PRE2018 3 Group17: Difference between revisions

No edit summary |

|||

| (756 intermediate revisions by 5 users not shown) | |||

| Line 1: | Line 1: | ||

<link rel=http://cstwiki.wtb.tue.nl/index.php?title=PRE2018_3_Group17&action=edit"stylesheet" type="text/css" href="theme.css"> | |||

<link href='https://fonts.googleapis.com/css?family=Roboto' rel='stylesheet'> | |||

<div style="width:calc(100vw - 150px);background-color:#EFEFEF;padding-bottom:40px;position:absolute;top:0;left:0;"> | |||

<div style="font-family: 'Roboto','q_serif', Georgia, Times, 'Times New Roman', serif; font-size: 15px; line-height: 2; max-width: 1000px; word-wrap: break-word; color: #333; font-weight: 400; box-shadow: 0px 25px 35px -5px rgba(0,0,0,0.75); margin-left: auto; margin-right: auto; padding: 70px; background-color: white; padding-top: 25px;"> | |||

== Group members == | == Group members == | ||

| Line 24: | Line 29: | ||

| 1260529 | | 1260529 | ||

|} | |} | ||

= Abstract = | |||

Drones are being used for in more situations than ever before, this is due to their versatility. One of these situations is information gathering in disaster areas to efficiently lend help to the survivors. The main problem with drones, however, is the fact that they don't have a long battery life and need to be recharged quite often. This hampers the efficiency of these systems. It is therefore important that a solution to this problem is devised. The solution to this problem is a gas powered service drone that can replace the batteries of the surveillance drones in disaster areas, this drone can fly to its destination making it independent of the infrastructure of the environment. The surveillance drones can land on the service drones, which allows for the replacement of the batteries as seen in the animation below. Other important factors that are taken into account are the ability to land on many different kinds of terrain, the lifetime of the service drone and how wireless communication is handled. It should be noted that only hardware problems are discussed here as software problems could be follow-up research for this problem. | |||

[[File:Animation.gif|600px|center|Animation final system]] | |||

= All Robot Ideas = | = All Robot Ideas = | ||

| Line 36: | Line 45: | ||

= Problem Description = | = Problem Description = | ||

The employment of drones in disaster areas is an obvious application which can aid in the fast gathering of information concerning the situation and | The employment of drones in disaster areas is an obvious application which can aid in the fast gathering of information concerning the situation and locate survivors. In recent years, extensive research has been conducted using drones for this purpose. The focus of these studies was, among other topics: | ||

* Computer vision for recognizing survivors [ | * Computer vision for recognizing survivors [36]. | ||

* Communication among drones [ | * Communication among drones [37]. | ||

* Optimal routing [ | * Optimal routing [38]. | ||

Past research has created a good foundation towards the development of an actual product, however a practical issue that still remains is the limited operation time of these drones. This problem is especially challenging because when applied to disaster areas, a solution must be independent of existing infrastructure which is likely to be damaged. The aim of this project is to develop a solution to extend the operation time of aerial drones, which are very suitable for disaster area monitoring due to their independence of ground infrastructure | Past research has created a good foundation towards the development of an actual product, however, a practical issue that still remains is the limited operation time of these drones. This problem is especially challenging because when applied to disaster areas, a solution must be independent of existing infrastructure which is likely to be damaged. The aim of this project is to develop a solution to extend the operation time of aerial drones, which are very suitable for disaster area monitoring due to their independence of ground infrastructure but have an especially limited operation time compared to e.g. ground vehicles. Drones can be applied to many kinds of disaster, for the scope of this project only earthquakes will be considered. | ||

= Users = | = USE aspects = | ||

The USE aspects must be taken into account when designing a proper solution. The USE aspects are the Users, Society and Enterprise. Each of these has their own needs when designing for them. In general, the stakeholders want that the system would be fast and effective in what it does, which in this case is the extending of the operation time of drone systems used in different kinds of scenarios. It is important to also think about situations for which the solution is not designed for. This is done through a stakeholder analysis and to see what the different USE aspects would require from such a system. This analysis is done below and these will be used to set up the Requirements, Preferences and Constraints of the to be designed system. | |||

===Users=== | |||

The biggest group of stakeholders are the users, which consists of civilians, government organizations, and private or non-government organizations. These would all take advantage of the solution that is provided, in particular, those which are the intended end-users, i.e. the groups which will be involved during a natural disaster. Next, it will be described how these groups use the solution. | |||

==== Government Organizations ==== | |||

Organizations formed by the government to combat natural disasters will take the most advantage of the solution. When a natural disaster has taken place, emergency services or other organizations would want to gather information as quick as possible. With the designed solution, this will be possible in a shorter period of time and with less involvement of personnel necessary. | |||

==== Civilians ==== | |||

Civilians struck by natural disasters benefit from this solution. The quicker the help comes, the more beneficial it will be for the civilians. This counts for medical care, but also search and rescue. This also requires the solution to be quick when extending the flight time of the surveillance drones as taking too long will diminish the benefits of the given solution. The civilians will also come into direct contact with the drone if it were to come close to them. This means that the drone must also be safe for human interaction when it is present in the field. | |||

=== | ==== Private organizations/non-government organizations ==== | ||

Private organizations would be organizations that could use the designed solution for different purposes. Examples of these could be the security of property or delivery of packages. Contact between different companies was attempted and out of all of them, Aerialtronics was the only one to reply. | |||

'''Aerialtronics''' <br> | |||

Aerialtronics is the company that has been contacted during the project. The expertise and knowledge of the company provided a good view of the user. The user requires a highly efficient solution for limited operation time. The user struggles with the dilemma of the weight of the drones and the limited operation time. The balance is important and the solution could aid in finding this balance. <br> | |||

The Altura Zenith is one of the most commercially versatile drones in the world. This drone was kept in mind when designing a solution. The drone has a maximum flight time of up to 40 minutes and has eight brushless electric motors. The maximum payload of the drone is 3.0 kg and the maximum take-off weight is 9.65 kg. The drone makes use of a frequency of 2.4 GHz for the controller and the bandwidth for telemetry is 900 MHz. The range is 1000 m and the used material is 3k carbon fibre monocoque. The drone has a length and a width of 600 mm and a height of 470-550 mm. The maximum cruise speed is 20 m/s, so 72 km/h. A battery of 22.2 V and 20000 mAh is used. The maximum wind speed it is able to handle is 16 m/s and it could function in dry weather to light rain- and snowfall. <br> | |||

The major issue of the limited operation time of the drones could also be tackled in other ways. The company provided an example of the potential use of power pylons to recharge the batteries of the drones by means of induction. Another example provided by the company is making use of circulating drones in an area. So while one drone is recharging on a recharging platform, for example, the other drones are then circulating to cover the entire area. There has to be a certain overlap to make this work. If one drone is an area of for example 50 x 50 m, then another drone close by should cover a part of the area of the previously mentioned drone, to create an overlap. <br> | |||

The company has been very curious about the design during the project. Contact was mainly between the business development manager. The technical staff of the company has however also seen the final design and they have read the wiki page. They have provided some feedback. The montage of the batteries on the surveillance drones, so, not the drone that has been designed, was not clear to them. This point was elaborated on and explained fully and this explanation was also added to the wiki as this means that it was not explained well enough. They were also curious about the use of the GPS in the system, but due to the fact that this was not a focus of the project, it was decided that this was mainly present so an implementation could be devised by another group. In general, they were impressed by the design and thought it was a well thought-out design. After explaining the montage of the batteries on the surveillance drones they were impressed with the solution.<br> | |||

===Society=== | |||

Society as a whole would benefit from a solution to this problem. Considering that this solution can also be implemented into other drone systems and the fact that drone systems are becoming more common, think about drone delivery done by Amazon, this results in a benefit for the society due to these systems becoming more efficient. For people present in a disaster area this solution would be especially beneficial. This is due to the fact that this solution will save lives when implemented. This stakeholder will, therefore, want that the system is fast and efficient in what it does. | |||

===Enterprise=== | |||

Enterprise would consist of businesses that would market this solution. This drone could give interesting opportunities when marketed. Depending on the total cost of the system, the drone could be marketed as a replacement for using multiple drones at a time. This drone can then be seen as an expansion to the existing drone. This stakeholder would want the design to be marketable, this means that the cost must be low enough for the solution to be a valid alternative to other options for a given problem. This cost extends to both the manufacturing and operating cost of the system. | |||

= Approach = | = Approach = | ||

| Line 76: | Line 92: | ||

*4. The system needs to be able to communicate their location to drones and receive information on battery levels and location of drones. | *4. The system needs to be able to communicate their location to drones and receive information on battery levels and location of drones. | ||

In order to keep a narrow and well-defined problem, a general solution for the design will be chosen based on the benefits and drawbacks of some chosen concepts. This general design will then be used to choose an optimal design for each function in order. That means, for instance, that the design for function 4 will | In order to keep a narrow and well-defined problem, a general solution for the design will be chosen based on the benefits and drawbacks of some chosen concepts. This general design will then be used to choose an optimal design for each function in order. That means, for instance, that the design for function 4 will be chosen to work best combined with the designs for the other three already chosen functions. Once each function has been chosen, they will be worked out in greater detail, this time making sure all designs are fully compatible. In short, only one design option will be researched at a certain time, and the design of any option will be constrained by choices already made for the other options. | ||

==Deliverables== | |||

The final deliverables will consist of a design concept that has been expanded using technical drawings and a 3D model. These drawings and the model will be based on decisions made with the help of a MATLAB model. This MATLAB model will also be provided to show the effect of changing different properties of the design and whether or not changing these parameters to see if they have a positive effect on the system's effectiveness. | |||

All of these technical drawings, 3D models and mathematical models will also be uploaded here, this ensures that any group following up on this idea can start properly without having to reconstruct everything from scratch. | |||

= RPCs = | = RPCs = | ||

The RPCs for the system | The RPCs were constructed based on the needs of the stakeholders, the environment and any additional functions the system should be capable of handling. The full list of RPCs for the system is as follows: | ||

=== Requirements === | === Requirements === | ||

* | * The system must extend the operation time of surveillance drones. | ||

* | * The vehicle needs to be mobile. | ||

* | * The vehicle must be fully autonomous. | ||

* The vehicle must be able to return to the base after task completion or when in need to service. | |||

* | * The servicing one drone should take less than one minute. | ||

* | * The system must service at least 1 drone at a time. | ||

* | * The vehicle should be safe for human interaction. | ||

=== Preferences === | === Preferences === | ||

* The system should still function in "bad" weather conditions (rain, wind up to a certain speed). | * The system should still function in "bad" weather conditions (rain, wind up to a certain speed). | ||

* The | * The system should have low manufacturing and operation costs. | ||

* The system should be easily deployable. | |||

* The system should be | |||

=== Constraints === | === Constraints === | ||

* The system | * The system functions independently of available infrastructure. | ||

* | * The vehicle is operational on rough terrain. | ||

= Phase 1: Traversal of environment = | = Phase 1: Traversal of environment = | ||

In this section, several different concepts for the transport of the system will be discussed. The benefits and drawbacks of each concept in the given environment will be discussed so a well-informed choice can be made. | |||

In this section, several different concepts for the transport of the system will be discussed. The benefits and drawbacks of each concept in the given environment will be discussed so a well informed choice can be made. | |||

=== Ground vehicle === | === Ground vehicle === | ||

A ground drone that can move around the disaster area that can serve as a charging platform for drones. This comes with some up- and downsides. First of all the drone could move a bigger payload with the same amount of fuel when compared to a flying drone. It will also be less sensitive to weather conditions than an airborne drone. It does however have limited speed and movement depending on the state of the terrain. | A ground drone that can move around the disaster area that can serve as a charging platform for drones. This comes with some up- and downsides. First of all the drone could move a bigger payload with the same amount of fuel when compared to a flying drone. It will also be less sensitive to weather conditions than an airborne drone. It does, however, have limited speed and movement depending on the state of the terrain. | ||

This last point could prove troublesome after an earthquake. After such a disaster the rubble will prevent proper movement for smaller drones, larger drones could, however, have less trouble with this but can also need more space to move through. It is clear that a ground vehicle cannot follow the searching drones as well as it could if it were flying, this further complicates its function as a mobile charging platform. | |||

It also operates in a more dangerous environment compared to aerial drones. It must be mindful of unstable areas and if they hit an obstacle. It could, for example, cause some walls or a building to collapse. This then further endangers the lives of both the drone and survivors of the disaster. | |||

Ground drones do need to be given more attention to how they move around a disaster area. In general, some path planning has to be done from beginning to end. Considering that the area will be difficult to traverse and certain locations are destroyed, the drone will need some type of advanced vision analysis [2][4][5]. This would either require a constant connection to a computation server, or a considerable amount of processing power to achieve this. | |||

=== Balloon UAV === | === Balloon UAV === | ||

A balloon is added to a quadcopter, this balloon's lift partially cancels the weight of the quadcopter. This allows it to stay in the air for a considerably longer amount of time. The drone also does not have any problem with broken infrastructure due to the ability to fly. | A balloon is added to a quadcopter, this balloon's lift partially cancels the weight of the quadcopter. This allows it to stay in the air for a considerably longer amount of time. The drone also does not have any problem with broken infrastructure due to the ability to fly. | ||

This idea also has some downsides. First of all it would be difficult to keep stable in windy areas. It would therefore have difficulty with charging the drones using any method due to the movement of the two drones. The size of the balloon would also have to be large to cancel the weight enough for it to fly considerably longer. This is therefore not an ideal solution for the main drone design. | This idea also has some downsides. First of all, it would be difficult to keep stable in windy areas [6]. It would, therefore, have difficulty with charging the drones using any method due to the movement of the two drones. The size of the balloon would also have to be large to cancel the weight enough for it to fly considerably longer [7]. This is therefore not an ideal solution for the main drone design. | ||

=== Continuous flying large drone === | === Continuous flying large drone === | ||

A drone that can fly continuously without having to land. This drone uses up a lot of energy especially considering that drones usually only have a battery life of about 30 minutes during operation. The obvious solution to this would be by using alternative fuel sources or additional batteries. Alternative fuel sources could include diesel or petrol, which have a considerably higher energy density and therefore extend its range, even considering the lower efficiency of combustion engines. Such a large drone is however very costly to manufacture and uses a lot of resources during operation, which may be limited in a disaster scenario. More power cells could also be an improvement, but this would also increase the total weight of the drone and therefore decrease the flight time. This drone also suffers from other problems that aerial drones usually face. Its relatively large size and mass | A drone that can fly continuously without having to land. This drone uses up a lot of energy especially considering that drones usually only have a battery life of about 30 minutes during operation. The obvious solution to this would be by using alternative fuel sources or additional batteries. Alternative fuel sources could include diesel or petrol, which have a considerably higher energy density and therefore extend its range, even considering the lower efficiency of combustion engines. Such a large drone is however very costly to manufacture and uses a lot of resources during operation, which may be limited in a disaster scenario. More power cells could also be an improvement, but this would also increase the total weight of the drone and therefore decrease the flight time. This drone also suffers from other problems that aerial drones usually face. Its relatively large size and mass make it more stable in daunting weather conditions [6]. | ||

=== Hopping drone === | === Hopping drone === | ||

| Line 124: | Line 142: | ||

=== Large drone with chain of recharging drones === | === Large drone with chain of recharging drones === | ||

Fuel powered large drone. Can fly for around 1 hour without being | Fuel powered large drone. Can fly for around 1 hour without being refuelled or recharged itself. With a chain of refuelling drones, the large drone will be refuelled/recharged. The hopping drone is a concept that combines the best of both worlds in regards to aerial and terrestrial drones. It solves the traversal of the environmental problem in the ground drone, but also solves the stability problem of aerial drones, as it can land and charge the drones on the ground. | ||

== Conclusion == | |||

Out of the ideas and concepts discussed, the hopping drone seems to be the best solution. This concept combines the positive aspects of the aerial- and ground-based drones, these positive aspects are: | |||

* Use less power than an aerial drone due to the fact that it will rest on the ground when it has reached its destination. | |||

* Will stay stable when changing batteries due to standing on the ground when it does so. | |||

* Solves the terrestrial navigation problem by being able to fly over obstacles. | |||

* Drones can easily reach a target that is standing still. | |||

These aspects are all contributing factors to choosing this concept over others. | |||

= Phase 2: Increasing flight time of drones = | |||

For the drone to succeed in its function, it would need a method to extend the flight time of the drone. This can be done in a multitude of ways, below several concepts for increasing the lifetime of the search drones are discussed. The pros and cons will both be discussed so an informed decision can be made. | |||

=== Changing Batteries === | |||

Changing the batteries of a drone is one of the quickest methods to extend the drone's flight time. In this case, the downtime of the drone only consists of the time it takes to change the battery. This method also has zero power loss, which is a considerable advantage compared to charging the battery in the field. | |||

It does, however, have a few drawbacks. The relative positioning of the drone has to be far more precise compared to some charging methods. Multiple solutions have already been made for this problem, the solutions range between a 50% success rate to an almost 100% success rate [9][10][11][12]. These systems are quite similar, however, the system of [10] has the biggest success rate and will therefore be the basis for the design. | |||

=== Refuelling === | |||

Refuelling a drone using liquid fuel has its benefits. It is more energy dense, therefore, carrying fuel containing an equal amount of energy as batteries will be lighter. It is also already possible to refuel UAVs in the air, which means that refuelling on the ground would be easier to implement [13]. The major drawback to this idea is the fact that the drones would have to be fuel based drones. These drones usually aren't common and are more difficult to develop, complicating the surveillance drone design. Also, the fact that fuel-based vehicles and machines are slowly being phased out, makes an alternative solution more desirable. | |||

=== Charging === | |||

Recharging the drone's batteries is the most obvious choice to increase the flight time of the drones. This would require a way for the drone to be connected to the charging station. This can be approached by using the feet of the drone as charging points by making that and the contact point with the main drone conductive [14], it can also be approached by using wireless charging, a relatively new method of charging electronic equipment[8]. Both of these are relatively easy to implement, but they both have drawbacks. Both of these options suffer from power loss while transferring energy from one drone to the other, wireless charging is in this case worse than wired with an efficiency of around 65% [8]. The tradeoff made here is the ease of implementation and the efficiency of the transferal of power. | |||

=== Replacing Drones === | |||

This concept is an extension of the charging concept. This system will consist of a certain amount of fully charged drones that are transported using the main drone. When a currently flying drone is running low on battery, the drone can fly towards one of these 'Hub' drones and essentially get replaced by one of the dormant drones. This new drone will then continue with where the other drone left off in regards to its search for survivors. The drone that was just replaced can then be charged in the meantime. | |||

This idea has the smallest downtime, but will also require a lot of additional weight to be carried by the main drone. The charging time of the drones is also of importance, it should be able to finish charging a drone in the same time it takes for a drone to need a recharge. This means that an additional charging solution needs to be devised for it to function properly. The additional dormant drones are however also a waste of resources in a way, they could be used for searching instead of lying around not doing anything. | |||

== Conclusion == | |||

For this design step, it was decided to use the battery replacement concept. The reasoning for this is as follows: | |||

* As shown in the provided sources, it is possible to have a 100% success rate for changing batteries. | |||

* It is quicker than most conventional methods of charging. | |||

This concept does also have some drawbacks which come in the form of the weight of the added batteries. This problem is however alleviated because the system would still need to carry a set of batteries that can charge an equal amount of drones. The fact that the drone doesn't stay in the air for long also helps with the added weight, as it doesn't use as much power. Any additional problems with the longevity due to this weight will be solved in the next section which addresses it directly. | |||

= Phase 3: Energy storage = | |||

In order for the drone to keep flying, it will need to store the energy to do so. This can be done using batteries or fuel, and either bring their own possibilities and problems. In this phase, it is discussed how this energy storage will be executed. | |||

=== Big interchangeable batteries === | |||

[[File:PropellerData.PNG|350px|thumb|right|Propeller specifications for different dimensions [15]]] | |||

The energy density of Lithium metal batteries is 1.8 MJ/kg. | |||

From this, it can be deducted how much power is needed per hour to keep a large UAV of a given weight in the air. From that, an estimate of how big the battery must be, and how long it will keep in the air, can be given. <br> | |||

It is now known that the power needed to keep the drone in the air is 96.1683 W(J/s). This keeps 355.4167 g in the air. So, it takes 96.1683/0.3554167 = 270.579 W/Kg to keep the drone in the air. <br> | |||

So this means that for a drone of 2 kg, the drone would use 541.158W. Let's say this is including a 1 Kg battery. That would mean that the drone has 1.8 MJ energy stored. Using this, it is found that the drone would have: 1.8 MJ / 541.158 J/s = 3326.2s of battery power. That is 0.9240 hours of power. Of course, the drone would not have a 1 kg battery, when it is only 2 kg. So let's say that 1/8 is dedicated to its own battery. That would mean that the drone has 0.1155 hours of battery, which is equal to 6.93 minutes. This is only for hovering. Other systems were excluded here, for example, the control unit of the drone, the communication module, the refuelling/recharging of other batteries. That is why it was decided that 1/8th of the drone is dedicated to the battery. | |||

=== Big rechargeable batteries === | |||

The uptime of a rechargeable battery would be comparable to that of a replaceable one, but the time it takes for the system to be ready again when the battery needs to be recharged is significantly larger. While charging times are heavily dependent on the quality of the charger, but it is generally not recommended to charge a battery above 10 Ampere [16]. The expected battery charge time is about an hour per kg, which means the uptime of the system would be smaller than the downtime of the system, severely reducing usefulness. | |||

=== Solar energy === | |||

The option to instead charge the battery while in action is also available: Solar panels can ensure that the system does not have to return to a charging station to recharge, instead opting to simply land somewhere and wait until the battery is mostly recharged. The idea of making short flights with breaks in-between is already the idea behind the hopper drone, so these concepts might work well together. The downside of solar panels is that they are heavy, which increases the power consumption while in-flight. The question is whether or not the solar panels are feasible in terms of possible flight duration. | |||

Light-weight solar panels are produced by companies such as Flisom [17], and their products will serve as a benchmark for the potential of solar panels in drone applications. According to their datasheet [18], an 87*41 cm solar panel weighs approximately 0.8 kilograms. It has a peak nominal power of 30 Watt and is expected to be able to function properly for ten years when used at 90% of that power. This means that a light-weight solar panel of this kind is expected to deliver 80 Watt per square meter at a weight of 2.35 kgs. Using the previous metric of 270.579 W/Kg to keep a drone flying, a solar panel would increase the net power consumption while in-flight with 554 W/m^2, while offering an on-ground energy production of 80 W/m^2. The price would be a one time purchase of 70 euros per unit. | |||

=== Fuel === | |||

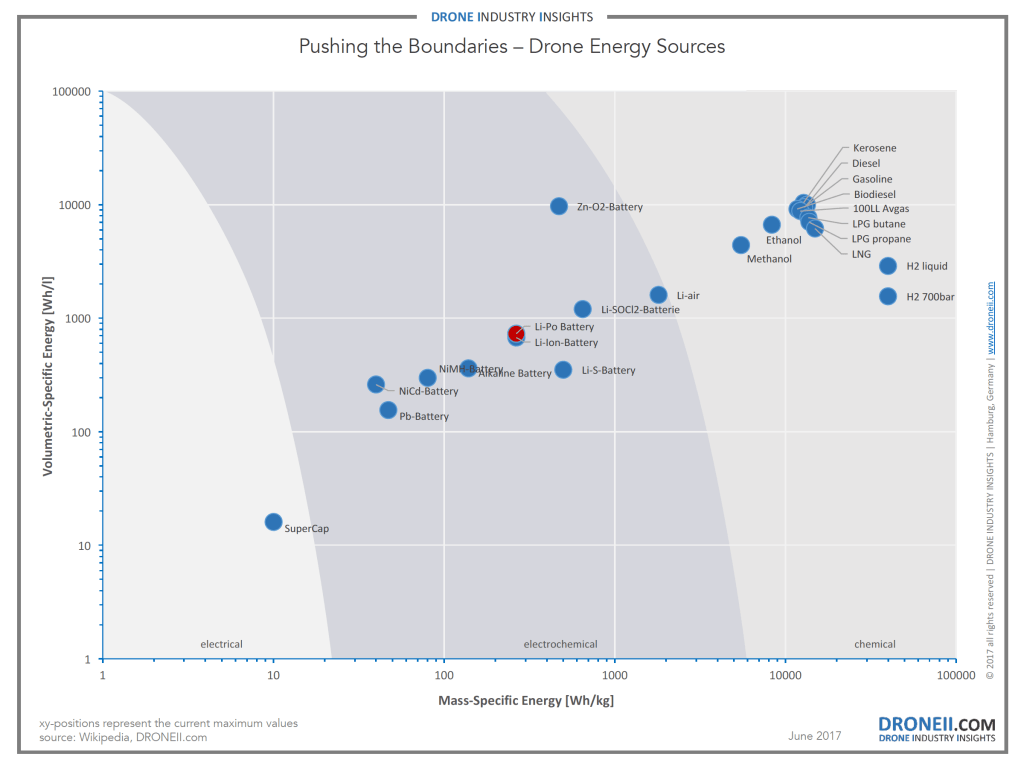

[[File:Drone-Energy-Sources.png|250px|thumb|right|energy production per fuel weight and volume [19](Click to enlarge)]] | |||

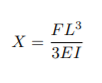

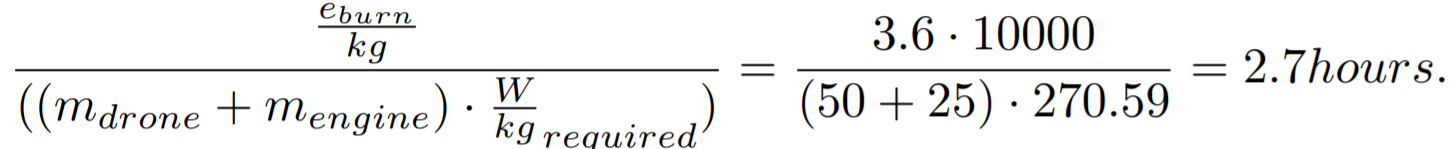

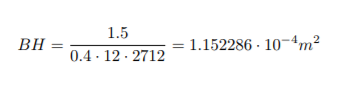

The above figure shows the amount of energy per mass that can be gotten from different energy sources and shows that chemical energy sources are much more effective than electrochemical energy sources. However, these energy sources require an engine to convert the energy to useful energy, reducing efficiency and adding more weight. According to [20], the power output of an engine and their weight are related linearly. Using the previous number of 270.59 W/kg for the drone to fly, a drone weighing 50 kg on its own would need an engine of 25 kg, which means that approximately a third of the drone's weight would be made up by the engine. Given the weight of the drone m, it can then be calculated that a kilo of gasoline or gas could power the drone will provide power for the order of magnitude of | |||

[[File:Formula1_latex.PNG|710px|left]] | |||

This means that using a fuel-powered engine to power the rotor blades of the drone is by far the most efficient method of storing energy. | |||

== Conclusion == | |||

Since a fuel engine and tank are the most efficient way to store energy for the drone, this is the concept that will be worked out further. Refuelling the service drone will still have to be done manually, but given the large potential range of fuel-powered flying vehicles, this should not serve to be too much of a problem. The drone can stay active for a long time using the hopper principle, and then return to a fuel station where it can be manually refuelled, a process which won't take very long, especially compared to charging a large battery/ The addition of an engine and a fuel tank does add the danger of explosions, which could cause the drone to crash down to earth causing danger to anyone standing below. This means that the engine should not be pushed to extreme operating points, and its temperature will need to be monitored. | |||

= Phase 4: Collecting Data from surveillance drones = | |||

A system consisting of a limited number of service drones which have to replace the batteries of multiple surveillance drones depend heavily on the communication between them. This is to determine which surveillance drone can go first and to determine where a service drone will be. To keep the system as cheap and simple as possible, communication should be limited to what is necessary. It should also be noted that here a communication method will be recommended, but the actual method of communication in regards to algorithms will be ignored. In essence, only the hardware will be determined. | |||

Key information to transmit by surveillance drone: | |||

* Position | |||

* Battery status | |||

* Surveillance data | |||

Information to transmit by service drone: | |||

* Position | |||

* Availability status | |||

* Battery status | |||

For these drones everything except the position are telemetries. This is simple data that can be sent via a transmitter. For the position for both drones, there is a need for some technology to locate the drones. There should also be a way for both drones to communicate information about their location. The communication method should preferably also be the same between the two types of drones, this allows for the communication to be handled by a central system easily without needing to take into account different signal types or overlapping frequencies. The most important aspect is how the two systems are going to locate each other. For this, GPS is used to locate drones of both systems. | |||

== Collecting Position Data == | |||

To control the system, the positions of both the surveillance and service drones are needed, this can be done by using the aforementioned GPS. In order for the ground station to determine where the surveillance and service drones should be at a given time, the location data provided by the GPS can be used. This does not cost much data, and can easily be used by multiple drones to keep track of the position. Also, GPS is a widely used technology which is almost available everywhere. The error of GPS is <= 0.175 meters [23]<br> | |||

Usually, GPS locating uses 88 bytes each time a location is uploaded, this is well in the range of the bandwidth that is provided to the system. Therefore, when the personal tracker uses 10 minutes interval time or even 1 minute, the monthly data consumption will be less than 30 Mb. | |||

== Controlling drones == | |||

This whole setup can be utilized together with the drones to create one large system where everything works together. Since the system is controlled by a ground system that has collected all of the data from the service and surveillance drones, it can make an efficient decision on the plan of action. This includes the decision on where the service drone should be to efficiently replace the batteries of the surveillance drones or communicating the location of said service drone to a surveillance drone in need of a new battery. In this way, the two subsystems can communicate with each other through a middleman, while still separated on a lower level. By only allowing the systems to communicate with both on a higher level, there is no need for a complicated and more sophisticated control unit on the drones. These will be placed at the ground station. | |||

== Conclusion == | |||

Instead of looking at a multitude of options, it was decided to ask a company that manufactures surveillance drone what their solution was to communicate with them. The reason for this was that the eventual battery replacement drone has to work for existing systems. This means that the type of communication would ideally have to stay consistent within such a system to minimize the number of different components present and modifications needed for the drones. After talking to the company Aerialtronics about their drones, they said that their drones use a radio control method that has a range of 1 km. This is not far enough for the system, so a ground system to control the system and to communicate between the systems will be used. | |||

= Final Concept = | |||

To summarise, the service drone will consist of the following components: | |||

* The drone will move around in short bursts but will rest on the ground to enable servicing of the surveillance drones | |||

* This servicing consists of replacing the batteries of the drones to prolong their flight time | |||

* The service drone will also function by using fuel | |||

* Communication with other drones will be handled with a radio control similar to model planes | |||

These components will all be worked into a final design of the drone in the detailing section. | |||

= MATLAB Model = | |||

A model has been constructed to figure out an effective combination of parameters to ensure that the system works properly. This model was constructed in MATLAB and is made to support design decisions in the detailing phase. The following aspects can all be changed individually in the model. | |||

[[File:model.gif|600px|thumb|right|MATLAB model visualization]] | |||

* Drone speed | |||

* Number of observation drones | |||

* Number of service drones in a grid of X*Y | |||

* Fuel cost per step | |||

* Total simulation time limit | |||

* Size of the environment | |||

* Amount of battery capacity of a surveillance drone | |||

* Number of batteries that the service drone carries | |||

* Time needed to change the batteries | |||

* The step size of the model | |||

* Whether to plot the visualization of the model or not (disabling this increases simulation time significantly) | |||

In this model, a certain amount of surveillance drones, and a certain amount of service drones are placed in an area with a defined size. The surveillance drones fly in a random pattern to prevent optimization for one specific search strategy or task. When a surveillance drone is low on battery (less than 50%), it flies to the nearest service drone that still has batteries in storage. A cost function is used to make some service drones more attractive than others. This cost function takes into account distance and whether a service drone is already busy with another drone or not. Only one drone can be serviced at a time and the service drones start with a limited amount of batteries. | |||

One step in in the model corresponds to a single second. To speed up execution time, a variable step size is implemented. A step sizes up to 5 yield similar results for a drone speed of 8 m/s (default surveillance speed of an MD4-200). The step size should be lower when faster drones are considered. | |||

The foremost purpose of this model is to analyze what amount of service drones, and what amount of batteries would be optimal to extend the operation time of the surveillance swarm for a desired duration. | |||

In the model, service drones are shown as squares and surveillance drones as black dots. The number next to the service drones shows the number of batteries still left in storage. When a surveillance drone is empty, it stops moving and a red cross appears in its place. The simulation is then stopped and the run time is shown in the Command Window in seconds. | |||

=== Results and analysis === | |||

The model is rewritten as a function in order to make an analysis of the effect of certain parameters easier. Due to the random nature of the flight paths of the surveillance drones, model output can vary. All results in this section are the average of four runs.<br> | |||

<br> | |||

[[File:NBat.jpg|500px|thumb|Effect of number of batteries]] | |||

To be able to decide the number of batteries the final service drone should be able to carry, the model was run for several configurations. The figure on the right shows the results of the model ran with 15 surveillance drones and 9 service drones. The parameters such as drone speed correspond to the MD4-200 (8 m/s speed, 25 minutes flight time on a single battery). The model clearly shows a linear relationship between the number of batteries a single service drone can carry and the operation time of the complete system. The time is the same for one and two batteries, this can be explained due to the fact that in both cases, the total amount of available batteries is smaller than the number of surveillance drones. In that case, the maximum flight time is limited by the flight time of a surveillance drone with only one battery. | |||

<br clear=all> | |||

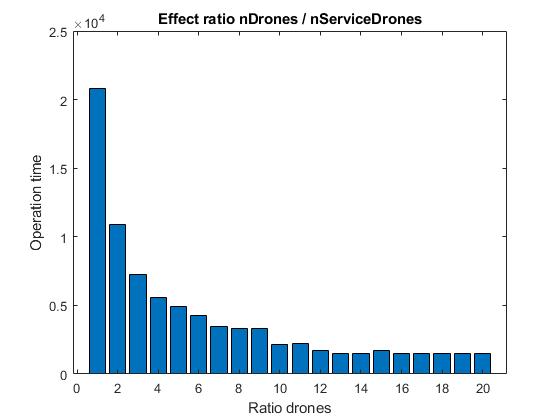

[[File:RDrones.jpg|500px|thumb|Effect or ratio surveillance / service drones]] | |||

On the right, the figure shows the relation between the total system operation time and the number of surveillance drones per service drone. For these results, the amount of service drones is 9, each carrying 4 batteries. The ratio of surveillance drones per service drones ranges along the x-axis from 1 to 20. It is clear that the operation time reduces quadratically with an increasing ratio. These results can be used to decide the number of service drones required for a certain situation. | |||

<br clear=all> | |||

= Detailing = | |||

When designing the drone itself, it is important to take into account the effect on the surveillance drone, as well as the performance of the service drone itself. The first is done by using the model described in the section above. These will mainly be used in the sections about the number of batteries and the final | |||

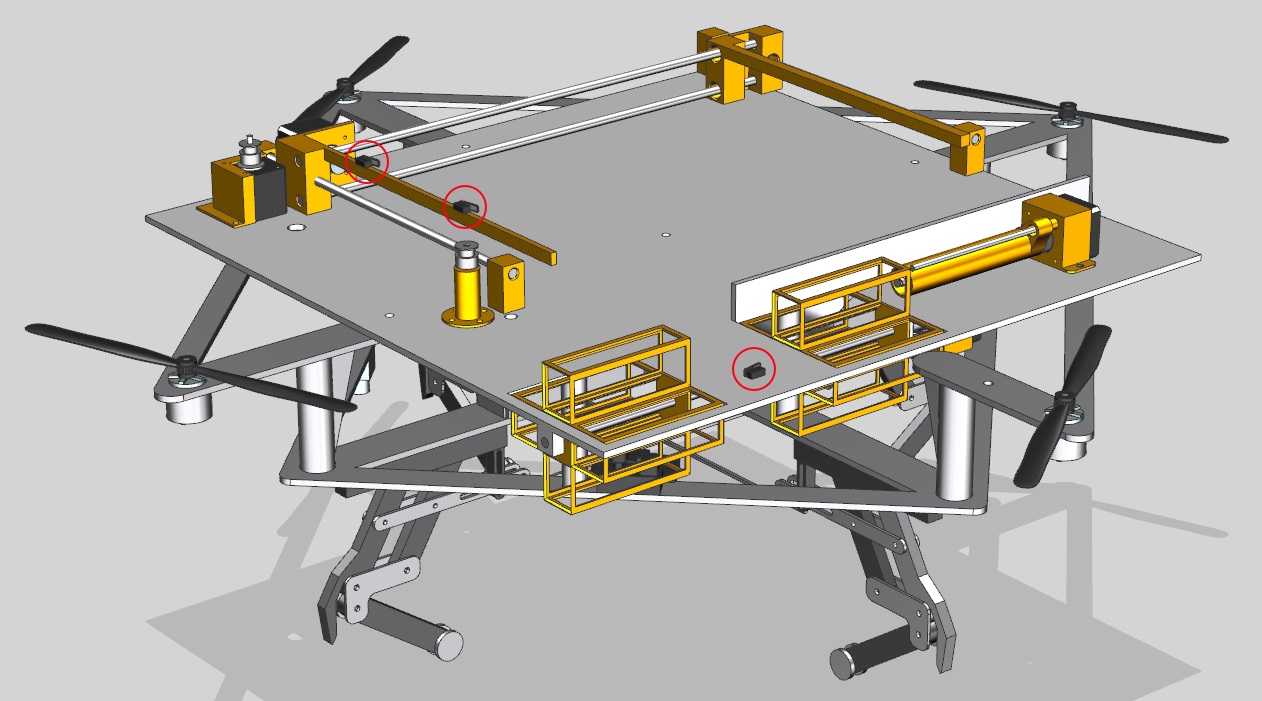

== General drone design == | |||

The general drone design is characterised by 3 different layers. The top layer is the plate on which the drones can land and where the batteries can be replaced. The middle layer is a frame where all of the electronic components needed for the system to function are stored, on the side of this frame, the propellers of the drone will be placed as well. Finally, the bottom layer is where the landing gear is located. Each of these has its own requirements to take into account. | |||

For the landing platform, it is important to take into account the size of the drone that must be able to land on top of it. In this case, it is assumed that the drones will be roughly 0.6 meters in length and width. This results in a free space between the rotors of at least this size to ensure that the drone will not accidentally hit the rotors. It is best to use a plate that can be placed on top of the frame on which the drone can land. | |||

For the rotors, it is important that the drone can fly in a stable manner but is also able to fly for a considerable amount of time. In general, more rotors will result in a more stable and controllable flight but will be at the cost of flight time. The optimal amount of rotors must be decided combined with the type of propeller and the motors used to turn these propellers. | |||

There must be a compartment for the batteries needed for the surveillance drones. This must also be able to be accessed by the manipulator which replaces the drone batteries with these stored batteries. There is also a location where the fuel tank is placed for the service drone itself, this will probably be one of the larger components due to the size of the main drone itself. The final component that has to be added here is the central computing component and a transmitter and receiver to connect with different surveillance drones. The general electric circuit should also be designed to show how everything is connected. | |||

The final layer is the landing gear. This landing gear must be designed in such a way that it can correct itself when standing on uneven terrain. This can be done by having the platform correct its orientation when detecting that the landing platform is not placed perfectly horizontal. This could, for example, be done by having the four legs of the drone be variable in length, and by using a gyroscope to measure the orientation a controller can change the length of the legs to ensure a horizontal orientation. | |||

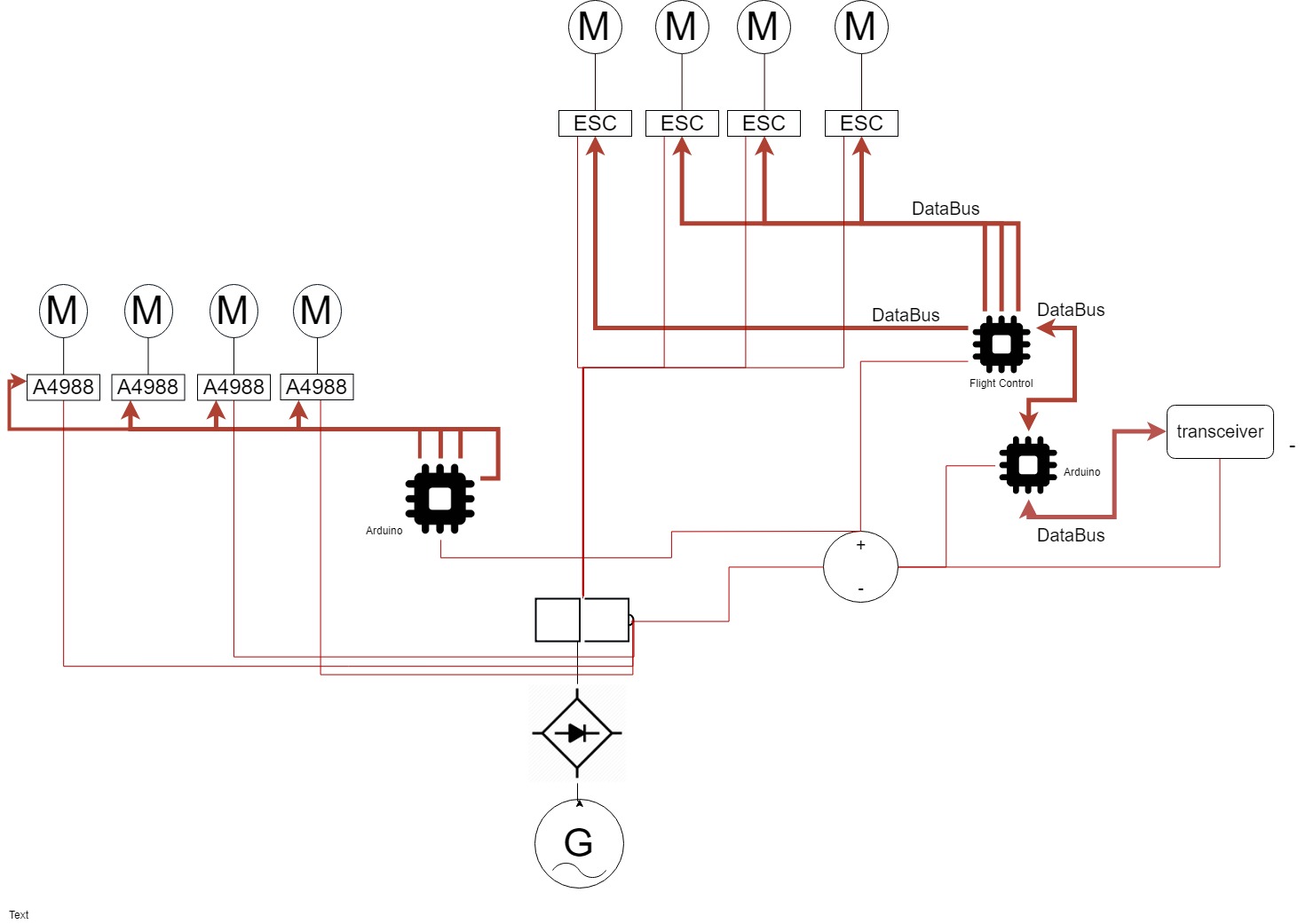

== Electric circuit == | |||

The electric circuit for the drone is pictured below. There will be an explanation per part how this circuit came into existence.<br> | |||

[[File:Circuit2.jpg|950px|alt=Puzzle globe logo]]<br> | |||

Icons are used to present real parts in the circuit. Not only does this make the diagram more compact, but it is also easier to understand. There are red wires, which are normal electric wires. Further, there are also black wires, these are 3 phase AC wires, which are more complex. | |||

=== Individual parts === | |||

*The generator is connected with the engine. When the engine is running, the generator outputs energy, which will be directly stored by the battery. Its output is 3 phase AC. <br> | |||

[[File:Generator.png|70 px|alt=Puzzle globe logo]]<br> | |||

*The motors are used for the rotors and mechanisms used in the drone. These are AC motors, so the energy provided to these engines must be AC. In the circuit, there are two different types of motors used. One is used for the rotors. These must turn very fast such that the drone can fly, and are less precise. The other type is more precise. These are step motors, which are motors which can turn per step(a small angle each time). This creates a very precise, but also slower motor. These are used for the battery changing mechanism. <br> | |||

[[File:Motor.png|70 px|alt=Puzzle globe logo]]<br> | |||

*The rectifiers are used to change the output of the generator, which is AC 3 phase out, to DC. This, because the battery in the system has DC input.<br> | |||

[[File:Rec.png|70 px|alt=Puzzle globe logo]]<br> | |||

*Microcontroller used to control the drone, translate the input data from the transceiver and create output data for the transceiver. One of these is the flight control, which handles the flighting of the drone, the direction it flies at and at what power and speed.<br> | |||

[[File:Arduino2.png|70 px|alt=Puzzle globe logo]]<br> | |||

*Converter used to lower the voltage. In this case, a buck converter was used. This is a DC-to-DC power converter, used to step down voltage from its input to its output. Different parts of the system use different voltages. Therefore, the output of the battery needs to be limited to what the part requires. To get to a certain voltage, these can be used in series.<br> | |||

[[File:Converter.png|70 px|alt=Puzzle globe logo]]<br> | |||

*Battery, which is recharged by the generator and provides power to the system. It gets power from the generator when the engine is turned on. It discharges at the same time. When the engine is shut down, the battery will provide power until it is out of power. The battery has AC output.<br> | |||

[[File:Battery.png|70 px|alt=Puzzle globe logo]]<br> | |||

*An electronic speed controller, or ESC, is needed to be able to control the electricity sent to the engine. This, such that the amount of power at which the motor works becomes independent of the output of the generator or battery. Thus, when the motor needs to turn slower or faster, the ESC can provide the motor with the correct amount of power.<br> | |||

[[File:ESC.png|70 px|alt=Puzzle globe logo]]<br> | |||

*The transceiver is used for receiving and transmitting information such that the drone can be controlled from a distance.<br> | |||

[[File:Transceiver.png|70 px|alt=Puzzle globe logo]]<br> | |||

*The A4988 Stepper motor driver carrier is used to control the step motors of the battery swap mechanism. It can output signals and power to the step motors to turn it very precisely. <br> | |||

[[File:A4988.png|70 px|alt=Puzzle globe logo]]<br> | |||

*The sensor is used by the battery swapping mechanism to know where the system is at currently. | |||

[[File:Sensor2.PNG|70 px|alt=Puzzle globe logo]]<br> | |||

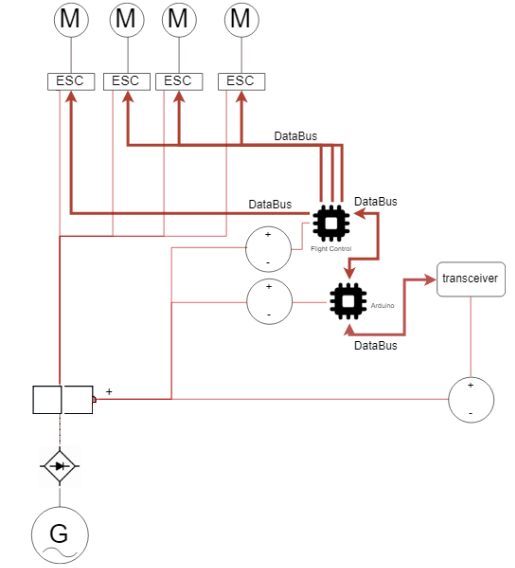

=== Rotor and drone controlling circuit === | |||

[[File:Right.png|500px|alt=Puzzle globe logo]]<br> | |||

This part of the circuit is to control the drone itself. This is done by two microprocessors, which analyses data and creates input for motors to control everything. One of these microprocessors is used to control and interact with the transceiver(receiver + transmitter), and one is used to control the motors and utilize the data gotten from the transceiver. These parts are called Arduino and Flight Control relatively. The energy for this part of the circuit is provided by the battery. The microprocessors use less power than provided by the battery. Therefore, both the microprocessors use a rectifier to step down the current gotten from the battery. | |||

One of the microprocessors, in this case, the Arduino, has a data bus from itself to the transceiver. Over this data bus, data is sent and communication between the transceiver and the Arduino is done. <br> | |||

The other microprocessor, the Flight Controller, has a data bus from itself to the Arduino. Over this data bus, data is sent. This data includes data received by the drone itself, and data needed to send to a ground station.<br> | |||

The transceiver gets information from the ground station to control the drone, which is sent to the Arduino. In turn, the Arduino sends information back to the transceiver, which it sends to the ground station. <br> | |||

The Flight Controller sends the information gotten from the Arduino towards the ESC's to control the rotors. <br> | |||

These ESC's are directly given power by the battery. This energy is not only used by the ESC's, but also by the motors. | |||

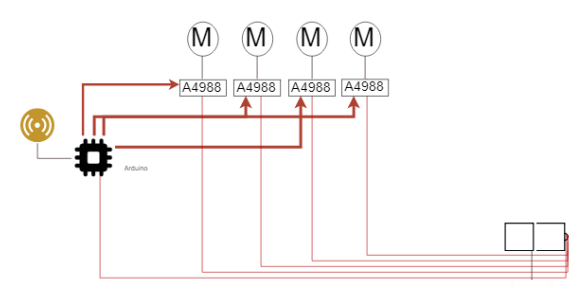

=== Battery change mechanism circuit === | |||

[[File:Left.png|500px|alt=Puzzle globe logo]]<br> | |||

This part of the circuit is for the control of the mechanism for changing the batteries. | |||

This is done by one microprocessor. The microprocessor sends information to the 4 A4988 and receives information from the sensors. It controls the four motors which are used by the mechanism. It does this by sending information via the data buses to the A4988's. Further, it provided energy to the sensors to function properly. The microprocessor uses DC power and uses less power than provided by the battery. Therefore, the energy from the battery needs to be stepped down by a rectifier to a lower voltage. | |||

The step motor drive carriers provide the energy to the motors, in turn, they receive power from the battery. It also uses the information gathered from the Arduino to properly control the motor. It receives power from the battery directly. | |||

The sensors are used to gather information about the state of the system. The energy is provided by the Arduino, and it returns the information it gathered back to the Arduino. | |||

== Drone propulsion== | |||

In this section, the number of propellers, shape of the propellers, rotors will be determined and fitted with a generator that can provide enough energy to keep the drone running. It will also be discussed what other components are needed to make the propulsion system run smoothly. | |||

=== Required thrust, amount of motors === | |||

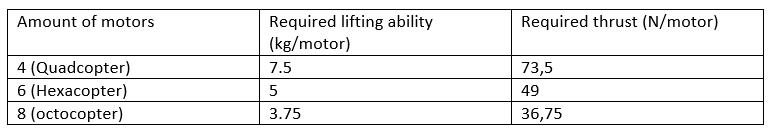

For this section, it will be assumed that the final weight of the service drone is going to be 15 kg. That means that the amount of thrust required can be determined depending on the number of motors used. In order for the drone to be controllable, it needs to have a thrust to weight ratio of at least 2 [30], which means the required thrust each motor can produce must be doubled. | |||

[[File:Tableee.PNG|1200px|thumb|Table of required thrusts]] | |||

Whichever amount of motors can be shown to be most efficient in terms of weight and the required power will be chosen. Properties of motors in the field of drones are generally described in terms of KV, a measurement of rotation speed against voltage in rotations per minute per Volt, and thrust, which is the thrust given a certain specified propeller size and usually expressed in kilograms [27]. | |||

=== Propeller choice === | |||

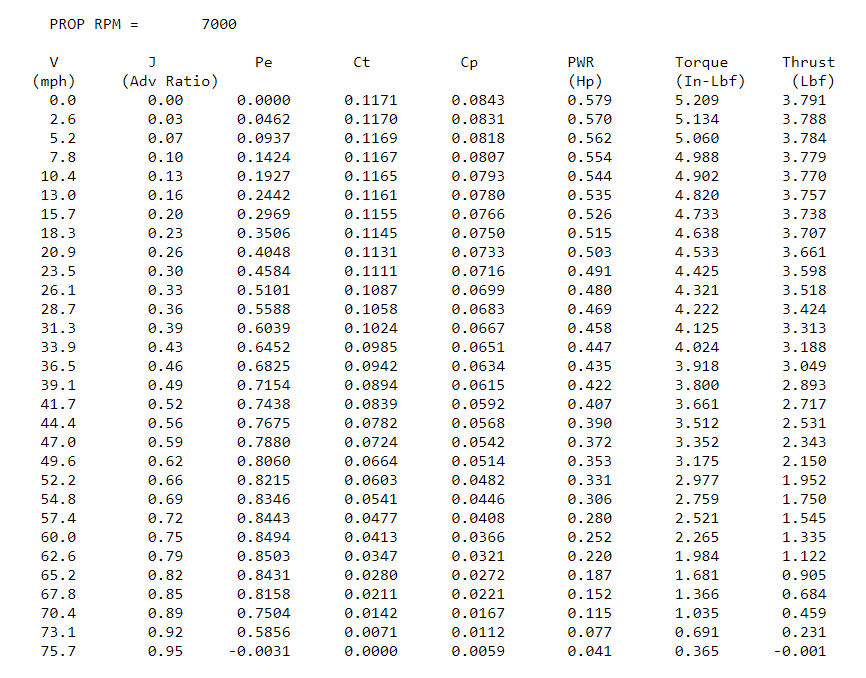

The thrust that a propeller can provide is mainly dependent on its size, pitch, number of blades and its RPM. Since propellers get a higher efficiency when the amount of blades decreases [29], a propeller with 2 propellers will initially be researched. Apcprop [28] provides a list of data regarding the thrust per RPM of a large number of propellers. Because the space available in the design is limited, a propeller with a diameter of 12 inches and a pitch of 9 was chosen. This pitch was chosen high because the higher the pitch of a propeller, the higher the potential efficiency when the system is moving at a higher speed [31]. In order for this propeller to reach the thrust necessary to be used in a quadcopter, it needs to have a thrust of 7.5 kilograms or 3.4 Lbf, which occurs at an RPM of 7000, according to the data provided. An octocopter with these propellers could work at 5000 rpm, but at a considerably lower velocity. | |||

[[File:Datatable.PNG|500px]] | |||

=== Motor choice === | |||

So a motor is needed that is able to perform at 7000 RPM, while the propeller requires approximately half a horsepower to operate. This need is fulfilled by a motor called the | |||

Dualsky XM3542CA-6 [35]. The motor has a KV of 940 and can handle a resistance of 450 Watt. It weighs 137 grammes. In combination with the chosen propeller, these motors have more than enough power to lift the drone. | |||

=== Generator choice === | |||

An engine/generator is now needed to produce enough power to make the drone able to fly. The DF70 Twin cylinder UAV engine seems like an ideal fit for this system. The DF70 UAV engine is a high performance four stroke engine offering a two-stroke performance and an excellent fuel economy. The engine is also able to run quietly. It has been developed especially for the aerospace market. The DF70 UAV engine is suitable for fixed and rotary wing vehicles.[33]<br> | |||

A comparable generator is the NOVA-2000 generator. The NOVA-2000 generator is a high-efficiency generator designed for multicopters and VTOL Fixed wings. The weight of the generator is four kg, which is much lighter than any other generator that is able to produce 2000W output power. The DF70 UAV engine, however, is with the generator included much lighter than the NOVA generator. And this is already a major disadvantage. The NOVA-generator is very efficient, but due to the weight, the generator is not favourable for this system. And on top of that, the NOVA generator is not able to run quietly and this is not a surprise, because of the weight of the generator.[34]<br> | |||

So the most suitable generator for this system is the DF70 UAV engine. DF70 UAV engine is much lighter than comparable engines and is able to run quietly.<br> | |||

== Wireless transmission system == | |||

The service drone needs to have a way to communicate with a ground station, which will control the drone. For this, information about the drone's position needs to be sent towards the ground station, along with the telemetry. The drone needs to be able to receive information such that it is controllable. Radio control to control the drones can be used, which uses radio waves in a certain frequency. | |||

Below different options to control the drone and to retrieve data from the drone will be discussed. Afterwards, a conclusion will be drawn and the real parts to control the drone will be provided.<br> | |||

=== Vanguard === | |||

The Vanguard made by Airborne Drones is a popular expensive UAV, which is capable of travelling a large distance. Its transmission range for the controller is 35 km. Although a 35-kilometre range for the drone is not aimed for, the fact that there is already technology for these ranges can be used as a comparison between the designed drone and the Vanguard. The Vanguard uses a transmission frequency of 433 MHz at 800 mW for radio control and telemetry transmission. <br> | |||

Further, it uses a 2.4 GHz frequency at 800 mW for video transmission and receiving. With this, it uses a SkyLink Ground Station to control the UAV, transmit data and receive video input. It is not known what transceiver is inside the UAV itself. The radio control frequency is for long-range control, while it uses a higher frequency for the video since the higher the frequency, the more data can be transmitted.<br> | |||

=== Frequencies === | |||

For the service drone, the working frequency must be chosen. The general rule is, that the higher the frequency, the more data can be sent, and the less the range is.<br> | |||

Only telemetry and location data will have to be transmitted to the ground station and receive input for the controlling of the drone. This is not a lot of data, thus a lower frequency is preferred.<br> | |||

A frequency of 2.4 GHz or 900 MHz is preferred: “Parts like the 315-915 MHZ … or the 240-960 MHz … provide fairly good data rates up to 128 Kbits/sec. While not high-definition, real-time video capable; control, telemetry, data gathering, and sensor interfaces are perfect applications for these rates.”[46].<br> | |||

These two frequencies will be discussed further.<br> | |||

Other websites with forums also suggest using 900 MHz for long range remote control. Although these are not scientific documents, these do provide a good look at what range is preferable for the system.[48] <br> | |||

From this, it can be concluded that 900 MHz is more preferable for this application than 2.4 GHz, although the latter was suggested by the company as frequency.<br> | |||

Another argument for the 900 MHz frequency, is data loss. The 2.4 GHz link uses Wi-Fi technology, while the 900 MHz frequency uses radio modems with serial data transmission. When the range is less than 100 meters, 2.4 GHz Wi-Fi transmission is used. At longer ranges, 900 MHz is used. This, because the signal at 2.4 GHz undergoes more signal loss at the same range than 900 MHz.<br> | |||

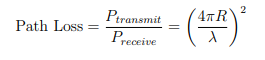

[[File:Pathloss.png|300px]]<br> | |||

Here, the wavelength is mu, whereas mu is equal to C divided by f, where C is the speed of light and f the frequency. Therefore, when the frequency rises, the path loss will be greater. According to the above formula, 2.4 GHz will receive 8.6 dB lower received signal power than at 900 MHz, which means that less data is received. <br> | |||

Further, the 900 MHz frequency has a longer range than the 2.4 GHz. This can be shown by the following formula:<br> | |||

[[File:receive.png|300px]]<br> | |||

Here, R is the range and mu is the wavelength in meters. From this equation, the received power depends on the wavelength. With higher frequencies, the wavelength is shorter, thus the received power is shorter. At the same power level, lower frequencies can achieve longer distances than higher frequencies. [47]<br> | |||

With this information, it can be concluded that a 900 MHz frequency would be preferred above a 2.4 GHz frequency. The Vanguard can be used as a proof of concept that using this frequency can provide the system with enough bandwidth to control the system and to receive data.<br> | |||

== Electronic and Propulsion components == | |||

Below the full list of electronic and propulsion components is as follows: | |||

{| border="1" style="margin-left: 0em;" | |||

|- | |||

|'''Component''' | |||

|'''Cost/part (€)''' | |||

|'''Weight/part (kg)''' | |||

|- | |||

|- | |||

| DF70 UAV engine | |||

| 200 | |||

| 2.700 | |||

|- | |||

| Gens Ace Tattu LiPo battery | |||

| 87.99 | |||

| 0.605 | |||

|- | |||

| Aikon AK32 32bit 6s 4in1 V2 ESC | |||

| 64.95 | |||

| 0.0135 | |||

|- | |||

| Aikon F42020 Flight Controller | |||

| 32.95 | |||

| 0.0070 | |||

|- | |||

| Beitian BN-220 GPS-module | |||

| 14.95 | |||

| 0.0053 | |||

|- | |||

| FrSky R9 900MHz 16CH Long Range Receiver With SBUS Output | |||

| 45.95 | |||

| 0.0158 | |||

|- | |||

| FrSky R9M Lite 900MHz Long Range RC Drone Transmitter Module | |||

| 41.36 | |||

| 0.0200 | |||

|- | |||

| FrSky Super 8 EU LBT Antenna | |||

| 14.95 | |||

| 0.0500 | |||

|- | |||

| Fuel Tank | |||

| 10.00 | |||

| 0.500 | |||

|} | |||

The total weight of these components is 3.92 kg and the combined price is €555.05. Now the full specifications of each of these components will be discussed and any additional reasoning and explanation will be given on why these components were chosen. In general, the most important factors that influence the choice of the electronic components are the kind of drone that is required, the compatibility between the components, the price of the components and the reviews and thus the experiences of other people/companies. | |||

1. '''DF70 UAV engine''' <br> | |||

Specifications:<br> | |||

* Capacity: 70cc | |||

* Speed Range: 2000 to 10000 rpm | |||

* Power (JP8): 4.0 kW (5.4 hp) at 8500 rpm | |||

* Fuel Consumption (JP8): 330g/kW.hr (0.54 lb/hp.hr) | |||

* Weight (complete assembly): 2.7 kg (6.6 lbs) | |||

* Time Between Overhaul (VTOL): 250 hrs | |||

* Time Between Overhaul (fixed-wing): 500 hrs | |||

2. '''Gens Ace Tattu LiPo battery''' [39]<br> | |||

Specifications: | |||

* Capacity: 6750 mAh | |||

* Voltage: 14.8 V | |||

* Discharge rate: 25 C | |||

* Weight: 605 g | |||

Since there is an abundance of energy created by the engine, and because other parts of the system will need power as well when the engine is not running, the abundance of energy needs to be saved in a battery, which will need to provide and store enough energy to power the battery swap system. <br> | |||

All TATTU batteries have passed the UN 38.3 battery test. The UN 38.3 battery test is the highest quality standard test for lithium polymer batteries. A lot of the manufacturers does not test their batteries according to the UN 38.3 battery test. <br> | |||

The TATTU batteries are affordable and are of high quality, so to decide which battery the system requires, the size of the drone and the other electronic components are of great importance. [40]<br> | |||

3. '''Aikon AK32 32bit 6s 4in1 V2 ESC (Electronic speed controller)'''[41]<br> | |||

Specifications: | |||

* Continious Current: 35A | |||

* Burst Current: 45A | |||

* BEC: 5V/2A | |||

* Mounting pattern: 30,5 x 30,5 mm | |||

* Weight: 13,5 gram | |||

An electronic speed controller is needed to be able to control the electricity sent to the engine so that the amount of power at which the motor works becomes independent of the output of the generator.<br> | |||

The compatibility of the ESC and the flight controller is of great importance. It is for this reason that a choice was made for an ESC and a flight controller from the same manufacturer. The ESC and the flight controller are also relatively cheap and this meets one of the preferences. <br> | |||

4. '''Aikon F42020 Flight Controller'''[43] <br> | |||

Specifications: | |||

* Mounting pattern: 20 x 20 mm | |||

* Weight: 7 gram | |||

The flight controller functions as the brain of the drone and it is therefore that the flight controller is compatible with the other electronic components.<br> | |||

Aikon is also an often used brand and the reviews are quite positive and it is therefore that the Aikon was chosen. <br> | |||

5. '''Beitian BN-220 GPS-module''' <br> | |||

Specifications: | |||

* Channels: 72<br> | |||

* Signal sensibility: -167 dBm (localization) | |||

* Fixation time : Cold startup: 26 seconds/ Heat startup: 3 seconds | |||

* Horizontal precision : 2 m | |||

* Speed precision: 0.1 m/s | |||

* Acceleration precision : 0.1 m/s2<br> | |||

* Working temperature: -40 - +85 degrees Celsius | |||

* Measurements : 22 x 20 x 6 mm | |||

* Weight : 5.3 gram | |||

The GPS module is relatively cheap and provides all the functions which the drone requires. <br> | |||

6. '''FrSky R9 900MHz 16CH Long Range Receiver With SBUS Output'''<br> | |||

Specifications: | |||

* Channels:16 | |||

* Measurements: 43.3 x 26.8 x 13.9 mm | |||

* Operating Voltage range: 4.0-10V | |||

* Operating range: Full range(>10 km) | |||

* Weight: 15.8 gram | |||

With the frequency known, a transmitter and receiver could be found that work at this frequency. It is important that the receiver is compatible with the transmitter. It is therefore that the transmitter and the receiver are from the same manufacturer. Another frequency than is usually used will also be used. The range will be about eight times bigger. With a frequency of 5.8 GHz, this is the most often used frequency, a range of >1.5 km can be reached. A frequency of 900 MHz, however, could provide a range of >10 km. The reviews about FrySky are positive and it is an often used brand and it also satisfies the required frequency. <br> | |||

7. '''FrSky R9M Lite 900MHz Long Range RC Drone Transmitter Module for Taranis X-Lite and R9 Series''' <br> | |||

Specifications: | |||

* Channels: 16 | |||

* Measurements : 62.4mm x 30mm x 14.5mm | |||

* Weight: 20 gram | |||

Transmitters of better quality could be bound with multiple receivers. It is sometimes the case that the receiver and the transmitters are required to be from the same manufacturer to make it compatible. The chosen receiver is from the same manufacturer as the chosen transmitter and it is therefore that they are compatible. <br> | |||

8. '''FrSky Super 8 EU LBT Antenna''' | |||

Specifications: | |||

* Frequency Range: 860 – 930MHz | |||

* Length : 90 mm | |||

* Weight: 50 gram | |||

* Compatible with modules: R9M / R9M Lite | |||

The antenna is also from the same manufacturer as the transmitter and the receiver, to ensure the compatibility between the components. The antenna is very efficient and is able to integrate quickly. The antenna has a frequency range of 860-930 MHz and is thus compatible with the frequency on which the service drone functions. <br> | |||

The yellow colour of the antenna will also draw attention to the drone if it would crash for example. | |||

9. '''Fuel Tank''' | |||

Specifications: | |||

* Weight (Including fuel): 0.500 | |||

* Capacity: 0.66 Liters | |||

For the amount of fuel that can be carried by a fuel tank of this size, a drone of 15 kg can fly for 30 minutes before needing to be refuelled. | |||

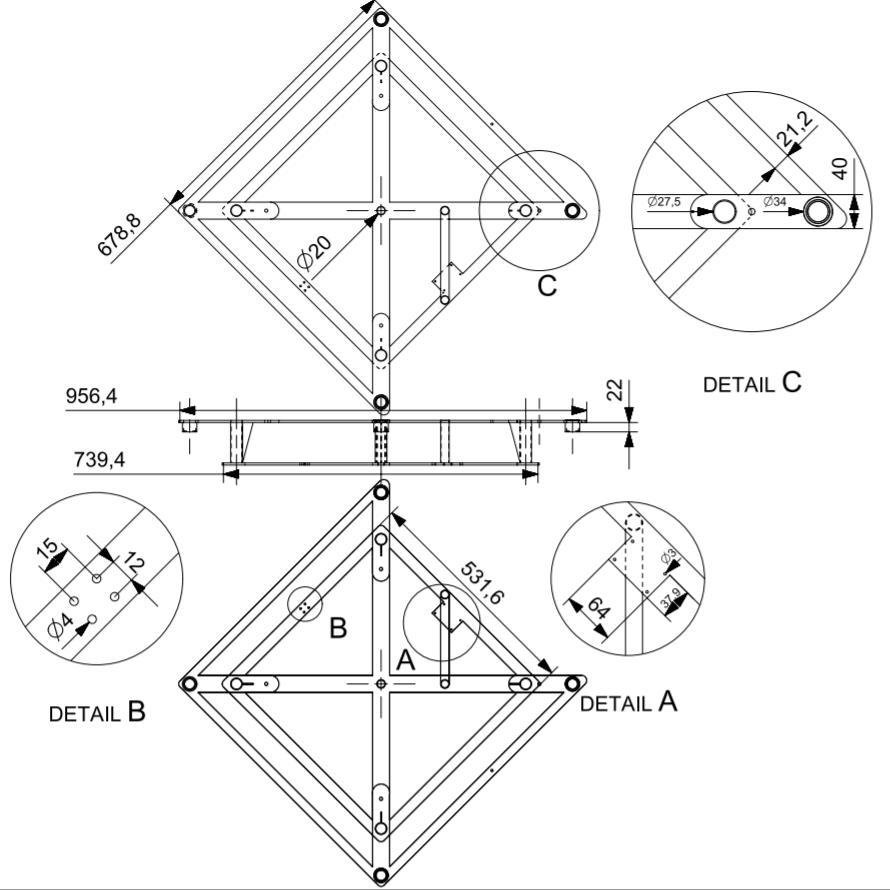

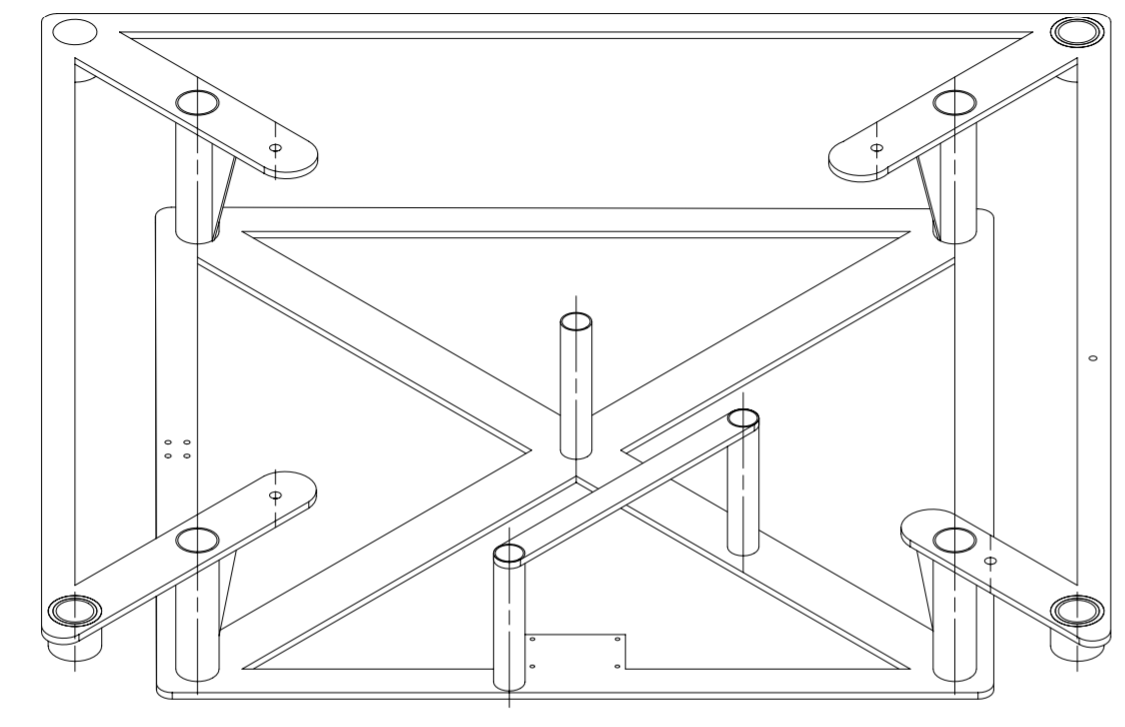

== Propulsion compartment and drone frame == | |||

In order for the components needed for propulsion to fit within the drone, a frame needed to be designed. This frame needed to be able to carry the battery replacement platform and the landing gear of the drone as well as provide the right placement for the propellors. A design was made that consist of two layers of aluminium connected by hollow cylinders. The full weight of this frame is 2.150 kg and has a material cost of 3.66 euros if aluminium is used. | |||

[[File:Frame5.PNG|500px|flush|center|Top, front and bottom view of the main frame]] | |||

[[File:Frame2.PNG|500px|flush|center|Trimetric view of the main frame]] | |||

== Replacing batteries == | |||

[[File:BatterySwapAnimation.gif|600px|thumb|Alignment and battery exchange animation]] | |||

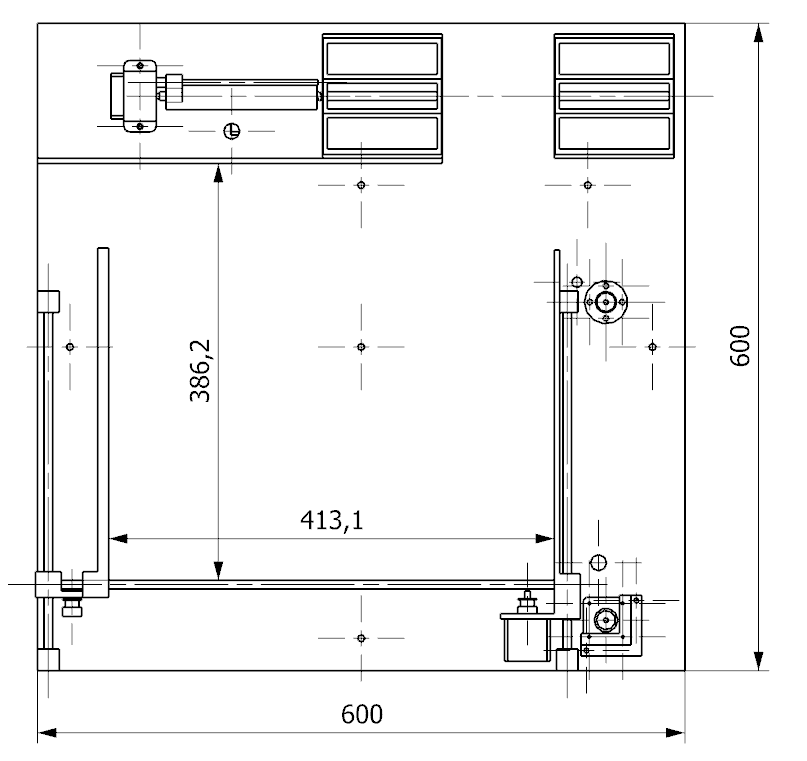

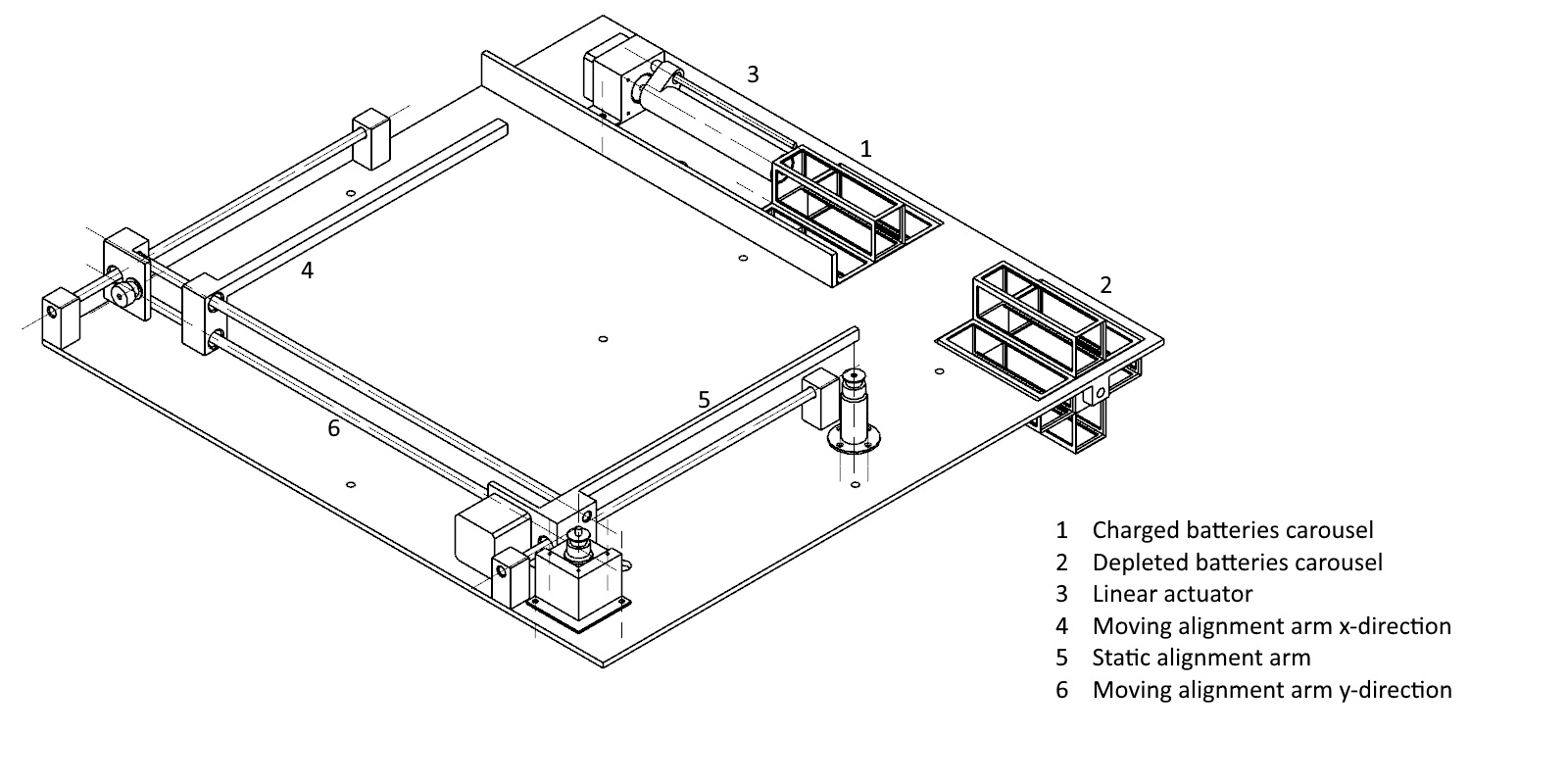

On top of the drone, a platform is mounted which can autonomously exchange batteries of surveillance drones. The platform offers 386 mm by 413 mm of space for a surveillance drone to land. The reference surveillance drone considered in the design, the MD4-200, only needs 250 mm by 250 mm leaving a reasonable tolerance for deviations during the landing procedure. After a surveillance drone has landed, two arms align and position this drone for the battery to be exchanged. The platform has two carousels, one for fully charged batteries, one for old batteries. The battery bay of the drone is positioned in between these carousels. A linear actuator pushes a new battery from one carousel into the battery bay of the drone while, simultaneously, the old battery is pushed out into the other carousel. Halfway this process, both batteries connect to the leads of the drone allowing for so-called hot-swapping: The drone can stay turned on while its battery is replaced. The whole process is shown as an animation in the figure on the right. | |||

[[File:SwapperTop.PNG|500px|thumb|Top view battery swap platform]]<br clear=all> | |||

[[File:SwapperOverview.jpg|490px|thumb|Overview parts and their function]]<br clear=all> | |||

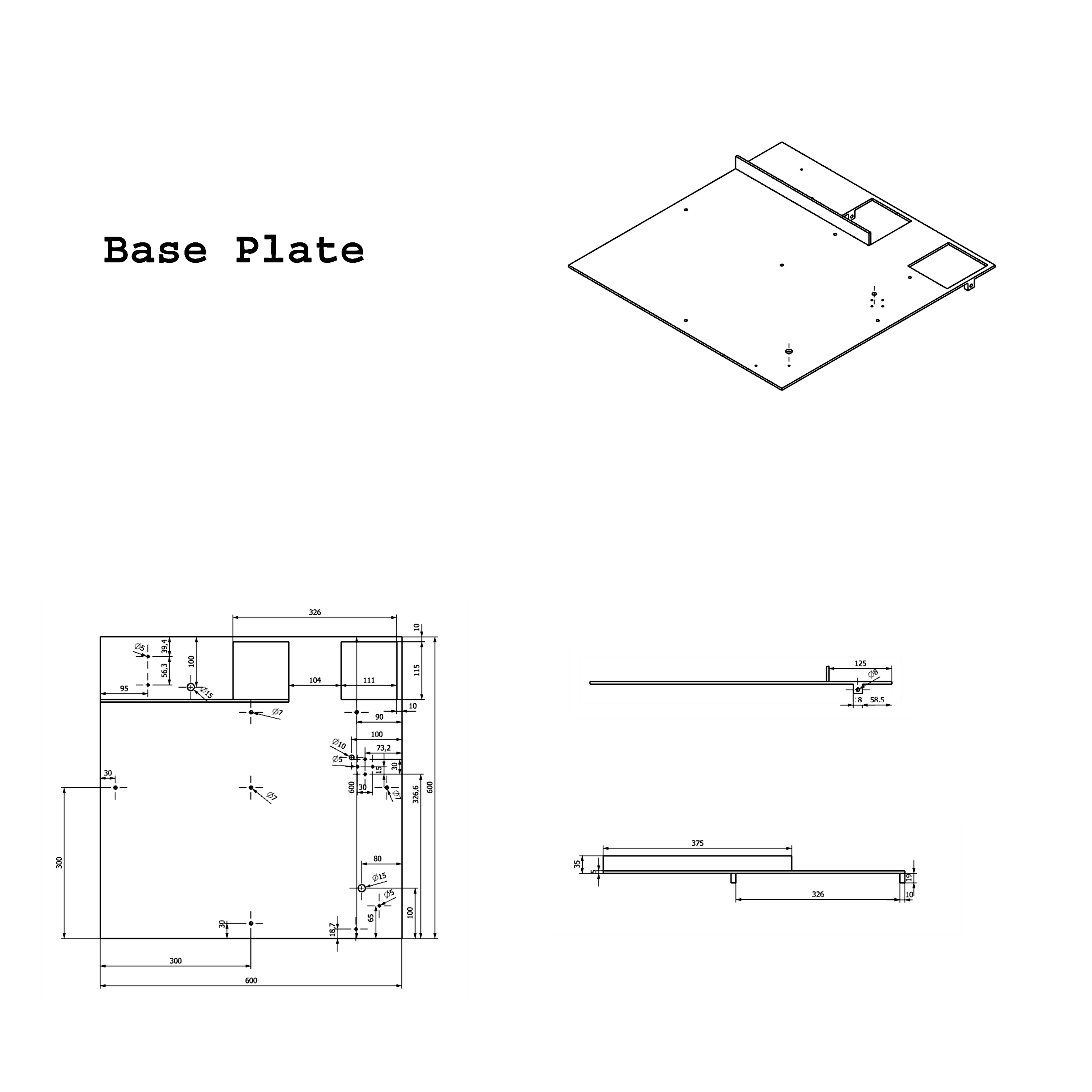

=== Base plate === | |||

The complete positioning and battery exchange system is mounted to a single base plate, which also acts as a landing platform for the surveillance drones. The plate consists of plastic due to its low density. The underlying quadcopter frame provides the rigidity necessary for the system. This plate is shown in the figure below. | |||

[[File:BasePlate.jpg|1000px|thumb|Plastic base plate]]<br clear=all> | |||

=== Battery swap system === | |||

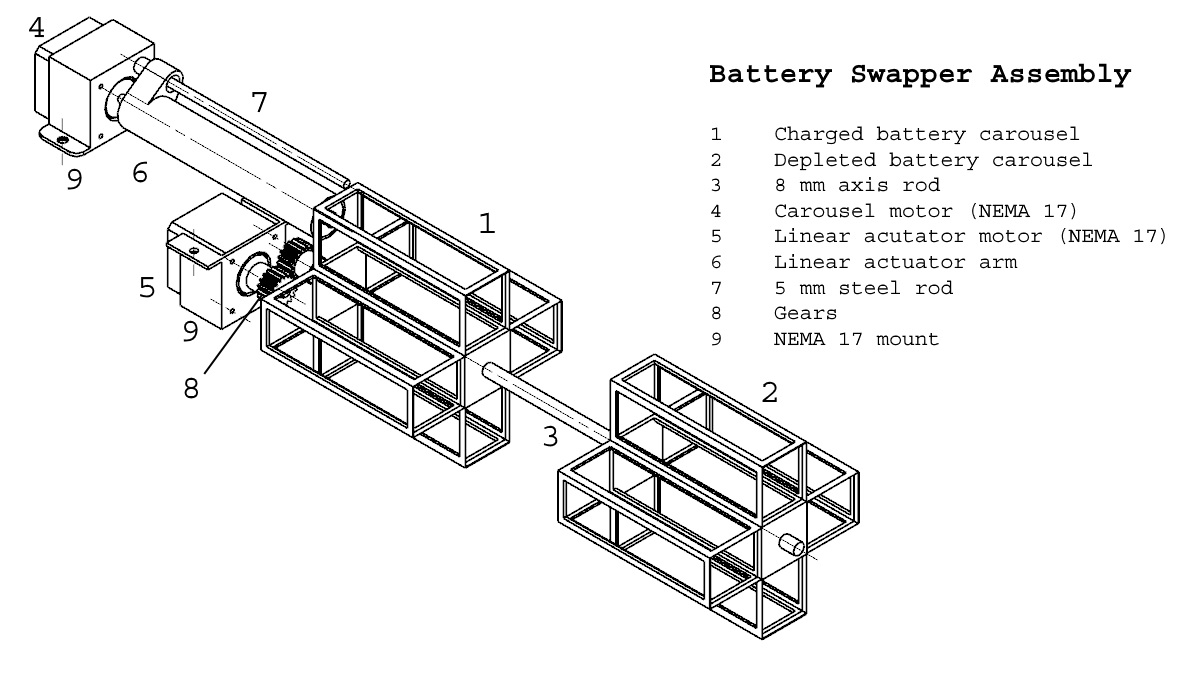

[[File:BatterSwapperAssembly.jpg|500px|thumb|Battery swap system]] | |||

The battery swap system consists of several parts as shown in the figure on the right. This section will consider each of these parts.<br clear=all> | |||

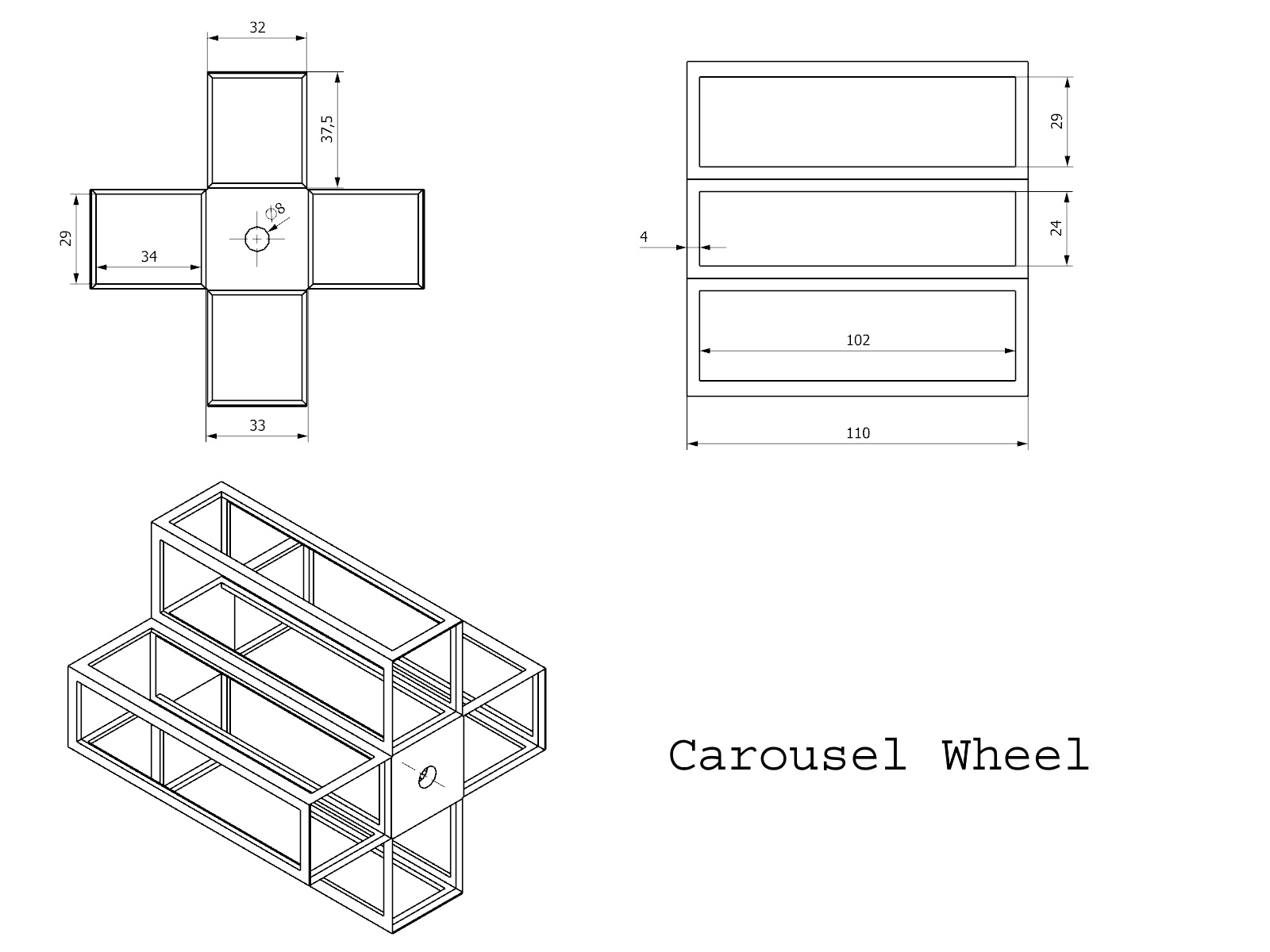

==== Carousel ==== | |||

[[File:CarouselWheelDraft.jpg|500px|thumb|Carousel wheel]] | |||

One carousel wheel can contain up to four batteries. The carousel is designed to store 2300 mAh 4S LiPo batteries as used in the MD4-200 surveillance drone. To work with the system that is proposed, the battery is packed into a container that will be shown later. Chamfers are added to the ends of the carousel to ensure that even slightly misaligned batteries will go in. The battery is kept in the carousel by pressure fit, making it necessary that they are a tight fit. The leaf springs of the battery container help with this. | |||

<br clear=all> | |||

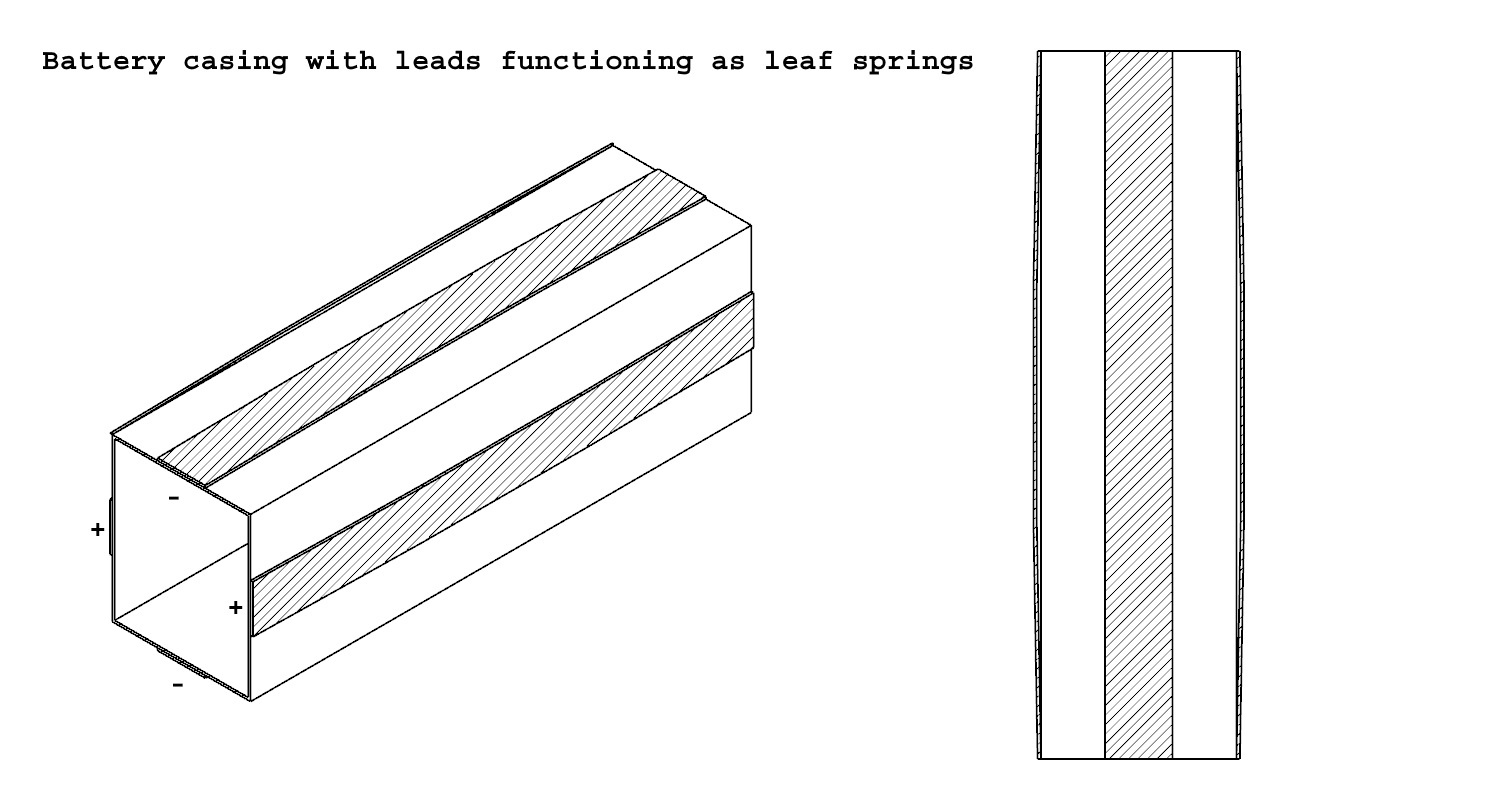

[[File:BatteryCasing.jpg|500px|thumb|Battery casing]] | |||

The carousel wheel is designed to hold a slightly larger body than the batteries. To ensure proper electrical contact between the sliding battery and the surveillance drone, and a certain stiffness to prevent the batteries from slipping out of the carousel unintentionally, a casing is proposed in which the battery fits. The case is surrounded by leads which have a double function as leaf springs. Because the rectangular cross-section of the casing is not exactly square, the battery can't be placed with the leads reversed. By adding leads to every outer surface of the casing as opposed to only two, the contact surface between the leads of the battery case and the surveillance drone is increased improving the electrical connection. Ideal stiffnesses and dimensions are hard to predict for a good balance between having the battery stick to its container under certain accelerations while still being able to be pushed out by the linear actuator. Therefore, a drawing without exact dimensions is provided on the right, but an exact design will have to be tried and tested. | |||

<br clear=all> | |||

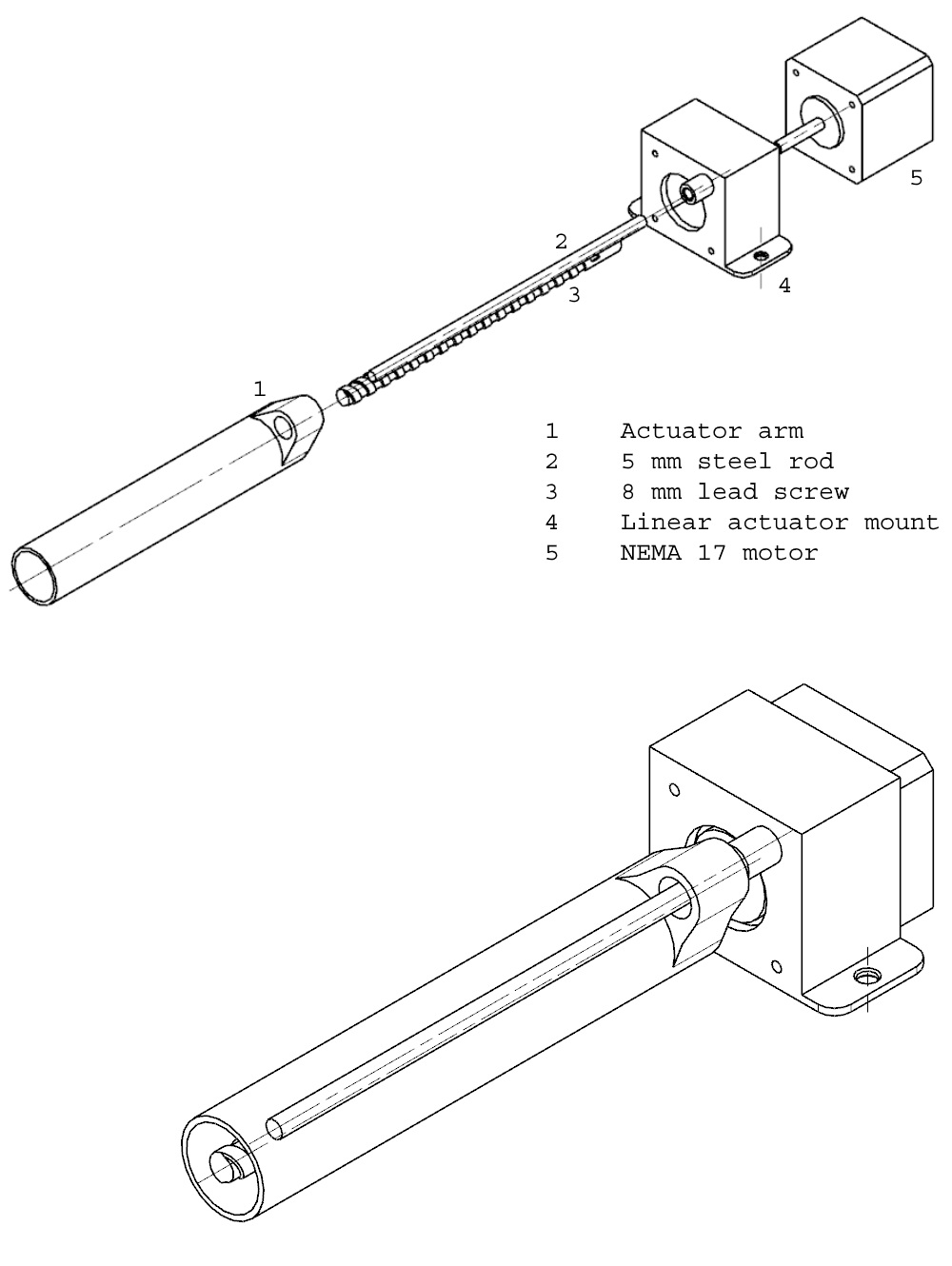

== | ==== Linear Actuator ==== | ||

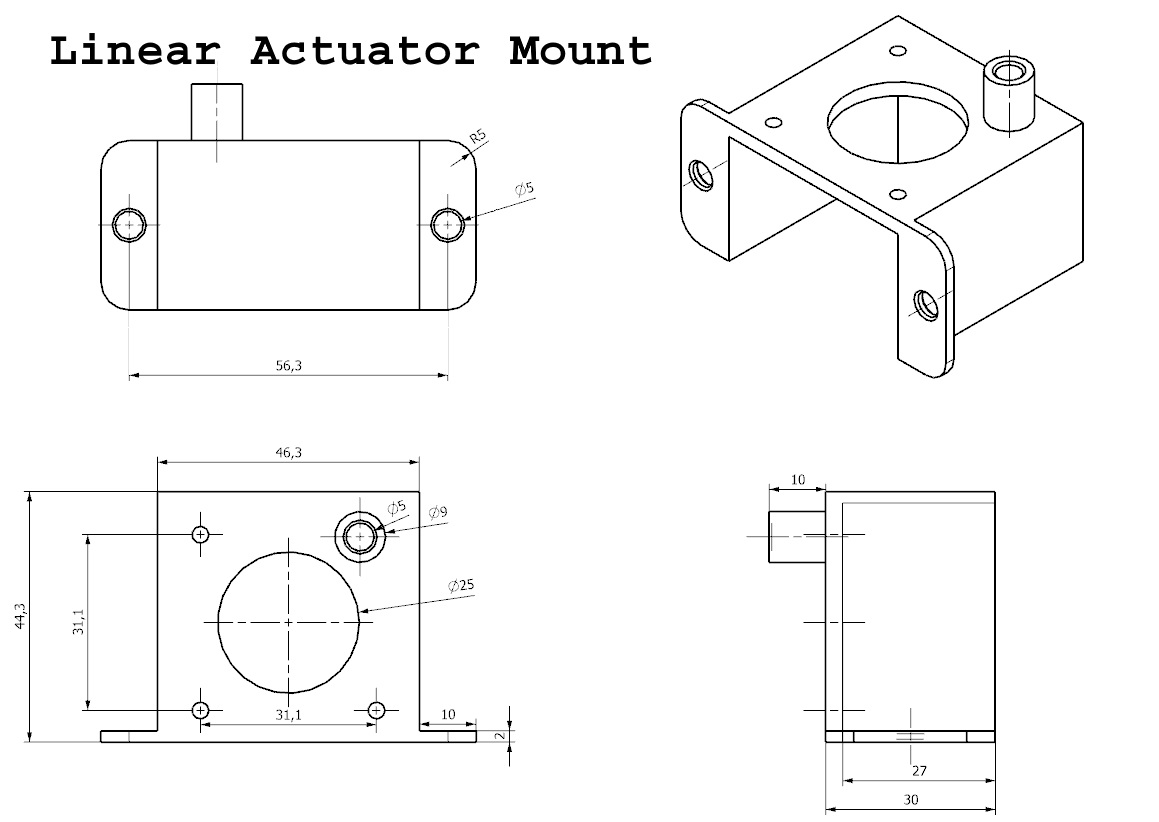

[[File:LinearActuator.jpg|500px|thumb|Linear actuator]] | |||

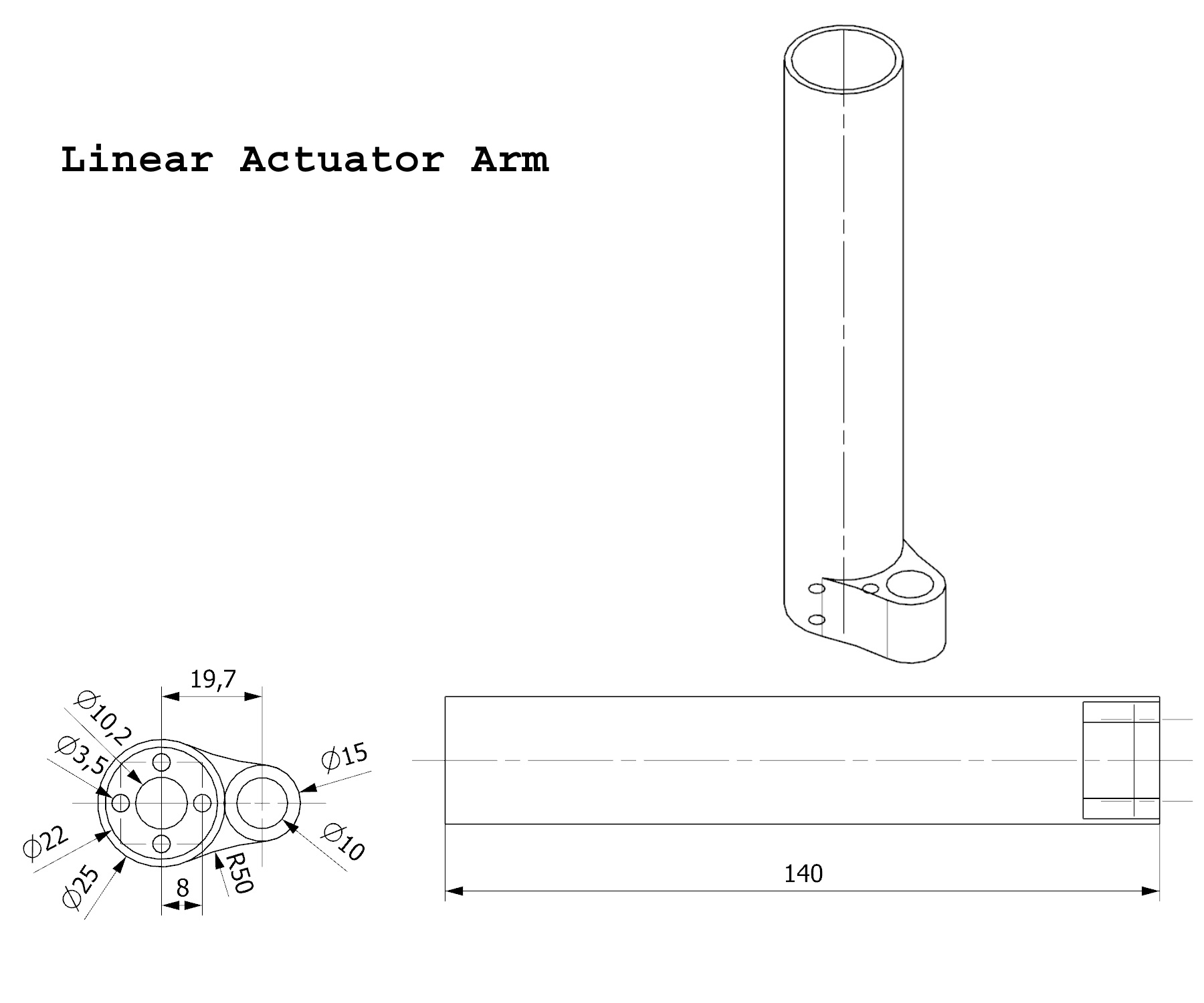

The linear actuator pushes batteries through the carousel wheels. The figures here show several parts of the actuator as an exploded view and an assembly. The arm is connected to the leadscrew by a standard 8 mm lead screw nut and to the steel rod by an LM5UU linear bearing. The leadscrew causes a large ratio between the motor and the output of the actuator, enabling the actuator to exert a relatively large force possibly needed to push the battery casing which is clamped by its leaf springs in the carousel. | |||

[[File:LinearActuatorMount.jpg|500px|thumb|Linear actuator mount]] | |||

[[File:LinearActuatorArm.jpg|500px|thumb|Linear actuator arm]] | |||

<br clear=all> | |||

=== Drone positioning system === | |||

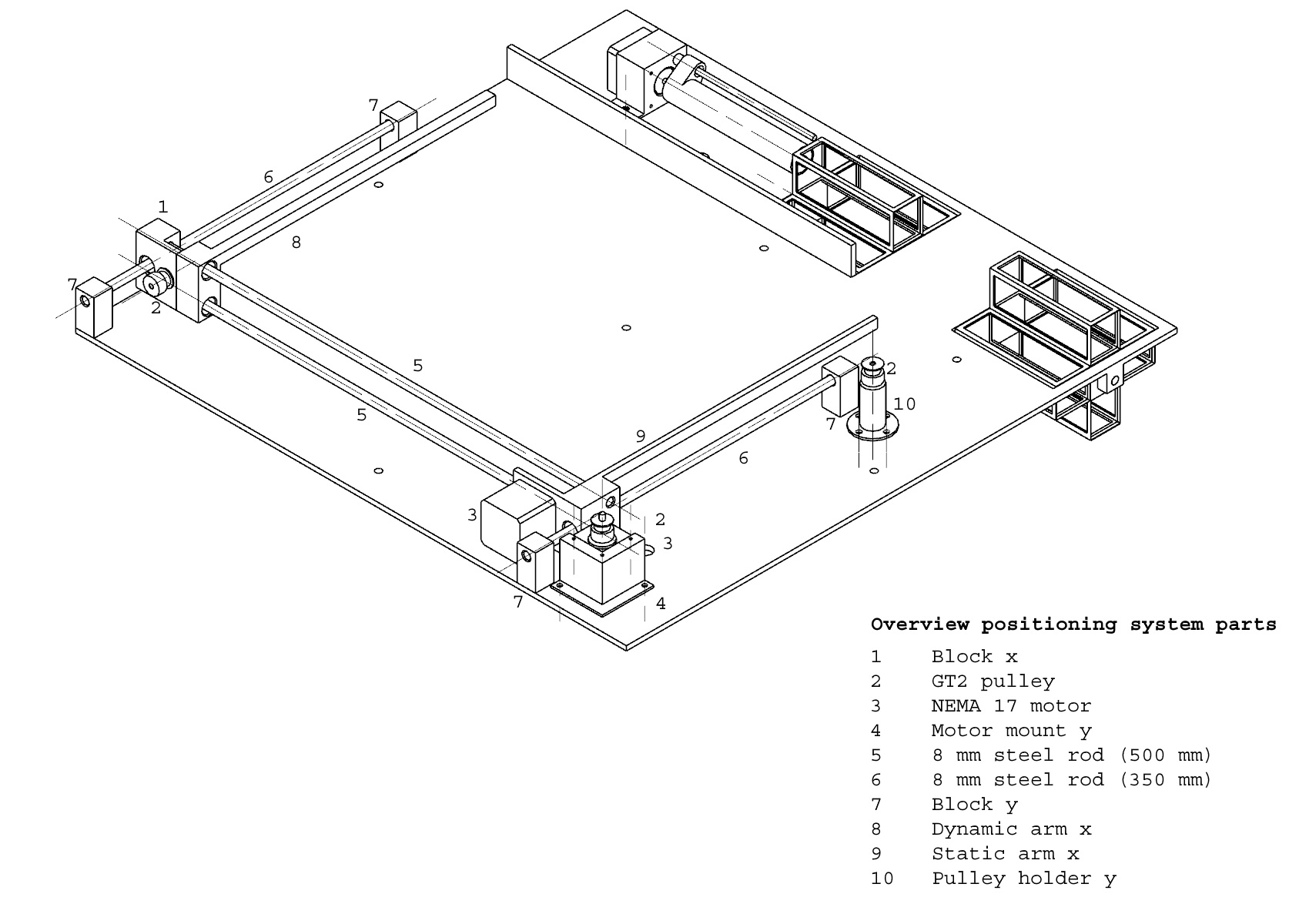

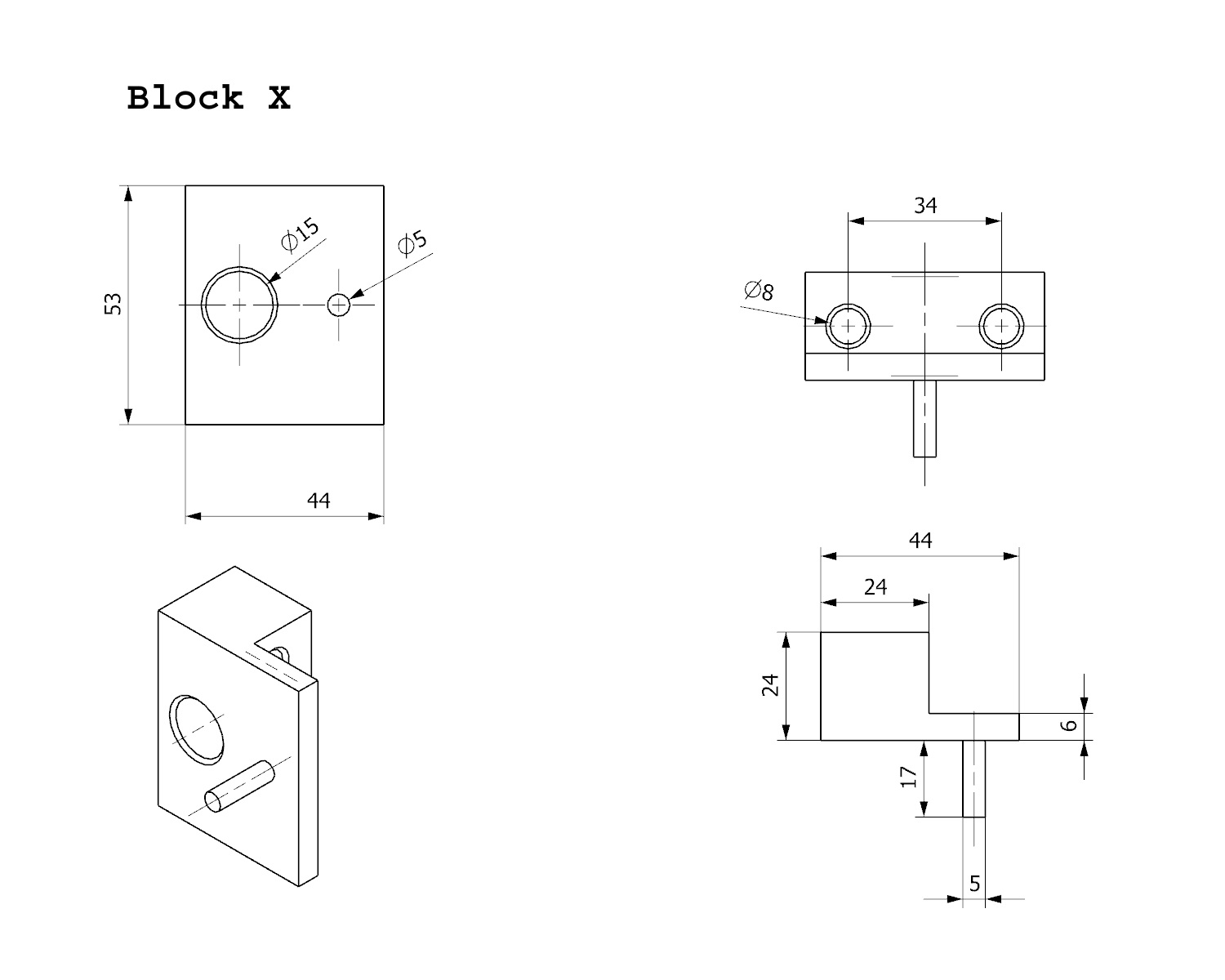

[[File:PositioningOverview.jpg|500px|thumb|Overview of positioning system parts]] | |||

Before any batteries are exchanged, the surveillance drone must be aligned and positioned with its battery bay exactly in between the carousels. This is done with plastic arms actuated with the help of NEMA 17 stepper motors and GT2 timing belts. The arms slide over 8 mm steel rods via LM8UU linear bearings. Apart from the custom made parts, two stepper motors, two timing belts, three GT2 pulleys and four LM8UU bearings are required. The figure on the right provides an overview of all parts of the positioning system. All parts are presented in detail in the images below. | |||

<br clear=all> | |||

[[File:BlockX.jpg|500px|thumb|Block X]]<br clear=all> | |||

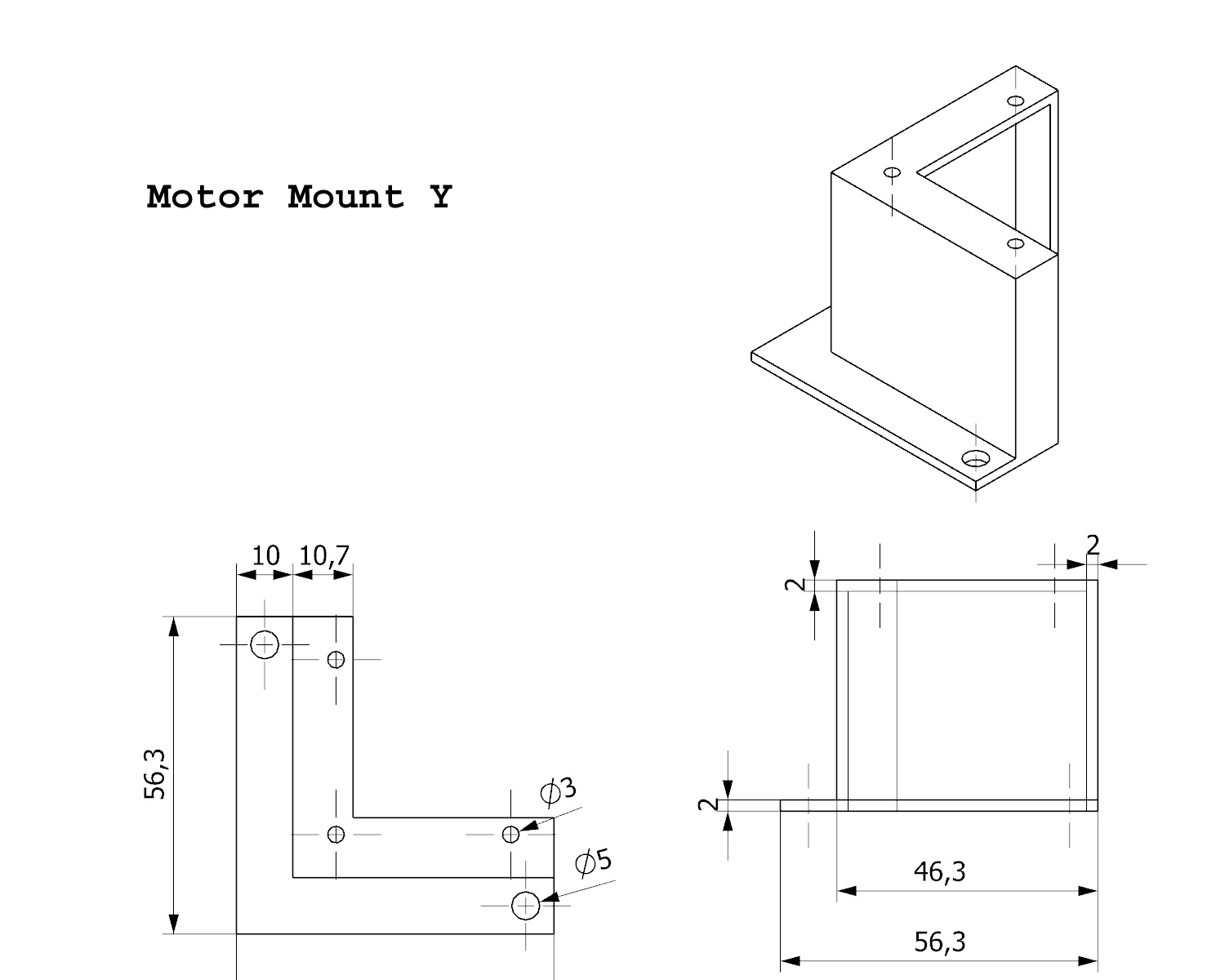

[[File:MotorMountY.jpg|500px|thumb|Block X]]<br clear=all> | |||

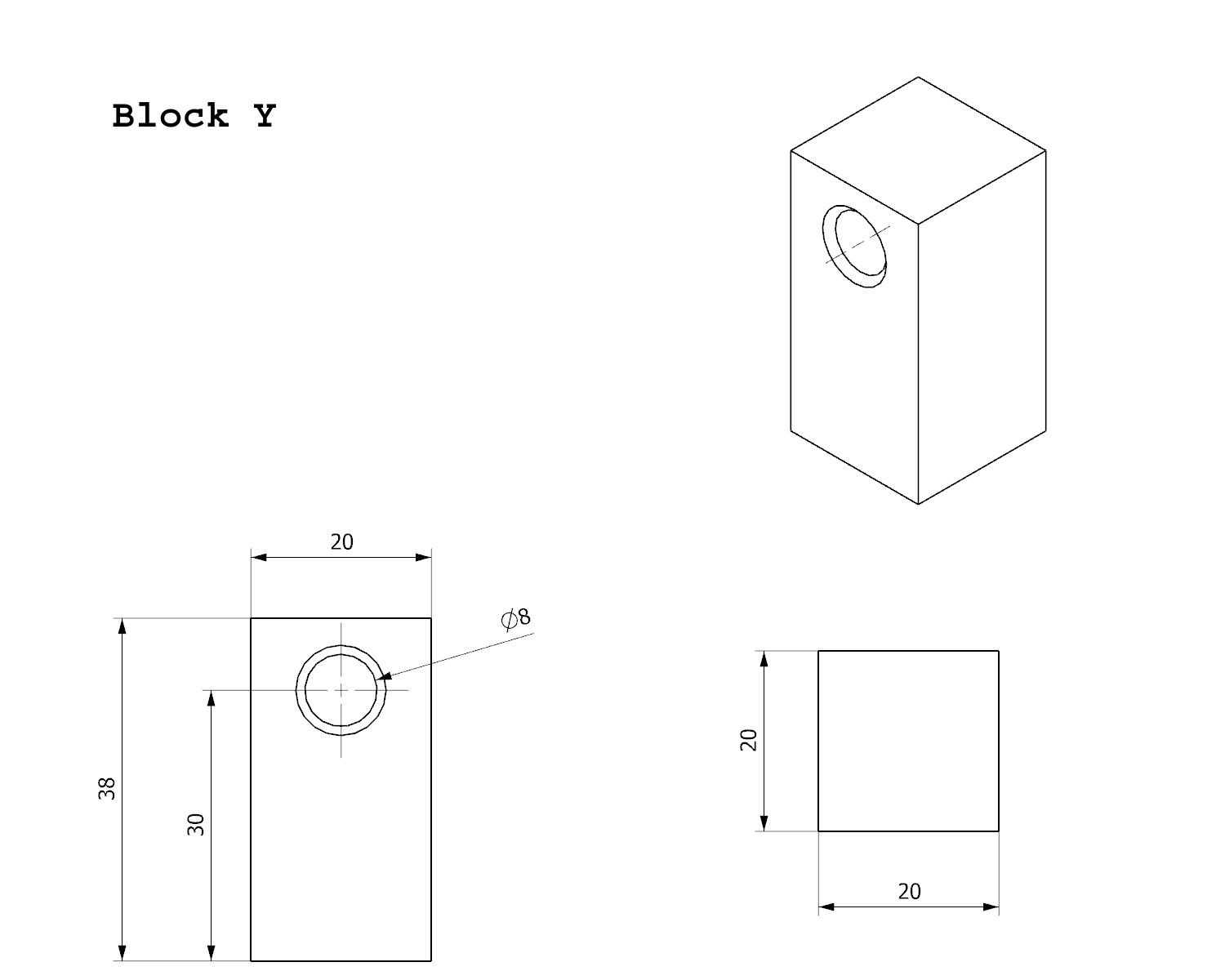

[[File:BlockY.jpg|500px|thumb|Block Y]]<br clear=all> | |||

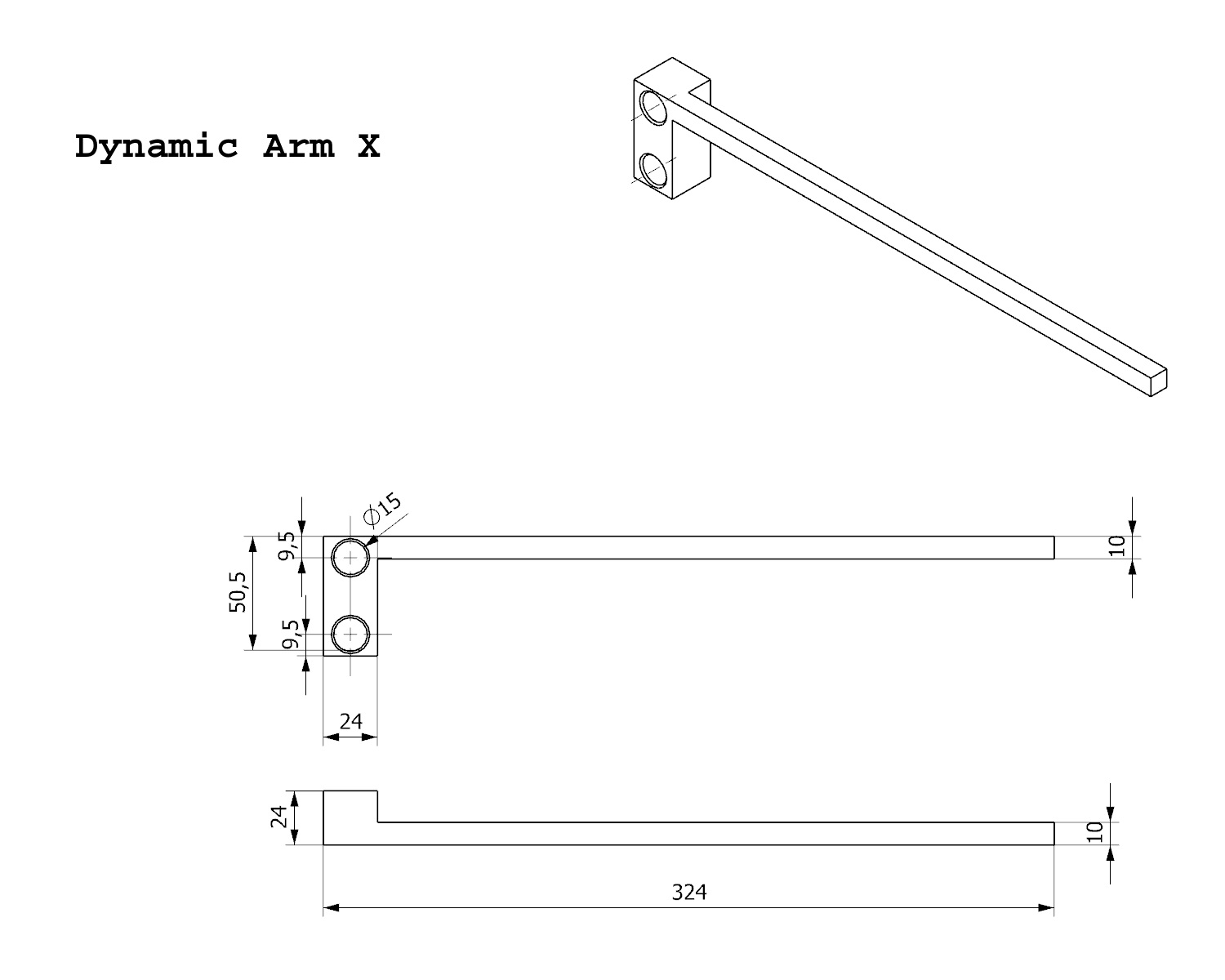

[[File:DynamicArmX.jpg|500px|thumb|Dynamic arm x]]<br clear=all> | |||

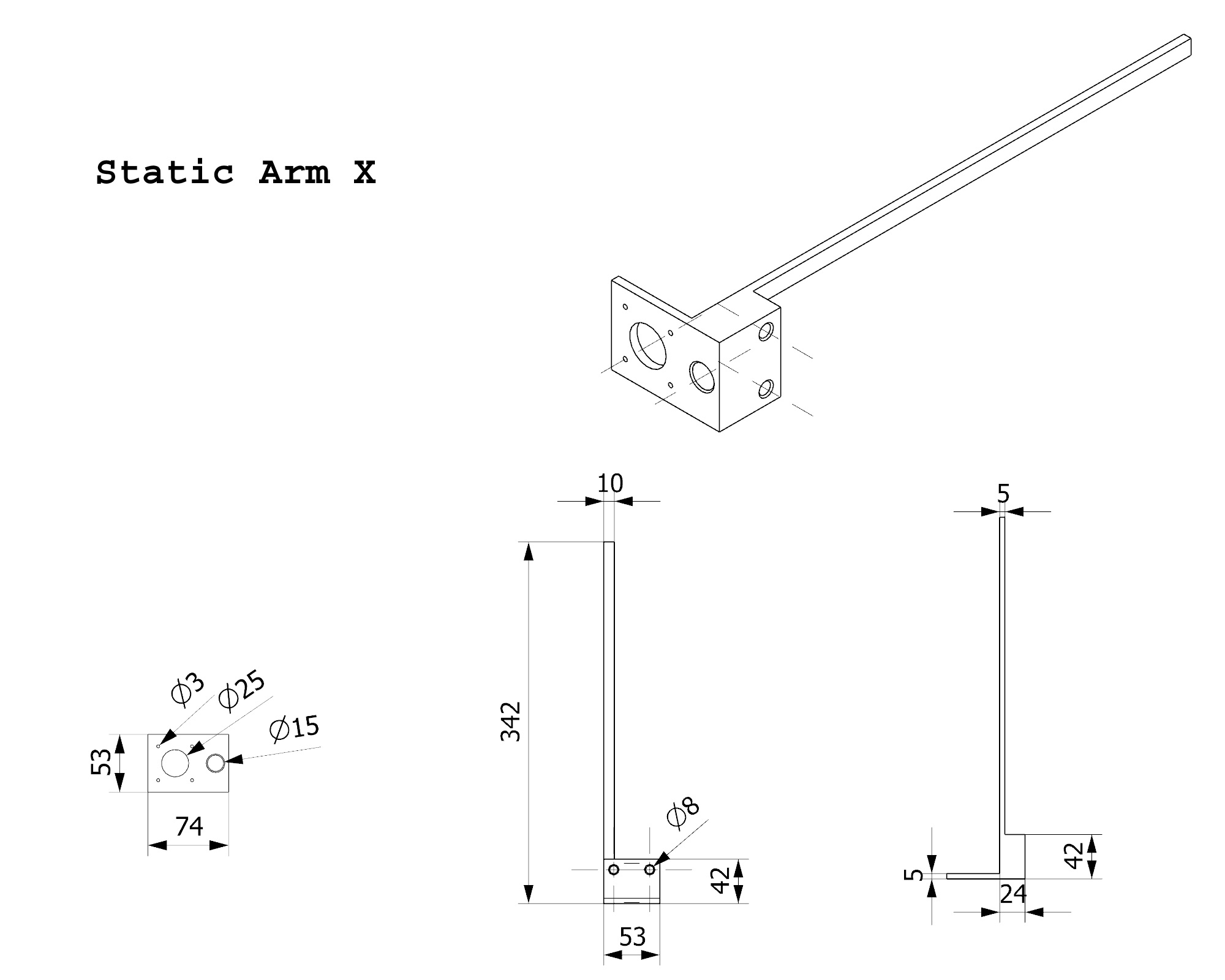

[[File:StaticArmX.jpg|500px|thumb|Static arm x]]<br clear=all> | |||

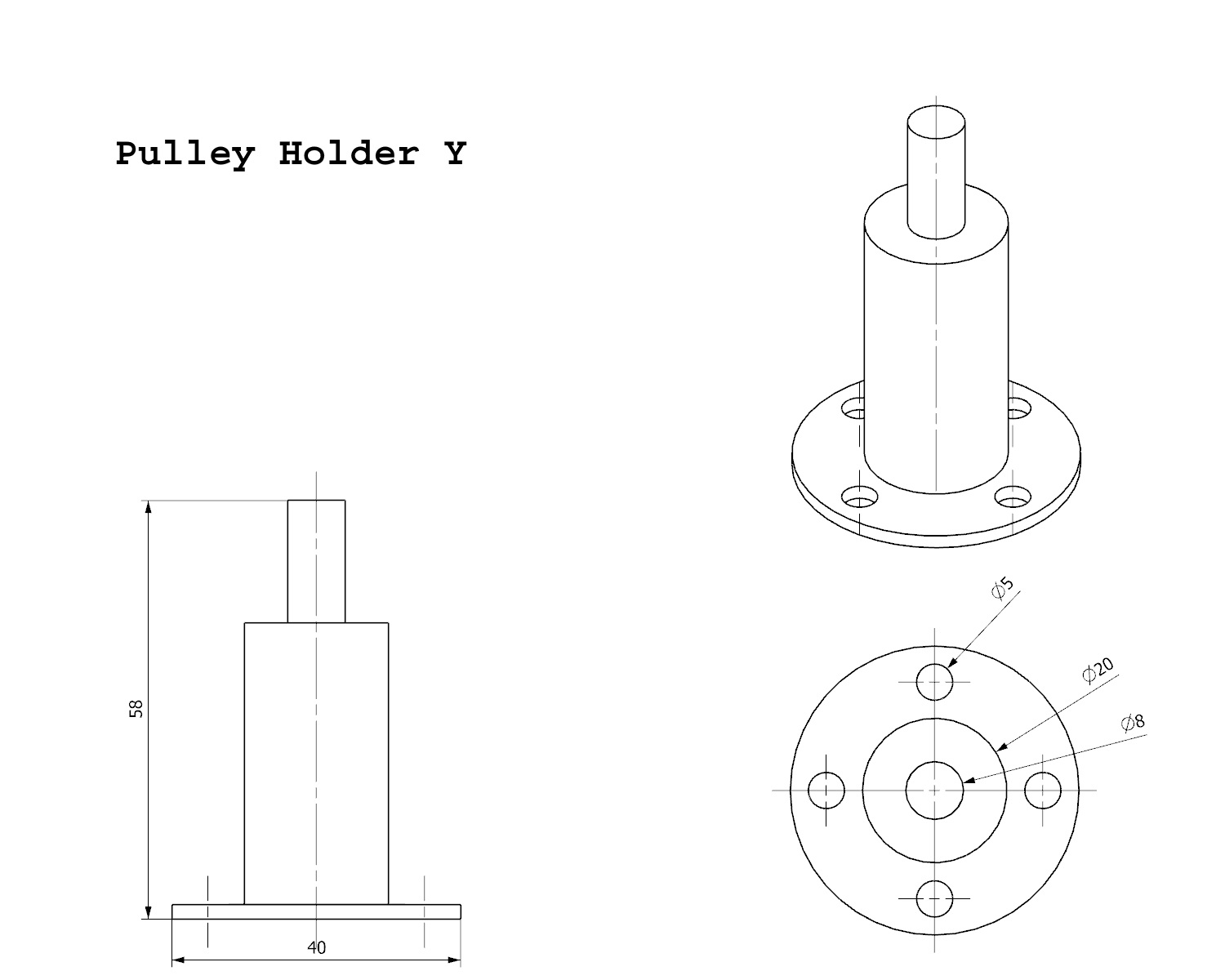

[[File:PulleyHolderY.jpg|500px|thumb|Pulley holder y]]<br clear=all> | |||

=== Electronics === | |||

[[File:EndStopPositions.jpg|500px|thumb|Contact switch positions]] | |||

The system has four NEMA 17 stepper motors which act as actuators to move the alignment arms, push batteries and turn the carousel. These motors can be powered and controlled via a stepper driver such as the A4988. For such a circuit, a voltage between 9V and 35V is required which means that it can be connected directly to the 14.8V battery in the powertrain of the drone. The behaviour of the platform can be controlled using an Arduino which would be compatible with the A4988, this would need a 5V supply which is available from the 5V bus (see the section about complete drone electronics). Contact switches like the KW11-N can be used as sensors to ensure the drone is properly aligned and positioned. The figure shows recommended contact switch positions (circled in red). The Arduino and motor drivers should be placed at the same position as the rest of the onboard electronics. The base plate provides holes to allow easy wiring. | |||

<br clear=all> | |||

=== Weight and costs estimation === | |||

This section provides a rough estimation of costs including both off the shelve components and custom manufactured parts. Series production would significantly lower the price, especially considering manufacturing costs. | |||

{| border="1" style="margin-left: 0em;" | |||

|- | |||

|'''Component''' | |||

|'''Cost/part (€)''' | |||

|'''Weight/part (kg)''' | |||

|'''Amount''' | |||

|- | |||

|- | |||

| LM8UU | |||

| 1.00 | |||

| 0.014 | |||

| 6 | |||

|- | |||

| NEMA 17 42BYGHW609 | |||

| 12.00 | |||

| 0.260 | |||

| 4 | |||

|- | |||

| Aruino MEGA | |||

| 35.00 | |||

| 0.037 | |||

| 1 | |||

|- | |||

| A4988 | |||

| 2.50 | |||

| 0.0013 | |||

| 4 | |||

|- | |||

| 150 mm steel rod (d = 5mm) | |||

| 1 | |||

| 0.023 | |||

| 1 | |||

|- | |||

| 2.4 m steel rod (d = 8mm) | |||

| 35 | |||

| 0.694 | |||

| 4 | |||

|- | |||

| 150 mm lead screw (d = 8mm) | |||

| 5 | |||

| 0.052 | |||

| 1 | |||

|- | |||

| Custom parts | |||

| 200 | |||

| 1.9 | |||

| - | |||

|} | |||

This results in a total weight of 3.9 kg and a total price of about €335 | |||

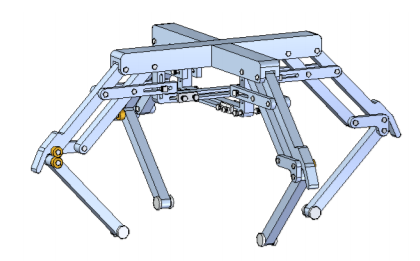

== Landing gear == | |||

The landing gear for this drone should be able to land on rough terrain. This rough terrain can take the form of slope or a place with uneven terrain. This means that the landing gear will need to adapt for multiple situations to ensure that it will always land in a stable position, otherwise, it would complicate the ability for surveillance drones to land on this service drone. | |||

It is possible to solve this problem by using actuators [22] or using mechanical principles[21]. Considering that actuators will both be a lot heavier than using mechanical principles, and the fact that the drone should be able to land safely regardless of how much battery power is left. It was decided to use landing gear designed around mechanical principles. | |||

[[File:Landinggear.PNG|300px|thumb|right|Original passive landing gear for drones to land on rough terrain]] | |||

The landing gear that seemed most suitable for the task was a passive landing gear designed at the University of Queensland in Brisbane, Australia [21]. This design uses the principle of a shared load between objects that are usually mechanically isolated. This design can then be worked and improved on and will result in the landing gear on the right. This landing gear was however designed for a smaller drone and will need to be upscaled to properly handle the service drone in its entirety. Things to keep in mind are the weight, strength and cost of the entire landing gear. These will all be worked into a 3D model and a technical drawing to show the exact dimensions of this landing gear. | |||

Starting with the weight of the landing gear, it was decided that it should not weigh more than 2 kilograms. This is due to the fact that using a heavier landing gear will result in more fuel consumption for the drone, and thus impacting the longevity of the design. Another constraint on the system is to only use steel and aluminium, this is to keep the landing gear relatively cheap. Another material that was considered was carbon fibre, but this would cause the construction to be a lot more expensive due to the manufacturing of these components using carbon fibre. | |||