PRE2023 3 Group12: Difference between revisions

| (47 intermediate revisions by 6 users not shown) | |||

| Line 40: | Line 40: | ||

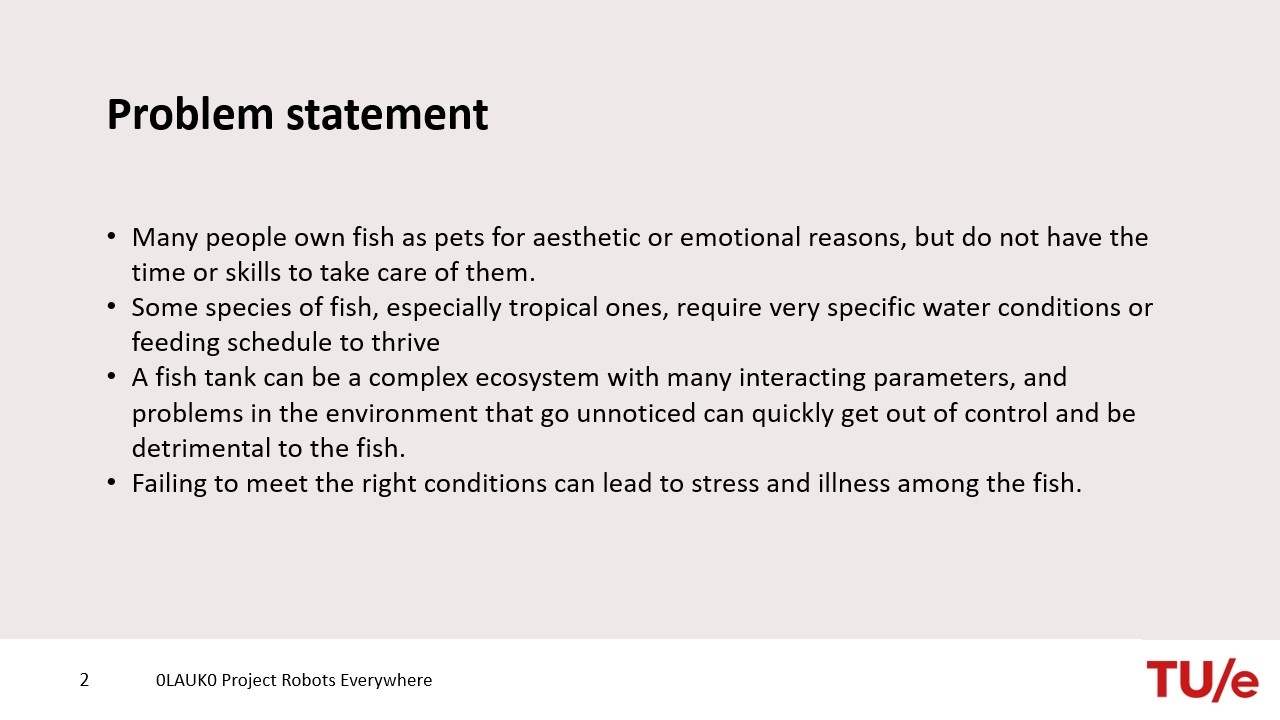

Many homeowners have aquatic pets of certain kinds either for aesthetic reasons or out of genuine compassion for the animals. In the world of aquariums and fish, one of the most important things is ensuring healthy water conditions. There can be various reasons for people to wanting to own an aquatic pet. It can be difficult to ensure these parameters with insufficient knowledge or time constraints. An aquarium owner comes across various tasks and problems. Owning and maintaining a fish tank can be difficult. These include feeding schedules, water parameters, pH-levels and temperature. It can be difficult to test regularly and keep values on certain levels. All these factors can have negative impact on the fish their health and happiness. For many aquatic pet owners, it can be helpful to have a tool that takes care of the fish during periods of absence. This will prevent stress and illness among the animals in the tank. | Many homeowners have aquatic pets of certain kinds either for aesthetic reasons or out of genuine compassion for the animals. In the world of aquariums and fish, one of the most important things is ensuring healthy water conditions. There can be various reasons for people to wanting to own an aquatic pet. It can be difficult to ensure these parameters with insufficient knowledge or time constraints. An aquarium owner comes across various tasks and problems. Owning and maintaining a fish tank can be difficult. These include feeding schedules, water parameters, pH-levels and temperature. It can be difficult to test regularly and keep values on certain levels. All these factors can have negative impact on the fish their health and happiness. For many aquatic pet owners, it can be helpful to have a tool that takes care of the fish during periods of absence. This will prevent stress and illness among the animals in the tank. | ||

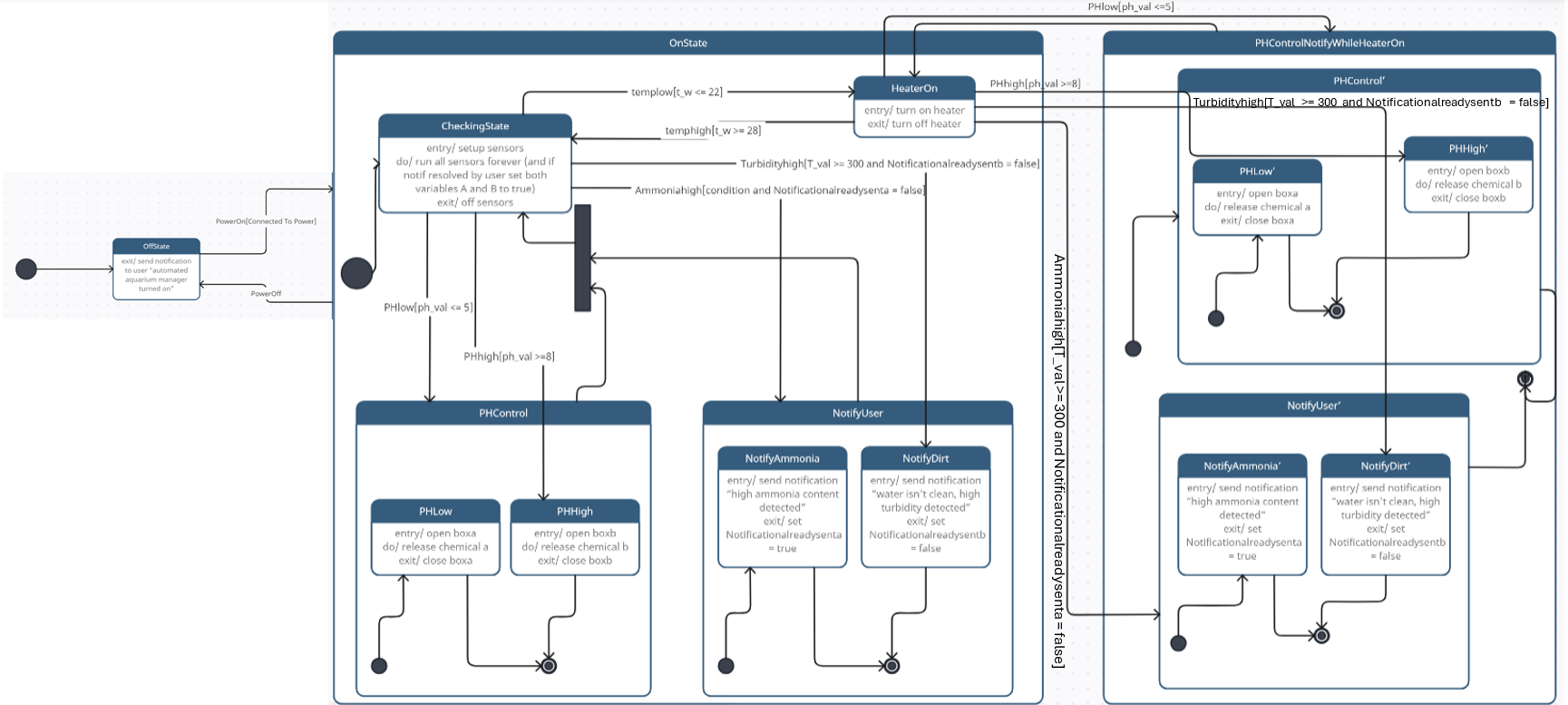

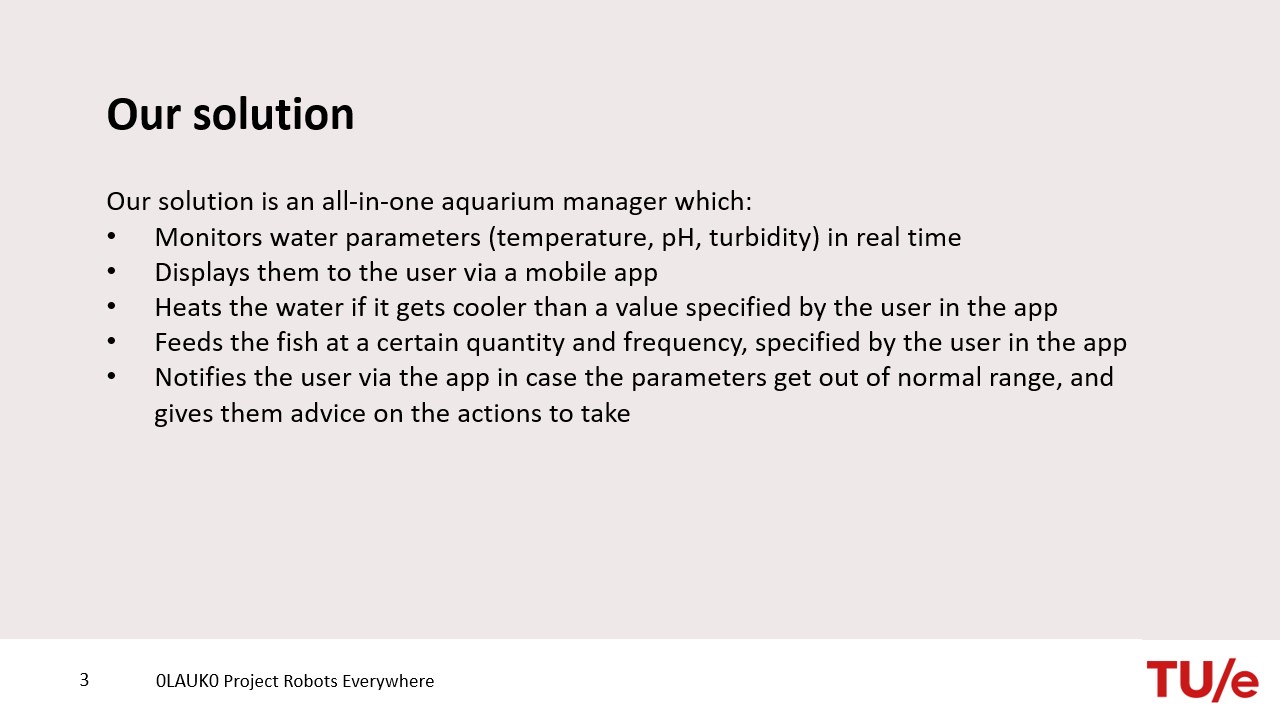

Our proposed solution is an aquarium robot, that will be able to monitor and maintain water parameters. Our system aims to take away most difficulties that arise when owning an aquarium. This enables the user to ensure optimal chemical levels and temperature. Our system will be able to sense the tank its temperature, pH, turbidity and ammonia levels. The sensors are selected such that they will withstand the constant exposure to water and give accurate results. A microcontroller acts when certain levels get out of balance. Dispensing the correct amount of food on certain times during the day can be important too. The system will be able to dispense food when needed. By using Wi-Fi and an application, the system will be able to contact the user and send real-time values to the user. This and other actuators will ensure safe, preset values inside the aquarium. The user will get notified when a problem arises, and inform the user about its actions. | Our proposed solution is an aquarium robot, that will be able to monitor and maintain water parameters, as well as feeding the fish. Our system aims to take away most difficulties that arise when owning an aquarium. This enables the user to ensure optimal chemical levels and temperature. Our system will be able to sense the tank its temperature, pH, turbidity and ammonia levels. The sensors are selected such that they will withstand the constant exposure to water and give accurate results. A microcontroller acts when certain levels get out of balance. Dispensing the correct amount of food on certain times during the day can be important too. The system will be able to dispense food when needed. By using Wi-Fi and an application, the system will be able to contact the user and send real-time values to the user. This and other actuators will ensure safe, preset values inside the aquarium. The user will get notified when a problem arises, and inform the user about its actions. | ||

'''Objectives:''' | '''Objectives:''' | ||

| Line 141: | Line 141: | ||

The rapid development of new, cheaper sensors makes it possible to create systems that can support aquarium owners [14]. This development is crucial in allowing the creating of these systems. More extended sensors are also worked on, to allow the monitorization of fish farms [12]. | The rapid development of new, cheaper sensors makes it possible to create systems that can support aquarium owners [14]. This development is crucial in allowing the creating of these systems. More extended sensors are also worked on, to allow the monitorization of fish farms [12]. | ||

==== Current products on the market: ==== | |||

<u>Superfish Aquarium Start 70:</u> This is a self-contained automated aquarium specifically targeted to beginners with tropical fish. It contains a heater, thermometer, filter and LED lighting. However only nothing is automated except for the filter, and everything coming with the actual tank means no possibility for the user to choose a different size. The whole kit costs €90. | |||

<u>ReefATO+</u>: This is a system to add to an already existing tank. It monitors water level and temperature, and sends notification to the user via a mobile app in case these values are out of a predefined range. It also pumps the water and detects leak. It costs €200. | |||

The company Neptune Systems also provides a large range of Aquarium automation products, among which one can find: | |||

<u>A3 Apex Jr Aquarium Controller:</u> This system is composed of water and pH sensors, a water level sensor and a leak detector. It sends all of the collected information to a mobile app via wi-fi. It costs €300. | |||

<u>DOS Dosing and Fluid Metering System:</u> This system performs automatic water changes by pumping water while injecting chemicals thanks to a precise fluid metering and dosing system. The price is €325. | |||

<u>Trident - Marine Aquarium Water Analyzer:</u> This system regularly tests the alkalinity, calcium, and magnesium of the water and sends notifications to the user when they are out of range via an app. It can be combined with the previous system to automatically release chemicals when the water parameters are abnormal. As a standalone, it costs €625. | |||

<u>Automatic Feed System:</u> This system releases fish food at a fixed frequency. It costs €145 | |||

According to our research there exists no product yet that monitors water parameters, regulates them and feeds the fish, so our product would bring an important improvement in the market. The addition of a mobile app also seems a very appreciable feature for the user. Moreover, most of the products have a very high price due to the small number of companies selling them, so the ability to manufacture a system at a reasonable price would be another improvement, especially since our product is partially targeted towards everyday users and beginners. | |||

== USE Analysis == | |||

=== Users === | |||

'''''Homeowners with Aquatic Pets''''' | |||

These users need a reliable system that is easy to use and maintains the optimal conditions within their aquariums. Ideally, the solution can minimize the effort and time that is required for regular maintenance while also ensuring the health and well-being of their pets. This group can range from beginners who may have little knowledge about aquatic pets to experienced enthusiasts. The system should be user-friendly and provide educational resources for less experienced users. They need to be able to regularly check the app for updates on the aquarium's condition. Regular monitoring and adjusting of water parameters like pH, temperature, and ammonia levels can be tedious and time-consuming. There's also a risk of human error, leading to unhealthy conditions for the fish. | |||

'''''Aquarium stores''''' | |||

These users require a system that can manage multiple tasks efficiently, ensuring optimal conditions for the health and breeding of fish. They value accuracy and reliability, and most importantly, the system has to adapt to different species. Professional users have a deeper understanding of aquaculture and may require advanced features and greater control over the system. Some of the challenges may include consistent water quality across multiple tanks. Also, any issues that may occur have to be quickly addressed to prevent loss of stock. Therefore, these users need an alert system that can immediately send notifications for any parameters that fall outside safe ranges. | |||

=== Society === | |||

Society values products that prioritize sustainability and environmental responsibility. When it comes to a device for aquarium monitoring, there is a desire for energy-efficient solutions that minimize environmental impact. By reducing energy consumption and promoting responsible fishkeeping practices, such a device tries to limits it's impact on climate. Ensuring the safety aquatic environments is as important for society. Therefore, there is a need for monitoring devices that can quickly detect and respond to emergencies or fluctuations in water quality. By providing real-time monitoring and alerts, these devices help minimize risks to marine life and promote the overall safety of aquatic ecosystems. Fish shouldn't be harmed by the equipment, as holds for the user. Electronics should be kept dry, off-contact with the water. Innovation is highly valued in society, driving progress and advancements in various fields. A device that pushes the boundaries of technological advancement in aquarium monitoring resonates with society's appetite for innovation. By inspiring further exploration in environmental monitoring and conservation, such products contribute to the ongoing quest for innovative solutions to global challenges. | |||

=== Enterprise === | |||

Many systems that take care of this are designed to be user-friendly, offering various options for monitoring and controlling a wide range of parameters including temperature, pH level, ammonia concentration, ensuring optimal conditions for aquatic life. These systems provide programming and control capabilities through both computers and mobile devices, allowing for remote management<ref>Ash, E. (2024, February 26). ''Aquarium Controllers: 8 systems to control, monitor & Test your tank''. Fish Tank Advisor. <nowiki>https://fishtankadvisor.com/best-aquarium-controller-reviews/</nowiki></ref>. This is particularly beneficial for aquarium stores managing multiple tanks and homeowners who need to maintain their aquariums while away. A product like described could lower costs for these stores. Data security is a critical concern for enterprises handling sensitive information. In the context of aquarium monitoring devices, robust data security measures are essential to protect monitoring data from unauthorized access or breaches. By implementing encryption protocols and secure storage mechanisms, these devices ensure the integrity and confidentiality of sensitive information, maintaining user trust and confidence. | |||

== Results From User Survey And Discussions == | |||

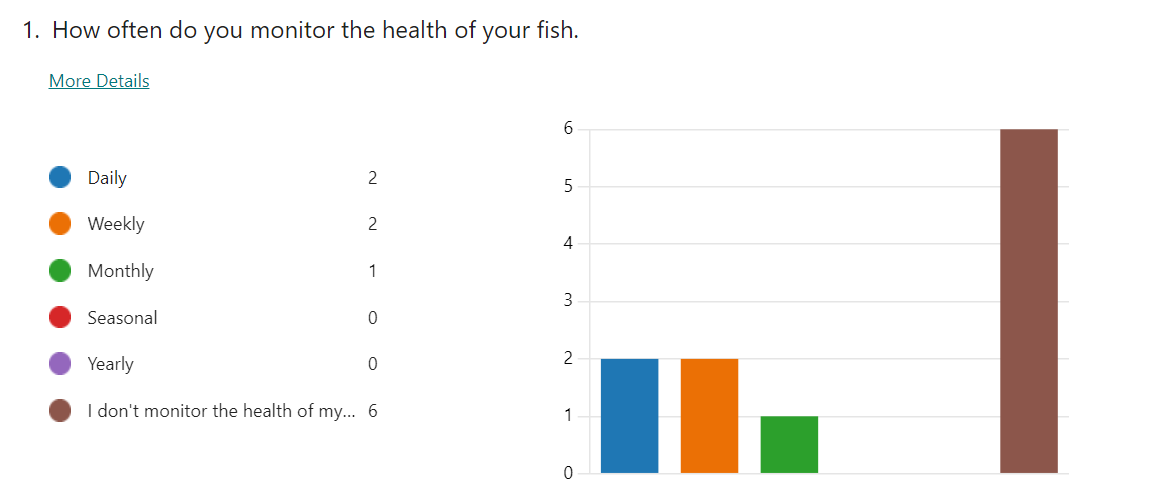

[[File:Survey Results 1.png|thumb|Fish Health Monitoring Survey Results]] | |||

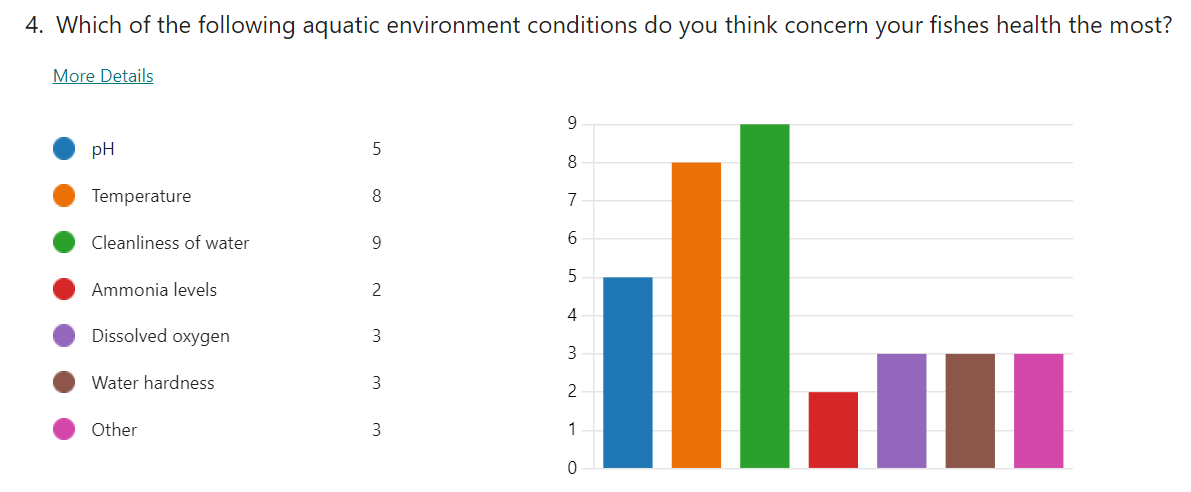

[[File:Image 2.png|thumb|Concerns From Users Survey Results]] | |||

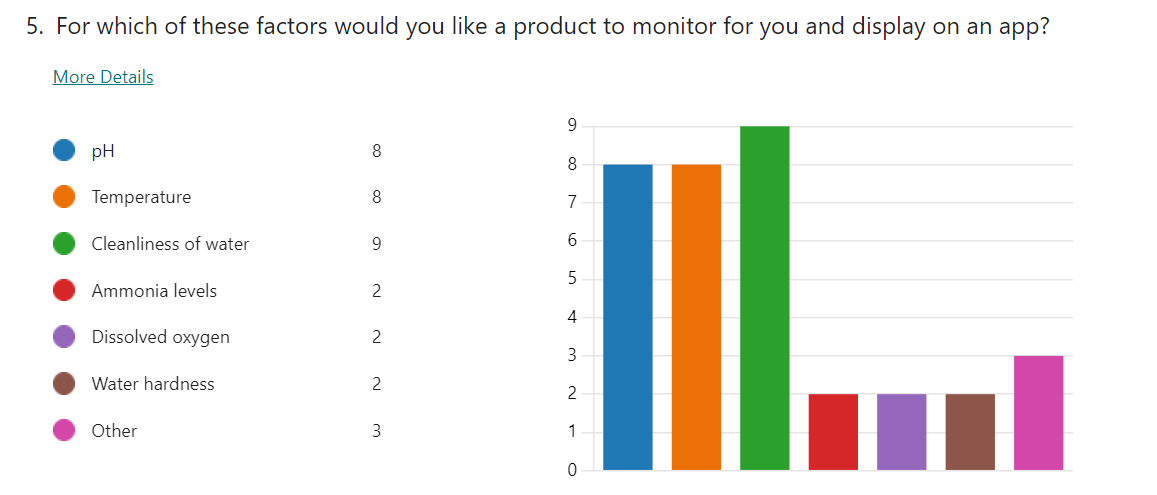

[[File:Image 3.png|thumb|App Preferance Survey Results]] | |||

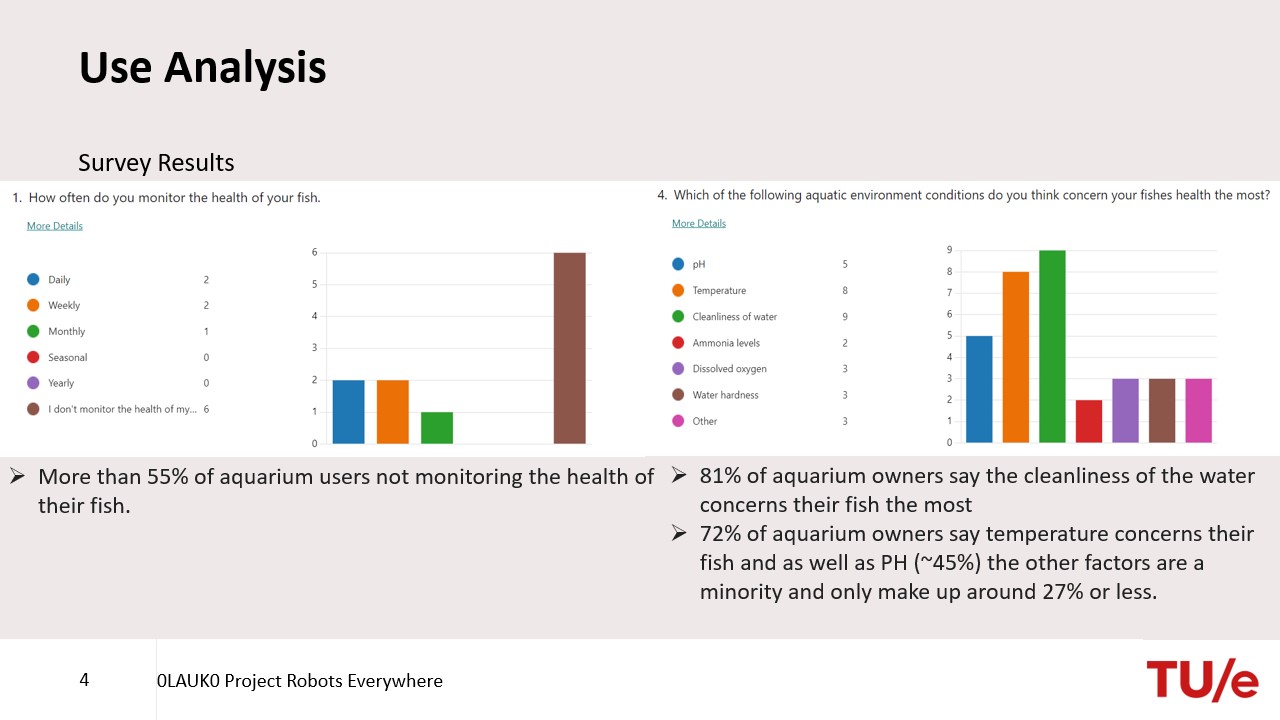

As previously mentioned, owning an aquarium can be a lot of work. There are certain tasks that need to be checked multiple times each month, as well as feeding and water filtering. This can be a burden for people, mostly during times of absence. This can be seen from the survey results with more than 55% of aquarium users not monitoring the health of their fish. | |||

Owners that go on a long trip or vacation will need to ask someone else to monitor their aquarium for them. Remembering to feed every day can be hard for some users too. An elderly women mentions that it can a lot of work to check and learn all important water parameters. Good information on how to keep certain species of fish would be useful. A automated system could be created to notify the user when a change of filter is needed. Many aquarium users in our survey said they don't know when to clean the wateer as there is no specified time to do this, the standard is every month but the truth is sometimes due to temperature, PH, climate and all other environmental, external and other factors this can vary a lot. This will be a better solution (notifying the user when a change of filter / water is needed) than just changing it once every month or so, as the filter may be clean enough to be us. | |||

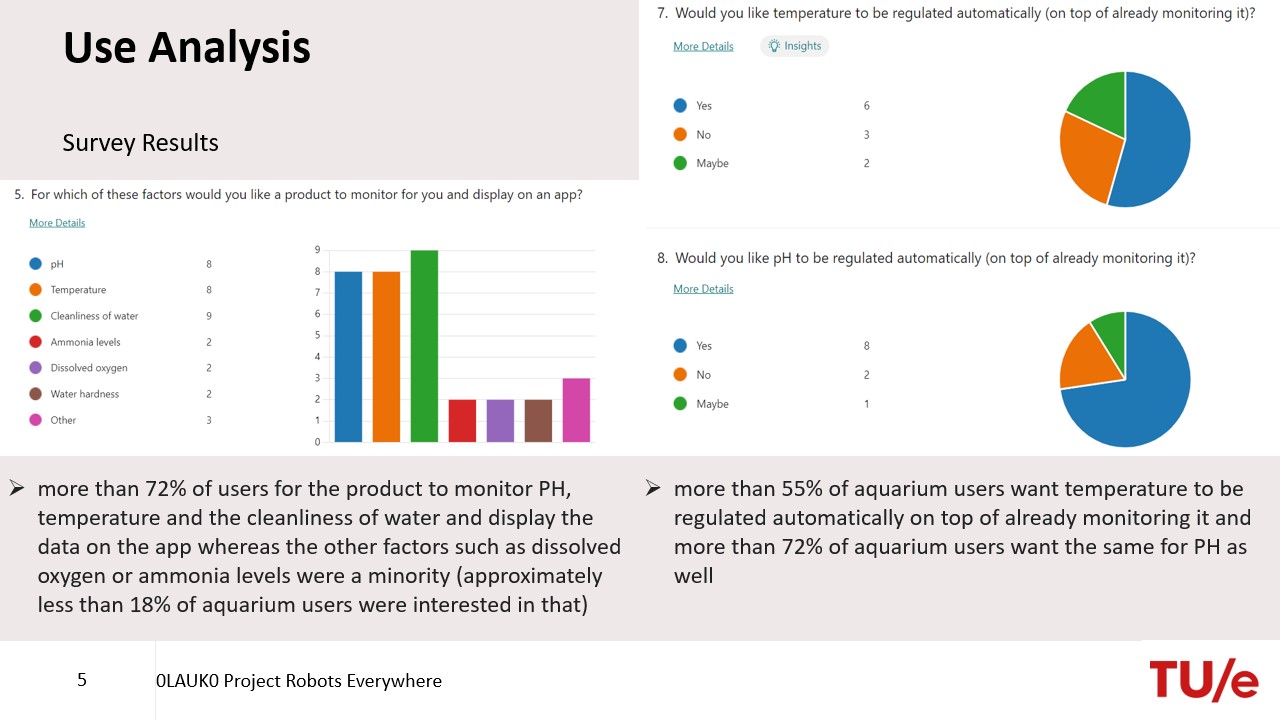

This can be seen from the survey result where 81% of aquarium owners say the cleanliness of the water concerns their fish the most hence as mentioned above a system to notify when cleaning the water is required is crucial. Furthermore 72% of aquarium owners say temperature concerns their fish and as well as PH (~45%) the other factors are a mintory and only make up around 27% or less. Therefore a system to monitor and regulate temperature as well as PH would be ideal as this was a suggestion by more than 72% of users for the product to mintor PH, temperature and the cleanliness of water and display the data on the app whereas the other factors such as dissolved oxygen or ammonia levels were a mintory (approximately less than 18% of aquarium users were interested in that). Moreover, more than 55% of aquarium users want temperature to be regulated automatically on top of already monitoring it and more than 72% of aquarium users want the same for PH as well, due to these being the most crucial aspects to cover and the most concerning according to aquarium users.[[File:Reg.png|thumb|Automated Regulating Survey Results]]Major fish community websites and blogs post information on the most common tasks of an aquarium owner. Some water parameters should be checked weekly to ensure good water quality. Most aquarium owners don't keep track of these parameters, or only measure the most important ones. There are owners that enjoy the work they get from owning an aquarium, but this is different for users who own these aquatic pets for their esthetics or their addition to a calm environment. For these users it would be useful to create a system that takes care of the fish, such that the user can enjoy their fish not worrying about anything. A common response as well for any other extra functionaly in the system was to incoperate feeding facilities this is a good option and can be implemented using the <Time.h> library in Arduino alongside a servo motor, the time library in Arduino can "count" time in a background thread whilst the servo motor can spin and "drop" food at the time specified on the app which the information for this is sent to the Arduino via BLE. | |||

_____________________________________________________________________________________________________________________________________ | |||

== Research on aquarium environment parameters and optimal conditions for ornamental fish == | |||

As the selected user group for this project is home owners with ornamental fish aquariums and aquarium stores that may also breed their indoor ornamental fish, the optimal conditions coincide for these user groups as they all involve small scale indoor freshwater aquariums as the environment. The water condition factors that affect general living and breeding conditions of ornamental fish are temperature, hardness/softness, pH, ammonia concentration, chlorine concentration, carbon dioxide and oxygen. | |||

'''Temperature of the water''' | |||

The temperature of a fish tank is usually a main concern during the transport and introduction of new fish due to risks of thermal shocks the fish can get that can be caused when a rapid change to the temperature in their environment occurs<ref name=":1">https://www.researchgate.net/publication/268195853_Aquarium_Water_Quality_Management</ref>. For general health and well being of fish, temperature requirements are split into two types: cold water fish and tropical fish. Common cold water fish include gold fish, Koi and certain species of barbs, tetras and loaches. Common tropical fish include bettas, Guppies, Mollys and certain species of laches and tetras. These two types different types of fish should generally not be in the same aquarium due to the different temperature needs. While tropical fish can tolerate 21 °C up to 30 °C, the optimal conditions for tropical fish are 24°C to 27°C with 27°C to 28 °C being suitable for breeding of many types of tropical fish<ref name=":2"><nowiki>https://courseware.cutm.ac.in/wp-content/uploads/2020/06/Session-7-1.pdf</nowiki> short good info with table</ref>. Temperatures above 32°C, are detrimental to the health of most fish. As for cold water fish, they can tolerate from 15°C up to 24°C. With some specifies preferring temperatures lower than 15°C<ref>https://www.thesprucepets.com/aquarium-water-temperature-1381896</ref>. | |||

In cases of the fish tank temperature getting too low for the fish types, solutions include simply increasing the temperature of the room or installing water heaters that are generally heating coils enclosed in a glass tube. A water heater of 5 to 6 watts is required per gallon of water<ref name=":1" />. | |||

In cases of the fish tank’s temperature being too high, solutions include reducing artificial lighting over the tank or blocking out natural lighting, cooling down the room that the tank is present in, installing better filtration systems to cycle water faster and even simply running a fan on the water’s surface<ref><nowiki>https://fishlab.com/aquarium-temperature/</nowiki> non research paper website mainly about temperature and fish</ref>. | |||

'''Hardness of the water''' | |||

General hardness or total hardness refers to the measure of calcium and magnesium salts as well as other ions such as sulphites and chlorides of magnesium and calcium present in the water. Below 75 ppm water is considered as soft. From 75 to 150 ppm is moderately hard and 150 to 300 ppm is hard. Beyond that water is considered very hard. Most freshwater fish can thrive in a wide range of hardness and most of the time does not require any water treatment unless fish known to come from regions of extreme total hardness (either soft or very hard) is being raised (6). Water hardness anywhere from 100 to 300 ppm is known to be optimal for growth of most ornamental fish. Only when general hardness is below 12 ppm would require liming<ref name=":2" />. | |||

'''pH''' | |||

pH refers to a logarithmic scale of hydrogen ion (H<sup>+</sup>) concentration in aqueous solutions. For most ornamental fish, a pH of 7 to 8 is suitable for growth, breeding and general health<ref name=":3">https://www.researchgate.net/publication/339285368_Importance_of_Optimum_Water_Quality_Indices_in_Successful_Ornamental_Fish_Culture_Practices</ref>. But the pH levels must never fall below 5 and raise above 8.5 for aquarium water. Certain ornamental fish prefer slightly acidic water (with pH of 6.2 to 7) such as rosy barb, tiger barb, tetra, angel and daino. Fishes like koi, goldfish and cichlids prefer slightly alkaline water<ref name=":2" />. pH can be increased if necessary with doses of calcium hydroxide and decreased if necessary with acids like hydrochloric acid. | |||

'''Ammonia concentration''' | |||

Fish waste contains many end products of nitrogen metabolism such as uric acid, urea ammonia. With ammonia being one of the most hazardous to fish. In water, ammonia exists as either NH<sub>3</sub> in its gaseous state or in an ionized state as NH<sub>4</sub>+. It is the unionized state (NH<sub>3</sub>) that is harmful to fish as it damages gills and causes fish to gape for air at the water surface (although other issues could also lead to similar symptoms). According to Subhendu Datta’s paper on aquarium water quality management, 0.4 ppm of NH<sub>3</sub> is considered acute toxicity level meaning a short term or single dose can be lethal. While 0.05 ppm of NH<sub>3</sub> with long term exposure can lead to the above mentioned symptoms. Damage to gills can already occur at 0.25 mg/lt <ref name=":1" />. Ammonia poisoning is mainly a concern when the fish tank is first established and still lacks a strong cultivation of bacteria that break down these harmful compounds. These bacteria mainly reside in the filters of the water cycling and filtering system and hence require ample time with batches of feeder fish before the ornamental fish can be introduced to an aquarium. The ideal ammonia concentration in the system should be trace amounts (it should be noted that ammonia testing kits usually measure both NH<sub>3</sub> and NH<sub>4</sub> combined). In events of sudden ammonia spikes, fish should be transferred to other tanks (being mindful of the necessary procedures to avoid thermal shocks) and allow the bacteria load to increase and break down the ammonia. Other discouraged solutions include using ammonia detoxifiers<ref name=":1" />. | |||

Other than when the aquarium is first established, ammonia concentrations can also increase when too many fish are added at once, the fish tank is heavily populated, the filtration system is not functioning properly or is insufficient and when the fish are being overfed. Apart from factors that increase ammonia concentration, the toxicity of ammonia can also increase at higher water temperatures and pH levels above 7.0<ref>https://www.aqueon.com/articles/freshwater-aquarium-water-quality</ref>. This is because the equilibrium between NH<sub>3</sub> and NH<sub>4</sub>+ is dependant of pH and temperature and yield of NH<sub>3</sub> is preferred at higher temperatures and pH which should be taken into account as NH<sub>3</sub> is 300 to 400 times more toxic to fish than NH<sub>4</sub>+<ref name=":3" />. | |||

'''Chlorine concentration''' | |||

Tap water is a readily available source of clean water that can be used to fill fish tanks. However, the main issue with this is chlorine content in tap water. Chlorine amounts as low as 0.1 ppm is enough to be considered toxic for most ornamental fish<ref name=":2" />. However, this can easily be solved by letting the water sit in the tank for a few days to let the chlorine escape and make the water suitable for fish. Aerating the water with air pumps can greatly help this process. Alternatively, if time is of concern then the water can also be treated with commercially available chemicals such as sodium thiosulphate<ref name=":1" />. Once initially dealt with, chlorine concentrations do not need to be monitored unless more tap water is added when water changes. | |||

'''Dissolved Oxygen''' | |||

For warm water fishes, the recommended level of dissolved oxygen is 4 to 5 mg per litre. Dissolved oxygen may be a crucial to monitor as low dissolved oxygen levels may stunt growth, affect feeding and can lead to hypoxia. This causes high levels of stress for the fish and cellular damage (1). To prevent this, most aquarium systems have a aerators. The capacity and amount of aerators required depends on the volume of water and is always indicated by the product’s description. So as long as ample aeration is occurring in the system, the use of analog dissolved oxygen monitors may be omitted as they are expensive and inessential for home users keeping ornamental fish. | |||

'''Refrences:''' | |||

== Functional specifications and requirements == | == Functional specifications and requirements == | ||

Due to the limited time and resources for this project, we decided to only focus on a few water parameters to monitor and control. Our system will therefore monitor pH, temperature and turbidity, and will act upon temperature via a heater. It will also dispense a certain quantity of food at a certain interval of time indicated by the user. | |||

'''Sensors''' | '''Sensors''' | ||

{| class="wikitable" | {| class="wikitable" | ||

| Line 149: | Line 236: | ||

|- | |- | ||

|R1 | |R1 | ||

|The system senses pH with an accuracy of at most ± 0. | |The system senses pH with an accuracy of at most ± 0.3pH | ||

|Must have | |Must have | ||

|- | |- | ||

| Line 166: | Line 253: | ||

|R5 | |R5 | ||

|The system senses turbidity with an accuracy of at most ± 40 NTU | |The system senses turbidity with an accuracy of at most ± 40 NTU | ||

| | |Must have | ||

|- | |- | ||

|R6 | |R6 | ||

|The system senses turbidity at intervals of at most 1 minute | |The system senses turbidity at intervals of at most 1 minute | ||

| | |Must have | ||

|- | |- | ||

|R7 | |R7 | ||

|The system senses ammonia (NH3) concentration with an accuracy of at most ± 0.005 ppm | |The system senses ammonia (NH3) concentration with an accuracy of at most ± 0.005 ppm | ||

| | |Could have | ||

|- | |- | ||

|R8 | |R8 | ||

|The system senses ammonia (NH3) concentration at intervals of at most 1 minute | |The system senses ammonia (NH3) concentration at intervals of at most 1 minute | ||

| | |Could have | ||

|- | |- | ||

|R9 | |R9 | ||

| Line 196: | Line 283: | ||

|- | |- | ||

|R11 | |R11 | ||

|The system dispenses the quantity of food specified by the user, with an precision of ± 0. | |The system dispenses the quantity of food specified by the user, with an precision of ± 0.25g | ||

|Must have | |Must have | ||

|- | |- | ||

| Line 238: | Line 325: | ||

|- | |- | ||

|R20 | |R20 | ||

|The app allows the user to set food quantity and frequency | |||

|Must have | |||

|- | |||

|R21 | |||

|The app displays the time the fish have last been fed | |The app displays the time the fish have last been fed | ||

|Should have | |Should have | ||

|- | |- | ||

| | |R22 | ||

|In case of abnormal values, the app displays information on how to fix the problem | |In case of abnormal values, the app displays information on how to fix the problem | ||

|Should have | |Should have | ||

|- | |- | ||

| | |R23 | ||

|The app has different parameter presets for cold water and tropical fish | |The app has different parameter presets for cold water and tropical fish | ||

|Could have | |Could have | ||

|- | |- | ||

| | |R24 | ||

|The app displays information on different species of fish | |The app displays information on different species of fish | ||

|Could have | |Could have | ||

| Line 259: | Line 350: | ||

!Priority | !Priority | ||

|- | |- | ||

| | |R25 | ||

|The main case have IPx4 water resistance | |The main case have IPx4 water resistance | ||

|Must have | |Must have | ||

|- | |- | ||

| | |R26 | ||

|The wires have IPx8 water resistance | |The wires have IPx8 water resistance | ||

|Must have | |Must have | ||

|- | |- | ||

| | |R27 | ||

|The system is powered by 12 V 2A barrel connector power supply | |The system is powered by 12 V 2A barrel connector power supply | ||

|Must have | |Must have | ||

|- | |- | ||

| | |R28 | ||

|The | |The system can easily and safely be attached to any cover-less, rectangular tank | ||

| | |Must have | ||

|} | |} | ||

| Line 285: | Line 376: | ||

Actuators/sensors on all important water parameters. | Actuators/sensors on all important water parameters. | ||

== | == Design Of Our System == | ||

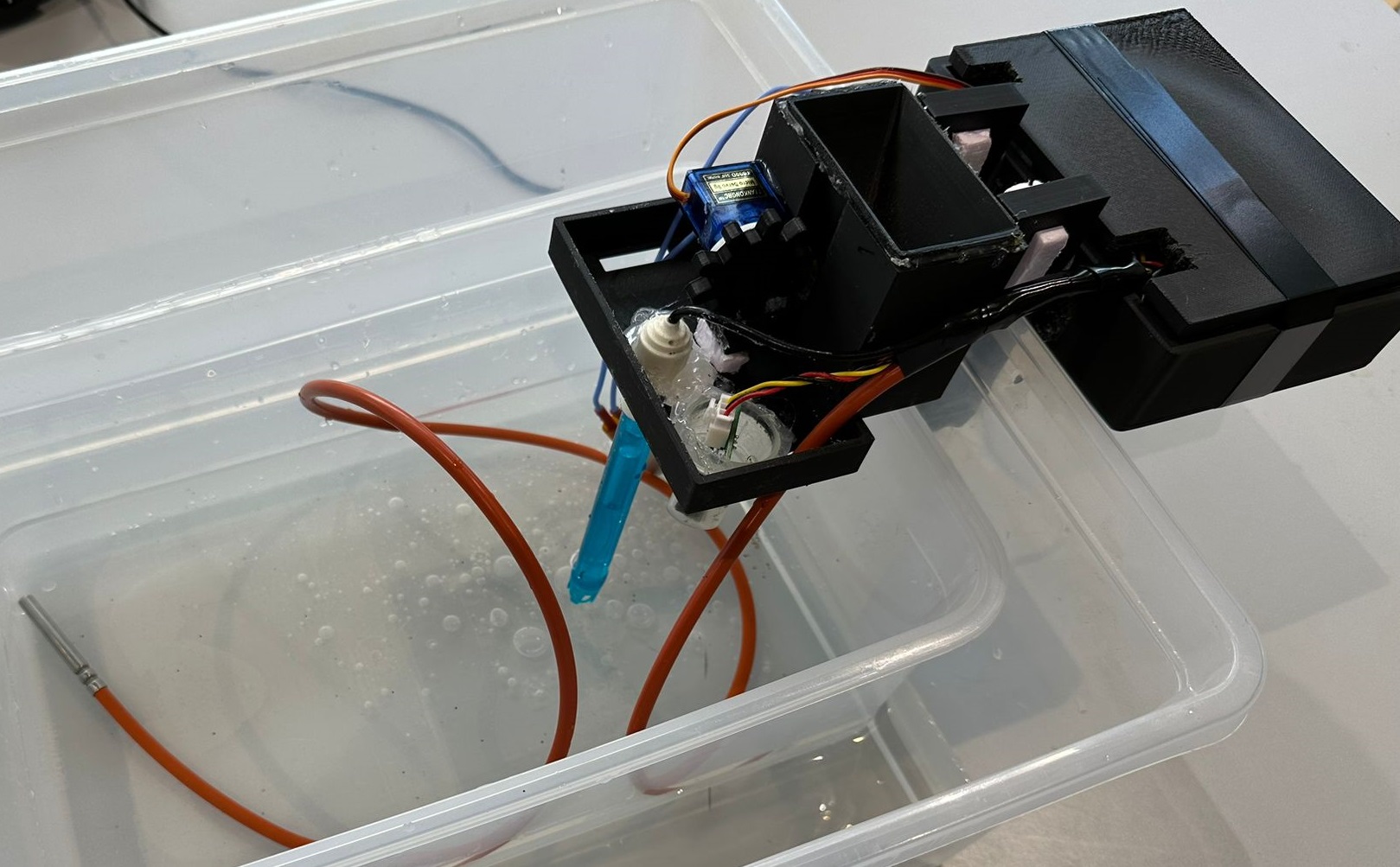

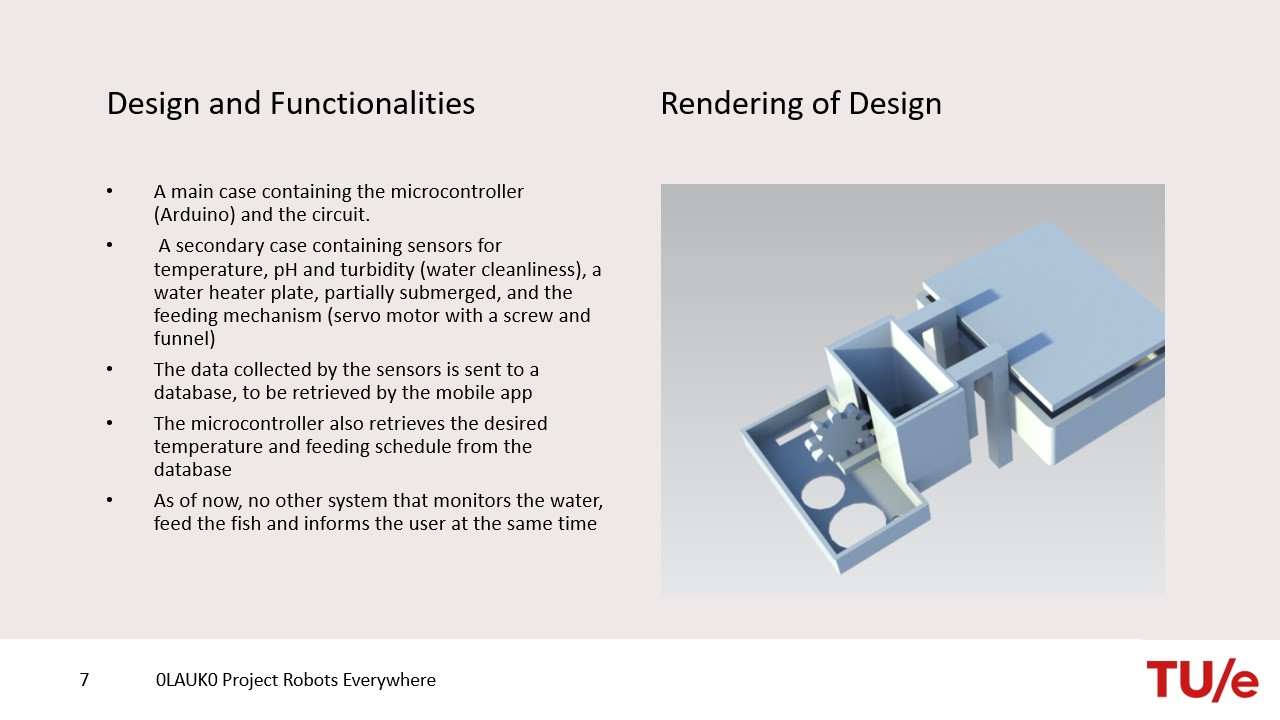

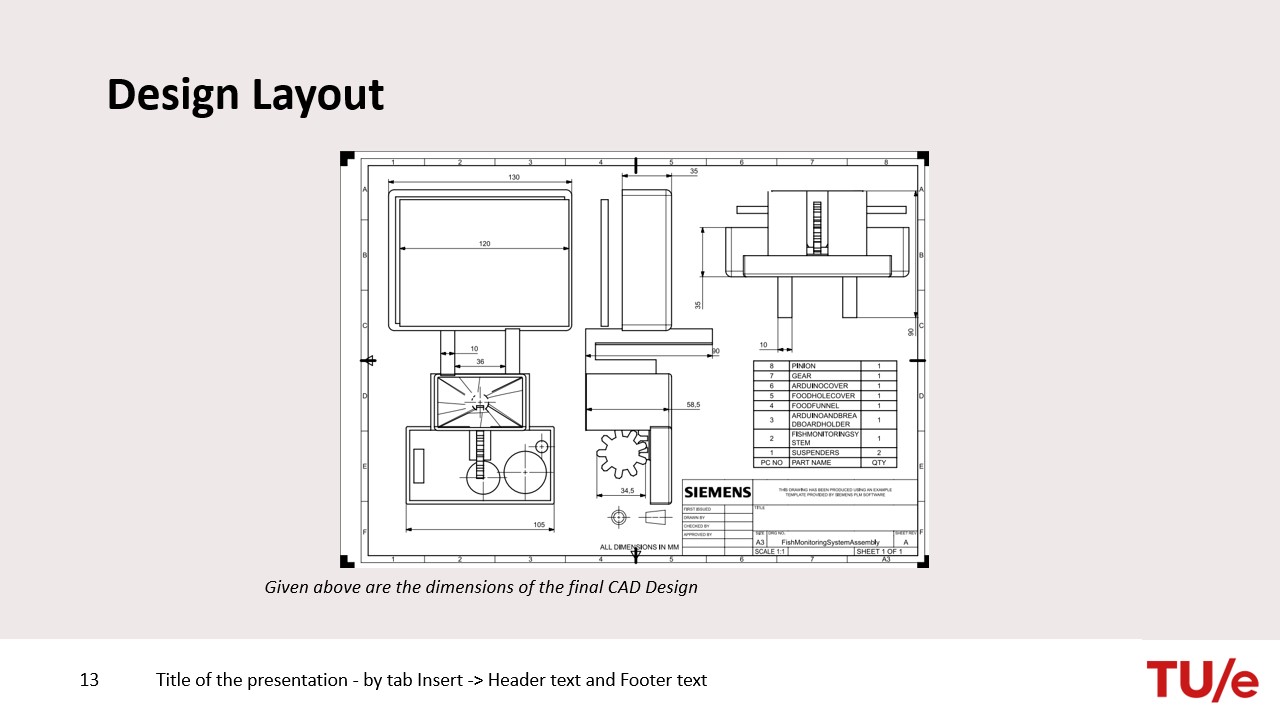

The choice has been made to make a all-in-one connected fish tank automation system. The system would keep track of the water temperature, pH, turbidity and ammonia levels. Temperature would be adjusted automatically with the activation of a heater if it falls below a threshold. Furthermore the system would dispense a certain amount of fish food at a certain frequency given by the user. The system would be a box to be attached at the top of a wall of the tank, just above the water. Temperature, pH, turbidity and ammonia sensors, as well as the heater would at the bottom of the system, submerged in the water. Inside of the box would be a microcontroller, a wi-fi module, and the food dispensing system, composed of an Archimedes screw controlled by a servo motor and a food tank. All of this would be enclosed in a 3D-printed case taking as less space as possible. | |||

We chose to let the pH control as a could have because of the difficulty to implement it. Indeed, there is no real way to automate with an actuator. The only possibility would be to dispensed pH product, but this would require a whole pumping system, making the system larger and significantly more expensive. Moreover the dosage would have to be extremely precise not to harm the fish. More generally, pH change in a aquarium is something that is usually done very precautiously, only a few times in a year, and often with a portion of the water being replaced as well, so it does not seem to really profit from automation. | |||

Likewise, we decided to let ammonia monitoring aside, since we already have quite a few parameters to monitor, and that ammonia sensors are quite expensive. | |||

This system would be coupled with a mobile app, on which the user would be able to see the parameters in real time and be notified if one of them is out of its normal range, with advice to fix them. The user would also be able to input parameters to decide on the quantity and frequency of food dispensed. It would also access other information on the fish tank like the time the fishes were last fed, or any alert if the system is malfunctioning. The communication between the app and the system can be done remotely from anywhere with the use of a database that stores the water parameters and other values of every device, which would be constantly updated by data from the respective sensors or user inputs. | This system would be coupled with a mobile app, on which the user would be able to see the parameters in real time and be notified if one of them is out of its normal range, with advice to fix them. The user would also be able to input parameters to decide on the quantity and frequency of food dispensed. It would also access other information on the fish tank like the time the fishes were last fed, or any alert if the system is malfunctioning. The communication between the app and the system can be done remotely from anywhere with the use of a database that stores the water parameters and other values of every device, which would be constantly updated by data from the respective sensors or user inputs. | ||

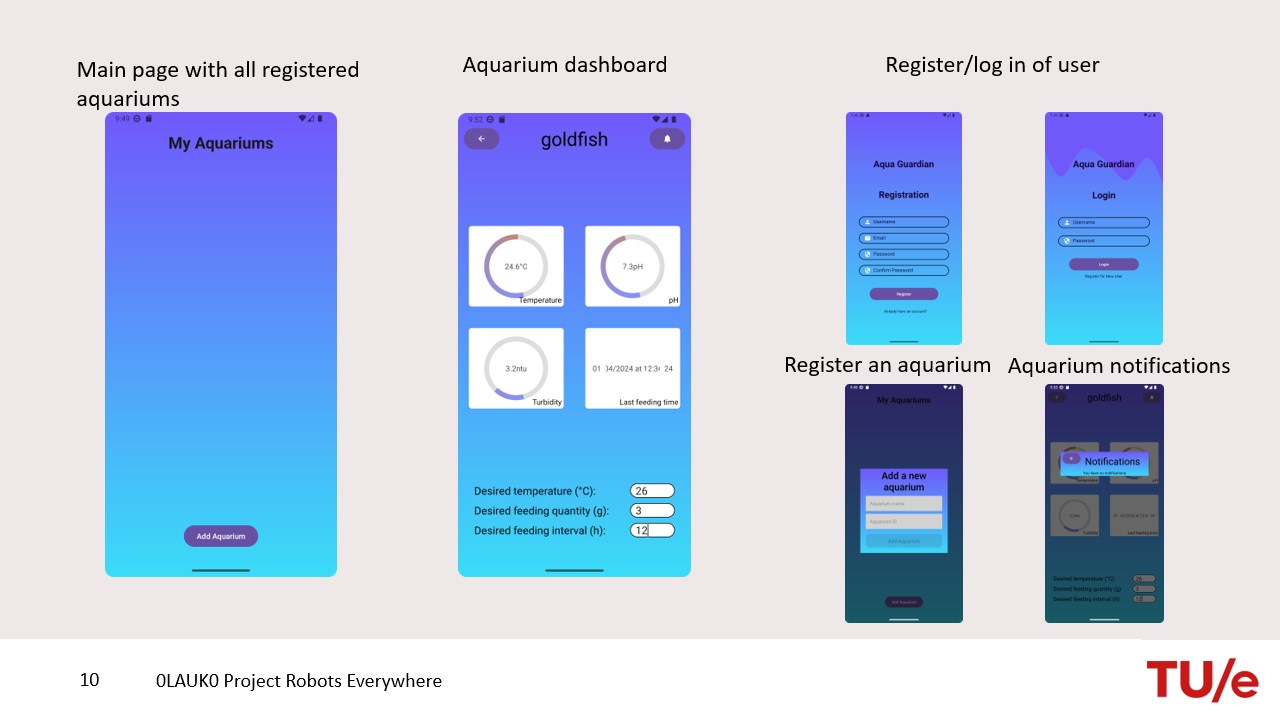

== App Design == | == App Design == | ||

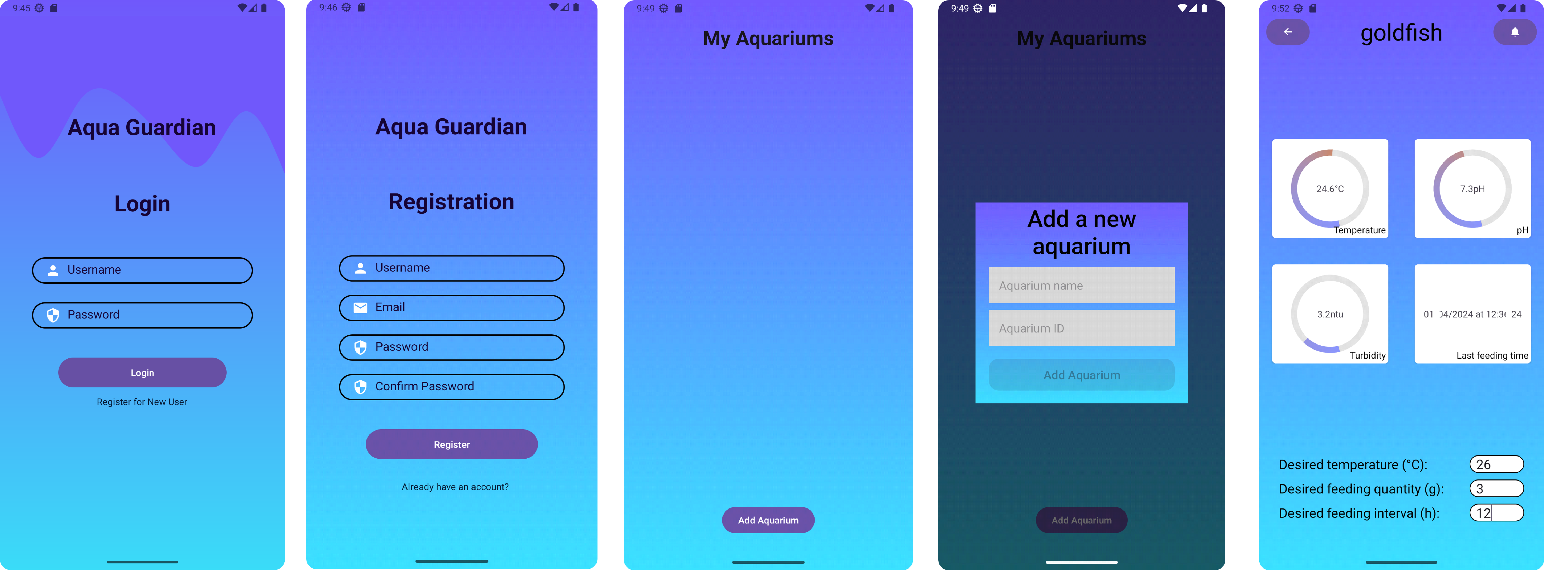

[[File:Screenshotss.png|thumb|800x800px|The different pages of the app]] | |||

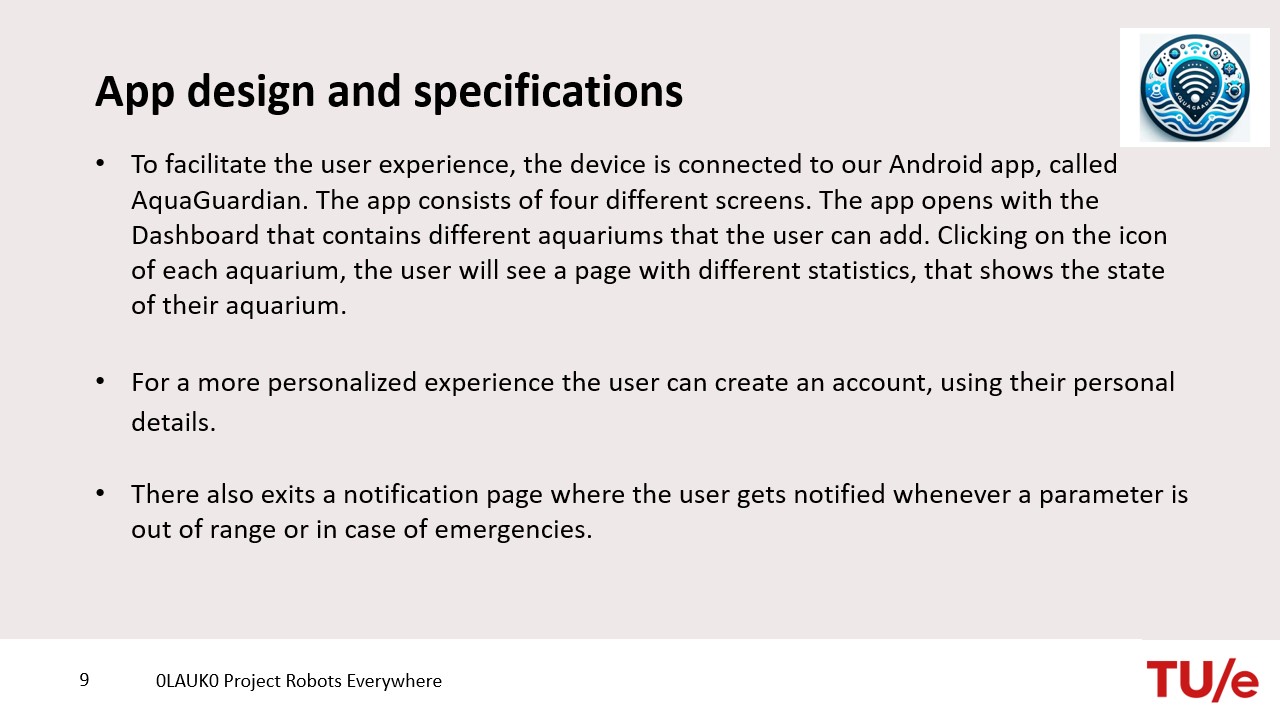

'''Design of the app''' | '''Design of the app''' | ||

To facilitate the user experience, the device is connected to an Android app. | |||

''First Design:'' | |||

The app contains eight possible pages, which include: the start page, a log-in and sign-up page, a profile page, page that contains all of the monitored aquariums, a page that shows graphs about parameters and an extra page that can be used to ask questions in case any problems arise. | |||

''' | ''Second design''The original design of the app has been modified according to the most important features for the user. The app was developed in Android Studio using Kotlin as the programming language. The final version of the app has four different pages. When first opening the app the user will be introduced to the main page ('Dashboard') where it can find all of the aquariums that were introduces on the profile. The user can always add aquariums if necessary. By clicking on an aquarium the user will be taken to a separate page that will contain statistics about the aquarium such as pH level, temperature etc. | ||

For a more personalized experience, the user can create a profile, where it can add personal details and a profile picture. It can also use Google accounts do directly create a profile. The profiles are added to a data base. The app is very easy to use. The user can navigate from page to page using the menu that can be found at the bottom of the page. | |||

The notifications of the app will be displayed on a separate page. In this way the user will be up-to-date to any modifications regarding the parameters, or in case any interventions may arise. | |||

== IP-code for safeness == | == IP-code for safeness == | ||

Our design will have to meet certain standard to be able to operate safely close to the water. This is needed for the fish’s and user’s protection. There are certain requirements defined by the European union on levels of protection against multiple factors. This ingress protection code is useful for finding viable sensors and actuators for our project. The IP-code is build up out of multiple layers. Generally the code looks like : IPXXA, with X being a number and A a letter. If there isn't any specified value, the x will either remain or be left out (if on the end of the code). The first X can have levels from 0 to 6, representing different levels of dust-resistance. The second 0-9 levels is for water-resistance. | Our design will have to meet certain standard to be able to operate safely close to the water. This is needed for the fish’s and user’s protection. There are certain requirements defined by the European union on levels of protection against multiple factors. This ingress protection code is useful for finding viable sensors and actuators for our project. The IP-code is build up out of multiple layers. Generally the code looks like : IPXXA, with X being a number and A a letter. If there isn't any specified value, the x will either remain or be left out (if on the end of the code). The first X can have levels from 0 to 6, representing different levels of dust-resistance. The second 0-9 levels is for water-resistance. | ||

| Line 411: | Line 420: | ||

|} | |} | ||

If the microcontroller is placed on the outside of the tank, there will only be splashing water from time to time. Therefor there will be less need for good water resistance. IPx8 requires an object to be functional when submerged for longer periods. This should always be specified by the manufactures. For our project, it will be necessary to aim for the longest durability possible. A 3d printed casing for the microcontroller and small tubes for the wires will be useful for their water resistance. It is important to create no expose from the copper wires or any other electrical connection to the water, as this could have consequences. | If the microcontroller is placed on the outside of the tank, there will only be splashing water from time to time. Therefor there will be less need for good water resistance. IPx8 requires an object to be functional when submerged for longer periods. This should always be specified by the manufactures. For our project, it will be necessary to aim for the longest durability possible. A 3d printed casing for the microcontroller and small tubes for the wires will be useful for their water resistance. It is important to create no expose from the copper wires or any other electrical connection to the water, as this could have consequences. | ||

Different materials could be used to ensure a water-resistant casing. High density plastics created in a vacuum are particularly good at keeping out water. | |||

Other materials like wood could be used, but need a coating to ensure water resistance. | |||

To create a watertight seal, there are multiple options. We could choose to apply a liquid coating, which is quite cheap, but needs to be applied multiple times. | |||

The liquid tape should be applied with a brush, and should rest for half an hour before applying the next layer. | |||

Another option would be to use self fusing silicon tape. This tape is made from a special cured rubber, which sticks to itself with ease. It is easy to apply and could be used to protect the wires from water. | |||

The wires can be wrapped in the tape, which will create a water tight seal after a couple minutes. The tape should be used to seal of connections, as it only sticks to itself. | |||

Multiple layers should be applied, this will create a firm watertight connection. | |||

epoxy gels or coatings are used in a lot of different situations. These are applied when liquid, but get solid to create a watertight seal. | |||

Rubber rings or strips are also watertight. They could be used to seal of the entrances as well. it will be hard producing such rings that fit, as a bundle of wires could have a irregular shape. | |||

<nowiki>https://thecavepearlproject.org/2023/03/17/waterproofing-your-electronics-project/</nowiki> | |||

Like shown in the following article, water and living creatures have an influence on the materials. Hard casings with connections like screwcaps are good options. | |||

The final options for sealing the electronics are potting them, coating them or using a hard casing. | |||

Tape can be used to seal of excess gaps or connections. | |||

== Sensors == | == Sensors == | ||

| Line 556: | Line 592: | ||

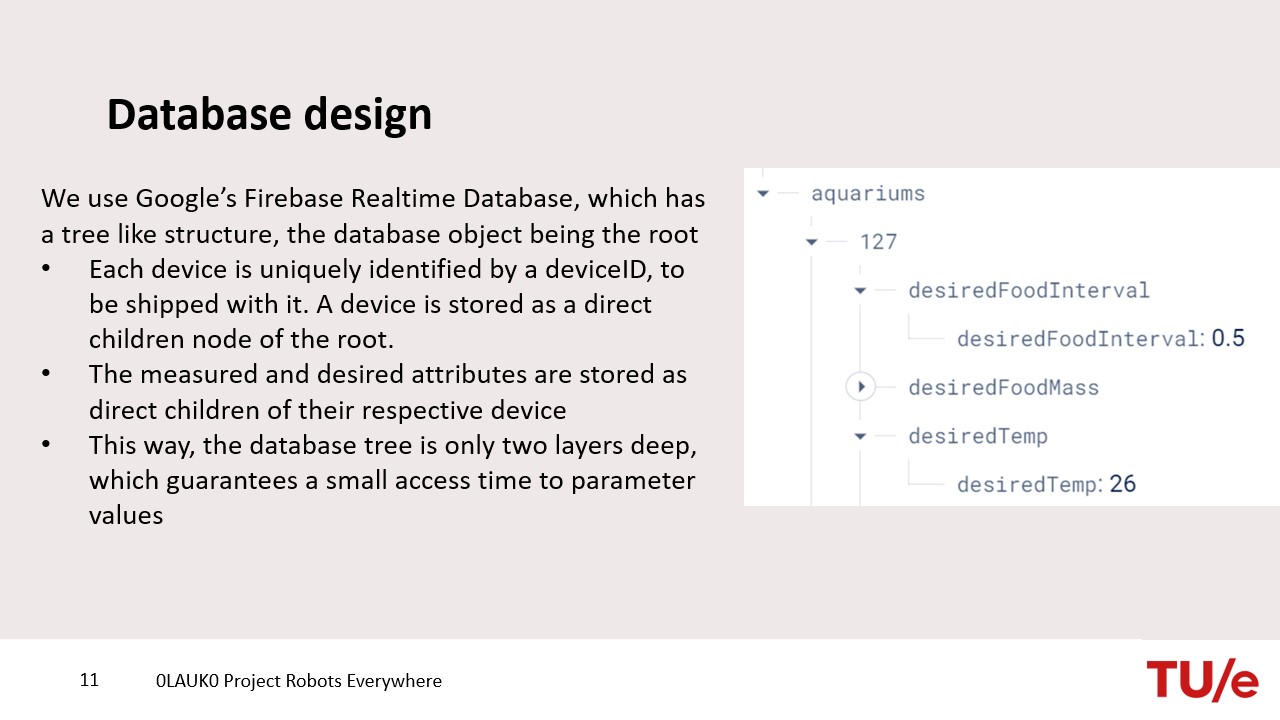

The database could be organised in the following way: each record would be uniquely identified by a deviceID that is bound to a physical deviced and is shipped with it to users. Users could then enter it in the app when they set up the device to reference it. This way they are able to control several different devices from the app. In each record there would also be all the current and desired water parameter values, as well as other useful values such as the time the parameters were last measured, the time the food was last dispensed, or a boolean value indicating if the system is still functioning correctly. These values can then be accessed to read or write by both the Arduino and the mobile app, which are linked by the deviceID. | The database could be organised in the following way: each record would be uniquely identified by a deviceID that is bound to a physical deviced and is shipped with it to users. Users could then enter it in the app when they set up the device to reference it. This way they are able to control several different devices from the app. In each record there would also be all the current and desired water parameter values, as well as other useful values such as the time the parameters were last measured, the time the food was last dispensed, or a boolean value indicating if the system is still functioning correctly. These values can then be accessed to read or write by both the Arduino and the mobile app, which are linked by the deviceID. | ||

The Firebase Real Time Database is organized in a tree-like manner where each node is a associated with a number of children nodes, the database object being the root node. In this format, each device is a direct children of the root node, identified by its unique deviceID, and its children are the following attributes: | |||

- ''desiredTemp,'' the desired water temperature set by the user, | |||

- ''currentTemp'', the last recorded water temperature, | |||

- ''pH,'' the last recorded pH, | |||

- ''turbidity'', the last recorded turbidity | |||

- ''desiredFoodMass'', the desired food mass to de dispensed at each cycle of the feeding process, | |||

- ''desiredFoodInterval'', the desired interval at which fishes are fed. | |||

- ''malfunction,'' a boolean indicating if the device is malfunctioning | |||

-''lastFedTime'', the date and time at which the fish have last been fed | |||

== Equations To Model Temperature == | == Equations To Model Temperature == | ||

| Line 582: | Line 636: | ||

Q<sub>ev</sub>/dt is the amount of heat lost due to evaporation. Evaporation will be the main cause of heat loss, and will cause drops below room temperature. Therefor the heater will need to help bring the system back to room temperature. | Q<sub>ev</sub>/dt is the amount of heat lost due to evaporation. Evaporation will be the main cause of heat loss, and will cause drops below room temperature. Therefor the heater will need to help bring the system back to room temperature. | ||

'''Q<sub>ev</sub>/dt = h<sub>fg</sub> * A* (P-P<sub>vapor</sub>)''' | '''Q<sub>ev</sub>/dt = h<sub>fg</sub> * A* (P-P<sub>vapor</sub>) = c2''' | ||

H<sub>fg</sub> is the evaporation heat of water, O the evaporation coefficient, A the surface area and P the humidity ratio. This is specific for each water temperature, which creates a difficult differential equation (as the formula for P is difficult). It is better to take an average value for the temperatures the system will lay around. | H<sub>fg</sub> is the evaporation heat of water, O the evaporation coefficient, A the surface area and P the humidity ratio. This is specific for each water temperature, which creates a difficult differential equation (as the formula for P is difficult). It is better to take an average value for the temperatures the system will lay around. | ||

| Line 588: | Line 642: | ||

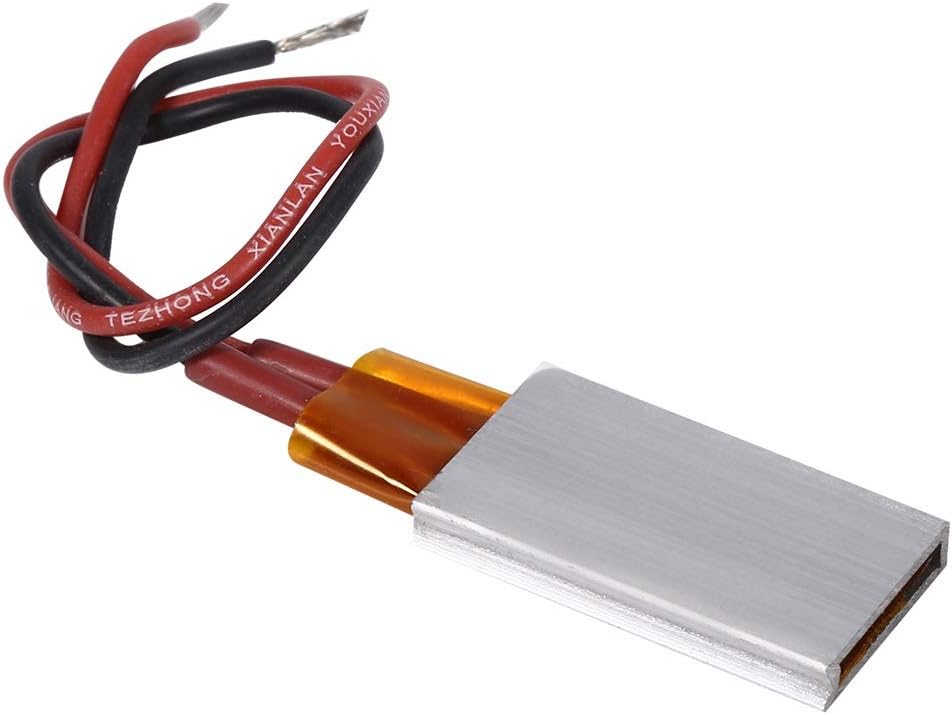

The heater will be able to transfer a certain amount of energy into the tank. For this it will need to heat up and cool down. We can use the formula to predict when to power the heater to end up at the right temperature each time. When the power is switches off, there is an finite amount of heat or energy still left inside the plate, this plate will then cool off until it reaches the same temperature as the water, during which this energy transfers into the water. This could be tested, so the formula is adjusted/shifted. | The heater will be able to transfer a certain amount of energy into the tank. For this it will need to heat up and cool down. We can use the formula to predict when to power the heater to end up at the right temperature each time. When the power is switches off, there is an finite amount of heat or energy still left inside the plate, this plate will then cool off until it reaches the same temperature as the water, during which this energy transfers into the water. This could be tested, so the formula is adjusted/shifted. | ||

'''T(t) = (e^(-k t) P)/(-A U + c k m) + (-c2 + P)/(A U) + e^(-((A U t)/(c m))) ((c2 - P)/(A U) + P/(A U - c k m) + T0 - Te) + Te''' | |||

P is the maximum power of the heater, A the surface area the tank could lose heat through. A bigger tank will lose less heat relative to a smaller tank, as the surface area / volume ratio is bigger. c2 is the energy lost per time due to evaporation. As stated this should be constant for small disturbances in T. Te is the environmental temperature, and T0 the starting temperature. | |||

t=0 gives T0 and t-> inf gives T=Te +(P-c2)/(A U) | |||

A and U can be large, which shows that sufficient power is needed to heat a system to a high temperature. Normally U lays around 10, as air does not take up a lot of heat due to conduction. | |||

The model does not make any sense for t < 0, so this can be left out. For aquarium that remain room temperature, a material like glass should be chosen, as it lets through heat more easily. IF the desired temperature is above room temperature, a strong heater and a different material is needed, like acrylic. Heating for longer periods will eventually reach the limit temperature. | |||

temperature spreading through a body can be described by the heat equation. If u(t,x,y,z) gives the temeprature in time and space, du/dt = a*▼<sup>2</sup> u , with ▼<sup>2</sup> the Laplacian operator. Heat spread can be influenced by a lot of factors, like movement of the water through the tank. Therefor it is hard to estimate the temperature in different parts of the tank. Therefor no exact calculation can be done. As can be seen in the temperature model, it is hard to reach a high temperature/ it will take long. If the heater is heating too much for a short period of time, this wont have any big influence. | |||

The heater plate itself is small in size. When the power of the heater is turned of, the only energy that will still enter the water is that which is already inside the plate, determined by its temperature, specific heat and mass. The temperature could be big, but the mass and specific heat won't be, and so an overshoot will not happen. | |||

== Equations To Model PH == | == Equations To Model PH == | ||

'''pH = -log(H+)''' | '''pH = -log(H+)''' | ||

| Line 660: | Line 728: | ||

'''Q<sub>mass</sub> =''' '''π/4*φ*(D<sub>o</sub><sup>2</sup>-D<sub>i</sub><sup>2</sup>)*S*n/60*ρ''' | '''Q<sub>mass</sub> =''' '''π/4*φ*(D<sub>o</sub><sup>2</sup>-D<sub>i</sub><sup>2</sup>)*S*n/60*ρ''' | ||

Finally, to determine the amount of time t the motor is activated for in seconds, assuming a fixed rotational speed, we divide the needed food mass m by the conveyor capacity: | Finally, to determine the amount of time t the motor is activated for in seconds, assuming a fixed rotational speed, we divide the needed food mass m by the conveyor capacity: | ||

| Line 672: | Line 738: | ||

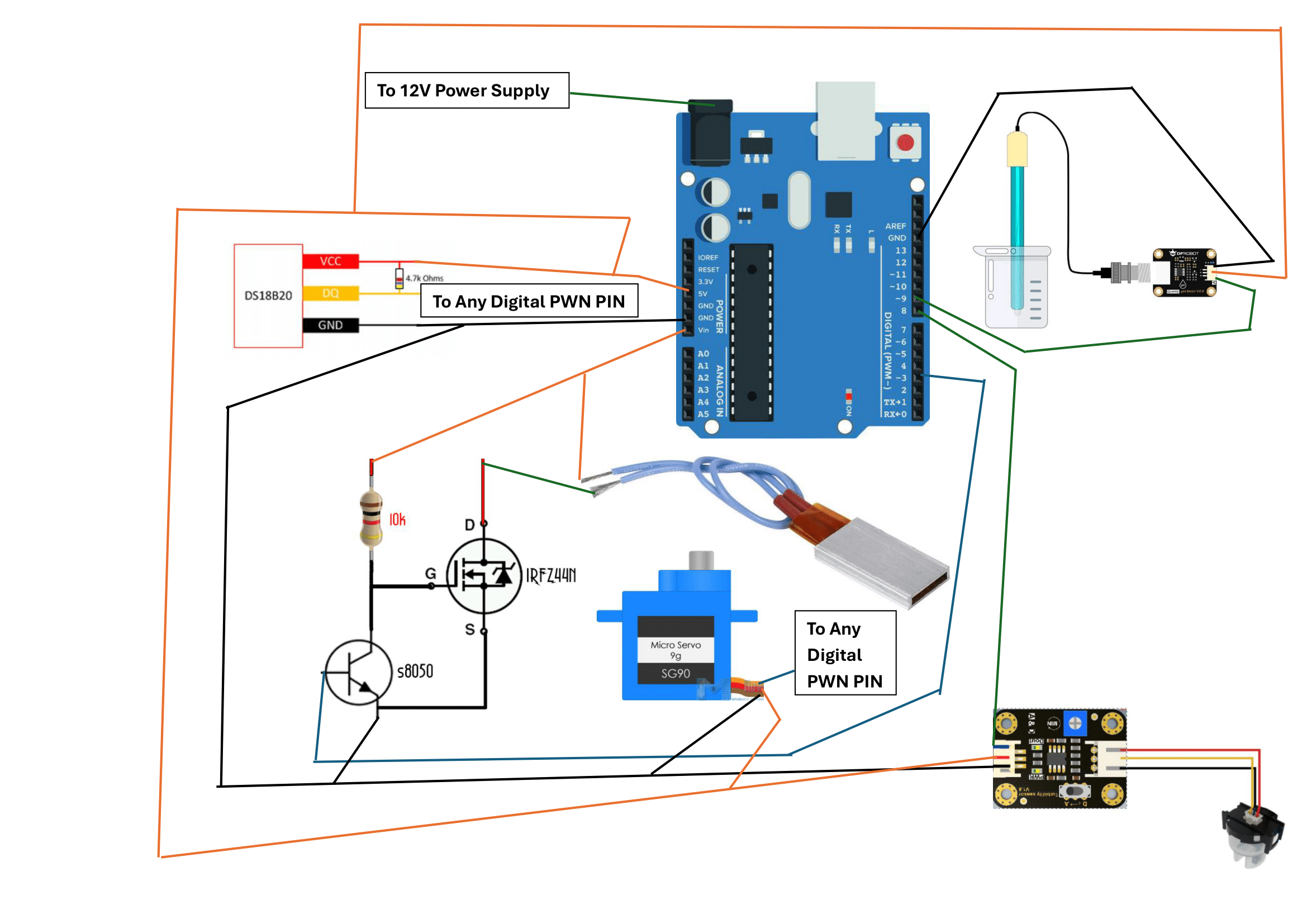

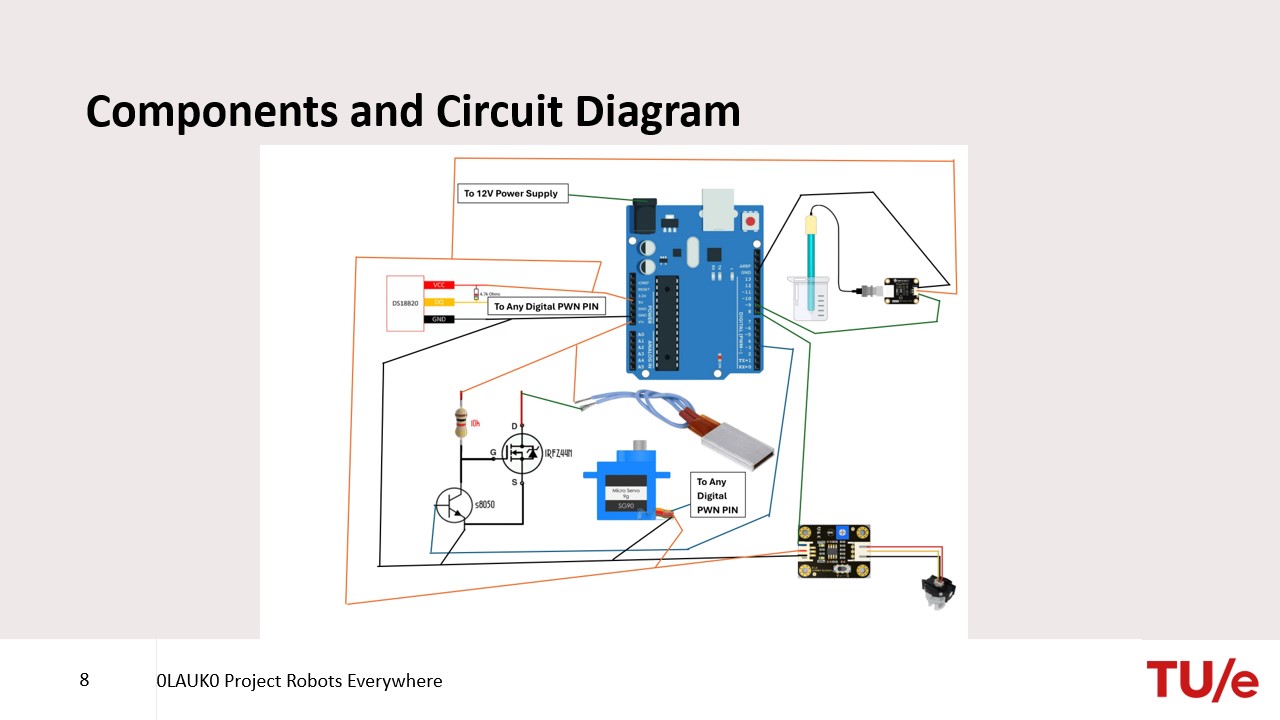

== Circuit Diagram == | == Circuit Diagram == | ||

work | [[File:Circuit Diagram.png|thumb|475x475px|Circuit Diagram]] | ||

To work the whole system, different compoents are invovled. For the PID control a S8050 npm transistor was used with the left terminal being connected to a 10k ohm resistor to the VIN pin (to get 12V power supply) and the gate of the IRFZ44N mosfet. The middle terminal was chosen to be connected to the digital PWN pin 2 and the right terminal is connected to the source of the mosfet. The mosfets drain is connected to one terminal of the 12V heeating plate and the other temrinal of the heating plate is also connected to the VIN pin for 12V power supply. The other components such as the turbidity sensor, servo motor and the ph sensor were connected as expected to the arduino with one wire to a common ground (shared on a breadboard taken from the Arduino) and another wire to a common 5V output (shared on a breadboard taken from the Arduino) and the last wire to a chosen digital PWN pin on the arduino. The temperature sensor was a little different, the ground was connected to the common ground (shared on a breadboard taken from the arduino) however in between the 5V pin of the temperature sensor and the data pin there was a 4.7k ohm resistor placed to allow the temperature sensor to "read the data" and then the data pin was connected to any digital PWN pin and the 5V pin was connected to the common 5V channel on the breadboard. | |||

== Power Source == | == Power Source == | ||

The power source that will be used for this project depends on factors around the specification of the project as well as the parts that are going to be used in order to create the final prototype. We specify the constraints that will determine what kind of power source will be appropriate for this project below. | The power source that will be used for this project depends on factors around the specification of the project as well as the parts that are going to be used in order to create the final prototype. We specify the constraints that will determine what kind of power source will be appropriate for this project below. | ||

| Line 684: | Line 750: | ||

- temperature sensor | - temperature sensor | ||

- Turbidity sensor | - Turbidity sensor | ||

| Line 693: | Line 757: | ||

The microcontroller chosen will be a variant of the Arduino board, Arduino boards including both nano and uno require a minimum input voltage of 7V and a maximum of 12V. Arduino uno models all have a 5V output pin as well as 3.3V pins. The pH, turbidity and ammonia sensors can all operate with 5V minimum however the temperature sensor can operate using just the 3.3 volt pin. Based on these power requirements, we can power all of the sensors in two configurations, either powering all of the sensors in parallel off the 5V pin or powering all sensors but the temperature sensor with 5V pin while powering the temperature sensor with the 3.3V pin. This can be done on all uno boards, some IoT nano boards however only have a 3.3V pin, these can hence not be used. | The microcontroller chosen will be a variant of the Arduino board, Arduino boards including both nano and uno require a minimum input voltage of 7V and a maximum of 12V. Arduino uno models all have a 5V output pin as well as 3.3V pins. The pH, turbidity and ammonia sensors can all operate with 5V minimum however the temperature sensor can operate using just the 3.3 volt pin. Based on these power requirements, we can power all of the sensors in two configurations, either powering all of the sensors in parallel off the 5V pin or powering all sensors but the temperature sensor with 5V pin while powering the temperature sensor with the 3.3V pin. This can be done on all uno boards, some IoT nano boards however only have a 3.3V pin, these can hence not be used. | ||

The prototype also requires additional components that will draw power outside of the sensors. These components are the heater plate as well as the servo motor. The servo motor requires 5V of power and can hence be connected to the 5V pin as well along with the other sensors. The heater plate requires 12V of power meaning that it cannot be powered by the Arduino. The heater needs to be powered by an external power supply. It is a possibility to use a step up buck convertor to convert the 5V input to 12V but then the current drawn by the 5V pin would exceed the | The prototype also requires additional components that will draw power outside of the sensors. These components are the heater plate as well as the servo motor. The servo motor requires 5V of power and can hence be connected to the 5V pin as well along with the other sensors. The heater plate requires 12V of power meaning that it cannot be powered by the Arduino. The heater needs to be powered by an external power supply. It is a possibility to use a step up buck convertor to convert the 5V input to 12V but then the current drawn by the 5V pin would exceed the Arduino’s limit potentially and also buck convertors generate a lot of heat under such intense application which would not be desirable. | ||

A good solution in order to power the entire circuit would be to power both the Arduino and it’s connected sensors and components as well as the heater in parallel. This can be done as both the Arduino as well as the heater can take 12V of power. The maximum rating of the Arduino is 12V, hence the rating can be met. | A good solution in order to power the entire circuit would be to power both the Arduino and it’s connected sensors and components as well as the heater in parallel. This can be done as both the Arduino as well as the heater can take 12V of power. The maximum rating of the Arduino is 12V, hence the rating can be met. | ||

There are two ways to power the entire circuit and they depend on the use cases, one would be if the product can be connected to a power outlet, in that case it would be possible to use a cheap 12 V 2A barrel connector power supply that can be connected to the wall. The cable would need to be sliced and an additional wire would need to be soldered to the power supply in order to power the heater plate in parallel. Another possibility could be to use a pack or rechargeable cells that have a total power output of 12V. This could be done using regular alkaline battery cells/ rechargeable cells in parallel. Another solution could be to use a Li-Po battery pack however these would require a BMS circuit in order to prevent the battery from overcharging and undervoltage problems. | There are two ways to power the entire circuit and they depend on the use cases, one would be if the product can be connected to a power outlet, in that case it would be possible to use a cheap 12 V 2A barrel connector power supply that can be connected to the wall. The cable would need to be sliced and an additional wire would need to be soldered to the power supply in order to power the heater plate in parallel. Another possibility could be to use a pack or rechargeable cells that have a total power output of 12V. This could be done using regular alkaline battery cells/ rechargeable cells in parallel. Another solution could be to use a Li-Po battery pack however these would require a BMS circuit in order to prevent the battery from overcharging and undervoltage problems. | ||

== Acceptance test plan == | |||

Requirements 1, 3, 5, 7, 14, 15 and 27 are internal to the already existing components and are therefore satisfied, since the components have been chosen based on them. | |||

Requirements 7, 8, 13, 23 and 24 are could haves and were not implements. They are still included in the test plan for completeness. | |||

{| class="wikitable" | |||

!ID | |||

!Description | |||

!Precondition | |||

!Action | |||

!Expected Output for Success | |||

|- | |||

|R2 | |||

|The system senses pH at intervals of at most 1 minute | |||

|The system is correctly positioned with the pH sensor submerged in water, and the system is powered. | |||

|Pour pH product in the water, and monitor the pH value on the app. | |||

|The pH value changed after at most 60 seconds. | |||

|- | |||

|R4 | |||

|The system senses temperature at intervals of at most 1 minute | |||

|The system is correctly positioned with the temperature sensor submerged in water, and the system is powered. | |||

|Pour boiling water in the tank, and monitor the temperature value on the app. | |||

|The temperature value changed after at most 60 seconds. | |||

|- | |||

|R6 | |||

|The system senses turbidity at intervals of at most 1 minute | |||

|The system is correctly positioned with the turbidity sensor submerged in water, and the system is powered. | |||

|Pour some colored powder (e.g. coffee powder) in the water, and monitor the temperature value on the app. | |||

|The turbidity value changed after at most 60 seconds. | |||

|- | |||

|R8 | |||

|The system senses ammonia at intervals of at most 1 minute | |||

|The system is correctly positioned with the ammonia sensor submerged in water, and the system is powered. | |||

|Pour ammonia solution in the water, and monitor the ammonia value on the app. | |||

|The ammonia value changed after at most 60 seconds. | |||

|- | |||

|R9 | |||

|The sensors have IPx8 water resistance | |||

|None | |||

|Submerge the sensors in water for an hour. | |||

|The sensors show no water damage or moisture on them, and they output the correct values. | |||

|- | |||

|R10 | |||

|The system always stabilizes the water temperature at at most 3 ° C below the temperature set by the user, | |||

assuming this temperature is between 10° C and 30° C, the room temperature is at least 25° C | |||

|The room temperature is at least 25° C, and the system is powered. | |||

|Set a desired temperature on the app between 10° C and 30° C, and monitor the temperature value on the app. | |||

|The water temperature increases continuously before staying higher than ''desiredTemperature'' - 3. | |||

|- | |||

|R11 | |||

|The system dispenses the quantity of food specified by the user, with an precision of ± 0.25g | |||

|The food container contains at least the quantity specified in the app, and the system is powered. | |||

|Input a desired food quantity in the app, with a small feeding interval (e.g 1 min). Collect the dispensed food and weigh it. | |||

|The mass of the dispensed food is between ± 0.5g of the given interval. | |||

|- | |||

|R12 | |||

|The system dispenses food a the interval specified by the user | |||

|The food container contains at least twice the quantity specified in the app, and the system is powered. | |||

|Input a desired food quantity and feeding interval in the app. Start a timer when the food is dispensed a first time, and stop it when the food is dispensed a second time. | |||

|The measured interval is equal to the one specified in the app. | |||

|- | |||

|R13 | |||

|The system keeps the pH within ± 0.5pH of the value specified by the user | |||

|The system is correctly positioned with the temperature sensor submerged in water, and the system is powered. | |||

|Set a desired pH in the app | |||

|The pH increases/decreases continuously before staying within ± 0.5pH of the desired value | |||

|- | |||

|R16 | |||

|The heater plate has IPx8 water resistance | |||

|None | |||

|Submerge the heater plate in water for an hour. | |||

|The heater plate shows no water damage or moisture on it, and still produces heat. | |||

|- | |||

|R17 | |||

|The app displays the last registered water parameter values | |||

|The system is correctly positioned with the sensors submerged in water, the system is powered and connected to a computer. | |||

|Add a line in the code to print the water parameters when they are sensed, then run the program. | |||

|The pH, temperature and turbidity values in the app are the same than the respective one printed on the computer. | |||

|- | |||

|R18 | |||

|The app allows the user to preset water parameters | |||

|None | |||

|Add an aquarium in the app and open its dashboard page. Fill the desired temperature. Close the app, open it again and go back to the aquarium dashboard. | |||

|The previously filled in value is still in the app, and is enforced by the system (see R10) | |||

|- | |||

|R19 | |||

|In case of abnormal value, the app sends a notification to the user | |||

|The system is correctly positioned with the sensors submerged in water, and the system is powered. | |||

|Register the aquarium in the app. Then pour boiling/cold water, pH product or colored powder in the water, open the notification panel of the aquarium in the app. | |||

|A push notification appears on the phone, with a message containing the corresponding abnormal parameter. The notification also appears in the panel. | |||

|- | |||

|R20 | |||

|The app allows the user to set food quantity and frequency | |||

|None | |||

|Add an aquarium in the app and open its dashboard page. Fill the desired feeding quantity and interval. Close the app, open it again and go back to the aquarium dashboard. | |||

|The previously filled in values are still in the app, and are enforced by the system (see R11, R12) | |||

|- | |||

|R21 | |||

|The app displays the time the fish have last been fed | |||

|The system is powered. | |||

|Add an aquarium in the app and open its dashboard page. Fill the desired feeding quantity and interval. Monitor the value displayed in the "last feeding time" field. Wait for the device to dispense food, monitor the current time and look at the value again. | |||

|The "last feeding time" value changed and now displays the time when the food was dispensed. | |||

|- | |||

|R22 | |||

|In case of abnormal values, the app displays information on how to fix the problem | |||

|The system is correctly positioned with the sensors submerged in water, and the system is powered. | |||

|Register the aquarium in the app. Then pour boiling/cold water, pH product or colored powder in the water, open the notification panel of the aquarium in the app. | |||

|The push notification and the notification in the panel display a message on how to fix the corresponding problem. | |||

|- | |||

|R23 | |||

|The app has different parameter presets for cold water and tropical fish | |||

|None | |||

|Add an aquarium in the app and open its dashboard page, then the preset button, and choose a fish type. | |||

|The displayed desired water parameters have changed for the ones of the chosen fish type, and these parameters are enforced by the system (see R10, R13) | |||

|- | |||

|R24 | |||

|The app displays information on different species of fish | |||

|None | |||

|Add an aquarium in the app and open its dashboard page, then the information button, and choose a fish species. | |||

|Information on the chosen fish species is displayed | |||

|- | |||

|R25 | |||

|The main case have IPx4 water resistance | |||

|The case is closed. | |||

|Spray water from all directions on the main case for 10 minutes. | |||

|The inside of the case contains no water, and does not show signs of discoloration, deformation, or other physical changes. | |||

|- | |||

|R26 | |||

|The wires have IPx8 water resistance | |||

|None | |||

|Submerge the wires in water for an hour, leaving both ends above the surface. | |||

|The wires show no water damage or moisture on it, and the wire still transmits current. | |||

|- | |||

|R28 | |||

|The system can easily and safely be attached to any cover-less, rectangular tank at least 15cm deep | |||

|None | |||

|Position the system on a cover-less, at least 15cm deep rectangular tank | |||

|The system stays horizontal and does not move. | |||

|} | |||

== Implementation and Testing == | |||

After printing the 3d model, we sanded the parts and glued them together. We then attached the sensors to the case by putting them through their corresponding hole and gluing them with waterproof sealant, before we tidied the wires and attached them together. We also drilled a hole for the Arduino power jack and the sensors and motor wires. After that we calibrated the sensors to get the correct values. | |||

[[File:Prototypee.jpg|thumb|800x800px|The prototype on a box simulating a fish tank (the tape is temporary while waiting to glue the lid)]] | |||

==== Testing ==== | |||

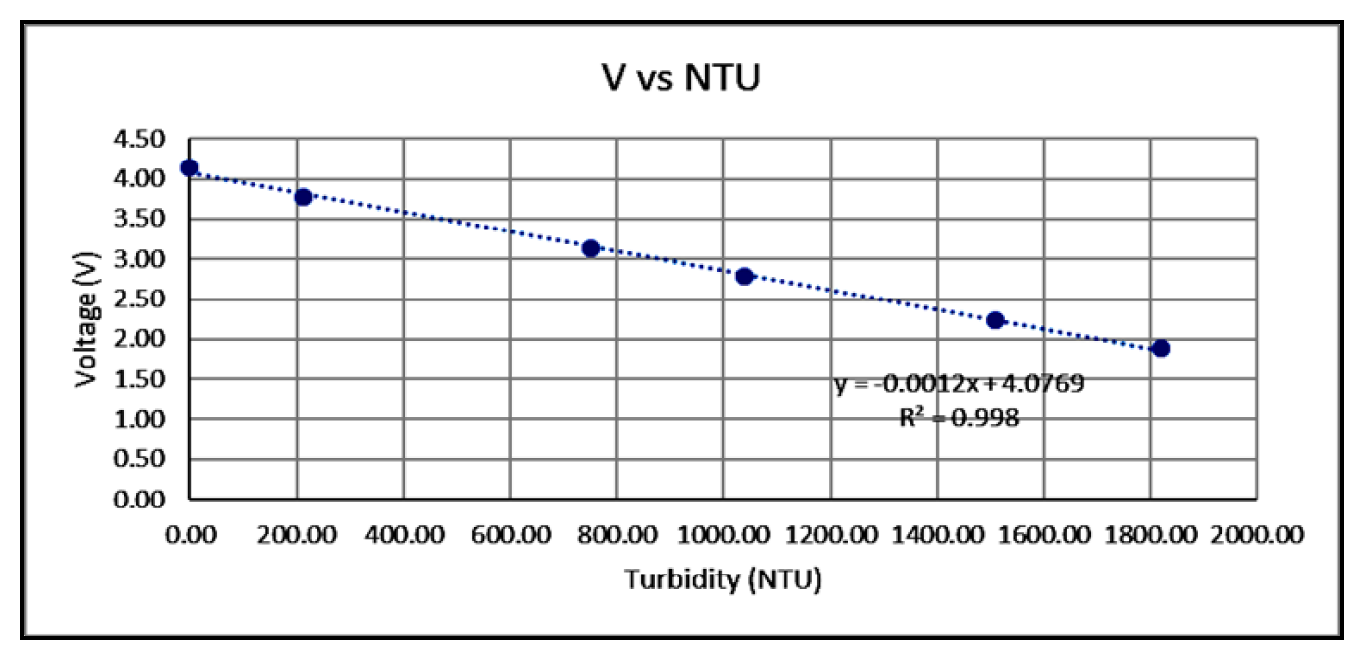

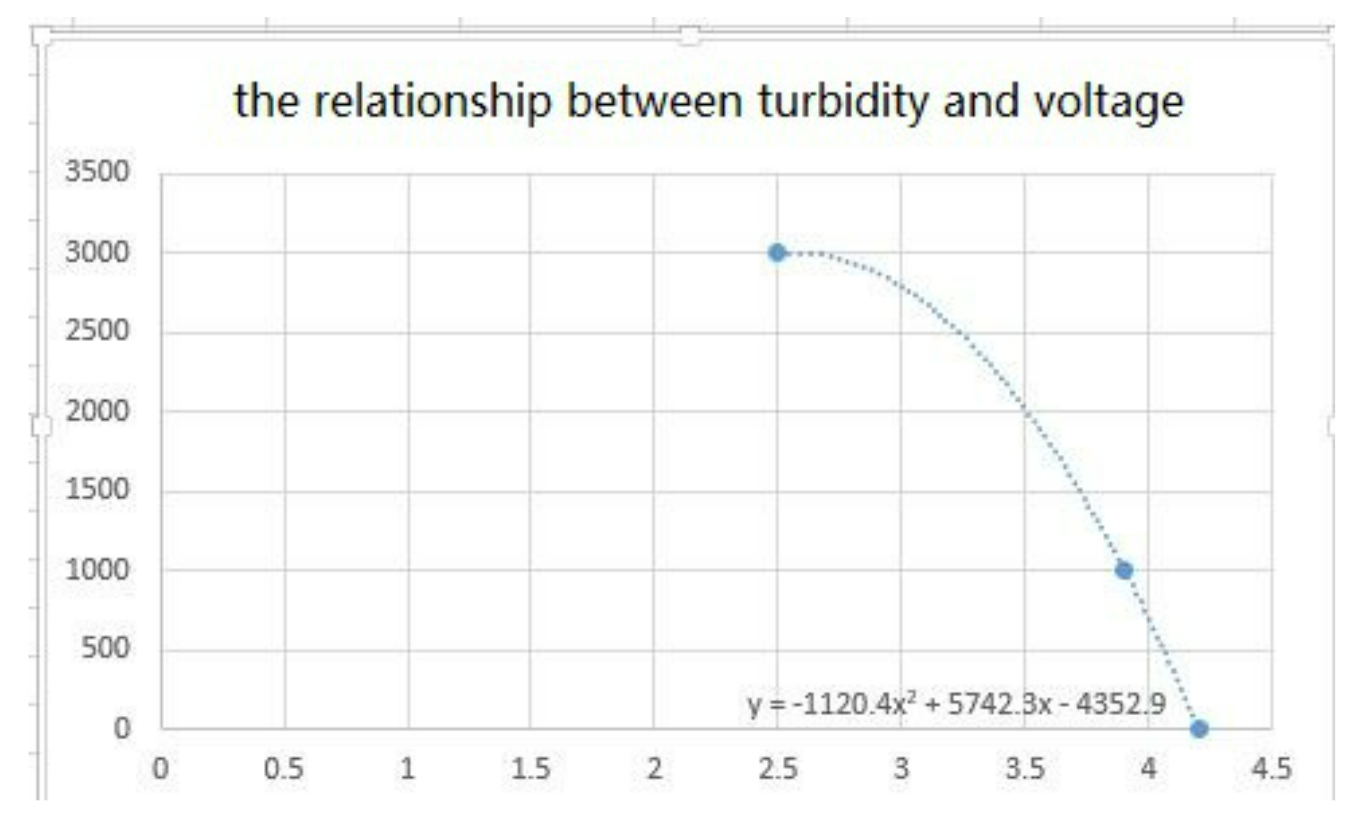

Most of the requirements (2, 4, 9, 12 ,16, 17, 18, 19, 20, 21, 22, 25, 26, 28) were satisfied at the first testing iteration, however more work was needed to satisfy 6, which is the turbidity sensing. | |||

This was due to the fact that the turbidity sensor was really sensitive which made the output values very inconsistent, independent of the actual water cleanliness. After trying the different relationships between the actual turbidity and the output voltage, we finally reached coherent results. The testing was done by progressively pouring coffee powder in the water. | |||

Requirement 10 was difficult to test because the heating process takes a long time in a real sized fish tank. This is due to the relatively low power of the heater plate, which is rather undersized for the kind of aquariums we are aiming for. Due to time constraints we decided to test is in a smaller water volume (4L) and use the equations described before to estimate the heating time in a real fish tank environment. Our estimation is that for a normal sized tank (40L), it would take approximately 1.5h to heat the aquarium by 1°C at around 24°C. This seems rather long but is actually better for the fish, as it would reduce the risk of thermal shock. Nonetheless, a more powerful heater would have given more adaptability and scalability of the system. | |||

Requirement 11 is on the food actual quantity dispensed compared to the value specified by the user in the app. Because fish usually require very low quantities of food, the dosage needs to be precise, so we decided to do 10 tests with different values. We used the equation described above to compute the time the motor has to rotate for. We measured the loading ratio, diameters and blade pitch and imputed them in the equation, but changed the values several times to get more accurate results. These are the results we got after tweaking the parameters, with a precise scale: | |||

{| class="wikitable" | |||

|+ | |||

!Expected value (g) | |||

!Actual value (g) | |||

|- | |||

|0.5 | |||

|0.74 | |||

|- | |||

|0.75 | |||

|0.96 | |||

|- | |||

|1 | |||

|1.17 | |||

|- | |||

|1.25 | |||

|1.48 | |||

|- | |||

|1.5 | |||

|1.72 | |||

|- | |||

|1.75 | |||

|1.89 | |||

|- | |||

|2 | |||

|1.90 | |||

|- | |||

|2.25 | |||

|2.34 | |||

|- | |||

|2.5 | |||

|2.34 | |||

|- | |||

|2.75 | |||

|2.53 | |||

|- | |||

|3 | |||

|2.78 | |||

|} | |||

This makes the mean absolute difference between the expected and actual value 0.2g, which is smaller than 0.25. Moreover no absolute difference exceeded 0.25g, so the requirement is satisfied. | |||

== Discussion and Conclusion == | |||

The goal of this project was to demonstrate that, although there is none on the market yet, it is possible to create an all-in-one aquarium manager robot. Our prototype achieves water monitoring, autonomous feeding, and water heating, all of this controlled by a mobile app, meaning that is actually improves the existing solutions in the market. It firstly took us some time to decide on the actual scope of the project, and we had to make several iterations and design decisions such as which water parameters to monitor and control, but we finally made a design that addressed the most important problems of fish tank managing and automating. We managed to physically implement all of the must and should have requirements and test them, all of this supported by litterature and physical equations. Moreover the final prototype should be relatively cheap, especially compared to the other products on the market, since the parts costed us around €150, which could be reduced by scale economies of scale if it were to be mass produced. The prototype nonetheless presents a few limitations. | |||

==== Limitations ==== | |||

The most important possible improvement of the system would be to automate other parameters such as the pH. However as stated above pH is quite hard to automate as it requires a lot of precaution and a lot more hardware such as pumps, which is not worth it considering that it only needs to be done once in a while, and often with a water change. A more feasible improvement would be to monitor the other parameters that we studied, such as ammonia or dissolved oxygen. This would give the user a more complete overview of the state of the tank, though it would make the system significantly for expensive, at least a few hundred euros more, as this is the price for the needed sensors. However, it would be relatively easy to add these functionalities, as most of the implementation could be reused from the other sensors. The Arduino and App code would be almost exactly the same, and our database design is easily expandable. Only the calibrating equations would have to be figured out. | |||

Another limitations of the current prototype is the heater plate. Because we wanted to power it together with the Arduino, we chose a small one with limited power. This causes the water to heat up quite slowly, which is not necessarily bad as it prevents thermal chocks. However this impacts the adaptability of the system, especially for larger tanks, as now the heater needs to always be on full power to be efficient. A larger plate would be a significant improvement to the system, however it would require a larger power supply, probably independent of the Arduino's, which would increase the cost and make the device larger. | |||

Moreover, another good improvement would be a notification on the app when the food container is nearly empty. This would make the system even more autonomous, since the user won't have top check regularly the food level. However to be require some sort of pressure or weight sensor in the funnel to check the amount of remaining food, which would be difficult to implement due to the steep slope of the funnel and the fact that the food is quite light, making it difficult to sense small amount of it. Another option would be to compute the total capacity of the container and substract the dispensed quantity, but this would require a) that the user always refills the container entirely, which is not guaranteed, b) that the amount of food dispensed is exactly as expected, and c) that the user indicated on the app that they have refilled the container. | |||

Finally, a limitation in our approach is the lack of feedback from potential users. Even though we made a survey to determine user needs, it only has a few answer, and me way need specific feedback from more involved people, such as fish shop employees or fish hobbyists. This would confirm or invalidate our assumptions on the most needed functionalities for our product.To address, this problem, it would be nice to support the technical tests with usability tests in order to get feedback from actual users and improve the design. | |||

==== Conclusion ==== | |||

During this project, we have explored in depth the issues in fish tank automating, which is way deeper than it seems as it involves many different areas and subjects. We had to learn about which water parameters affect the quality of life of fish, what are their suitable ranges, how to control them and which physical equations control them. We also learned a lot on databases, wi-fi communication, and application design and building. This multidisciplinary aspect of the project made it very interesting and engaging, though also quite challenging, as we had to gain knowledge in computer science, physics and biology at the same time, while also having the requirements of delivering a complete, working physical prototype. The initial idea was very broad and ambitious, and we did not implement every idea we had at the beginning, and an important part of the challenge was to decide on the scope and functionalities of the product. | |||

Our final prototype successfully addressed the main functionalities to automate a fish tank, combining hardware building and experimenting, physical theory and software design. We believe that it makes a significant improvement in the area by relieving the user from the most frequent and important tasks, which are now automated, while ensuring a good care of the animals. We also make all of this easy and intuitive for the user with the help of the app. All of this addresses our original problem of making fish caring easy and accessible to people with skills and time limitations. Furthermore, we think that it brings a lot of novelty on the market since there is simply no other device that monitors the water while controlling the temperature and also feeding the fish, all controlled by a mobile app. To improve it further, we suggest to conduct more testing and surveys from prototype user to improve it and make it for suitable to real situations. | |||

== Final Presentation == | |||

[[File:PresSlide2.jpg|thumb|391x391px]] | |||

[[File:PresSlide1.jpg|left|thumb|391x391px]] | |||

[[File:PresSlide3.jpg|left|thumb|391x391px]] | |||

[[File:PresSlide4.jpg|thumb|391x391px]] | |||

[[File:PresSlide6.jpg|thumb|391x391px]] | |||

[[File:PresSlide5.jpg|left|thumb|391x391px]] | |||

[[File:PresSlide7.jpg|left|thumb|391x391px]] | |||

[[File:PresSlide8.jpg|thumb|391x391px]] | |||

[[File:PresSlide10.jpg|thumb|391x391px]] | |||

[[File:PresSlide9.jpg|left|thumb|391x391px]] | |||

[[File:PresSlide11.jpg|left|thumb|391x391px]] | |||

[[File:PresSlide13.jpg|none|thumb|391x391px]] | |||

_____________________________________________________________________________________________________________________________________ | |||

== Sources With Summaries == | == Sources With Summaries == | ||

| Line 935: | Line 1,284: | ||

|- | |- | ||

|Mara | |Mara | ||

| | |Feedback session (0.5 hrs), Research for app(2 hrs), Worked on the design in Figma (4 hrs) | ||

| | |6.5 | ||

|- | |- | ||

|Aseem | |Aseem | ||

| Line 985: | Line 1,334: | ||

|- | |- | ||

|Mara | |Mara | ||

| | |Research on app development (2hrs), App development (5hrs), Meeting session (1 hrs) | ||

| | |8 hrs | ||

|- | |- | ||

|Aseem | |Aseem | ||

|Feedback session (0.5 hrs), meeeting (1 h), research on pH regulation for fish tanks (2 h), arduino code review (1 h), research on PDI for temperature control (5 hrs) | |Feedback session (0.5 hrs), meeeting (1 h), research on pH regulation for fish tanks (2 h), arduino code review (1 h), initial research on PDI for temperature control (5 hrs) | ||

| | |9.5 hrs | ||

|- | |- | ||

|Adrien | |Adrien | ||

|Feedback session (0.5 hrs), meeting (1 h), research on feeding mechanism (5h), formalize requirements (6h) | |Feedback session (0.5 hrs), meeting (1 h), research on feeding mechanism (5h), formalize requirements (6h) | ||

|12. | |12.5 hrs | ||

|- | |- | ||

|Nout | |Nout | ||

|feedback (0.5h), theory research and formula work(11h) | |feedback (0.5h), theory research and formula work(11h) | ||

|11. | |11.5 hrs | ||

|- | |- | ||

|Sanshray | |Sanshray | ||

|Conceptual Designing (4 hrs), Design Sketches (1 h), Component prototype modelling (8 hrs) | |Conceptual Designing (4 hrs), Design Sketches (1 h), Component prototype modelling (8 hrs) | ||

| | |13 hrs | ||

|- | |- | ||

| rowspan="6" |5 | | rowspan="6" |5 | ||

|Saqib | |Saqib | ||

| | |Feedback session (0.5 hrs), Meeting session (1.5 hrs), Learning about Firebase and the realtime Database (2 hrs), Implementing PID in code (2 hrs), Implementing connecting Arduino to Firebase via WIFI (2 hrs), Ziegler and Nichols Tuning Methods Learning (1 hrs) | ||

| | |9 hrs | ||

|- | |- | ||

|Mara | |Mara | ||

| | |Meeting session(1.5 hrs), App designs (features related to the design of the app using Photoshop) (1hrs), App development (6.5 hrs) | ||

| | |9 hrs | ||

|- | |- | ||

|Aseem | |Aseem | ||

| | |Feedback session (0.5 hrs), learning systems and control, PID and tuning (8 hrs), | ||

| | |8.5 hrs | ||

|- | |- | ||

|Adrien | |Adrien | ||

| | |Feedback session (0.5 hrs), Meeting session (1.5 hrs), Research on Firebase and realtime Database (3hrs), working on the app backend (4hrs) | ||

| | |9 hrs | ||

|- | |- | ||

|Nout | |Nout | ||

| | |Feedback session(0.5 hrs), Temperature modelling and plotting (8 hrs) | ||

| | |8.5 hrs | ||

|- | |- | ||

|Sanshray | |Sanshray | ||

| | |Feedback session(0.5 hrs), prototyping (7hrs) | ||

| | |7.5 hrs | ||

|- | |- | ||

| rowspan="6" |6 | | rowspan="6" |6 | ||

|Saqib | |Saqib | ||

| | |Feedback session (0.5 hrs), Meeting session (1 hrs), Worked on building circuit for PID and temperature (6 hrs), Verified and checked components and circuit for PH and turbidity (4.5 hrs) | ||

| | |12 hrs | ||

|- | |- | ||

|Mara | |Mara | ||

| | |App development (10hrs), Final presentation (0.5 hrs) | ||

| | |10.5 hrs | ||

|- | |||

|Aseem | |||

|Feedback session (0.5 hrs), Worked on building circuit for PID and temperature (6 hrs), research for arduino pinout and powering system in stand-alone mode and laptop connected (4 hrs) | |||

|11.5 hrs | |||

|- | |||

|Adrien | |||

|Feedback session (0.5 hrs), Meeting session (1 hrs), Database (2hrs), Connecting Arduino to Firebase (3hrs), Final presentation (4hrs) | |||

|10.5 hrs | |||

|- | |||

|Nout | |||

|feedbck session (0,5 hrs), improving wiki (5 hrs), waterproofing research (3 hrs) | |||

|8.5 hrs | |||

|- | |||

|Sanshray | |||

|Feedback session(0.5 hrs), circuit implementation(5 hrs), physical prototype construction(4 hrs) | |||

|9.5 hrs | |||

|- | |||

| rowspan="6" |7 | |||

|Saqib | |||

|Feedback session (0.5 hrs), Meeting and working in innovation space (4.5 hrs), Implementing code (5 hrs), Circuit diagram (1 hrs) | |||

|11 hrs | |||

|- | |||

|Mara | |||

|Feedback session(0.5 hrs), Implemented code (9hrs) | |||

|9.5 hrs | |||

|- | |||

|Aseem | |||

|Feedback session (0.5 hrs), Meeting and working in innovation space (4.5 hrs), assemble product (3 hrs) | |||

|8 hrs | |||

|- | |||

|Adrien | |||

|Feedback session (0.5 hrs), Meeting and working in innovation space (4.5 hrs), Connecting Arduino to Firebase (2 hrs), App coding (6 hrs), Building prototype (4hrs) | |||

|17 hrs | |||

|- | |||

|Nout | |||

|Feedback session (0.5 hrs), meeting (2 hrs), working on presentation (3 hrs), improving wiki (4 hrs) | |||

|9.5 hrs | |||

|- | |||

|Sanshray | |||

|Feedback session(0.5 hrs), Cad modelling(3 hrs), assembling final product in innovation space(6 hrs) | |||

|9.5 hrs | |||

|- | |||

| rowspan="6" |8&9 | |||

|Saqib | |||

|Connecting parts, creating product, glueing, soldering, optimizing code and paramters (feeding, temperature), testing, presentation work, demo video (15 hrs), Wiki Cleanup (2 hrs) | |||

|17 hrs | |||

|- | |||

|Mara | |||

|Prepared slides final presentation (4hrs), presentations session(2hrs), Preparation final presentation (2hr) | |||

|8 hrs | |||

|- | |- | ||

|Aseem | |Aseem | ||

| | |Working in innovation space on final product (assembly, tweaking, optimizing, testing etc.) (15 hrs), presentation session (2 hrs) | ||

| | |17 hrs | ||

|- | |- | ||

|Adrien | |Adrien | ||

| | |Working in innovation space on final product (assembly, tweaking, optimizing, testing etc.) (6 hrs), Shooting video demo (5 hrs), App coding (12 hrs), presentation session (2 hrs), working on wiki page (8 hrs) | ||

| | |33 hrs | ||

|- | |- | ||

|Nout | |Nout | ||

| | |working on wiki page (6hrs) | ||

| | |6hrs | ||

|- | |- | ||

|Sanshray | |Sanshray | ||

| | |Feedback session(0.5 hrs), assembling final product(8 hrs), testing final product(3 hrs), recording video(2 hrs), presentation session (2 hrs) | ||

| | |15.5 hrs | ||

|} | |} | ||

Latest revision as of 00:40, 12 April 2024

Members

| Name | Student ID | |

|---|---|---|

| Aseem Mahamood | 1789767 | a.mahamood.aseem@student.tue.nl |

| Sanshray Malhotra | 1792318 | s.malhotra1@student.tue.nl |

| Nout Van Bommel | 1842110 | n.g.h.v.bommel@student.tue.nl |

| Saqib Khan | 1783432 | s.a.s.khan@student.tue.nl |

| Mara Pop | 1671820 | m.pop@student.tue.nl |

| Adrien Verriele | 1710303 | a.a.m.verriele@student.tue.nl |

Introduction

Problem Statement: