SkyScraper-I: Tethered Whole Windows Cleaning Robot: Difference between revisions

No edit summary |

No edit summary |

||

| (One intermediate revision by the same user not shown) | |||

| Line 8: | Line 8: | ||

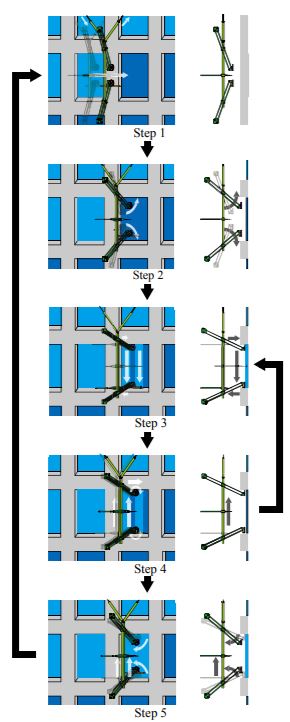

Step 4: Driving the SkyScraper-I sideways toward a new cleaning position while the squeegees return to the top position by rolling of the CS rollers and by the synchronized control of the length of the tethers | Step 4: Driving the SkyScraper-I sideways toward a new cleaning position while the squeegees return to the top position by rolling of the CS rollers and by the synchronized control of the length of the tethers | ||

Step 5: Unclamping of the CS rollers and moving to the next window and returning to Step 1.</p> | Step 5: Unclamping of the CS rollers and moving to the next window and returning to Step 1.</p> | ||

<p> In the next paragraphs, some of the mechanisms are explained in greater detail. First the Cramping and Suction Roller (CS Roller) serves two main functions. It permits movement on the window frames and it acts as a clamping device to grip the frame. This clamping action is realized in two ways. The roller is covered in sponge for better grip and it is equipped with a noncontact suction pad.</p> | <p> In the next paragraphs, some of the mechanisms are explained in greater detail. First the Cramping and Suction Roller (CS Roller) serves two main functions. It permits movement on the window frames and it acts as a clamping device to grip the frame. This clamping action is realized in two ways. The roller is covered in sponge for better grip and it is equipped with a noncontact suction pad.</p> | ||

<p> To ensure that both CS rollers are parallel to the window surface, a parallel link mechanism is installed in both clamping arms. In order to keep the same distance between the two CS rollers and the window surface, both clamping arms are driven at the same angle by the wire-driving mechanism. Two wires of this mechanism are stretched between the diagonal joints of the parallel mechanism. In order for the lengths of the wires to be changed at the same rate, they are driven by the same reel motor assembly. Because this motor is a worm-geared motor, the clamping arms maintain the clamping motion even when the power supply is stopped. By means of the reeling action of the motor, the two clamping arms fold outwards. They fold inwards when springs in the assembly apply a spring force. To adjust the system to different window heights, the connecting joints of the clamping arms can be slided along the main body of the SkyScraper and locked in place before the cleaning task is started. In addition, a unit for adjusting the wire length is included in the system.</p> | <p> To ensure that both CS rollers are parallel to the window surface, a parallel link mechanism is installed in both clamping arms. In order to keep the same distance between the two CS rollers and the window surface, both clamping arms are driven at the same angle by the wire-driving mechanism. Two wires of this mechanism are stretched between the diagonal joints of the parallel mechanism. In order for the lengths of the wires to be changed at the same rate, they are driven by the same reel motor assembly. Because this motor is a worm-geared motor, the clamping arms maintain the clamping motion even when the power supply is stopped. By means of the reeling action of the motor, the two clamping arms fold outwards. They fold inwards when springs in the assembly apply a spring force. To adjust the system to different window heights, the connecting joints of the clamping arms can be slided along the main body of the SkyScraper and locked in place before the cleaning task is started. In addition, a unit for adjusting the wire length is included in the system.</p> | ||

| Line 14: | Line 13: | ||

<p> If the adjustment of the lengths of tethers are not correct, then internal force on the CS roller will be generated and the SkyScraper-I will be separated from the surface of the window. To avoid this kind of problem, the Tether Compliance Mechanism (TC mechanism) is introduced in the YS links. It indirectly measures the traction force of the tether that it is attached to. Since both length and force of the tether are controlled, the clamping arms with the CS roller can easily follow the frame of the window.</p> | <p> If the adjustment of the lengths of tethers are not correct, then internal force on the CS roller will be generated and the SkyScraper-I will be separated from the surface of the window. To avoid this kind of problem, the Tether Compliance Mechanism (TC mechanism) is introduced in the YS links. It indirectly measures the traction force of the tether that it is attached to. Since both length and force of the tether are controlled, the clamping arms with the CS roller can easily follow the frame of the window.</p> | ||

<p> A preliminary experiment has been conducted where the SkyScraper moves from window to window. This motion took the robot 14 seconds on average. The clamping to window frames was also tested. The steps of this process are as follows: (1) the clamping arms are opened, (2) the CS roller starts touching the surface of the window, (3) while the clamping arms keeps being opened, the lower CS roller touches the window frame, (4) the tethers are slightly pulled and both of the clamping arms have contact with the window frames. At last, an experiment to verify the sideway drive motion was conducted. From these experiments, it could be confirmed that the Sky-Scraper-I has the ability to move from window to window and to drive the vertical sliding rod from one side to another of each window in order to clean the whole surface of the window. The cleaning mechanism will be discussed further in another paper.</p> | <p> A preliminary experiment has been conducted where the SkyScraper moves from window to window. This motion took the robot 14 seconds on average. The clamping to window frames was also tested. The steps of this process are as follows: (1) the clamping arms are opened, (2) the CS roller starts touching the surface of the window, (3) while the clamping arms keeps being opened, the lower CS roller touches the window frame, (4) the tethers are slightly pulled and both of the clamping arms have contact with the window frames. At last, an experiment to verify the sideway drive motion was conducted. From these experiments, it could be confirmed that the Sky-Scraper-I has the ability to move from window to window and to drive the vertical sliding rod from one side to another of each window in order to clean the whole surface of the window. The cleaning mechanism will be discussed further in another paper.</p> | ||

[[File:Capture17.JPG|200px]][[File:Capture18.JPG|200px]] | |||

Latest revision as of 10:53, 26 March 2018

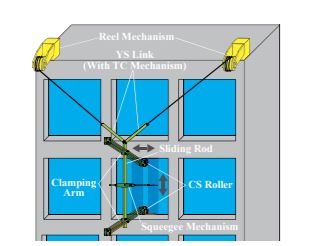

This paper proposes a novel tethered window cleaning robot named a “SkyScraper-I” and discusses its design. Since the manual window cleaning task of buildings is very dangerous, introduction of automated window cleaning robots is strongly demanded; although some of the modern buildings often install special guide frames for window cleaning machine, the majority of buildings are not equipped with such guide frames. Generally the window cleaning robot needs two types of mobility to realize the window cleaning task: “Mobility A” to move among the windows and “Mobility B” to drive a window cleaning squeegee on the surface of the window; in this paper, we call the robot with these two types of mobility the “whole windows cleaning robot”. Several types of window cleaning robots have been proposed. Most of them possess either Mobility A or Mobility B but few of them possess both kinds of mobility. In this paper, a new concept of a window cleaning robot named “SkyScraper-I” is proposed that possesses both kinds of mobility.

For the window to window locomotion (Mobility A), reels are installed on the top of the building to which tethers are attached that in turn are attached to the SkyScraper. This setup makes it possible for the robot to reach all the windows on one side of the building. The reels are somewhat extended from the facade to make sure that the tethers do not come into contact with obstacles such as windowsills. Only when the robot cleans the window, the window cleaning mechanism is thrust to the window by the driving arm making again sure that no contact is made with obstacles.

For the locomotion for cleaning of the whole surface of a window (Mobility B) the configuration of the SkyScraper needs to be considered. The main body of the SkyScraper consists of a long vertical oriented rod along which a squeegee can move up and down. At each end of this rod, a rotating arm is attached with a roller. These arms press the rollers to the window frame without making contact with the window. This makes sure that no trace remains after the window is cleaned. The squeegee can then move down to clean a part of the window. Next the rollers roll simultaneously a bit further and the squeegee moves back to the top again. This process is repeated until the whole window is cleaned. Note that the window frames are used as a guide for the motion of the robot with this driving method which is called the Window Frames Clamping (WFC) driving. Furthermore, the position control of this method is easy because it needs only to move along the guide.

The steps of cleaning of the window by the SkyScraper-I are shown in the figure and the sequence is as follows: Step 1: Window-to-window motion by the length control of a pair of tethers, Step 2: Clamping of the CS rollers between the frames by the control of the inclination angle of the clamping arms and by the synchronized control of the length of the tethers, Step 3: Cleaning of the window by the sliding motion of the squeegee mechanism from the top to bottom of the window surface Step 4: Driving the SkyScraper-I sideways toward a new cleaning position while the squeegees return to the top position by rolling of the CS rollers and by the synchronized control of the length of the tethers Step 5: Unclamping of the CS rollers and moving to the next window and returning to Step 1.

In the next paragraphs, some of the mechanisms are explained in greater detail. First the Cramping and Suction Roller (CS Roller) serves two main functions. It permits movement on the window frames and it acts as a clamping device to grip the frame. This clamping action is realized in two ways. The roller is covered in sponge for better grip and it is equipped with a noncontact suction pad.

To ensure that both CS rollers are parallel to the window surface, a parallel link mechanism is installed in both clamping arms. In order to keep the same distance between the two CS rollers and the window surface, both clamping arms are driven at the same angle by the wire-driving mechanism. Two wires of this mechanism are stretched between the diagonal joints of the parallel mechanism. In order for the lengths of the wires to be changed at the same rate, they are driven by the same reel motor assembly. Because this motor is a worm-geared motor, the clamping arms maintain the clamping motion even when the power supply is stopped. By means of the reeling action of the motor, the two clamping arms fold outwards. They fold inwards when springs in the assembly apply a spring force. To adjust the system to different window heights, the connecting joints of the clamping arms can be slided along the main body of the SkyScraper and locked in place before the cleaning task is started. In addition, a unit for adjusting the wire length is included in the system.

To make sure that the main body maintains the vertical posture, so that the SkyScraper can clamp the window frame properly, a couple of measures are taken. First, it suspends its weight at a high position while the center of gravity is very low due to its long body. This ensures that the postures around the roll and pitch axis can be stabilized. To generate stability around the yaw axis, a pair of Yaw Stabilization Links (YS links) is attached to the top joint that are rotatable around the pitch axis at the top joint. The tethers are connected to the other sides of these links. This way, when the SkyScraper rotates around the yaw axis, a large recovery moment is generated around this axis by the the traction forces of the tethers. Additionally, counter weights are added to the clamping arms. All these things together ensure the total stability of the SkyScraper.

If the adjustment of the lengths of tethers are not correct, then internal force on the CS roller will be generated and the SkyScraper-I will be separated from the surface of the window. To avoid this kind of problem, the Tether Compliance Mechanism (TC mechanism) is introduced in the YS links. It indirectly measures the traction force of the tether that it is attached to. Since both length and force of the tether are controlled, the clamping arms with the CS roller can easily follow the frame of the window.

A preliminary experiment has been conducted where the SkyScraper moves from window to window. This motion took the robot 14 seconds on average. The clamping to window frames was also tested. The steps of this process are as follows: (1) the clamping arms are opened, (2) the CS roller starts touching the surface of the window, (3) while the clamping arms keeps being opened, the lower CS roller touches the window frame, (4) the tethers are slightly pulled and both of the clamping arms have contact with the window frames. At last, an experiment to verify the sideway drive motion was conducted. From these experiments, it could be confirmed that the Sky-Scraper-I has the ability to move from window to window and to drive the vertical sliding rod from one side to another of each window in order to clean the whole surface of the window. The cleaning mechanism will be discussed further in another paper.