PRE2024 3 Group20: Difference between revisions

| (83 intermediate revisions by 5 users not shown) | |||

| Line 30: | Line 30: | ||

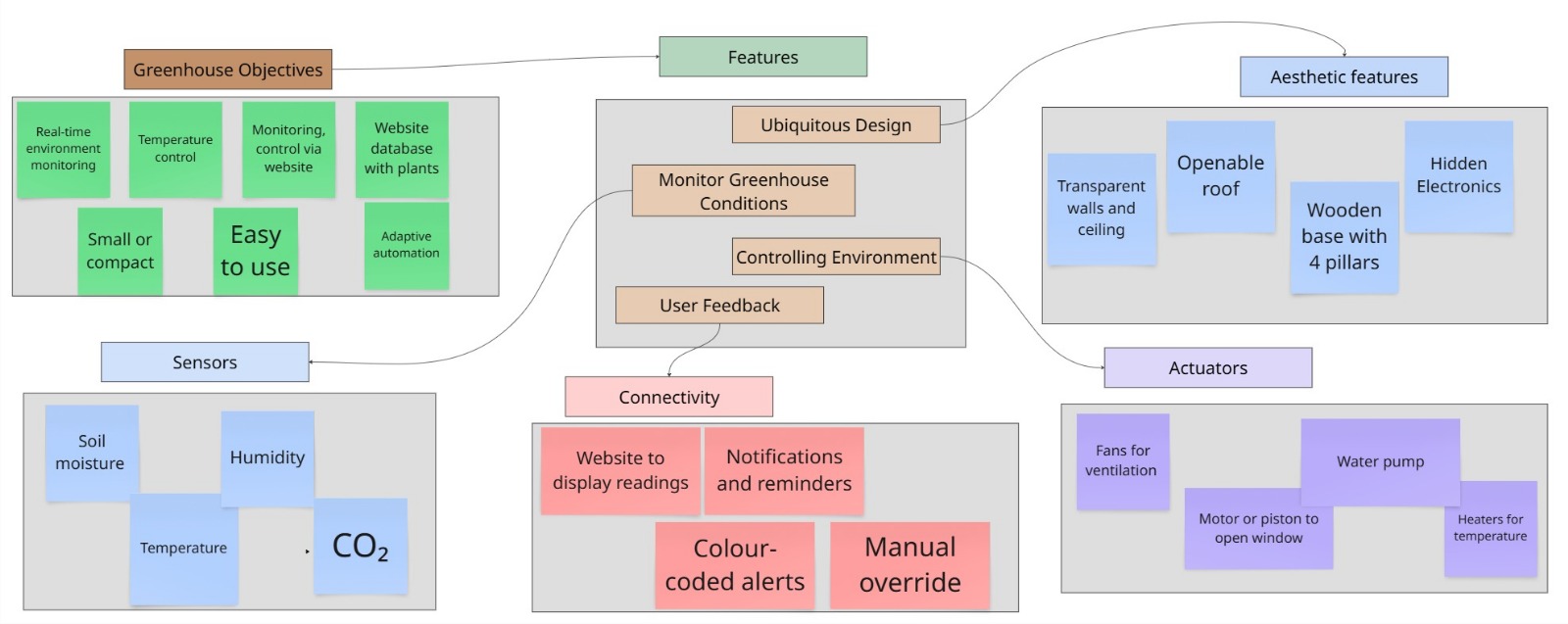

=== Problem Statement and Objectives === | === Problem Statement and Objectives === | ||

Home automation systems, including automatic lighting and temperature control have recently become widely adopted in modern smart homes, to save energy and serve as a convenient alternative to manual controls. This promotes sustainability and convenience while also serving the needs of people who are unable to manage their homes independently, such as the elderly or disabled. Though the market for home automation is highly saturated with companies such as Google, Philips and Amazon designing sophisticated, there is a lack of automation systems for greenhouses and gardens. While they exist, our group believes that there is significant potential and a gap in the market for such a series of products, which monitor and automatically control certain parameters in gardens and greenhouses such that plants and crops remain healthy in the absence of human intervention. | |||

=== | A holistic approach that monitors parameters such as temperature, carbon dioxide concentrations, soil moisture, and light, can be used to control a series of actuators that act such that each of the parameters are optimized for the crops grown by the user. To accompany the system, a smartphone app can also be developed such that the user can customize the settings depending on their crops. A more thorough description of the features and functionality of the product is given in subsequent sections of this page. The problem statement or main objective of this project is '''“to design a series of products that demonstrate the possibility of the automation of greenhouses, promoting sustainability and convenience in agricultural domains”.''' | ||

'''<u>Relevance of the problem:</u>''' | |||

In recent years, home automation systems have revolutionized modern living by offering energy-efficient, convenient, and user-friendly solutions for managing daily tasks such as lighting, temperature control, and security. The global smart home market is projected to reach $414.2 billion by 2034 [1]. Many existing smart home markets have been adopted worldwide, for instance, Alexa by Amazon. These systems enable efficiency by reducing household energy consumption by up to 40% in some cases [2]. They also allow for the tracking and better management of homes by providing data and metrics of their homes, this makes it easier for all groups of people to live more efficiently specifically marginalized groups like the elderly or those with disabilities. For instance, smart thermostats and lighting systems allow users to automate functions, saving time and reducing the physical burden of manual control. However, while the market for general home automation is highly competitive with several products, there is an underexplored gap in automation systems specifically designed for greenhouses and gardens, particularly for small-scale, personal use in urban settings. This gap is significantly pronounced/exaggerated when considering the growing demand for sustainable, tech-enabled solutions that cater to modern-day lifestyles where space, time, and expertise are often limited. | |||

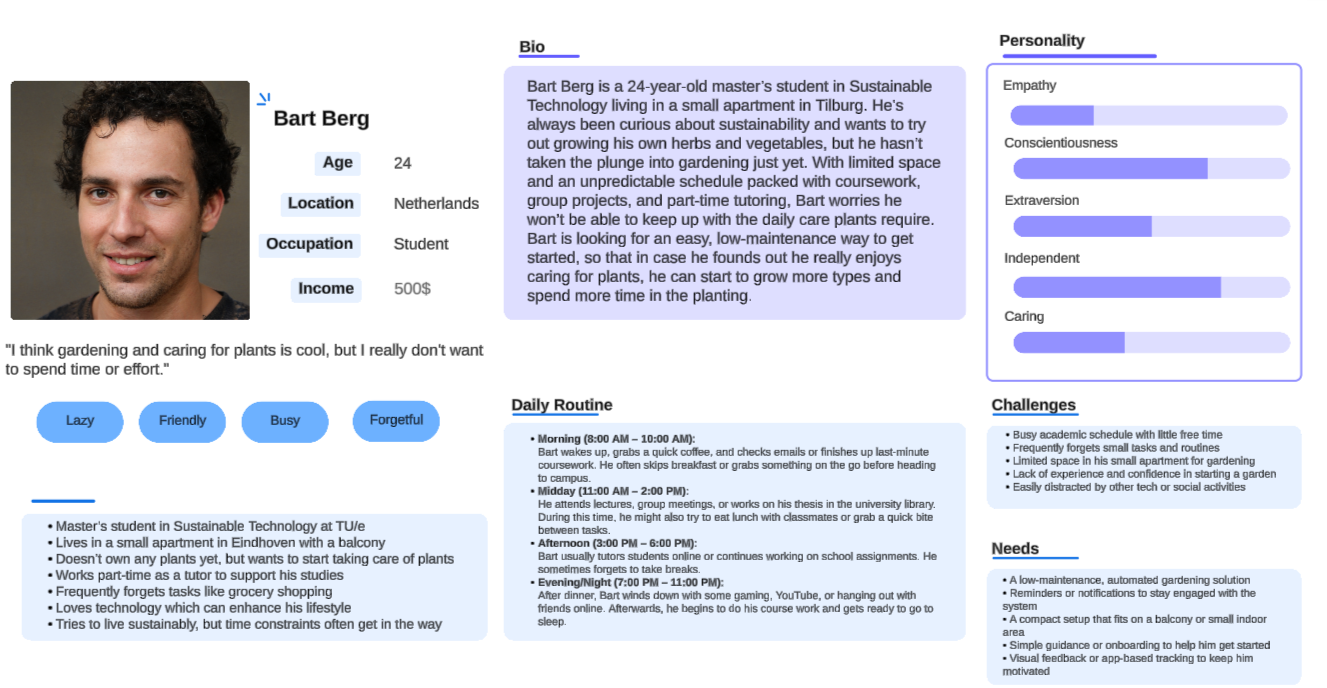

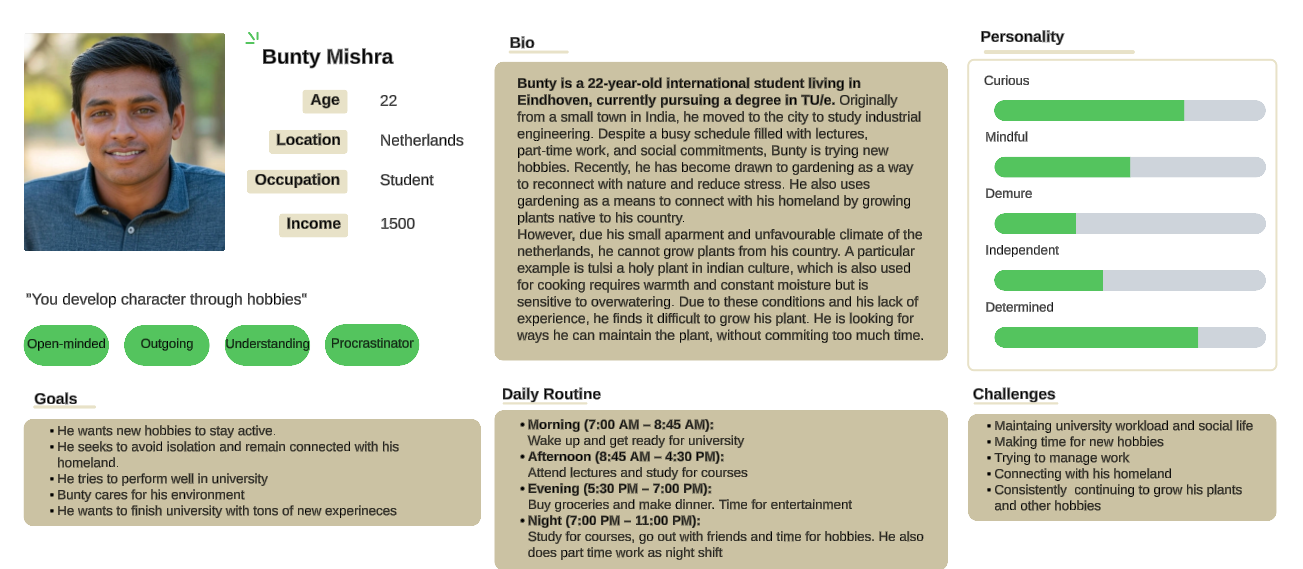

Our project directly addresses this gap by developing an automated mini greenhouse tailored for the residences of young adults and secondly educational institutions. Young adults, typically aged 18-35, represent a primary target audience due to their unique position in today’s society due to increasingly exploring new hobbies, sustainability oriented living, and bringing mental health concerns to the public. Gardening is therefore gaining popularity as a way to connect with nature amidst the stresses of living in our world. For example, in 2020 a study found that over 20 million Americans under 35 picked up gardening for the first time and have become active gardeners since [3], this trend is due to heightened environmental awareness (given the current climate crisis) and the rise of vegetarianism/veganism, which has increased demand for homegrown produce, and lastly due to the tech-centred nature of todays world, people are reconnecting with nature. However, given the housing crisis, young adults often face significant barriers when adopting gardening as a hobby. Namely, many live in apartments with limited space, have constrained budgets, and/or have busy lives with demanding schedules (e.g. due to work, studies, or other commitments). These constraints/limitations make traditional gardening impractical, as it has a steep learning curve, requiring time, effort, money and knowledge. | |||

The automated mini greenhouse addresses these challenges by offering a scaled-down, aesthetically pleasing system designed to be in an apartment setting. It is able to automate critical parameters such as temperature, soil moisture, humidity, CO2 levels, etc, It does so using actuators such as a servomotor for ventilation and a water pump for drip irrigation, this allows the system to respond in real-time to environmental changes, minimizing the knowledge and time needed on the users’ end. For instance, if soil moisture drops below a threshold (e.g., 30%), the system automatically activates the water pump, ensuring plants remain healthy even if the user is away, forgets to water them, or simply does not have time. Additionally, the greenhouse offers a website to track the analytics of the greenhouse's metrics. | |||

On a larger scale, the project promotes sustainability, a core value for both our primary and secondary audiences. "''Sustainability Insights 2024'' found that 78% of 18-24-year-olds ranked sustainability as a primary or secondary priority" [4]. Gardening allows for the reduced reliance on industrial agriculture, which accounts for 26% of global greenhouse gas emissions [5]. Furthermore, our system enhances this sustainability by incorporating energy and water efficiency (e.g. by optimally watering plants based on the type). By enabling young adults to grow their own herbs, vegetables, or plants in general, our mini greenhouse allows for a sustainable, eco-friendly lifestyle while reducing the users’ carbon footprint. | |||

Our secondary audience, educational institutions, further underscores the relevance of this project. Schools are increasingly integrating hands-on learning into their curriculums (specifically in subjects like biology and environmental sciences). The greenhouse in an educational environment could allow for the comparison of plant growth under ideal versus altered conditions, allowing children to understand/experiment with classroom principles in practice. Therefore, the greenhouse provides a practical, low-cost tool for classroom experiments. | |||

In summary, the problem being solved is highly relevant in today’s world. By developing an automated mini greenhouse, a market gap for small-scale is being filled, and personal gardening solutions are being offered to addressing the barriers faced by young adults while promoting sustainability and resource efficiency. For educational institutions, the greenhouse provides a hands-on approach to teach critical concepts in environmental sciences. All in all, the project contributes to a broader movement toward sustainable, tech enabled agriculture, empowering individuals. | |||

[1]: https://www.gminsights.com/industry-analysis/smart-home-market | |||

[2]: [https://www.blueridgeenergy.com/blog/2024/05/smart-home-devices-can-you-really-save-energy#:~:text=Still%2C%20homes%20equipped%20with%20these,how%20that%20technology%20is%20used. https://www.blueridgeenergy.com/blog/2024/05/smart-home-devices-can-you-really-save-energy#:~:text=Still%2C%20homes%20equipped%20with%20these,how%20that%20technology%20is%20used.] | |||

[3]: [https://www.pressherald.com/2024/04/15/indoor-gardening-hasnt-grown-old-for-millennial-and-gen-z-houseplant-owners/#:~:text=In%202020%2C%20over%2020%20million,them%20have%20stuck%20with%20it. https://www.pressherald.com/2024/04/15/indoor-gardening-hasnt-grown-old-for-millennial-and-gen-z-houseplant-owners/#:~:text=In%202020%2C%20over%2020%20million,them%20have%20stuck%20with%20it.] | |||

[4]: https://www.thepacker.com/news/sustainability/consumers-prioritize-sustainability-produce-purchase-decisions | |||

[5]: [https://ourworldindata.org/environmental-impacts-of-food#:~:text=Food%20production%20accounts%20for%20over,land%20is%20used%20for%20agriculture. https://ourworldindata.org/environmental-impacts-of-food#:~:text=Food%20production%20accounts%20for%20over,land%20is%20used%20for%20agriculture.] | |||

=== Product Overview: === | |||

'''Smart Indoor Gardens with Climate Control (e.g., Harvst H-Series, Rise Gardens)''' | |||

What They Offer: Automated indoor systems with LED lights, app-controlled watering, and ventilation (e.g., Harvst H-Series grows 90 plants). Rise Gardens offers modular shelves and a seed nursery, growing up to 16 plant types. | |||

Shortfalls: Expensive (e.g., Harvst H3 at £699.99, Rise Gardens at $500+). Limited to hydroponics, furthermore they lack soil-based options. Lastly, they don’t monitor CO2 or soil pH and aren’t designed for educational experiments. | |||

'''Automated Irrigation Systems for Greenhouses (e.g., Drip Systems, Ollas)''' | |||

What They Offer: Drip systems automate watering with timers and sensors, while ollas provide low-tech, slow-release irrigation. The main advantage is that they are scalable and water-efficient, which is ideal for greenhouses. | |||

Shortfalls: Focus solely on irrigation, they lack control over CO2, humidity, or temperature. Lastly, no remote monitoring or educational features, and ollas require manual refilling. | |||

'''Indoor Hydroponic Garden Kits (e.g., AeroGarden, Click & Grow)''' | |||

What Product Offers: Compact system for a countertop. Main use is for indoors, they have automated watering, LED grow lights, and provide hydroponics. Furthermore, some have an app for connectivity and tracking. They are usually for small plants to grow with minimal effort. | |||

Shortfalls: Lack environmental control (e.g., no CO2, humidity, or soil pH monitoring). They’re hydroponic-only, so no soil-based growing, and can lead to plant. Lastly, they’re also expensive (e.g., AeroGarden Harvest at $150) and they are not designed for educational use. | |||

'''Vertical Aeroponic Systems (e.g., Tower Garden, Gardyn)''' | |||

What They Offer: Vertical setups for small spaces. They can grow 12-36 plants via aeroponics (which is a nutrient mist sprayed to the plants). Some models (e.g., Gardyn) offer LED lights and app control. | |||

Shortfalls: No control over CO2, humidity, or soil pH, focusing only on water and nutrients. They tend to be expensive (e.g., Tower Garden at $500+) and most importantly require weekly maintenance (e.g., pH testing, nutrient refills). Lastly, they’re not tailored for educational use. | |||

'''How we fill the gap:''' | |||

Our automated mini greenhouse fills the gap of the current market alternatives by offering a low-cost solution that addresses the aforementioned shortfalls. Namely, we provide full environmental control (CO2, humidity, temperature, soil moisture), and include remote monitoring via a website, making it ideal for busy young adults. For educational institutions, our plant-based monitoring and parameter control enables schools to do experiments. Lastly, one of the key focuses was on the affordability, sustainability (e.g., energy and water efficiency), and beginner-friendliness in order to ensure accessibility for our target audience. All in all, by addressing the short falls of current products, we set ourselves apart in the market. | |||

=== Target Audience === | |||

The primary target audience for our mini-greenhouse automation system are young adults. This audience is particularly interesting as they are constantly exploring new hobbies and embrace technology enabled solutions. With an ever growing importance of the environment, this target group is more inclined to adopt an automated greenhouse system that helps them connected to nature. Moreover, the system provides a beginner friendly avenue to explore this hobby and learn to grow plants, without investing much time without a big investment. | |||

The project is a scaled-down, aesthetically pleasing greenhouse designed to fit in an apartment, similar to a shelf. This design makes it more accessible to young adults, who live in apartments and have limited budgets. The mini-greenhouse can therefore offer an affordable, low-maintenance solution, making it a great choice for those with busy schedules while still allowing them to grow plants. | |||

A secondary target audience could be schools/educational institutions who could use the mini greenhouse for educational purposes. For examples, the teachers could use two mini-greenhouses as a comparison, one with ideal conditions and the other with altered parameters and demonstrate their impact on plant growth to the students. However, since any greenhouse could serve this purpose, this is considered a natural use case rather than the primary focus of the project. | |||

=== Requirements of Target Audience === | |||

The user requirements of an automated greenhouse system are customizable greenhouses fitted with multiple devices to control the greenhouse environment. Sensors with the ability to measure CO<sub>2</sub>, humidity, temperature, soil moisture, and soil pH levels are required as an input to the system. Actuators to control the Windows, irrigation systems and heating systems are required to control the environment based on decisions made by the system. The system should set certain parameters such as temperature, soil moisture, humidity, and CO2 levels, based on the plants planted inside the greenhouse. The system then can use predicted weather patterns to further improve the efficiency of the greenhouse. | |||

'''MoSCoW''' prioritization method | |||

'''Must Have –''' | |||

* Environment Monitoring – CO<sub>2</sub>, temperature, humidity, soil moisture. | |||

* Environment Controlling Systems – Irrigation Systems, Ventilation, and Heating. | |||

* Continuous Monitoring – The system must monitor and control the environment in real time. | |||

'''Should Have –''' | |||

* Energy Management – Using electricity and water efficiently. | |||

* Notifications to the User – Notify user if something is malfunctioning. | |||

* Remote Access & Control – The user can monitor and control the greenhouse when on vacation or work. | |||

'''Could Have –''' | |||

* Al Monitoring – The AI can use predicted weather forecast to further utilize the energy consumption. | |||

* Plant based monitoring- The user enters the plants inside the greenhouse, the system uses existing research and databases to find the optimum environment conditions. | |||

'''Will not Have –''' | |||

* Pesticide Control – controlling pests and disease using AI powered Cameras. | |||

* Water Quality Control – Checking the water for contamination. | |||

* Automated Planting and Harvesting | |||

=== Approach, milestones and deliverables === | === Approach, milestones and deliverables === | ||

{| class="wikitable" | |||

|+ | |||

!Week | |||

!Plan | |||

|- | |||

|Week 2 | |||

|Introduction and Problem Statements | |||

Users and Target Audiences, and User requirements | |||

Literature Study and State-of-the-Art | |||

|- | |||

|Week 3 | |||

|User Survey and Survey Results | |||

User Requirements updated based on survey results | |||

Initial Planning and finalizing deliverables | |||

Task Division by deciding sub-modules | |||

|- | |||

|Week 4 | |||

|Research on Components, Arduino boards, and software to use | |||

Building an Initial prototype Design on a 3D software or make a drawing | |||

Ordering Components and the Arduino board | |||

Update Wiki-Page | |||

|- | |||

|Week 5 | |||

|Finalizing Components, Arduino boards, and software to use | |||

Finish and send it for 3D printing or build a Physical model. | |||

Start Arduino Coding | |||

Start Website Coding | |||

|- | |||

|Week 6 | |||

|Assembling the Product | |||

Finish Building the website to monitor | |||

Each sub-module individual testing | |||

Debugging and fixing errors | |||

|- | |||

|Week 7 | |||

|Final Testing with all sub-modules together | |||

Finalizing Wiki Site | |||

|} | |||

'''Final Deliverable:''' Miniature greenhouse automation system for American homeowner gardens. The automaton system will include: | |||

* Environment Monitoring – CO<sub>2</sub>, temperature, humidity, soil moisture levels. | |||

* Environment Controlling Systems – Irrigation Systems, Ventilation, and Heating. | |||

* Continuous Monitoring – The system must monitor and control the environment in real time. | |||

* Energy Management – Using electricity and water efficiently. | |||

* Notifications to the User – Notify user if something is malfunctioning -> '''Realized through a website''' | |||

* Remote Access & Control – The user can monitor and control the greenhouse when on vacation or work -> '''Realized through a website''' | |||

This will be realized using Arduino microcontrollers and low-cost electronics to ensure a cheap product for all homeowners. | |||

=== Literature Study and State-of-the-art === | |||

'''Gaurav -''' | |||

[https://pmc.ncbi.nlm.nih.gov/articles/PMC7013810/ '''An Analysis of Global Research Trends on Greenhouse Technology: Towards a Sustainable Agriculture'''] | |||

The study analyzes global research trends in greenhouse technology over the last two decades, focusing on sustainability and food security. The main key topics discussed in this article main cover the following topics: use of water for irrigation, the design of the greenhouse, conserving the soil conditions, total energy consumption of the system, temperature control and pest control. These are the main factors that make up a good greenhouse. | |||

[https://www.researchgate.net/publication/380875461_The_Role_of_Greenhouse_Technology_in_Streamlining_Crop_Production '''The Role of Greenhouse Technology in Streamlining Crop Production'''] | |||

This scientific article goes over the advantages of the greenhouse and its impact on crops. It goes over the best materials and design which should be used in the making of a greenhouse, such as glass and polyethylene. It also goes over the key components of automation and control systems such as lighting and irrigation. This article goes over the main advantages of a greenhouse, such as increased production and disease-free plants. It also lists greenhouse types and shapes which are most commonly used. | |||

[https://www.mdpi.com/2076-3417/14/13/5952 '''A Critical Review of the Status of Current Greenhouse Technology in China and Development Prospects'''] | |||

This article explains the status of greenhouse technology in China. It goes over the development of the green houses from the first few models made from simple materials like bamboo to better materials such as steel with automated equipment. It also goes over the main problems which come with the greenhouses, such as too much water usage and irrigation failures. | |||

[https://www.sciencedirect.com/science/article/pii/S0959652622033303?casa_token=1C1icYGXVEkAAAAA:1BR8_4h4NadQaMdOFNz6MW0jNuaEcUJMbktDrREyB9q0oVWm1FbGq0Qu8FABD3usTOPp0mijOw '''Design, technology, and management of greenhouse: A review'''] | |||

This review explores advancements in greenhouse technology for optimizing plant growth by controlling temperature, humidity, light, and CO2. It covers the many factors of greenhouse design such as climate control technologies, management systems, emphasizing automation, and energy efficiency. Key factors such as ventilation for humidity control and optimal temperature ranges for crops are also mentioned as well. The study highlights strategies to enhance yield while reducing costs and energy consumption. | |||

'''Prannoy -''' | |||

[https://patents.google.com/patent/US6499260B2/en '''Portable greenhouse structure and method and apparatus for assembling same'''] | |||

The present invention provides a portable greenhouse structure comprising a base in the shape of a right-polygonal cylinder having a top and a bottom, wherein the base comprises a plurality of wall panels connected along abutting edges. | |||

Introduces a climate control by also enabling a method of portable, structurally efficient, and easy to assemble and disassemble. This way a green house can be inexpensive and need not be permanent in nature. This way people can explore hobbies before completely committing. | |||

[https://patents.google.com/patent/US20110047868A1/en '''Mini-greenhouse and plant protector'''] | |||

A one piece, nestable, portable mini-greenhouse and plant protector for use in a substrate, such as soil, to protect plants and seedlings from extreme weather elements, bugs and pests. The mini-greenhouse has a light-transmitting shell that forms a protective chamber and integrated legs that act to anchor as well as support the shell. The unit has concave channels that facilitate watering without disturbing the apparatus. It has unique light filtering and dispersing properties to aid creating a nurturing and growing environment. | |||

[https://patents.google.com/patent/US8151518B2/en '''Vertically integrated greenhouse'''] | |||

A vertically-integrated greenhouse for growing plants in suspended trays. The design is particularly well-suited for installation in a double-skin façade of a building, or in an interior atrium, lobby, or similar structure. Introduces a system that uses a network of sensors to monitor key variables such as temperature, humidity, and soil moisture. This data is then used to control actuators connected to heating, cooling, ventilation, and irrigation systems, ensuring optimal conditions for plant growth. The system reduces energy waste by making real-time adjustments only when necessary by a tray-spacing mechanism, ultimately improving crop yield while conserving, thereby maximizing crop yield and building energy savings, or for esthetic considerations. | |||

[https://solarinnovations.com/our-products/aluminum-structures/greenhouses/hobby-greenhouses/ '''Hobby Greenhouses'''] | |||

With respect to the scope of the project, mini prototype of a green house for hobbyist is being developed, which are small-scale structures designed for casual gardeners to cultivate various plants, including orchids, bromeliads, bonsai, and even engage in hydroponics. Typically measuring less than 10 feet by 10 feet. The source is a company catering to US consumers who want to grow plants/flowers year round, which it made possible by their Solar Innovations which provides customization to create optimal environments tailored to specific plant cultivation needs | |||

[https://downloads.editoracientifica.com.br/articles/220910200.pdf '''Smart and efficient greenhouses: a systematic literature review in the agronomic, computational, and energy scope'''] | |||

The article "Smart and Efficient Greenhouses: A Systematic Literature Review in the Agronomic, Computational, and Energy Scope" presents a comprehensive analysis of controlled environment agriculture, focusing on the integration of intelligent computational techniques and energy efficiency in greenhouse cultivation. | |||

the researchers identified over 2,000 scientific publications within a 5 to 10-year timeframe and arrowed the publications down to just 66. | |||

The application of automation and control techniques in greenhouses began in the 50s, where temperature control was performed by thermostats. Subsequently, there was a great advance from the structural design to the technological aspects that make up the system, seeking improvement to allow the control of the parameters of temperature and relative humidity, solar radiation, CO2 concentration, ventilation, and fertigation. | |||

Furthermore, results relevant to the project are | |||

- The correct use of land and the efficient use of water and electrical resources stand out. The authors emphasize the need for mechanisms that optimize these environments. However, the use of control systems for these spaces and environments is relatively complex, due to the multiple variables involved and the interdependence between them. | |||

- several control strategies for greenhouses. These strategies aim to make the environment ideal for crops, considering energy savings. Among them, we can mention: mathematical modeling; experimental studies and simulations; control of parameters and components; the use of algorithms and computational intelligence techniques | |||

- The authors highlight that the cost of electricity is the second highest cost in cultivation in controlled environments, with the labor costs being the most expensive. | |||

- aiming to find optimal conditions for the growth and development of seedlings in a greenhouse environment. The authors conclude that the application of IoT associated with product traceability promotes | |||

'''Atreya -''' | |||

[https://www.priva.com/blog/horticulture/greenhouse-automation-systems '''Greenhouse automation system | Automated greenhouses | Priva'''] | |||

A company called Priva has recently developed a large-scale automation system which enables irrigation, lighting, climate control and even nutrients. These are all essential aspects of crop health and growth, and can be controlled using a smartphone app. While their target audience seems to be larger agricultural businesses, the concepts and ideas are relatively similar to our own project. The main goal is to automate the process such that energy can be saved, mistakes are made less often and to promote convenience for end users. The company seems to be targeting large businesses that specialize in farming and agriculture, and therefore the requirements are bound to be different. In our project, we will take inspiration from such existing state-of-the-art systems and build upon it to ensure user-friendliness, convenience for consumers (especially individual gardeners and greenhouse owners) and sustainability. | |||

[https://dutchgreenhouses.com/en/automation '''Greenhouse Automation - DutchGreenhouses'''] | |||

A competing brand named DutchGreenhouses has also developed a similar greenhouse automation system. Their main selling point is an advanced climate computer, software and sensors which ensure that temperature, moisture, etc., are all optimal for the crops. According to the company, this ensures peak efficiency of the growth as well as peak crop yield. | |||

[https://www.logiqs.nl/en/greenhouse-automation/ '''Greenhouse Automation - Logiqs B.V.'''] | |||

The brand Logiqs B.V. has a very innovative approach to greenhouse automation. It consists of “rolling benches” that move around the greenhouse upon which crops are grown. The company claims that this state-of-the-art technique is highly effective and efficient because physically moving plants across climate zones is far more energy-efficient compared to actively changing the temperature. They also believe that this creates better working conditions and ensures cleanliness due to automated cleaning procedures. The benches are also fitted with automatic irrigation with precise control over the frequency and amount of water and nutrients to be fed to the crops. | |||

[https://www.researchgate.net/profile/Redmond-Shamshiri/publication/259932487_A_Review_of_Greenhouse_Climate_Control_and_Automation_Systems_in_Tropical_Regions/links/02e7e52e99e4221f31000000/A-Review-of-Greenhouse-Climate-Control-and-Automation-Systems-in-Tropical-Regions.pdf '''A Review of Greenhouse Climate Control and Automation Systems in Tropical Regions'''] | |||

This paper by Shamshiri et al explores greenhouse climate control and its effectiveness. The authors also research the ideal levels of temperature and relative humidity to maintain healthy crops. For example, there is a table providing the ideal temperature and humidity conditions during each growth stage for tomato crops. This information is valuable for designers of greenhouse automation systems as they can design the systems to maintain by default the ideal parameters for optimal crop growth. Users can also refer to this information and customize their systems to ensure peak yield of their crops. | |||

'''Neesanth –''' | |||

[https://doi.org/10.1109/ICSCAN.2018.8541251 '''Automation of Hydroponics Green House Farming using IOT'''] | |||

This article explores the integration of Internet of Things (IoT) technology in hydroponic greenhouse farming to enhance efficiency, productivity, and sustainability. Hydroponics is a soilless farming technique that relies on nutrient-rich water to grow plants, making it highly suitable for controlled environments like greenhouses. The system uses sensors and actuators to monitors and controls essential parameters such as Temperature & Humidity, pH & Electrical Conductivity (EC) of Water, Light Intensity & CO₂ Levels, Water Level & Flow. The IoT-based system allows real-time data collection through sensors, which is then processed and analyzed via a cloud-based platform or mobile application. Automation is achieved through actuators that control irrigation, lighting, ventilation, and nutrient dosing without manual intervention. The observed advantages of the approach include Increased Crop Yield, Water & Resource Efficiency, Remote Monitoring & Control, and Reduction in Labor Costs. Overall, IoT-based automation in hydroponic greenhouses offers a smart, sustainable, and scalable solution for modern agriculture, addressing challenges related to climate change, water scarcity, and food security. | |||

[https://doi.org/10.1109/CCAC.2017.8276478 '''Robotic applications in the automation of agricultural production under greenhouse: A review''']This review paper examines the role of robotics and automation in modern greenhouse farming, focusing on their applications, benefits, and challenges. The paper focuses on plant monitoring & sensing, autonomous planting & transplanting, irrigation & nutrient delivery, pest & disease detection, harvesting & picking robots, pollination robots. The benefits include higher efficiency & yield, lower labor cost, sustainability and continuous protection. The challenges include high investment costs, careful handling of the plant by robots, and integrating AI and Machine Learning in a dynamic environment. | |||

[https://doi.org/10.1109/JRFID.2022.3204363 '''Parallel Control of Greenhouse Climate With a Transferable Prediction Model'''] | |||

This article explores an AI-driven parallel control approach for optimizing greenhouse climate management, using a transferable prediction model. The goal is to enhance energy efficiency, crop growth, and resource utilization by dynamically adjusting environmental parameters. The Main focus of this article is using parallel control strategies controlling parameters such as CO<sub>2</sub>, temperature, etc. It also focuses on energy optimization, data driven decision making using prediction model. This results produces benefits such as improved climate control, reduce energy costs, and faster adaptation. Future research could focus on enhancing model accuracy, integrating additional climate factors, and improving generalization across diverse greenhouse settings. | |||

[https://doi.org/10.1109/WCICA.2008.4593150 '''On-line modeling of air temperature system in a naturally ventilated greenhouse'''] | |||

This article presents a real-time (on-line) modeling approach for predicting and controlling air temperature in a naturally ventilated greenhouse. Since temperature regulation is crucial for optimal plant growth, the study focuses on developing a dynamic, adaptive model that responds to changing environmental conditions. This article focuses on real time temperature modelling, Influence of natural ventilation, and energy efficiency. The results produced benefits such as better ventilation managements, accurate temperature prediction and low energy costs. Future work could focus on integrating IoT, AI-based predictions, and multi-factor climate models to further enhance system performance. | |||

[https://doi.org/10.1109/ICCUBEA54992.2022.10010745 '''Smart Greenhouse Automation and Monitoring System'''] | |||

This article discusses the design and implementation of a smart greenhouse automation system that leverages IoT (Internet of Things) technology for real-time monitoring and control of greenhouse conditions. The system aims to improve crop productivity, resource efficiency, and ease of management by automating key agricultural processes. The article focuses on environmental monitoring, automated climate control, remote access, alerts and notifications, and data logging. The results produced benefits such as higher crop yield, water and energy efficiency, reduced labor costs, and remote accessibility. | |||

'''Chenwei -''' | |||

[https://climatecontrol.com/greenhouse-management-technology/ '''Greenhouse Management and Technology'''] | |||

This is a greenhouse management software developed by a group called “climate control systems”. In the description of the software, they give valuable information regarding what the top 100 North American greenhouse growers are investing in. The number one issue which needs to be addressed and solved is the efficiency of the greenhouse itself. Their software then focuses on monitoring the overall statistics of the greenhouse and seeks to adjust variables like temperatures using a lower energy cost with their software. | |||

[https://www.mdpi.com/2077-0472/13/7/1464 '''Agricultural Greenhouses: Resource Management Technologies and Perspectives for Zero Greenhouse Gas Emissions'''] | |||

This scientific article discusses the main problem of resource management regarding greenhouses, as they often contribute to 10-29% of the greenhouse gas emissions around the world. It also discusses the different control systems which are used in greenhouses, which consists of PIDs, fuzzy logic, and artificial neural networks. Sensors which measure different variables such as temperature, humidity, and CO2 are also mentioned as these variables are often the ones in need of control during the automation process. | |||

[https://cegt201.bradley.edu/projects/proj2019/aplant/aPLANTfinal1.45.pdf '''aPLANT: A Low-Cost Greenhouse Manager System'''] | |||

This report is about a low-cost greenhouse manager system called “aPLANT”. It discusses the main components of the system and the process for how it works. Soil and temperature/humidity sensors are used in the plant to extract the necessary data, which is sent to an ESP8266, which is a low-cost microcontroller. This microcontroller is linked to a raspberry pi which acts as a main database for the whole project. This allows the important variables such as temperature to be measured. | |||

[https://www.lannerinc.com/applications/intelligent-systems/greenhouse-intelligent-monitoring-and-control-solution '''Greenhouse Intelligent Monitoring and Control Solution'''] | |||

This article discusses the main challenges which are present in greenhouse control and intelligent monitoring. Some challenges presented are the controlling of microclimates for delicate crops such as orchids and exotic types of fruits. These plants require precision farming, which means that the exact variables such as temperature must be met. It also briefly discusses the modern greenhouse environment controls systems, and the controllers used. Lastly, it advocates for the use of an IoT intelligent monitoring system which uses climate, irrigation and other factors in order to properly control the environment to suit plants. | |||

[https://webbylab.com/blog/smart-greenhouse-solutions-iot-based-environmental-monitoring-and-control/ '''Smart Greenhouse Solutions: IoT-Based Environmental Monitoring and Control'''] | |||

This article discusses the advantages to using a IoT based approach to monitor and control smart greenhouses. It talks about the main components of a greenhouse environment, which includes the following: Lighting, air quality, ventilation, heat, and humidity. Many advantages to using a smart green automation are also discussed, some examples include improve irrigation and fertilization. It also lists the sensors which can be needed to improve the overall quality of the greenhouse. They include CO2 sensors, soil moisture sensors, temperature sensors, water sensors, light sensors, and humidity sensors. These controllers combined with a programmable controller can be extremely efficient in making a proper greenhouse automation system. | |||

== User Survey == | |||

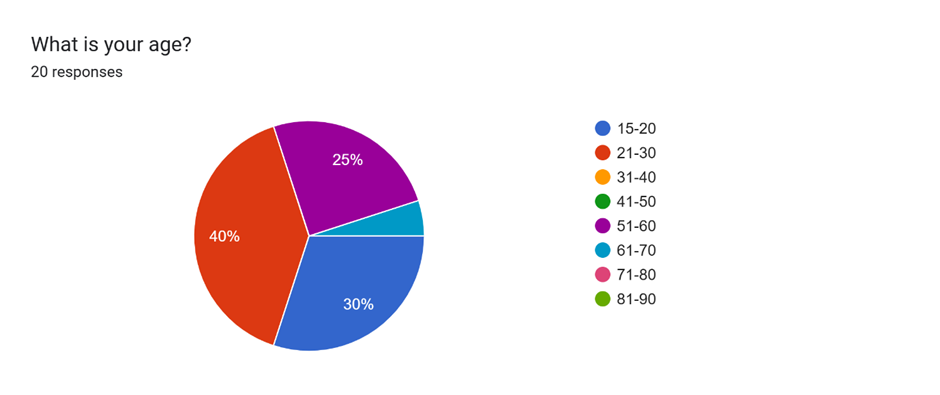

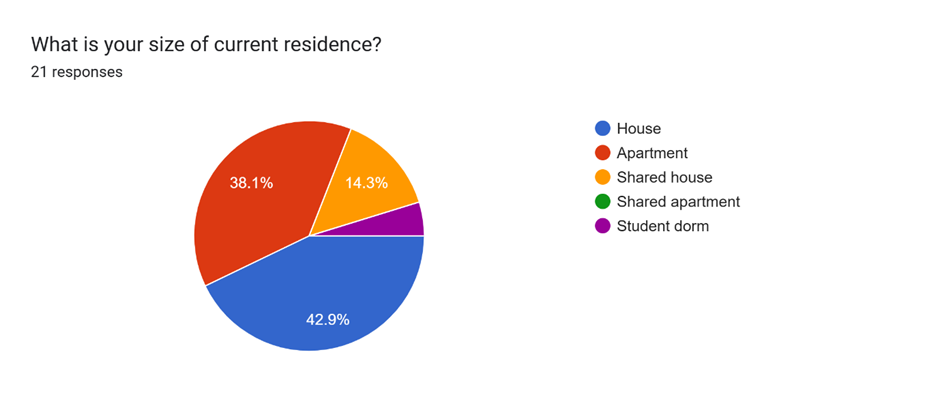

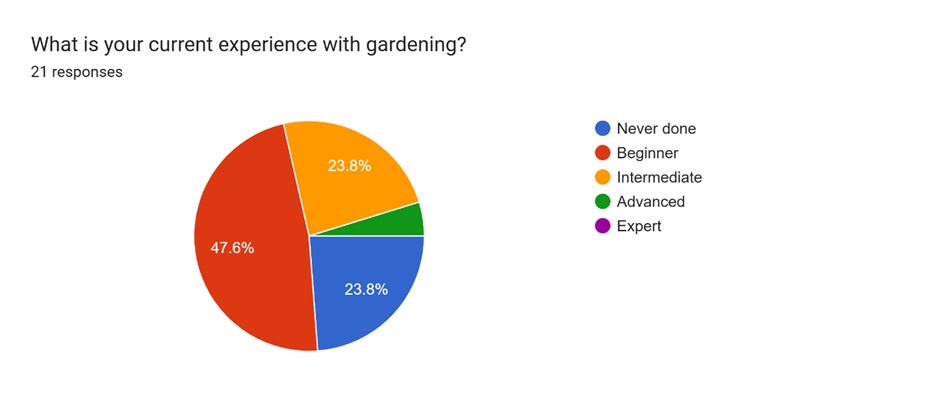

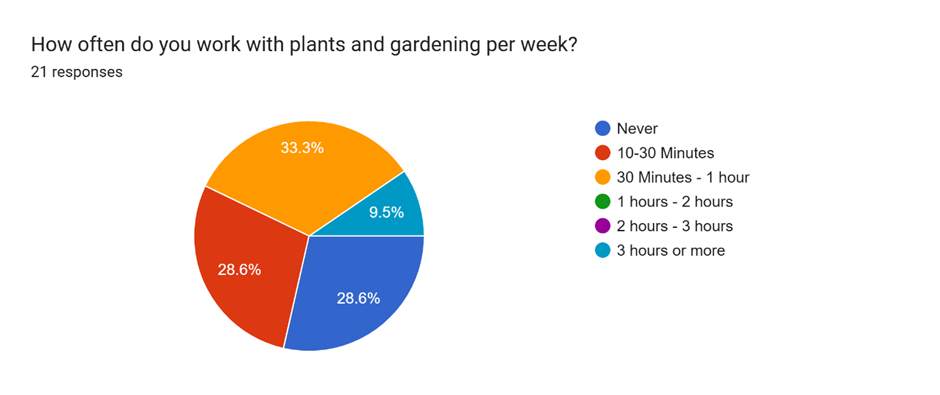

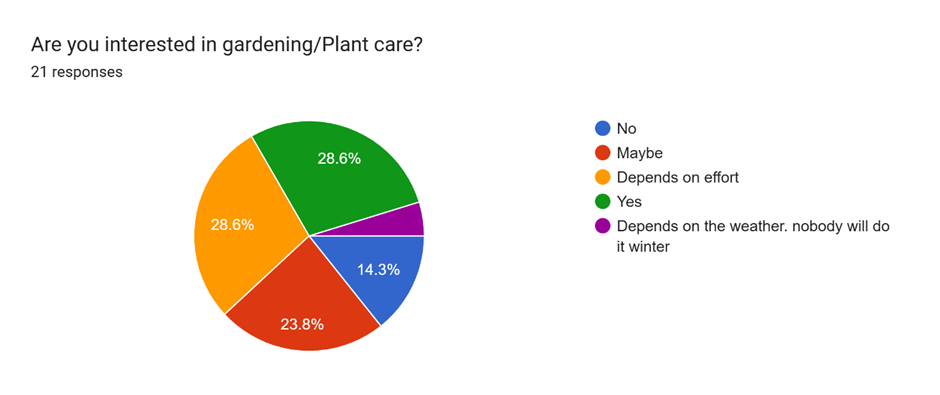

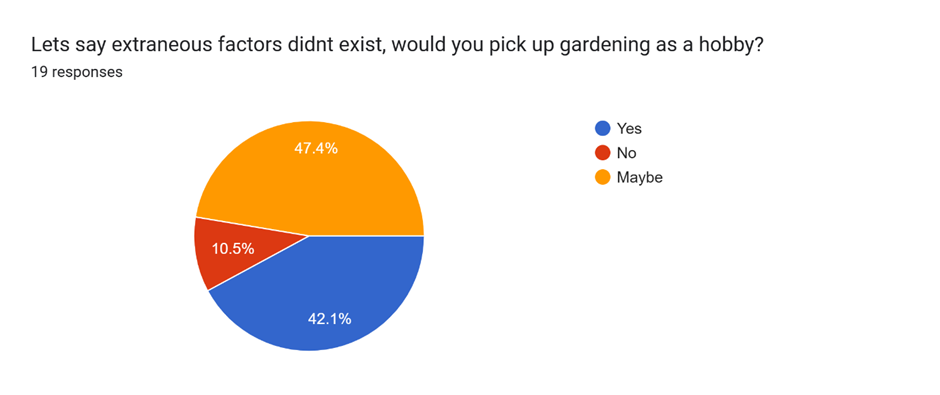

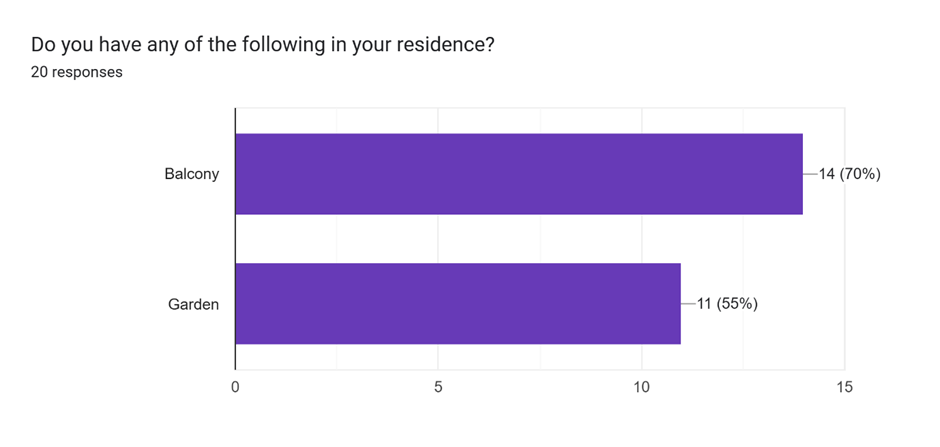

'''Part 1:''' Overall, from the above group of survey results, reveal that the population is predominantly young adults, who are mostly living in houses or apartments, with beginner-level gardening experience but showing moderate interest in gardening as a hobby. Most spend less than an hour per week gardening, and many would consider gardening if barriers were removed. The fact that most people have access to gardening spaces, which justifies the potential for a miniature greenhouse, therefore empowering the users to truly pickup gardening as a hobby. | |||

[[File:Survey a.png|thumb|815x815px|left]] | |||

[[File:Survey b.png|thumb|846x846px]] | |||

[[File:Survey c.png|left|thumb|860x860px]] | |||

[[File:Survey d.png|thumb|841x841px]] | |||

[[File:Survey e.png|left|thumb|871x871px]] | |||

[[File:Survey f.png|thumb|806x806px]] | |||

[[File:Survey g.png|thumb|631x631px|center]] | |||

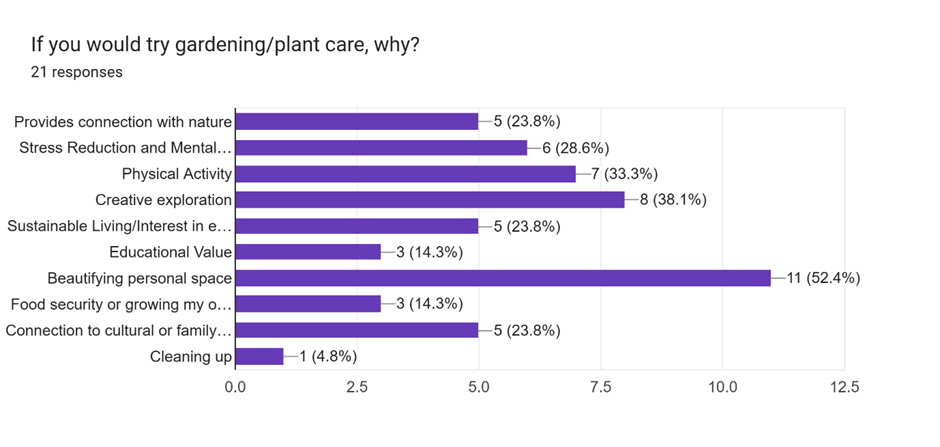

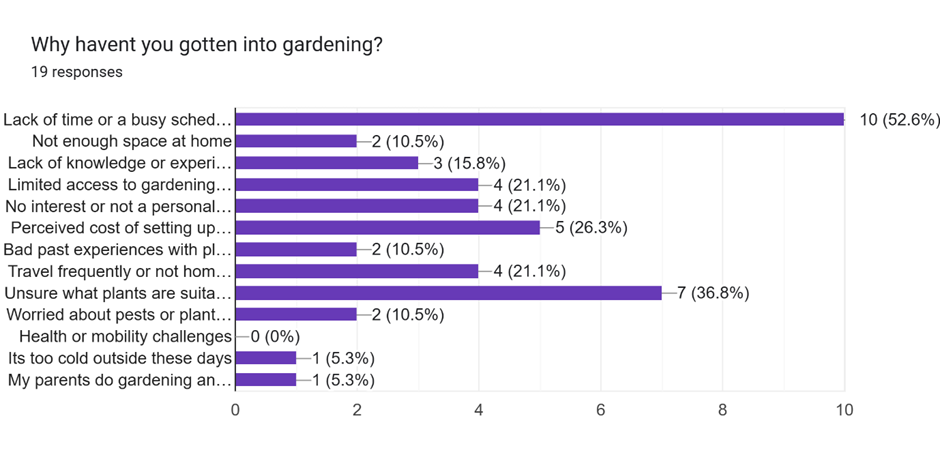

'''Part 2:''' The responses to the below two questions show the reasons that users would like to garden, and what factors have stopped them from doing so. The top two reasons that users would like to engage in gardening are: to beautify their personal spaces as a form of interior design, as well as to perform creative exploration of hobbies and to learn new things. On the other hand, the users also report that they have not engaged in gardening due to a lack of time from a busy schedule, and a lack of knowledge or uncertainty about the plants suitable for the environment they live in.[[File:Survey h.png|left|thumb|737x737px]] | |||

[[File:Survey i.png|thumb|764x764px|center]] | |||

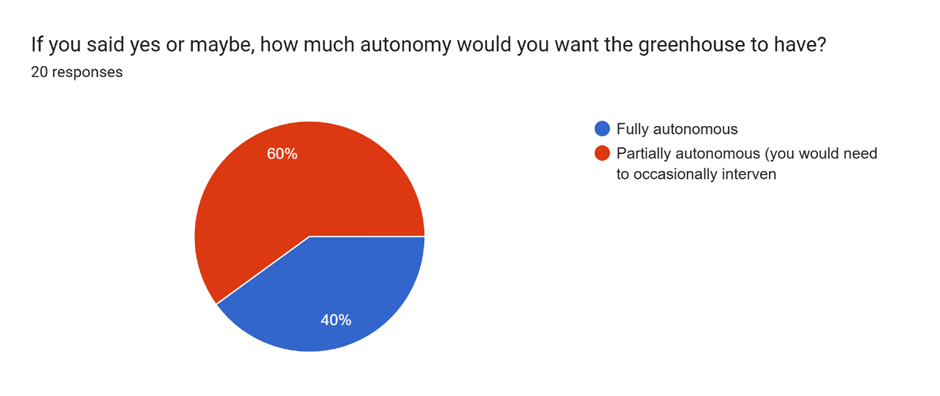

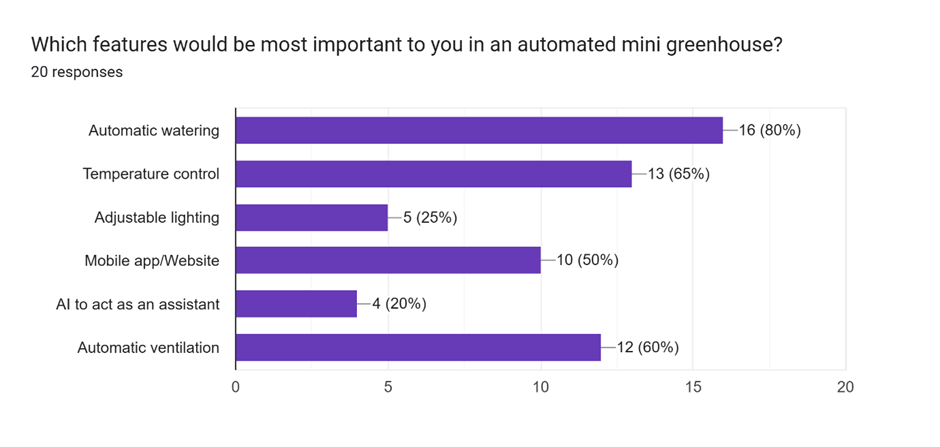

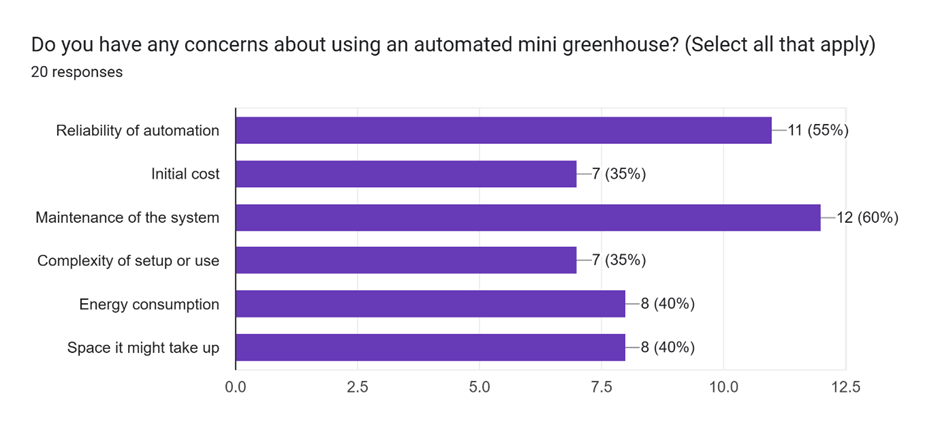

'''Part 3:''' The responses to the below three questions show the extent to which users would like automation, the desired features in a mini greenhouse, and any concerns that users have. Evidently, there is a relatively even split between users who would like partial and complete automation. This means that it is best to create a product that has some form of adaptive automation, where users can set the level of automation according to their requirements. The features that users ranked the most important include automatic watering, automatic ventilation and a mobile app/website, which we have made to sure to include in our product to varying degrees. The main concerns that users cited include the reliability of the system as well as the complexities associated with maintaining the device. This feedback is very useful for the design process of the prototype. | |||

[[File:Survey j.png|left|thumb|797x797px]] | |||

[[File:Survey k.png|center|thumb|777x777px]] | |||

[[File:Survey l.png|thumb|817x817px|center]] | |||

'''Part 4:''' There are also some limitations in the results of the survey. One of them being that not every age group was asked equally. A lot of results were from the younger generation and only a few from the older generation. This can potentially skew the results and bias the findings such that the responses only represent the perspective of the younger population. The results also say that many people are not into gardening due to a lack of time, which can potentially be attributed to the fact that most of the younger respondents are required to go to school, university, or have a day job. Furthermore, the age factor could also bias the results for opinions on the automation of the system because a lot of younger people responded positively to technology. | |||

Using the survey results, the following affinity diagram was created to summarise the results: | |||

[[File:Affinity.jpg|center|thumb|887x887px]] | |||

From the results of the user survey, the personas presented below were created to obtain an understanding of the target users/audience. | |||

== Personas == | |||

[[File:Bart.png|center|thumb|1000x1000px]] | |||

[[File:Bunty persona.png|center|thumb|1030x1030px]] | |||

== Design Process == | |||

'''Hardware:''' | |||

After obtaining the Arduino microcontroller, we began the testing process to ensure all components (sensors and actuators) work as intended. We tested each sensor and actuator individually to verify that they function correctly. These include the CO2, temperature, humidity and soil moisture sensors, as well as the servo motor and water pump actuators. | |||

We then wrote functions on the Arduino IDE such that each sensor or actuator can be “called” when necessary by the controller. For example, we created open/close functions for the servo motor, as well as functions which activate the sensors when measurements are required. The integration of these functions together was challenging because it required that the controller correctly manage all sensors and actuators simultaneously. To achieve this we wrote individual functions for each sensor/actuator and called those functions from the Arduino’s main loop program. | |||

'''Website and software:''' | |||

After verifying that the components work when integrated together, we began the development of the website which allows remote monitoring and control for users. The most convenient option was to use Google’s Firebase which can store a database of plants and crops online. Through our HTML website, the Firebase database can be connected to Arduino using its in-built Wi-Fi module. To test this, we set up the Arduino Wi-Fi module and performed a successful test connection with the database. After verifying the remote connection of the Arduino and the database, we proceeded to write Arduino code allowing data to be sent directly to the database. The data to be sent to the website includes sensor readings of temperature, CO2, etc., as well as the real-time status of the actuators (on/off) such that users can monitor it. | |||

The next step was to enable two-way communication such that the user can send commands to the controller through the website. This is a critical feature of the adaptive automation of the greenhouse, allowing the user to manually override the system and input their own parameters. This facilitates the educational and learning-based design of our product. For example, this feature allows users to set their own thresholding parameters that control the actuators. | |||

The final steps of the design process including refining the website code to ensure a user-friendly interface and colour-coded design that alerts users if urgent action is required. A JavaScript graph was created that plots the real-time sensor measurements, giving users a visual description of plant health and development. Finally, the code controlling the website/database and the Arduino were integrated together to create a coherent program. The final product was validated using the test cases described ahead. | |||

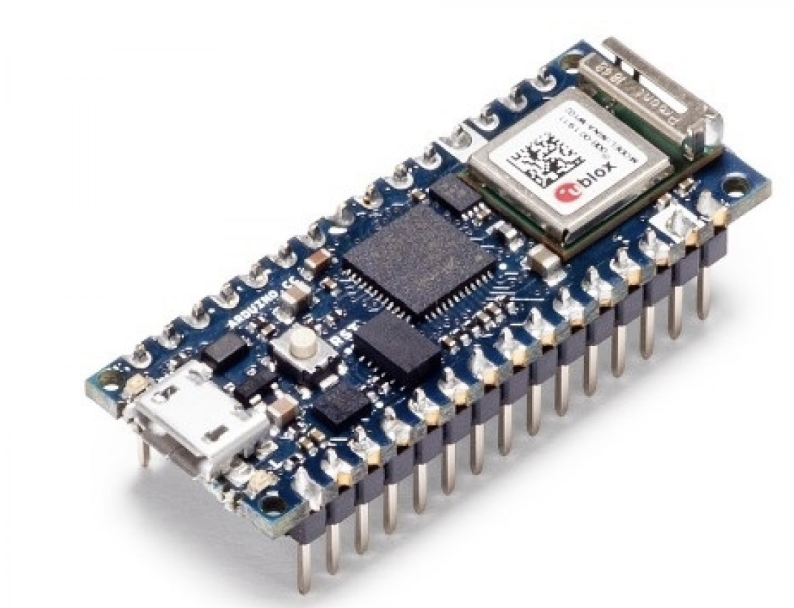

== Components Choices == | |||

The automation of the greenhouse is achieved using simple sensors and actuators. The sensors are used to monitor the levels of certain parameters, the microcontroller processes these levels and commands the actuators to act accordingly. With these three steps, the system is made into a coherent and self-sustaining process that requires minimal human intervention. The microcontroller used is: | |||

'''Arduino Nano 33 IoT:''' https://www.tinytronics.nl/en/development-boards/microcontroller-boards/arduino-compatible/arduino-nano-33-iot-1 (image below). | |||

This microcontroller is ideal for the project for many reasons. Firstly, its small size allows it to fit easily within the confines of the prototype greenhouse, without being visible such that the design look minimalistic and appealing. It has many analogue input/output pins which are required for the reading of values such as the soil moisture, temperature and CO2. An analogue output pin is also required for the servo motor in order to rotate its shaft to a particular angle (for opening and closing windows of the greenhouse). Furthermore, the digital pins are necessary for actuators such as the relay block which is essentially a voltage-controlled switch used for the water pump. Finally, the microcontroller board comes built in with an Internet of Things and Bluetooth chip which allows for information to be received and sent to/from the user website, where users can remotely monitor and control the system. Given these specifications and requirements, this microcontroller proved to be the ideal choice to manage the automated greenhouse system. | |||

[[File:Arduino Nano 33 IoT.png|center|thumb|Arduino Nano 33 IoT available at TinyTronics - EUR 32]] | |||

'''Sensors:''' | |||

* CO2 Sensor: '''GY-SCD40 Module - CO2 - Humidity - Temperature Sensor - I2C''' https://www.tinytronics.nl/en/sensors/air/humidity/gy-scd40-module-co2-humidity-temperature-sensor-i2c. Available in TinyTronics for Euro 19.00. This is a great sensor for our project because it integrates several sensors on one package. This include a CO2 sensor, a humidity sensor as well as a temperature sensor. Therefore, it can supply all these parameters to the microcontroller in intervals. These parameters can be used to control the opening/closing of windows, the heating/ventilation and more. The sensor is also compatible with the Arduino microcontroller platform through the I2C hardware interface, allowing it to be easily integrated with the other sensors/actuators in the automated greenhouse system. For CO2, the sensor can sense between a range of 0 to 40,000 parts per mille (ppm) with a measurement uncertainty of +/-50 ppm (or 5%), which is definitely sufficient for this project. Below is a labelled image of the sensor:[[File:CO2.png|center|thumb|Carbon dioxide Sensor]] | |||

* Soil moisture sensor: '''Capacitive Soil Moisture Sensor with Cable''' https://www.tinytronics.nl/en/sensors/liquid/capacitive-soil-moisture-sensor-module-with-cable. The sensor measures the humidity of moisture present in the soil and provides an output in the form of a voltage between 0 and 3.0 V, which correspond to measurements of 0% to 100%. Thus, the output voltage reading can easily be mapped into a soil moisture percentage using the Arduino microcontroller. This information will be used by the microcontroller to actuate the water pump if the soil moisture is too low. Below is an image of the sensor: | |||

[[File:Soil sensor.png|center|thumb|Soil moisture/humidity sensor available at TinyTronics]] | |||

'''Actuators:''' | |||

* Servomotor: '''MG90S Mini Servo''' https://www.tinytronics.nl/en/mechanics-and-actuators/motors/servomotors/mg90s-mini-servo. This is available from TinyTronics for 5 Euros. The reason for choosing a smaller servo motor compared to a larger one was due to the current requirement. Since this project involves the use of Arduinos, their current output is not enough to handle the larger currents drawn from the the bigger servo motors. The metal gears provide better speed and power compared to other mini servo motors on the market. The main use of this servo motor is to be able to control the ventilation within the greenhouse by opening and closing a window near the top. This helps ventilate the greenhouse in cases where the CO2 levels become too high/low.[[File:MG90S servo-600x600.jpg|thumb|230x230px|MG90S Mini Servo|center]] | |||

* Water Pump: '''Under Water Pump - Horizontal - 3-6V''' https://www.tinytronics.nl/en/mechanics-and-actuators/motors/pumps/under-water-pump-horizontal-3-6v. This is available from TinyTronics for EUR 4.00. This is a relatively low-powered pump but is more than sufficient for the 'drip' irrigation that our small-scale greenhouse requires. We found that the pump only activates when a DC voltage of at least 5V is supplied to its input pin. As the Arduino microcontroller can provide a maximum of only 3.3V, an additional relay switch, i.e., a voltage-controlled switch which can supply 5V, is also required to use the pump. An image of the water pump is given below: | |||

[[File:Water Pump.png|center|thumb|Water Pump - Available at TinyTronics for EUR 4.00.]] | |||

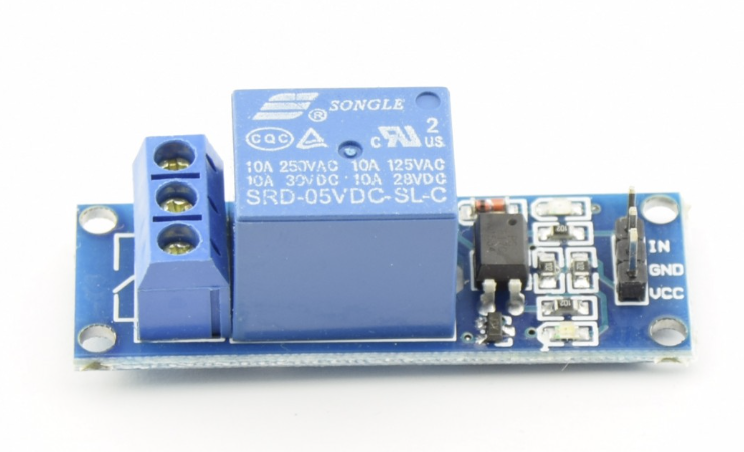

* Relay switch for water pump: '''5V relay 1-channel high-active''' https://www.tinytronics.nl/en/switches/relays/relay-modules/5v-relay-1-channel-high-active. This relay switch is available at TinyTronics for EUR 2.50. As mentioned previously, it is required for effective control of the water pump for the autonomous irrigation system. The relay switch requires a power source of 5V, which will be achieved through a 5V DC adapter connected to a wall outlet. The input "In" pin of the relay will be connected to the a digital pin on the Arduino, which is the control signal instructing the relay to switch on or off. When the Arduino supplies a "high" 3.3 V digital signal to its input pin, the relay switches on and provides 5 V to the water pump through its output pins (on left of the image below). | |||

[[File:Relay.png|center|thumb|Relay Switch - Available at TinyTronics for EUR 2.50]] | |||

== System Level Design == | |||

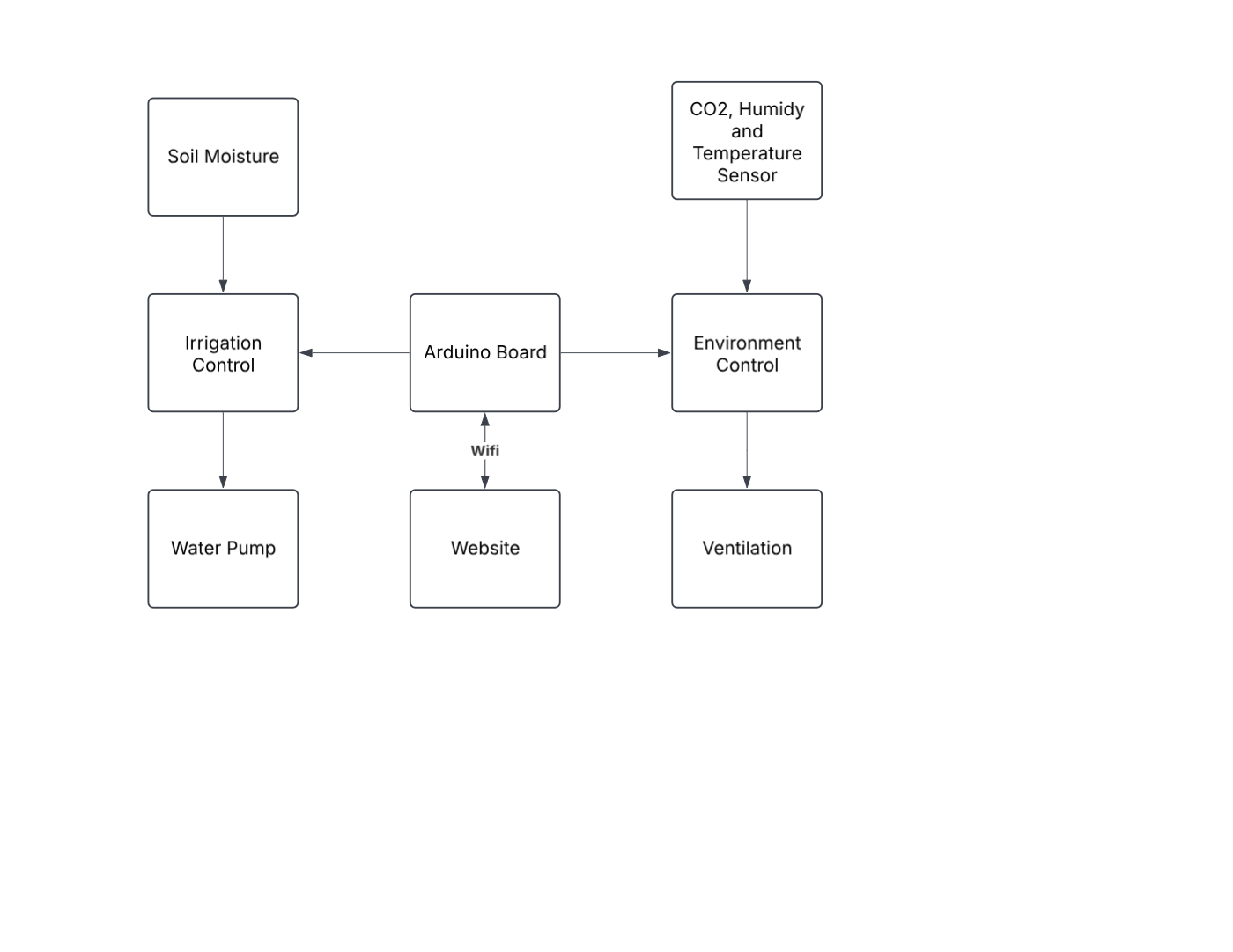

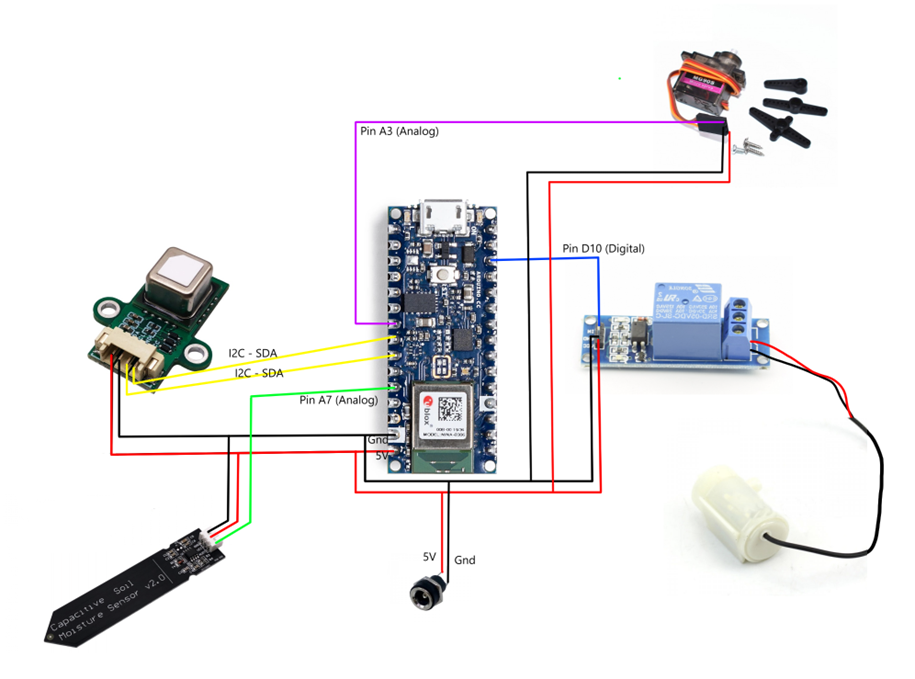

[[File:System Level Design Diagram.png|center|frameless|534x534px|System Level Design Diagram]]The figure above gives a general system level overview describing how the various components interact with each other. The central device is the Arduino microcontroller, which can access concurrently the irrigation system, the environment control system and the website through WiFi. On the left, the irrigation system involves the soil moisture sensor which sends real-time information to the Arduino about the soil moisture percentage. Environment parameters such as temperature and humidity are also sent simultaneously to the controller. This information is processed along with the threshold values set on the website to determine if any action is required from the actuators. This process is looped every few seconds allowing live control and monitoring. [[File:Circuit imager.png|center|thumb|509x509px|Greenhouse Circuit]] | |||

The above figure shows a circuit-level implementation of the system. The central Arduino microcontroller is connected through analogue pins to the CO2, temperature/humidity and soil moisture sensors. These provide analogue inputs in the form of a voltage in a given range. After processing this information along with the parameters set on the website, the Arduino sends commands through the digital pins to the actuators (relay for the water pump and servo motor for the window). As mentioned, this process is repeated in a loop. The specific pins used for each function are labelled on the diagram. | |||

== Brainstorming and Initial Designs == | |||

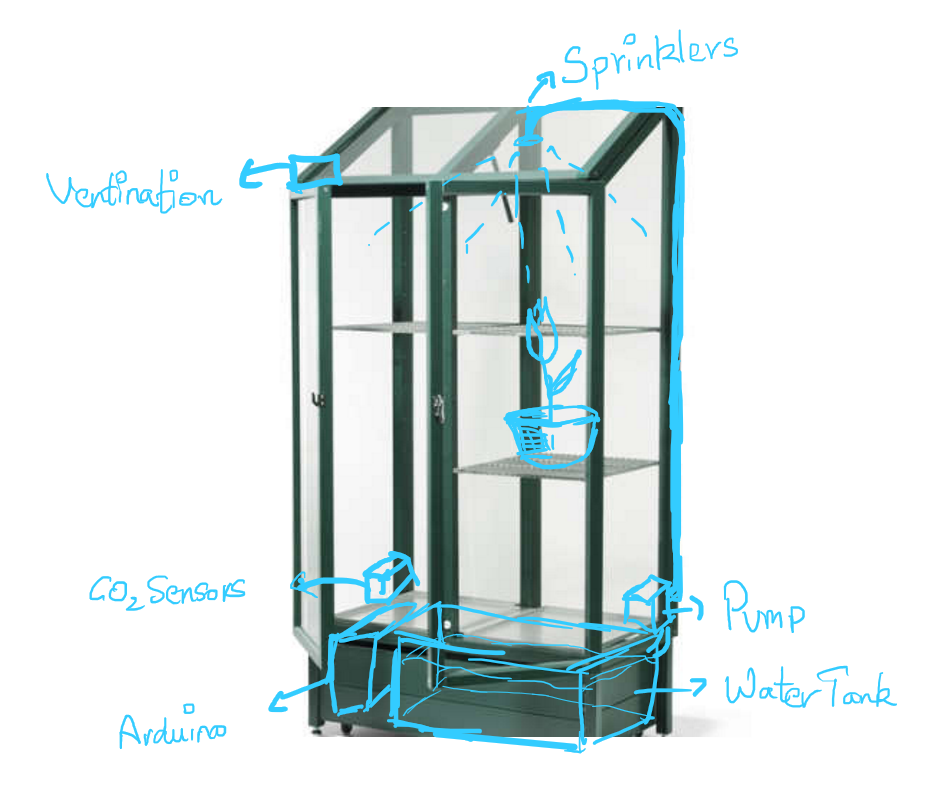

[[File:Greenhouse Prototype Sketch.png|thumb|430x430px|Greenhouse Prototype Sketch|left]] | |||

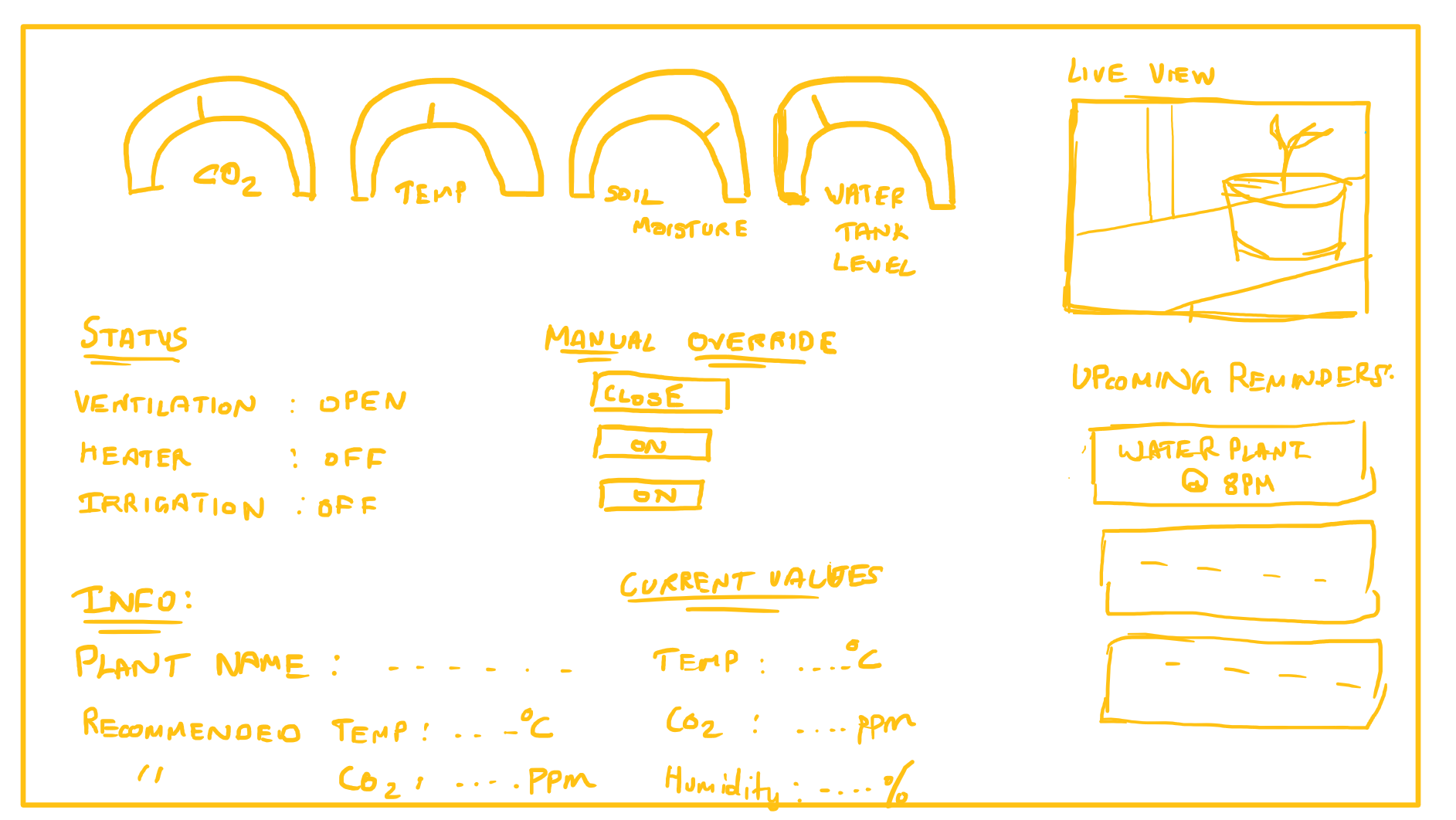

[[File:Website Initial Design.png|thumb|672x672px|Website Initial Design|center]] | |||

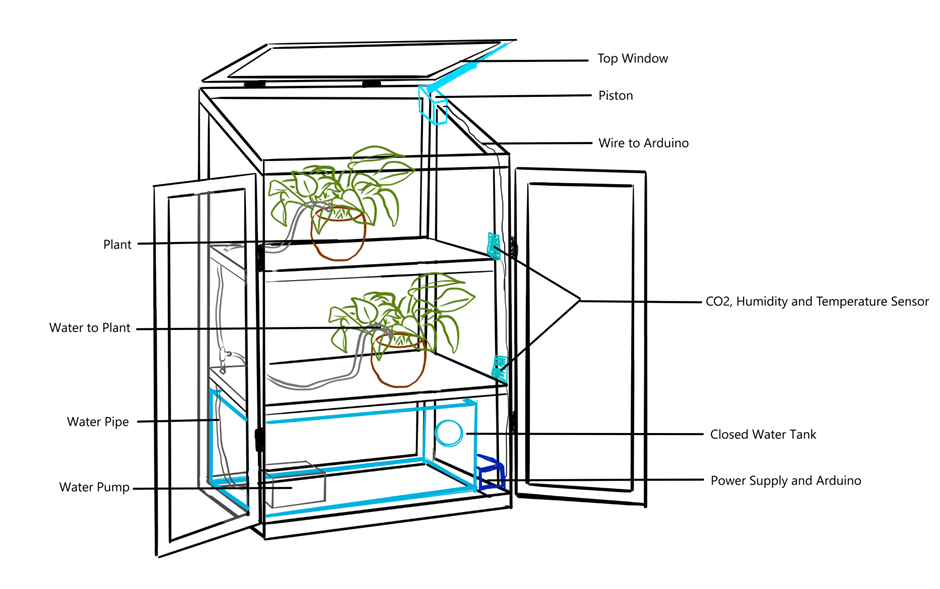

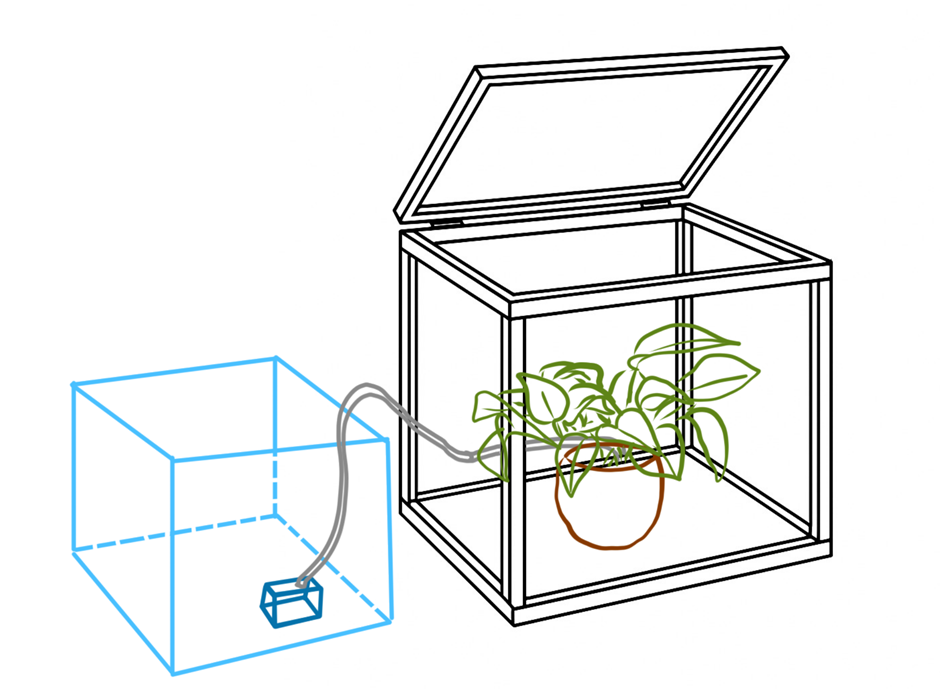

The above images show the initial brainstorming and ideation of the greenhouse prototype and the website design. Considering that the greenhouse is designed for use in balconies where space may be limited, we realised that a shape that resembles a glass cabinet or cupboard could suit our requirements sufficiently. The figure above (left) shows a potential design with sprinklers on the ceiling and an automated ventilation system on the side, along with the sensors, microcontroller and pump housed at the bottom base of the system. This ensures a low centre of gravity because most of the weight is concentrated in the bottom half of the housing, ensuring stability. | |||

The website design (top right) shows live gauges of the various parameters to be controlled within the greenhouse, such as CO2 levels, temperature and the soil moisture of the plants. It also shows the status of the various automated systems such as the automatic ventilation (window), the heater and the drip irrigation system. The website will also have a manual override system that allows users to override the automation system when they feel more comfortable managing their crops themselves, or when they suspect the system is not behaving optimally. The website will allow users to select the desired plant from a database, which then recommends the users of the optimal parameters for the selected plant (temperature, soil moisture, etc.). | |||

= Prototype Implementation: = | |||

In the case of the miniature greenhouse, design ideology must be form over function. This is primarily because of the target audience and use cases of the product. Since the target audience consists mainly of Gen-Z and millennials, they are known to be very rigid about their aesthetics, and often compromise form over function. Therefore, the design must be particularly appealing to the user’s aesthetics and integrate seamlessly in their homes. In addition, the spatial footprint of the product must be minimal, such that it fits in smaller accommodations and not interfere with living spaces. Finally, the use case of the miniature greenhouse is a hobby product, which allows the users to effectively grow plants and learn gardening. Therefore, the product's functionality should require some manual interaction with the plants to support their growth, which also assists in the learning gardening skills. Overloading the greenhouse with too much functionality may hinder the gardening learning process, which is not the goal of the product. Instead of providing with hardware functionality to grow plants, the miniature greenhouse has a website that shares all the necessary information about the plant and provides notifications on when any intervention is required. Using the above criteria, two designs of the greenhouse were shortlisted, which are show as follows: | |||

[[File:Shelf.png|thumb|531x531px|'''Shelf Mini-Greenhouse'''|center]] | |||

[[File:Standard.png|center|thumb|475x475px|'''Standard Mini-Greenhouse:''']] | |||

'''Design''' | |||

After evaluating both design options, the group chose the Shelf Mini-Greenhouse. This design offers several advantages. First, it allows for multiple plants to be housed within a single unit, enabling the user to grow a variety of plant types simultaneously, Unlike the standard option, which can house only one plant. Second, the shelf design has a better spatial footprint and more volume than the standard option as it can be mounted on a wall, minimizing interference with living spaces and complements existing plant arrangements. Whereas, the standard model can be awkward to position alongside other plants and is only suitable as a standalone item. Lastly, the shelf greenhouse is significantly more visually appealing than the standard model, as mentioned above, the shelf has a better potential to integrate with the living spaces of the user. Nonetheless, due to time constraints, the entire feature set of the shelf mini-greenhouse could not be incorporated. Therefore, the prototype consists of 2 floors, one for the plant and the other is for the hidden electronics and the water tank. Images of the final prototype are provided in the following section. | |||

'''AI-generated Visualisation of shelf-type design''' | |||

[[File:AI image.png|center|thumb|510x510px|AI-generated real-life representation of shelf-type design]] | |||

= Final Prototype = | |||

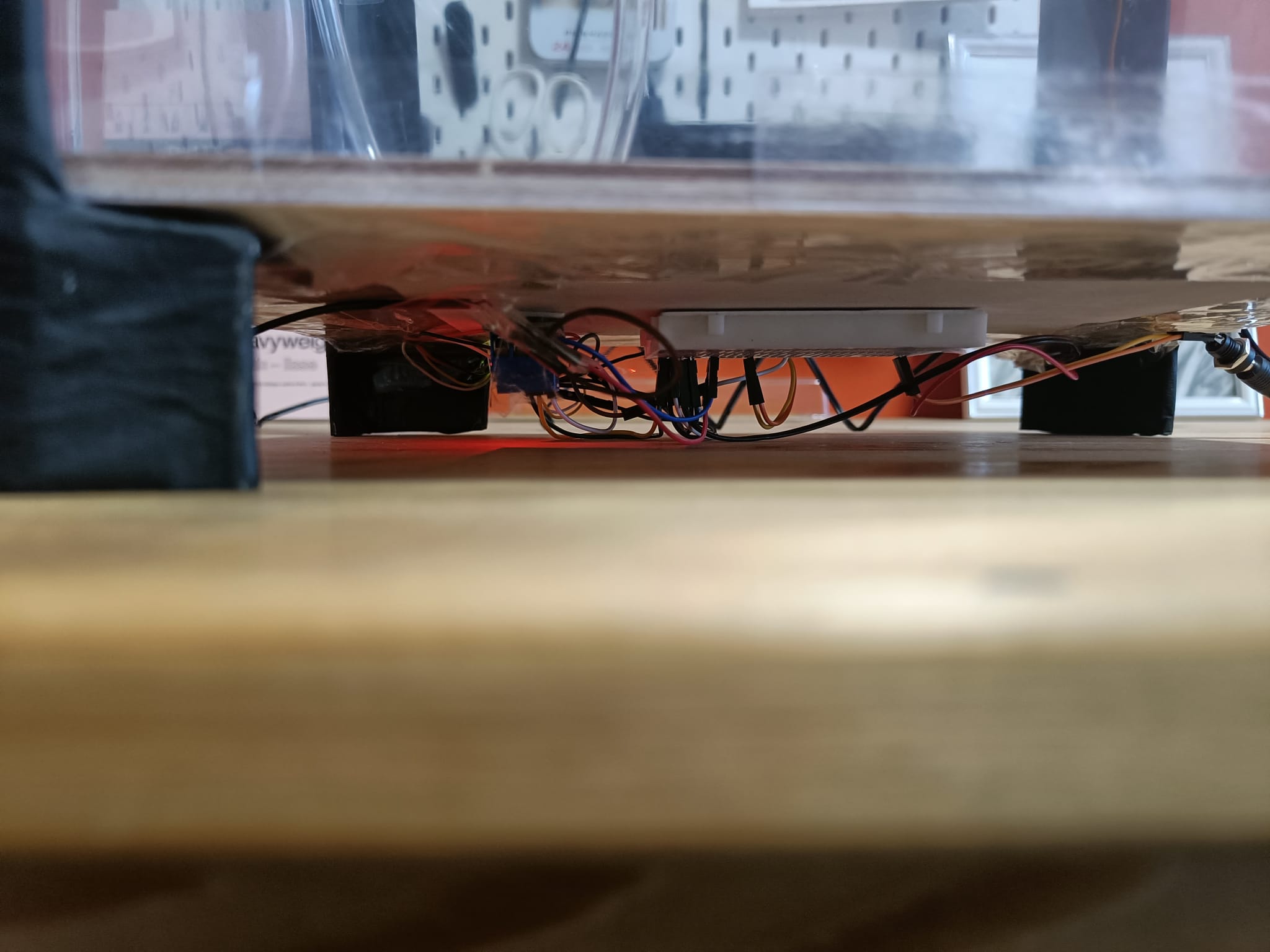

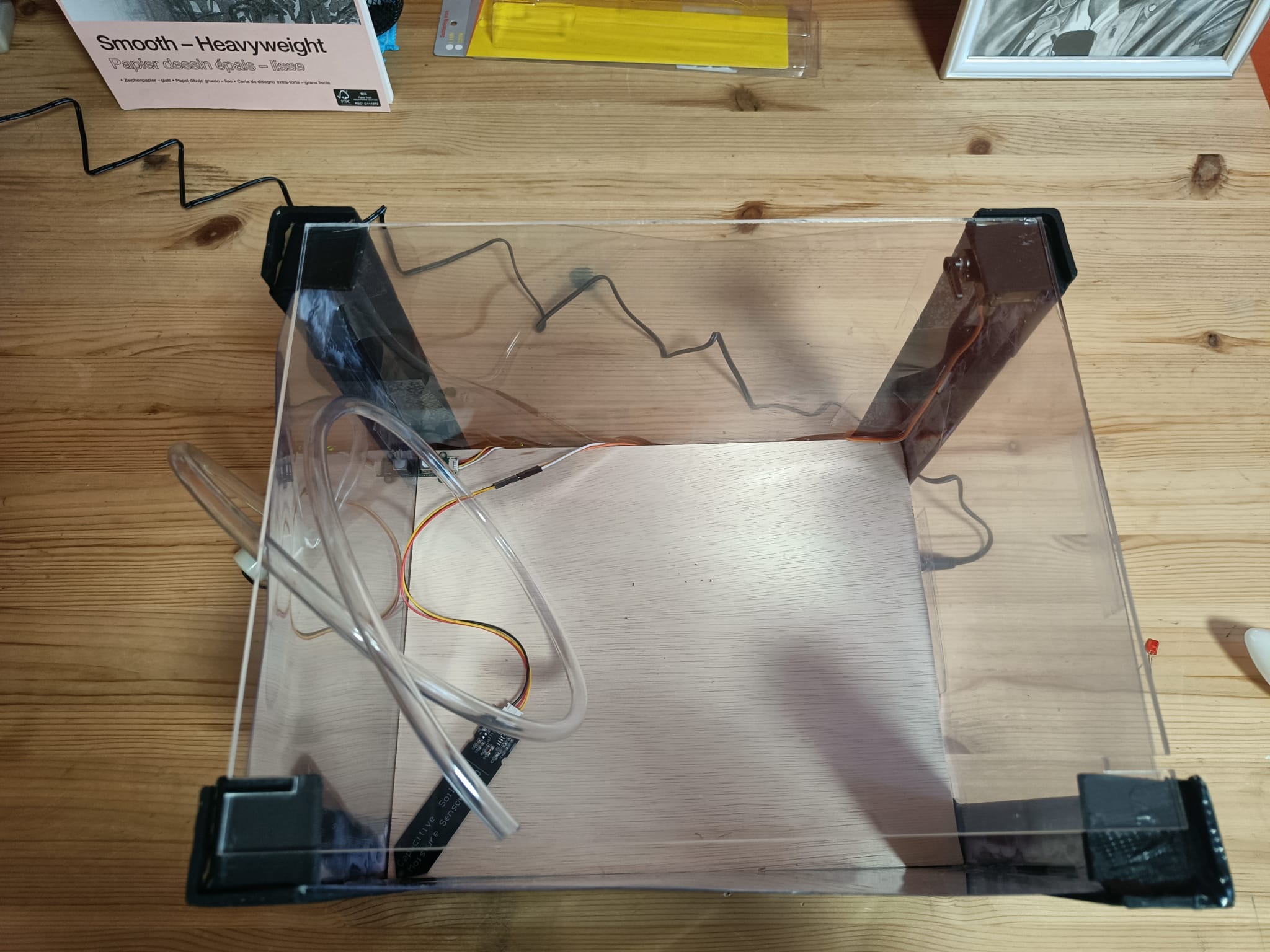

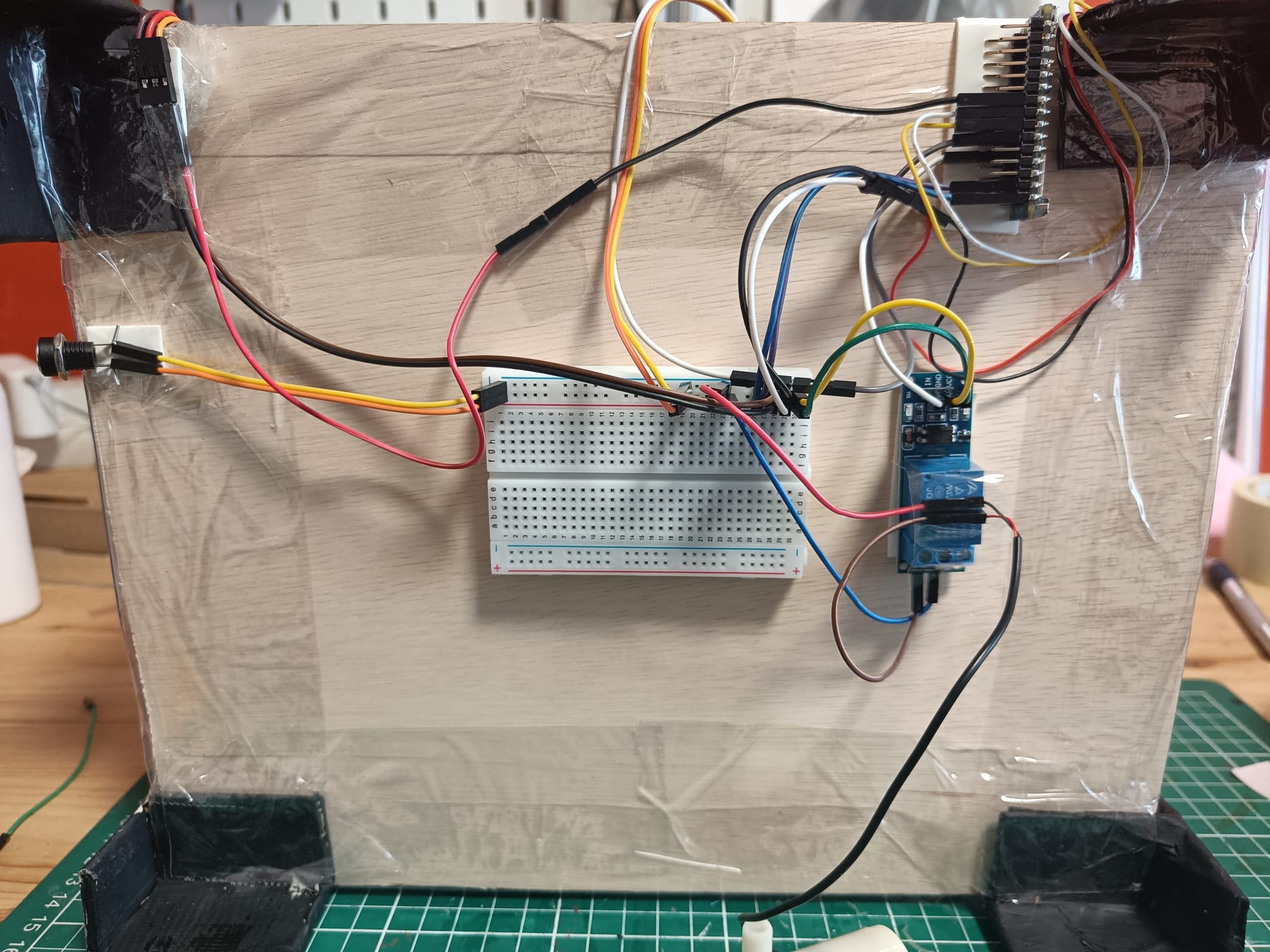

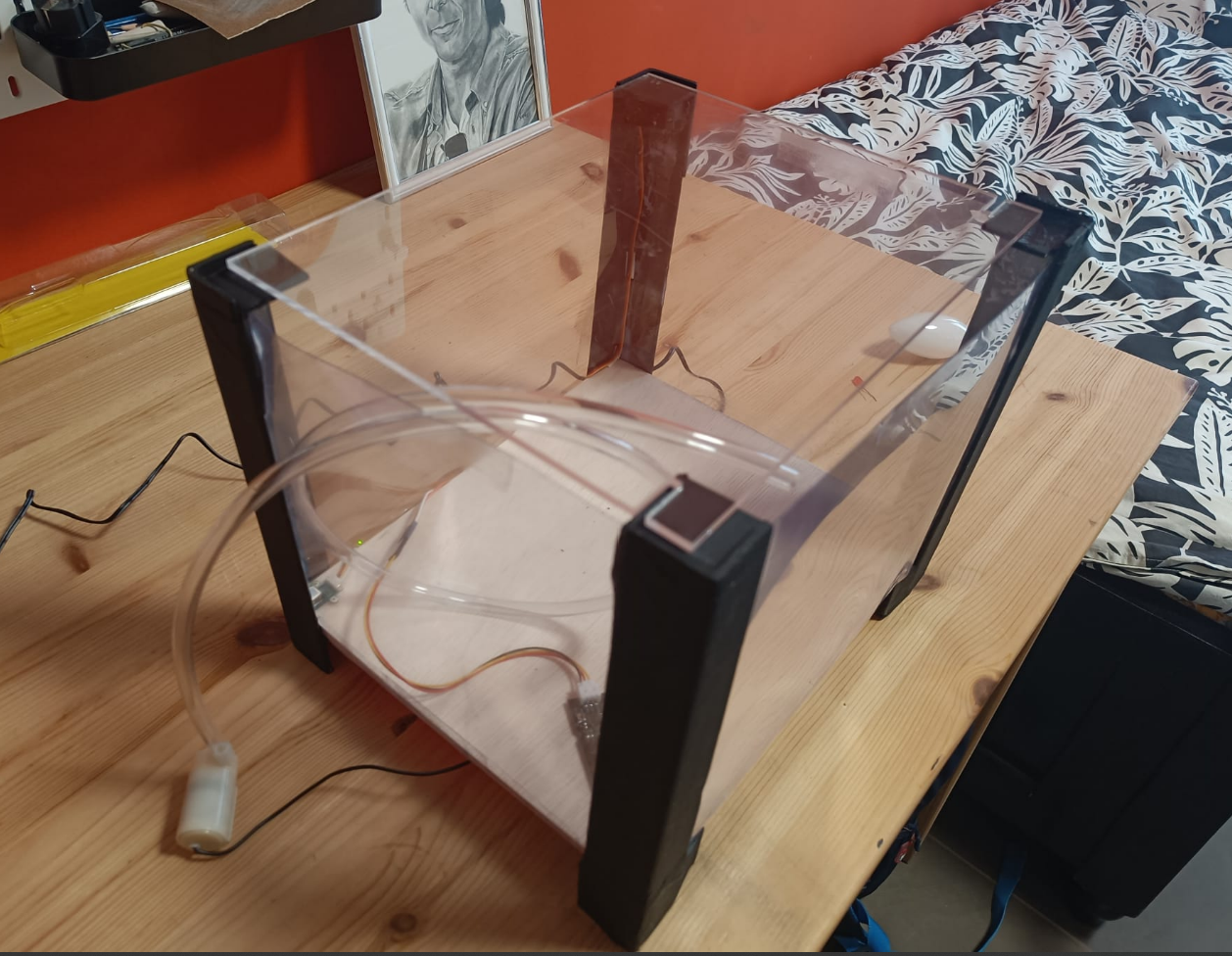

The figures below show the basic wooden structure of the greenhouse. It will later be fitted with windows on all four sides and a transparent ceiling to allow for sunlight and heat. The wooden base is where the plants will be placed by the user. The microcontroller and the breadboard, as mentioned previously, will be attached below the base to allow for stability of the frame. | |||

[[File:Framework of protoype.png|thumb|649x649px|Framework of protoype with legs and a wooden base|left]] | |||

[[File:Top view images of protype.png|thumb|675x675px|Top view of protoype framework]] | |||

[[File:Final Prototype (1).jpg|left|thumb|606x606px|View below the base of the final prototype, housing the microcontroller, breadboard and cables. ]] | |||

[[File:Final Prototype (2).jpg|center|thumb|590x590px|Top view of the final prototype, showing the transparent ceiling with the ventilation system and the pipe connected to the water pump]] | |||

[[File:Final Prototype (3).jpg|left|thumb|621x621px|Bottom view showing microcontroller, breadboard, cables and connections (attached underneath the base of the greenhouse).]] | |||

[[File:Final Prototype (5).png|thumb|554x554px|Diagonal view showing the final design of the prototype with sensors and water pump/pipe. |center]] | |||

[[File:WhatsApp Image 2025-04-01 at 21.07.04 ba25b604.jpg|center|thumb|658x658px|Front view showing greenhouse with a plant inside]] | |||

The figures above show the '''final prototype''' from different perspectives. As discussed earlier, the microcontroller and breadboard are placed underneath the base of the greenhouse to allow for stability and structural integrity, while also ensuring an aesthetically pleasing final design where the cables are not clearly visible. The breadboard connects the Arduino to all the sensors and actuators of the greenhouse. The sensors, including the CO2, temperature, humidity and soil moisture sensors, are located towards the bottom base of the frame (as seen in the diagonal view). The soil moisture sensor is to be placed relatively deep inside the plant. The servo motor actuator controlling the openable ceiling is activated when either the CO2 is too low or when the temperature is too high, depending on an algorithm designed to optimize plant growth. The following '''test cases''' were used to verify correct functionality of the greenhouse: | |||

{| class="wikitable" | |||

| colspan="7" |'''Individual Sub-Module Tests''' | |||

|- | |||

|'''Test ID''' | |||

|'''Test Case''' | |||

|'''Description''' | |||

|'''Precondition''' | |||

|'''Expected Result''' | |||

|'''Status''' | |||

|'''Comments''' | |||

|- | |||

|ID001 | |||

|Process sensor data | |||

|Read CO2, temperature, soil moisture and humidity from sensor | |||

|The sensors are connected to the microcontroller | |||

|CO2, temperature, and humidity are displayed correctly | |||

|Pass | |||

|All sensors worked | |||

|- | |||

|ID002 | |||

|Ventilation Control | |||

|Servo needs to open the ventilation hatch | |||

|Servo motor connected to microcontroller | |||

|Ventilation hatch is lifted open | |||

|Pass | |||

|The hatch could have been lifted higher. Some temperature control possible. Humidity can also be controlled via this method | |||

|- | |||

|ID003 | |||

|Heating element | |||

|Control temperature via incandescent bulb | |||

|The bulb is connected to a power outlet and is manually controlled to check effect on temperature | |||

|The greenhouse can be heated sufficiently | |||

|Fail | |||

|The plastic walls of the greenhouse started to melt | |||

|- | |||

|ID004 | |||

|Water Pump Control | |||

|Activate pump using microcontroller | |||

|Water pump connected to relay, which is connected to microcontroller | |||

|Pump turns ON successfully | |||

|Pass | |||

|The pump rate needs to be configured | |||

|- | |||

|ID005 | |||

|Web-Arduino Connection | |||

|Check data transfer between Arduino and website | |||

|The Arduino must be connected to Wi-Fi | |||

|The readings from the Arduino are displayed correctly in the website. Some delay is allowed | |||

|Pass | |||

|The Arduino and website have a delay of 5 seconds | |||

|- | |||

| colspan="7" |'''Integrated Module Tests''' | |||

|- | |||

|ID101 | |||

|Water pump - Soil Moisture | |||

|Pump turned on depending on soil moisture readings | |||

|The pump and sensor must be connected to the microcontroller | |||

|Pump turns on when soil moisture goes below a threshold | |||

|Pass | |||

|Works as expected | |||

|- | |||

|ID102 | |||

|Ventilation - CO2 levels | |||

|Ventilation hatch opens depending on CO2 levels | |||

|The servo motor and CO2 sensor must be connected to Arduino | |||

|Motor turns on when CO2 levels are high | |||

|Pass | |||

|Works as expected | |||

|- | |||

|ID103 | |||

|Website to Arduino Control | |||

|The actuators need to be controlled from the website | |||

|Arduino is connected to Wi-Fi and to a servo motor | |||

|The servo can be controlled through the website | |||

|Pass | |||

|The website is able to control the actuators connect to the Arduino | |||

|- | |||

| colspan="7" |'''Complete Module Test''' | |||

|- | |||

|ID201 | |||

|Connect all sensors and actuators to website | |||

|All modules are connected | |||

|All sensors are connected to Arduino and Wi-Fi connection is enabled | |||

|Arduino can automatically control actuators, based on sensor data. Website must display all sensor data and can manually override the actuators. | |||

|Pass | |||

|Works as expected | |||

|} | |||

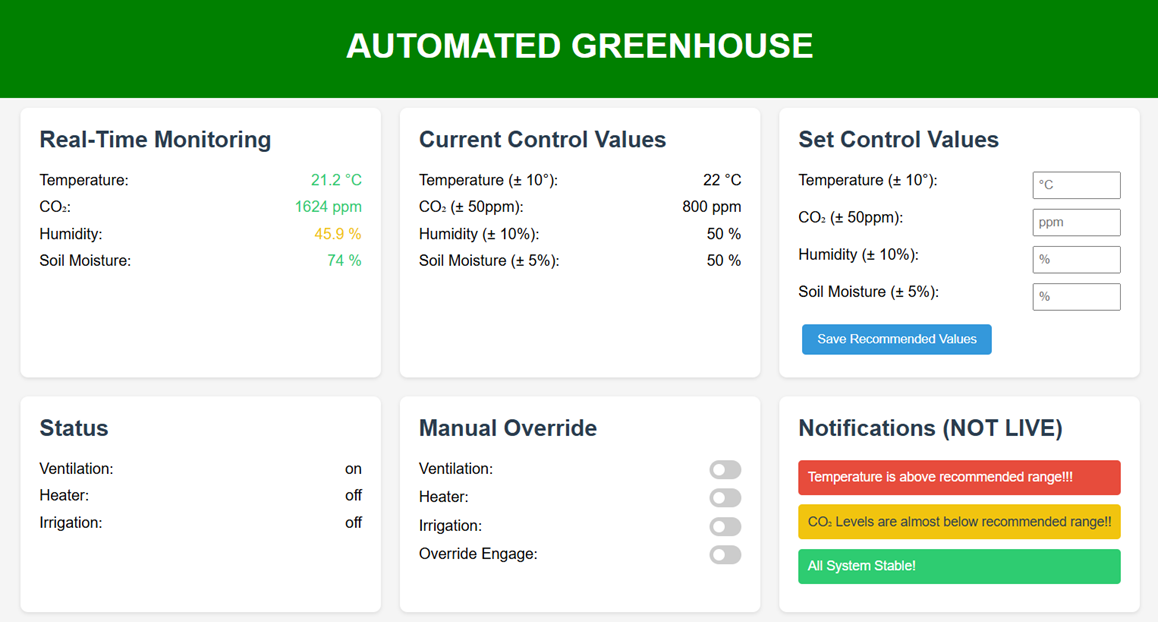

= Final Website = | |||

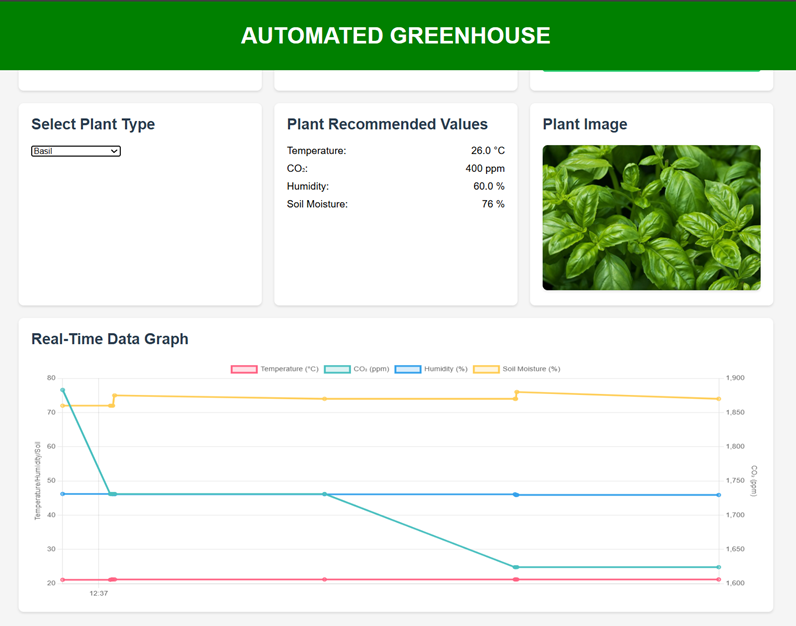

"Automated Greenhouse" website: Automated Greenhouse Dashboard. Images of the website are shown below: | |||

[[File:Website 1.png|center|thumb|901x901px|Website Monitoring and Control Section]] | |||

[[File:Website 2.png|center|thumb|796x796px|Website Graph Monitoring ]] | |||

The screenshots reveal the design of the final user website. The top image shows the various panels informing the user of real-time sensor measurements as well as the current thresholding or control values relevant for the plant. The user sees a live reading of the status of the ventilation and water pump actuators (on/off), and has the option to manually override the automated settings if necessary. Furthermore, once the user is comfortable managing the plants themselves, they can manually set control values which the controller then uses to determine when the actuators are (de)activated. Finally, there is a colour-coded panel displaying notifications that alert the user if any immediate action is necessary to maintain plant health. | |||

The bottom image shows the list of plants from the database that the user can choose from. The Google Firebase database stores the recommended parameters (thresholds) that are optimal for the selected plant, which is shown on the second tile. The user can either choose to use these parameters or, as mentioned previously, input their own values when they are comfortable or disagree with the recommended values. The bottom tile shows a graph which visualizes the real-time sensor measurements, giving users a visual description of the plant health. | |||

= Improvements and Limitations = | |||

Although the components listed in the "Components" section provide plenty of control over the greenhouse conditions, there are several improvements that can be made, which are stated as follows: | |||

'''<u>Components:</u>''' | |||

'''Piston''': A minor improvement would be to replace the servo with a piston. This would allow to open the top hatch of the greenhouse higher, improving the ventilation on the prototype. Nonetheless, the servo worked adequately to maintain the CO<sub>2</sub> levels in the greenhouse. | |||

'''Humidifier:''' This represents another improvement, serving as a specific actuator for humidity control. However, it is not essential, as humidity can be regulated using the ventilation hatch. Since the plant naturally contributes to humidity levels, the humidifier would offer only a marginal benefit. This is because, as the humidity rises, the hatch can be opened to reduce the overall humidity of the greenhouse and to maintain humidity the hatch can be kept closed. | |||

'''Grow lights''': They would be a valuable addition which would enable the greenhouse to support a wide variety of plants by providing the optimal light spectrum for growth. LED lights are ideal for this purpose, as they offer customizable light spectrums and an inexpensive addition. With the use of a microcontroller, both the spectrum and brightness could be adjusted based on the time of day and the specific needs of different plants. However, the lights were not added because, the greenhouse is designed to be placed outdoors in balconies, where the windows of the greenhouse allow for a lot of sunlight to enter. Therefore, the greenhouse relies on a natural source of light instead of artificial. Nevertheless, adding grow lights in the future would allow users to place the greenhouse indoors and still grow a diverse range of plants effectively. | |||

'''Heater''': Temperature regulation is another vital component of plant health. While the idea of integrating a heater was extensively discussed, it proved to be difficult to implement. Suitable compact heaters that could safely and effectively warm the small greenhouse space were not readily available. Therefore, the idea of building a custom heater for the greenhouse was considered. There are different methods to effectively heat a greenhouse which include, such as running heated water through copper tubes, high-current wires, and incandescent bulbs. The only feasible option was the incandescent bulb, as they are readily available and do not require specialized equipment to implement. During initial testing, the prototype’s plastic sheet walls began to melt when exposed to the heat from the standalone bulb. This indicated that the greenhouse structure would need to be redesigned with heat-resistant materials to safely accommodate the heating element. Additionally, due to the small size of the greenhouse, the plant could potentially be damaged from its proximity to the incandescent bulb. Due to these limitations of the prototype and time constraints, the heating element was not included. Nonetheless, a heating element remains a potential improvement. | |||

'''Artificial intelligence''': This is an ambitious improvement to the greenhouse, as it can significantly improve the user experience by providing personalized feedback on plant growth. Using AI, users can get tips on how to improve the growth of their plants, as well as insights into what they are already doing well. Integrating AI into the project enables weekly plant updates, which will improve the hobby experience and learning curve. Since extensive data is already being collected about the plants | |||

'''Design:''' The prototype could not be built to scale with the original shelf design, as a reduced version would not accommodate a plant. As a result, the prototype was constructed in a cube shape to ensure it could house a plant. Therefore, improving the resemblance to the shelf design is a necessary future improvement. Additionally, the design material used for the greenhouse was not heat resistant, due to which the heating element could not be added. Therefore, the materials incorporated into the greenhouse, must heat and water resistant. | |||

= Appendix = | |||

'''<u>Preliminary User Surveys:</u>''' | |||

'''For experienced gardeners and greenhouse owners:''' | |||

# How do you currently monitor and manage your greenhouse? | |||

a. Right now, I’m doing everything by myself. My family likes to grow vegetables in our greenhouse for our own cooking and to sell to our community. I have noticed that vegetarianism is becoming very common, and with that the demand for diverse produce has grown tremendously. Together with my family, I monitor and water the plants, maintain the temperature and ensure cleanliness. | |||

b. I have a greenhouse in my backyard, but it's too much of a hassle to constantly manage it properly with daily maintenance checks. I used to grow plants for the winter there. | |||

c. I own a relatively small greenhouse, which only houses a few plants and vegetables. I do all the monitoring and management by myself. | |||

2. What do you like about gardening and managing a greenhouse? | |||

a. It is a family passion. I also enjoy cooking with fresh produce knowing that it comes from my very own garden. It keeps us very healthy and connects us with nature and the environment. I also feel that we have developed a very sustainable and eco-friendly lifestyle. When we have extra vegetables, I also like to sell to our neighbors, and they seem to very much appreciate this initiative. | |||

b. I usually plant foreign vegetables which are hard to get here in my garden, so it’s very rewarding watching them grow and then cooking them when they become ready to harvest. | |||

c. I think gardening is a great way to pass time. Since I’m retired, I usually work in my garden at least 5 times a week. It's a very relaxing activity to do outside. Managing the greenhouse is very nice as well. | |||

3) For your region (US), what are some of the techniques or methods you use to best protect your crops? | |||

a. When the weather is particularly warm, I sometimes use shade cloths or thermal screens in order to protect my crops from excessive heat. Other than that, I use disinfecting tools to prevent any disease spread. | |||

b. I don’t use much to protect my crops from insects, but I do my best to keep them healthy to avoid diseases which sometimes can occur on the vegetables or plants in the garden. | |||

c. I use a mesh around my flowers, and sometimes I bring my plants indoors when it gets too hot in the summers. | |||

4) What are your main '''struggles''' with your greenhouse? | |||

a. There are very high heating/cooling costs depending on the weather – energy efficiency is very difficult. Preventing pests is also very difficult because they are often challenging to detect early. When I am busy with my day job, I often cannot ensure that the crops are getting the right amount of water and nutrients. | |||

b. Humidity levels are the biggest problem. Most of the time it rises at nighttime and is very dry during the day. | |||

c. During the winter the energy costs due to heating are the biggest problem. Cold nights require enough heat regularly in order to prevent the plants from being affected. | |||

5) What would you like to '''automate''' in your greenhouse, and what are your requirements for such a system? | |||

a. A watering system would be very helpful, in case I forget to water my plants. It doesn’t happen often but on the off chance I do forget, the plants won’t be as affected. A humidity regulator is probably the best as long as it keeps the right amount at all times throughout the day. | |||

b. I would like some kind of automatic watering or irrigation system and temperature regulation. However, I would also need to ensure quality control; maybe some way to monitor myself how the automated system is managing the crops. This would save me time while ensuring quality control. | |||

c. Maybe a temperature regulator, so I don’t have to constantly manage the temperature myself by closing the windows and such. | |||

6) What are some aspects of your greenhouse you believe are best monitored or managed '''manually''' (without automation)? | |||

a. In terms of pest control, I believe that humans are better at detecting them for now than automated systems. Humans can also treat specific areas of the greenhouse more easily for pests compared to automated systems that are set to monitor the entire greenhouse. I would also perform inspections of the irrigation lines and greenhouse structure to ensure safety of the crops. | |||

b. Pest control, doing inspections yourself are the best way of detecting them before they become a problem. Also with diseases. | |||

c. Watering during weather changes. Sometimes plants need more or less water depending on the current environment and weather. In those cases, manually watering them would be the best choice. | |||

'''For younger adults without experience in greenhouse management:''' | |||

1) Would you consider yourself to be an environmental enthusiast? | |||

a) I wouldn’t call myself an enthusiast, but I do enjoy the environment | |||

b) I care about the environment and try to make sustainable choices, but I wouldn’t call myself an expert. | |||

c) I am an enthusiast, I am studying biomedical sciences at Maastricht, and grew up in the US, where we directly see the effects of the climate crisis on the daily basis. | |||

2) Would you like to have any automation to grow plants in your area, or do you prefer managing everything on your own? | |||

=== | a) I would like some automation to get me through the initial problems | ||

b) I would love some automation to make growing plants easier! I think it would be helpful, especially since I don’t have much experience. But I’d still like to have some control over the process. | |||

c) Considering how busy I am, I would, it would be convenient for me, allowing me to spend my time more efficiently. | |||

3) What type of automation/monitoring would you need to start growing plants? | |||

a) Yeah, I would like automation systems such as talking care of watering the plants, maybe insects | |||

b) I’d need automation for watering and soil conditions. A simple app that tells me when to take action or adjusts settings automatically would be ideal. | |||

c) Watering most likely, as I (regrettably) have forgotten to do so in the past. This would be the most important part for me. | |||

4) How much empty space do you have in your garden? | |||

a) I have lived with my parents and I have plenty of space in my garden for plants. | |||

b) I live in an apartment and have a balcony with maybe a few square meters, placing a full green house will not be possible. A small setup like vertical gardening against one of the walls would work best that wouldn’t require any drilling as it is an rented apartment. | |||

c) I reside in an apartment, which roommates, so I only have my own room to myself (very limited), so you could say that is my “garden space” | |||

5) How much time are you willing to spend on developing this hobby? | |||

a) I do have some time during the weekends, where I usually spend time with my family, so any type of gardening could be a good combined activity. | |||

b) I’d be willing to spend a few hours per week, my work keeps me busy so I wouldn’t want it to feel like a chore. If it’s too time-consuming, I might lose interest. | |||

c) Not too many (2-3 hours), as I am studying my bachelors, but it is something that I would like to explore more thoroughly in the future, such a product would make it easier for me to get into this hobby already. | |||

=== Weekly Team Role Division === | |||

{| class="wikitable" | |||

|+ | |||

!Name | |||

!Week 1 | |||

!Week 2 | |||

!Week 3 | |||

!Week 4 | |||

|- | |||

|Neesanth Murugesh | |||

|Research and article summaries, | |||

User requirements (6h) | |||

|Finish user requirements, | |||

make/send survey (7h) | |||

|Brainstorm of concept designs, | |||

matching user requirements (8h) | |||

|Begin website programming (8h) | |||

|- | |||

|Atreya Viswanathan | |||

|Research of existing literature/state-of-the-art, | |||

Problem Statement/Objectives (6h) | |||

|Find survey respondents, research | |||

alternative solutions (7h) | |||

|Brainstorm of concept designs, | |||

component research (8h) | |||

|Initial testing of components, writing | |||

functions to test individual | |||

sensors/actuators (8h) | |||

|- | |||

|Chenwei Gao | |||

|Research and article summaries, | |||

User research (6h) | |||

|Find survey respondents, additional | |||

research on greenhouse automation (7h) | |||

|Analysis of survey results, | |||

component research (7.5h) | |||

|Firebase database research of plants, | |||

testing components | |||

(8.5h) | |||

|- | |||

|Prannoy Kapoor | |||

|Research and article summaries, | |||

user research/survey (6h) | |||

|Alternative solutions to mini | |||

automated greenhouse, make/ | |||

send survey (7h) | |||

|Analysis of survey results, concept | |||

designs, initial 3D modelling (8h) | |||

|Ordering and collection of | |||

components, initial testing | |||

of individual components (8h) | |||

|- | |||

|Gaurav Sharma | |||

|Research and article summaries, | |||

user research/survey (6h) | |||

|Make/send survey, user | |||

requirements, research (7h) | |||

|Survey analysis, research on | |||

microcontroller, required sensors/ | |||

actuators (8h) | |||

|Initial testing of components, research | |||

on Arduino libraries and programming (8h) | |||

|} | |||

{| class="wikitable" | {| class="wikitable" | ||

|+ | |+ | ||

!Name | !Name | ||

! | !Week 5 | ||

! | !Week 6 | ||

!Week 7 | |||

!Week 8 | |||

|- | |- | ||

|Neesanth Murugesh | |Neesanth Murugesh | ||

| | |Establish connection between | ||

| | Arduino and website, sending | ||

data back and forth through WiFi (8h) | |||

|Design of website, and | |||

begin building prototype (10h) | |||

|Finish prototype and testing with website | |||

(10h) | |||

|Completing Wiki website (5h) | |||

|- | |- | ||

|Atreya Viswanathan | |Atreya Viswanathan | ||

| | |Integration of components in Arduino | ||

| | IDE, writing functions to control actuators | ||

(8h) | |||

|Building final prototype (10h) | |||

|Finish prototype, testing, and preparing | |||

presentation (10h) | |||

|Completing Wiki website (5h) | |||