

</div> | </div> | ||

<div style=" | <div style="display: inline; width:300px; float: right;">[[File:vacuum.png|200px|thumb|left|''Figure 3: Vacuum gripper system'']] | ||

[[File:vacuum.png| | |||

''Figure | |||

</div> | </div> | ||

</div> | </div> | ||

<br><br><br><br><br><br><br><br><br><br><br><br><br><br> | |||

This research was important to realise what systems | This research was important to realise what systems exist right now. However, we also found out that these systems are not applicable for our product. These systems are indeed very accurate and useful, but as we stated before, we want a affordable product. This means that we cannot use these systems. The attachment system we ended up using is very simple and described in the 3D printing section. | ||

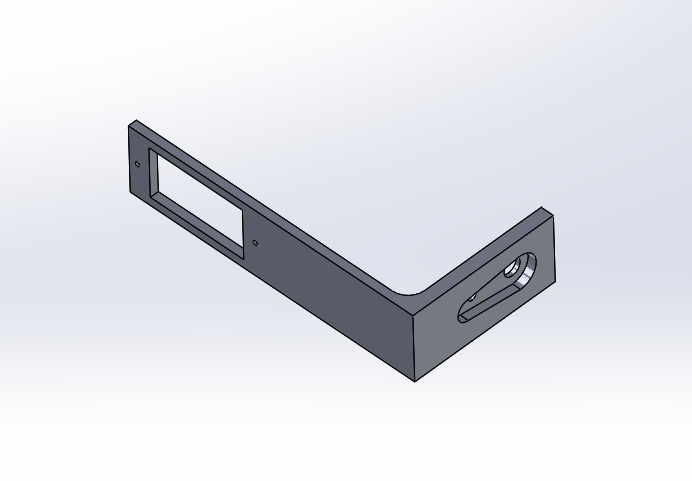

== 3D printing == | == 3D printing == | ||

To make the case for all the electronics, we decided to use 3D printing to our advantage. However before we can print something, we first need to draw the case. For this we decided to use Solidwork. With this program we are able to accurately draw a case | To make the case for all the electronics, we decided to use 3D printing to our advantage. However, before we can print something, we first need to draw the case. For this we decided to use Solidwork. With this program we are able to accurately draw a case since Solidwork makes it very easy to draw shapes with precise lengths. Solidwork also allows for easy fixes since if you change the length of one part Solidwork changes the other parts to fit this change. | ||

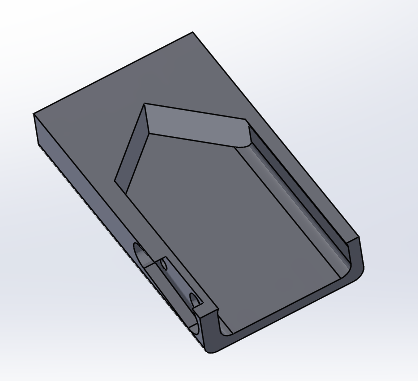

The first step in designing the case is finding a way to hold most spoons without damaging it. Since we want our design to work for many different spoons, and every spoon has a different handle design, we needed to find a cheap way in which we could attach all spoons to our design. We decided to make a tube to put the spoon | '''Holding the spoon''' | ||

[[file:screwKey.jpg|thumb|100px|''Figure 5: Screw key to make turning easier'']] | |||

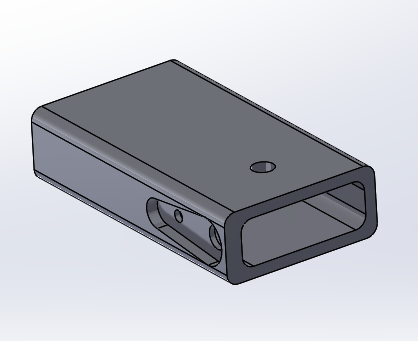

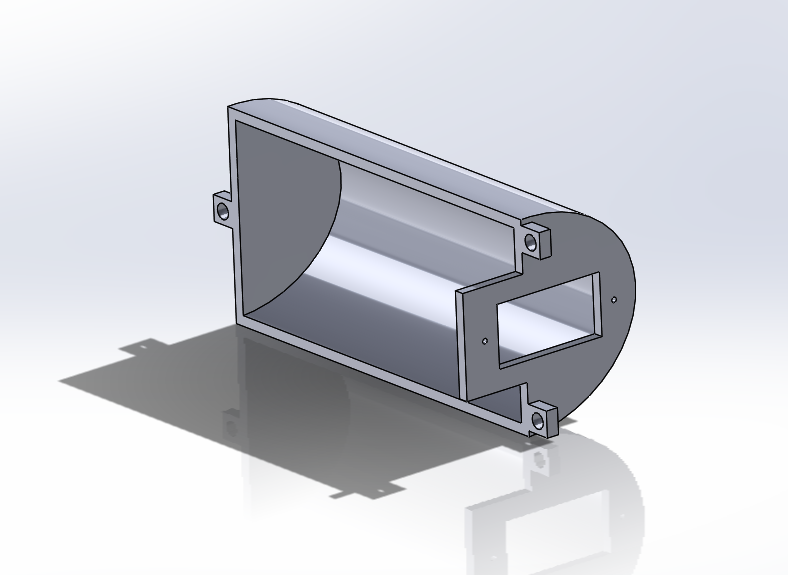

The first step in designing the case is finding a way to hold most spoons without damaging it. Since we want our design to work for many different spoons, and every spoon has a different handle design, we needed to find a cheap way in which we could attach all spoons to our design. We decided to make a tube to put the spoon into, and then secure the spoon with a screw. To prevent damage to the spoon a piece of rubber can be added to the screw, however even without the rubber we did not damage the spoon by jamming it. To make it easier to turn the screw we could also add an attachment to the screw which you can easily turn, which would look like the one in Figure 5. Another problem was that it could be difficult to get the spoon in the center of the holder. To make this easy we made a V shape in the back of the holder which moves the back of the spoon to the center of the holder, shown in Figure 7. | |||

<div style="display: inline; width:1200px; float: right;"> | <div style="display: inline; width:1200px; float: right;"> | ||

<div style="display: inline; width: | <div style="display: inline; width:550px; float: left;"> | ||

[[File:holder.png|300px|thumb|''Figure | [[File:holder.png|300px|thumb|''Figure 6: 3D drawing of holder '']] | ||

</div> | </div> | ||

<div style="display: inline; width: | <div style="display: inline; width:600px; float: right;">[[File:vInside.png|250px|thumb|left|''Figure 7: v shape inside holder to center the spoon'']] | ||

</div> | </div> | ||

</div> | </div> | ||

| Line 589: | Line 579: | ||

{{break}} | {{break}} | ||

{{break}} | {{break}} | ||

<br> | |||

'''Place servo's''' | |||

[[File:connection.png|300px|thumb|''Figure 8: connection piece'']] | |||

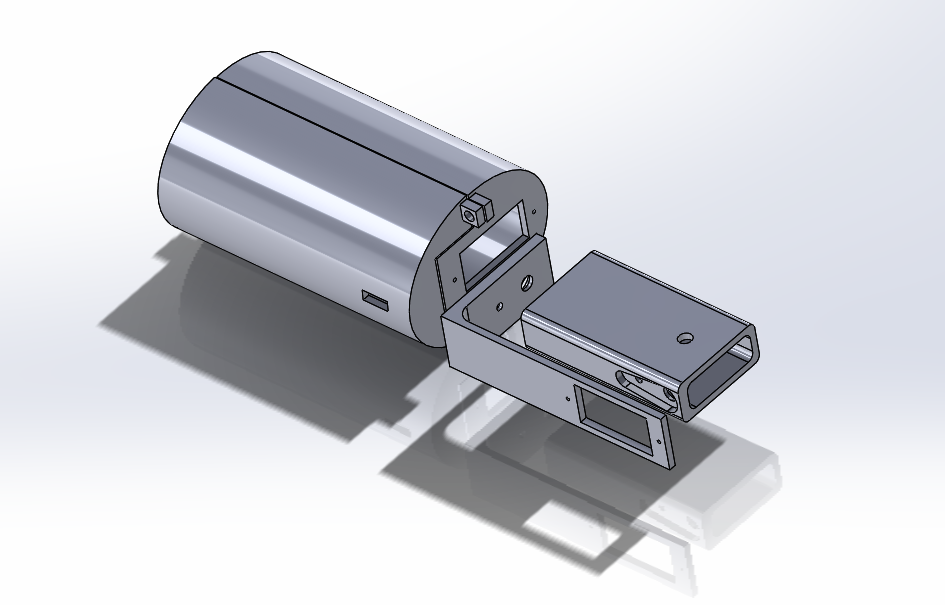

The second step in our design was to find a place for the servos. We could not just attach both servos to the handle and the holder, since then the holder would have two attachment points with the handle and would not be able to turn. We thus needed to either first correct the pitch or the roll axis relative to the handle. If we tried to correct the pitch axis before the roll axis, we would need to attach the pitch servo to the handle, then attach the roll servo to the pitch servo, and lastly attach the holder to the roll servo. This would however not be possible since rotating the handle around the roll axis would change the axis the pitch servo would correct in. Thus we first needed to correct the roll axis and then correct the pitch axis. We had to attach a handle to the roll servo, attach the roll servo to the pitch servo and finally connect the pitch servo to the holder. The roll servo needs to be behind the spoon in order to turn around the spoons roll axis, the pitch servo needs to be to the side of the spoon. Thus to be able to attach the roll servo to the pitch servo we need to make a connection piece. This connection piece needs to move from the side of the holder to the back of the holder while giving the holder enough space to turn along the pitch axis. The pitch servo needs to be attached to the connection on the body itself, while the roll servo needs to be connected to the connection with the feet of the servo. | |||

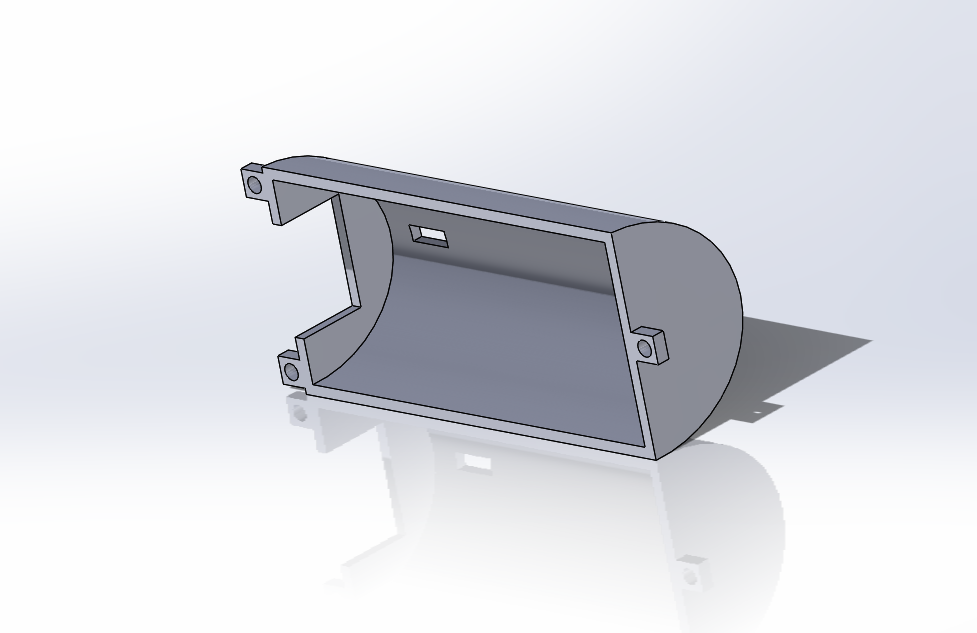

'''The handle''' | |||

Finally, we need to design a handle to hold the device with. This handle needs to be attached to the body of the roll servo, and have enough room inside it for the rest of the electronics. Because all the electronics need to be in the handle we also needed a way to open and close the handle. We decided to make the handle in two pieces, which we can attach together with screws. This also allows us to easily open the handle to replace batteries or remove broken electronics. Since one of the servos is outside the handle we needed a way for the cable to get inside the handle. In order to do this, we made a little cut in the side of one of the parts of the handle. With all the electronics that need to fit in the handle, the handle is bigger than we would have liked. This could be solved by using electronics particularly developed for this product, such that the shapes of the electronics allow for a more compact design. | |||

<div style="display: inline; width:1200px; float: right;"> | <div style="display: inline; width:1200px; float: right;"> | ||

<div style="display: inline; width: | <div style="display: inline; width:400px; float: left;"> | ||

[[File:handleSide1.png|300px|thumb|''Figure | [[File:handleSide1.png|240px|thumb|''Figure 9: part 1 of the handle with servo hole'']] | ||

</div> | |||

<div style="display: inline; width:300px; float: right;">[[File:assemble.png|280px|thumb|left|''Figure 11: Placement of the parts without electronics'']] | |||

</div> | </div> | ||

<div style="display: inline; width: | <div style="display: inline; width:400px; float: right;">[[File:handleSide2.png|300px|thumb|left|''Figure 10: part 2 of the handle with cable hole'']] | ||

</div> | </div> | ||

</div> | </div> | ||

<br><br><br><br><br><br><br><br><br><br><br><br><br><br> | |||

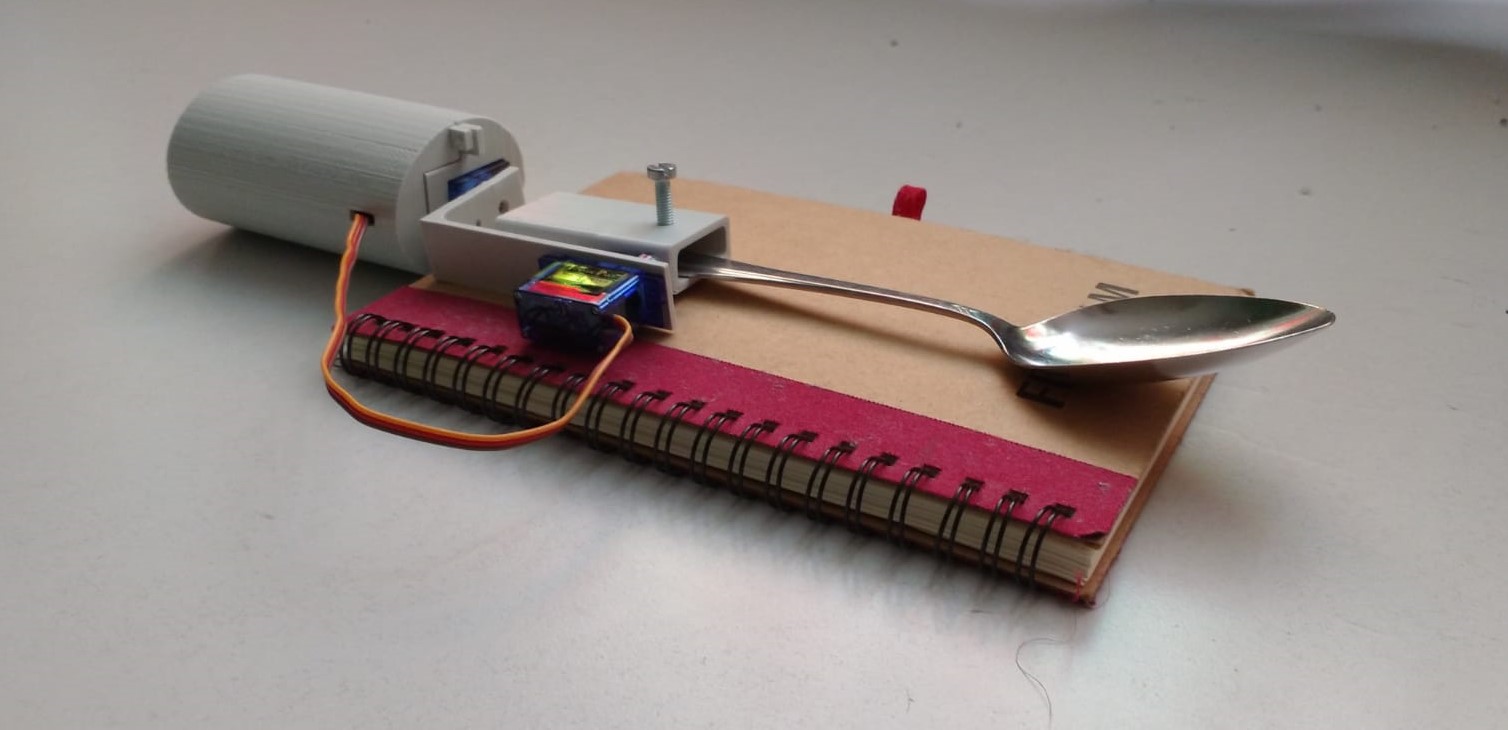

'''The results''' | |||

[[File: | Below the printed results can be seen. The idea was to use the 3D printed case in the prototype, but because of the COVID-19 outbreak, we were unable to put the electronics together with the 3D printed component. This means that all these pictures are without most of the electronics. Since the servos used in the pictures are borrowed, we were unable to connect them to the parts thus in Figure 12 a notebook was put under the spoon in order to get the spoon on the correct height such that it looked like the product is fully attached. | ||

<div style="display: inline; width:1200px; float: right;"> | |||

<div style="display: inline; width:400px; float: left;"> | |||

[[File:3DPrintFull.jpeg|345px| thumb |''Figure 12: Prototype without electronics'']] | |||

</div> | |||

<div style="display: inline; width:300px; float: right;">[[File:handleRoom.jpeg|300px | thumb | left | ''Figure 14: Inside of the handle'']] | |||

</div> | |||

<div style="display: inline; width:400px; float: right;">[[File:servoConnection.jpeg|300px | thumb | left | ''Figure 13: Connection piece with servo's'']] | |||

</div> | |||

</div> | |||

== Prototype == | == Prototype == | ||

===Circuit=== | ===Circuit=== | ||

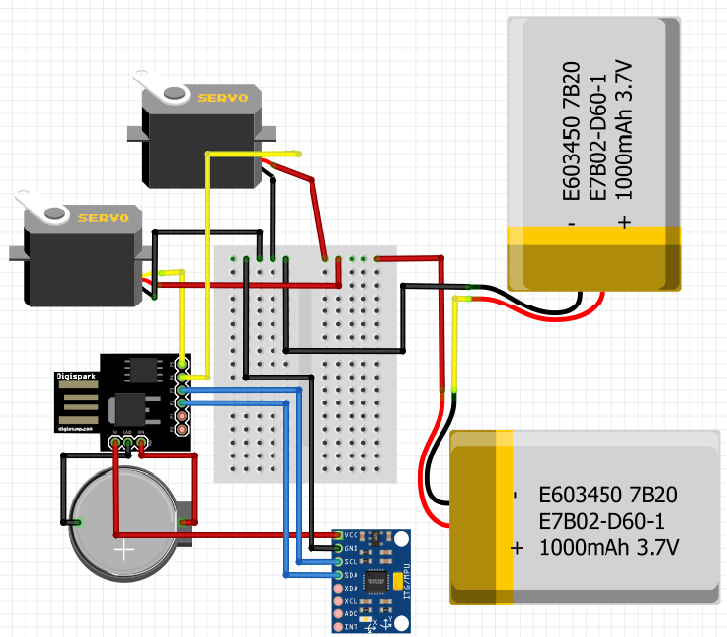

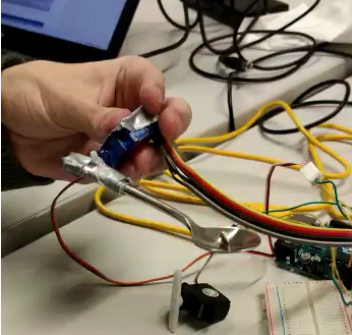

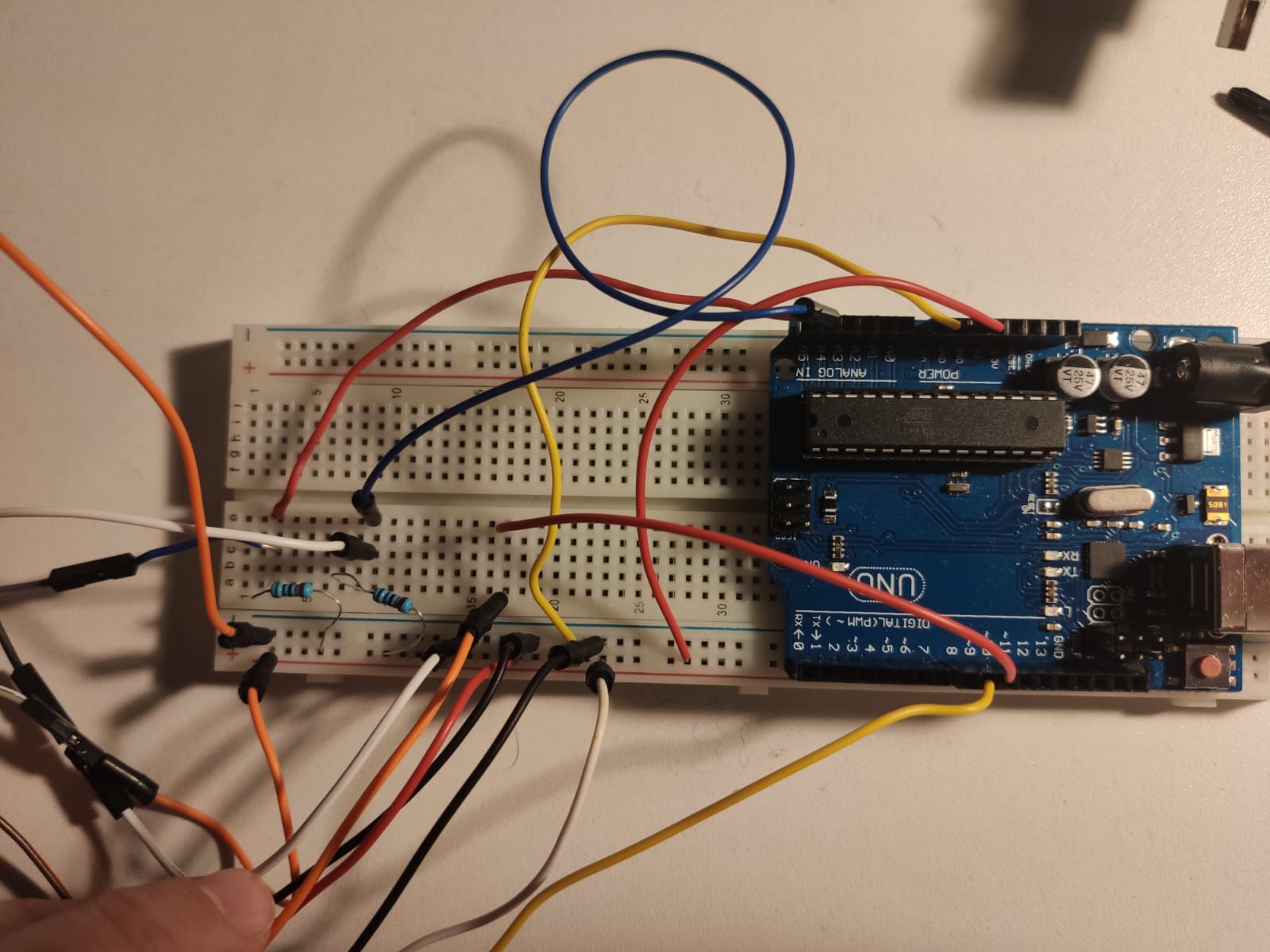

To get an idea of how such a spoon would work we started with a very simple prototype in week 3. This prototype works with the active force method. The prototype will first be focused on spoons, since not all cutlery (spoons, forks and knives) have to be stabilized in the same way. Two servos will be used to compensate movements on the pitch and roll axis of rotation ([https://en.wikipedia.org/wiki/Six_degrees_of_freedom#/media/File:6DOF.svg]). A picture showing | To get an idea of how such a spoon would work, we started with a very simple prototype in week 3. This prototype works with the active force method. The prototype will first be focused on spoons, since not all cutlery (spoons, forks and knives) have to be stabilized in the same way. Two servos will be used to compensate movements on the pitch and roll axis of rotation ([https://en.wikipedia.org/wiki/Six_degrees_of_freedom#/media/File:6DOF.svg]). A picture showing a graphical representation of the pitch, roll and yaw axes can be seen in Figure 16 in the section Design Choices, further on in the wiki. The movement of the spoon will be measured by an MPU6500 accelerometer. The servos and sensor will be attached to a Digispark Attiny85 microcontroller. 4 AAA batteries will be used to power the circuit. The prototype works with a PID controller by inducing a force opposite of the measured acceleration, which then aims to bring the spoon to the reference position. The connection of these components can be seen in the following Figure: | ||

[[File:Circuitstabilizingspoon.PNG]] | [[File:Circuitstabilizingspoon.PNG|thumb|center|600px|''Figure 15: Circuit for Prototype'']] | ||

=== Arduino code === | |||

'''Active force method''' | |||

The Arduino code for the very first prototype without PID controller is shown below. | The Arduino code for the very first prototype without PID controller is shown below. | ||

[[Arduino code 1]] | [[Arduino code 1]] | ||

'''Prototype with PID controller''' | |||

The Arduino code for the prototype with the PID controller can be seen below. Some comments have been added to explain the code. | The Arduino code for the prototype with the PID controller can be seen below. Some comments have been added to explain the code. | ||

| Line 630: | Line 641: | ||

=== Design Choices === | === Design Choices === | ||

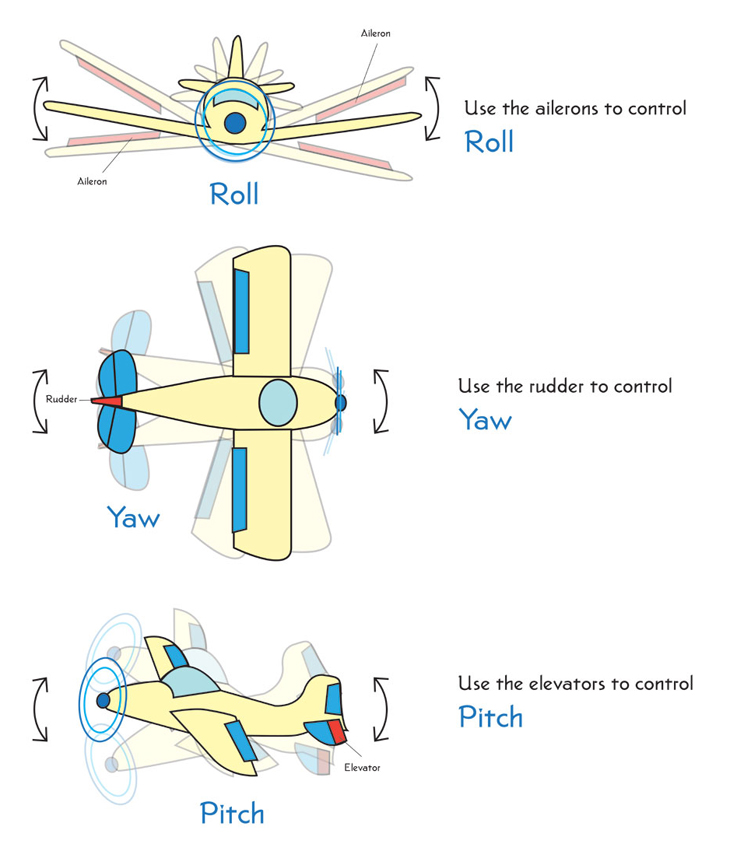

'''Stabilizing two or three axes?''' | '''Stabilizing two or three axes?''' | ||

How many axes the spoon should stabilize is a question that quickly came up. We use the pitch, roll and yaw axes that are usually used in planes. These axes are also frequently mentioned in literature and they are perfect for the stabilization of the spoon. Figure | How many axes the spoon should stabilize is a question that quickly came up. We use the pitch, roll and yaw axes that are usually used in planes. These axes are also frequently mentioned in literature and they are perfect for the stabilization of the spoon. Figure 16 below shows these axes for clarity. It is obvious that the pitch and roll axes are necessary to stabilize, to make sure that food doesn’t fall off the spoon. However, the question arose whether the yaw axis is necessary, helpful, or completely useless. Below some of the arguments for and against using 3 axes instead of 2 are outlined. | ||

[[File:Aircraft axes.jpg|thumb|center|300px|x350px|Figure | [[File:Aircraft axes.jpg|thumb|center|300px|x350px|Figure 16: The roll, pitch and yaw axes, displayed from the viewpoint of an aircraft<ref>Roll, Pitch and Yaw, How things Fly. https://howthingsfly.si.edu/flight-dynamics/roll-pitch-and-yaw</ref>]] | ||

The main argument for only stabilizing two axes is that the yaw axis simply doesn’t have to be stabilized. The movement in the same plane as the spoon (the yaw axis) would not contribute to many difficulties with eating. If this axis were to be stabilized, you even run the risk of stabilizing voluntary motions. Another argument for not using 3 motors is that it would make our design bulkier. It is critical that the stabilizing mechanism is as small and light as possible for ease of use, shown and discussed in our requirements of the product. | The main argument for only stabilizing two axes is that the yaw axis simply doesn’t have to be stabilized. The movement in the same plane as the spoon (the yaw axis) would not contribute to many difficulties with eating. If this axis were to be stabilized, you even run the risk of stabilizing voluntary motions. Another argument for not using 3 motors is that it would make our design bulkier. It is critical that the stabilizing mechanism is as small and light as possible for ease of use, shown and discussed in our requirements of the product. | ||

'''Type of controller''' | '''Type of controller''' | ||

| Line 644: | Line 657: | ||

We already had a preference for a PID controller after we saw that many studies in the literature were also using them for prototypes and initial designs for self-stabilizing devices. A few of us already have experience with PID controller so it would take less time to set up. We do realize that PID controllers are outdated in the sense that the technology is pretty old, but for the sake of building an initial prototype in the limited timeframe that we had in this course (8 weeks) we think this is a good stepping stone for the prototype, which could be improved further with state of the art technology if this product is further worked out. | We already had a preference for a PID controller after we saw that many studies in the literature were also using them for prototypes and initial designs for self-stabilizing devices. A few of us already have experience with PID controller so it would take less time to set up. We do realize that PID controllers are outdated in the sense that the technology is pretty old, but for the sake of building an initial prototype in the limited timeframe that we had in this course (8 weeks) we think this is a good stepping stone for the prototype, which could be improved further with state of the art technology if this product is further worked out. | ||

'''Choice of components''' | '''Choice of components''' | ||

The individual physical components for the first prototype have been chosen with the following things in mind. First is the compatibility. The component must do what it is expected to do (shown in the circuit and description above) and have enough strength to fulfill the tasks (e.g. the servos) Second is the size of the component. As mentioned in the requirements, the total device should be as small and light as possible, in order to make it as comfortable and easy to use. The last important property of the component that was looked at is the price. Again the requirements mention the price should be as low as possible because many comparable but way more expensive products are already on the market. | The individual physical components for the first prototype have been chosen with the following things in mind. First is the compatibility. The component must do what it is expected to do (shown in the circuit and description above) and have enough strength to fulfill the tasks (e.g. the servos). Second is the size of the component. As mentioned in the requirements, the total device should be as small and light as possible, in order to make it as comfortable and easy to use. The last important property of the component that was looked at is the price. Again the requirements mention the price should be as low as possible because many comparable but way more expensive products are already on the market. | ||

===The First Prototype: Proof of Concept=== | ===The First Prototype: Proof of Concept=== | ||

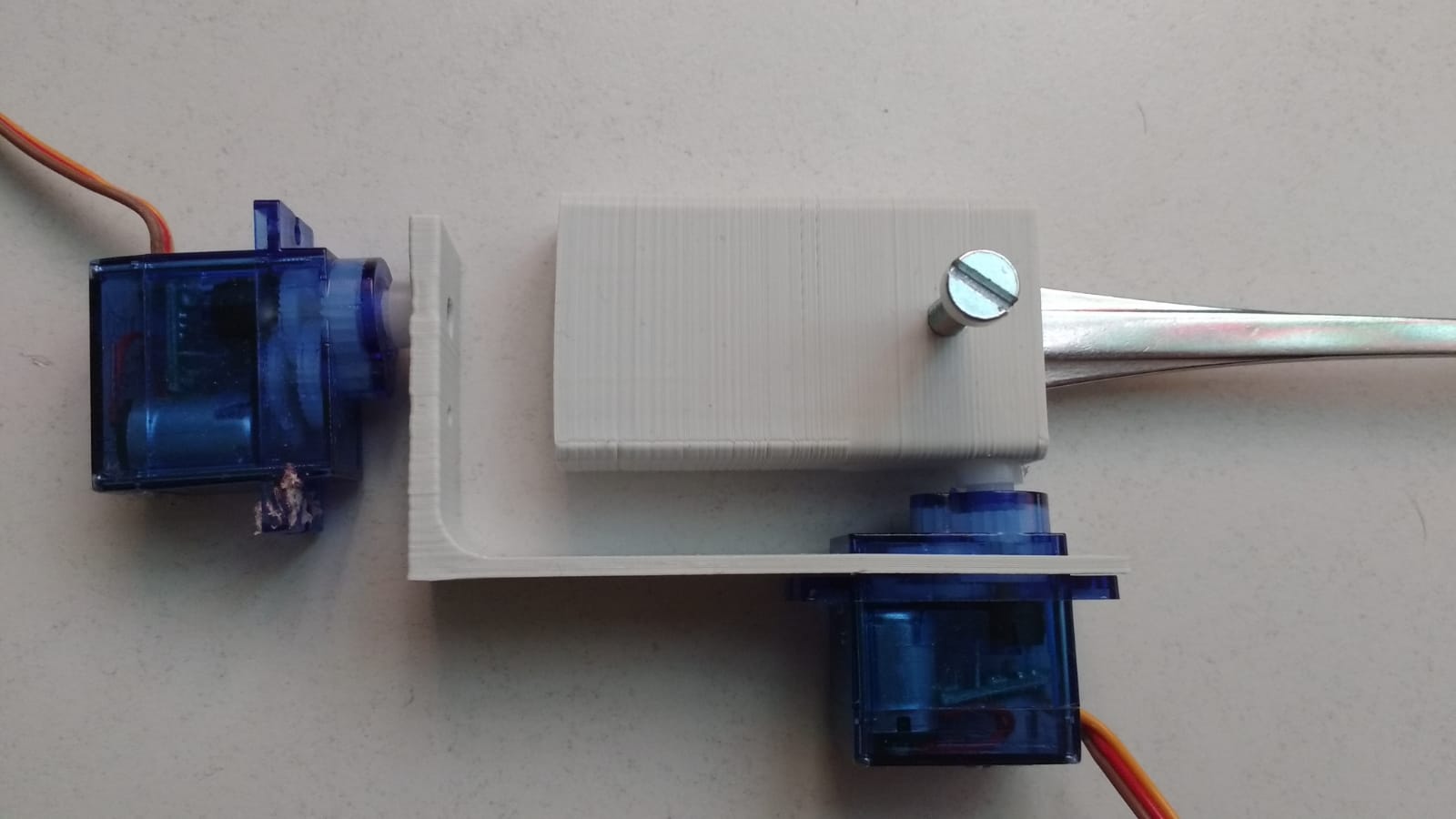

The initial prototype has been made in week 3. The goal of this test is to see whether our ideas about stabilizing the spoons actually work. Figure | The initial prototype has been made in week 3. The goal of this test is to see whether our ideas about stabilizing the spoons actually work. Figure 17 below shows this initial prototype. The initial prototype consists of the Inertial Measurement unit, one servo motor and a spoon, all connected to the Arduino. The code that is used is the first one shown in the section Arduino code. Even though this code is written for two motors, it still works for any set-up with one motor as well. So now we have only one sensor present, but we see that when the sensor and motor with spoon attached are rotated in the pitch direction, the spoon keeps stays level. From this we conclude that the proof of concept is a success and from here we integrated the other components into the final prototype. | ||

[[File:Prototype.png|280px|thumb|center|''Figure 17: First Prototype: only pitch axis stabilized'']] | |||

===The Process=== | |||

After typing a few keywords in Google it seemed like making the prototype wouldn’t be a particularly hard task. There are lots of examples of people who made something like we are attempting<ref> https://create.arduino.cc/projecthub/RupinC/assistive-spoon-for-patients-with-parkinson-s-3628b6 </ref><ref>https://www.instructables.com/id/Gyro-Stabilizer-W-Arduino-and-Servo/</ref><ref>https://howtomechatronics.com/projects/diy-arduino-gimbal-self-stabilizing-platform/</ref>. The first approach was to write our own PID controller based on the codes used in these projects and the help from the examples in the Arduino PID library <ref>https://playground.arduino.cc/Code/PIDLibrary/</ref>. After that the idea was to improve the controller in order to get the desired stabilization. | |||