PRE2020 4 Group6: Difference between revisions

TUe\20192010 (talk | contribs) |

TUe\20182078 (talk | contribs) |

||

| (154 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

=Group members= | |||

{| border="1" cellpadding="2" | {| border="1" cellpadding="2" | ||

|---- | |---- | ||

| Line 31: | Line 33: | ||

The following concept was the basis on which we started designing. (Of course, things change during development when new insight or limitation come to light. But this is normal when designing a larger project and it shows that we have learned new things, based on which adaptations are made.) | The following concept was the basis on which we started designing. (Of course, things change during development when new insight or limitation come to light. But this is normal when designing a larger project and it shows that we have learned new things, based on which adaptations are made.) | ||

The idea is to create a smart plant system that notifies the user if the plant needs more water or more or less sunlight. The target group is a social workspace or carehouse for mentally disabled people, Down syndrome in particular. These people can see or hear when a plant needs attention and get that plant what it needs. The mentally disabled will therefore do something useful (taking care of plants) which is valuable to them and the surroundings. The caretakers in this social workspace will also get work relief because of this system because they don’t have to tell the impaired person what to do with the plants anymore. The plant pot will probably get a nice face so that it looks friendly. It will need water sensors implemented in the soil and light sensors around the plant to monitor the amount of light the plant gets. The pot will also give positive feedback when given water or sunlight. | |||

=Approach= | |||

In order to realize this idea, a well-structured approach need to be made and followed. First a schedule and a plan was made together with a global task-division, the plan, task-division and logbooks can be found in Appendix A. Then the goals were defined to make sure we had something to work to. To broaden our perspective of our target audience we did literature study on several subjects, from articles of the state-of-the-art, to information on plants and their effects on humans and of course articles on our target audience: people with Down Syndrome. | |||

The next step was to make analyze whether our idea had purpose for user, society and enterprise and how to improve our idea on their needs and preferences. When we had a clear vision about the goals and the target audience the technical part could begin. We had to make a list of requirements, preferences and constrains of our idea and future-prototype so that we could finally start building it. | |||

Before the actual assembling, a list of electrical components needed to be made as well as a design for the housing, software and hardware. So that finally the hardware would be ordered and assembled, the housing could be printed and the software would be coded and thus the prototype could be made. | |||

Parallel to the technical part, we still needed to test whether our design in the end would have the effect on the user, society and enterprise as we wanted it to have. We decided that the user was the most important of those three and thus we contacted actual care houses if we could place our prototype in their house for a few days or a week to see whether our design would have potential for a real manufactured product. | |||

We needed to address also the enterprise-part of the process in order to gain publicity. In the first place this was necessary for us to convince care houses that our prototype was worth testing. However, in the second place, in a real assemble process, you need costumers and sponsors before the prototype can actually be made. | |||

The point came where we finished assembling two prototypes and we had found two different care houses where we could test our prototype, now named Fleur. Therefore an experiment was set-up and a hypotheses must be written. After the test week, the results needed to be processed and a conclusion and discussion on the test and on the whole process should be made. And last but not least the presentation to our colleagues and tutors must be prepared and given. | |||

Every step of the way will be discussed in much detail in this Wikipedia page. | |||

=Goals= | |||

To make a successful project and in the end prove that the design was successful (or not), we need to define clear and measurable goals. Besides this, we need to think about how the achievement of these goals will be proven. | |||

'''Our main goal''' is to add something to the daily lives of people with DS. We want to give them a way to spend their time, and give them something to care for. Interacting and caring for the plant should be a hobby, something that they enjoy doing and spending time on. This is a beautiful idealistic goal that improves the wellbeing of these people and can therefore be marketed as a healthcare product that could even be covered by healthcare insurance. | |||

This can be measured by keeping track of how much time is spent interacting with our pot compared to a control plant that does not have our systems attached to it. Secondly, we can question the users about their overall experience with our product. We do this by asking the users to rate individual aspects of this product on a 5 point scale as an improvement over normal plants? This way we get a quantitative measure of what our system adds to the weekly routine (time and enjoyment wise). | |||

'''Our second goal''' is to improve the independence of the users with DS and teach them how to care for something. Our product provides routine and clear simple instruction. This will help the people with DS to take care of the plants themselves without any external help from caretakers. This improves their independence which is a trait that is heavily valued by the caretakers we interviewed. When these people become more independent they require less care and gain more freedom, which improves their quality of life. Secondly, this product will develop the skill to care for something. This is a useful skill for people who need care. If you teach these people basic caring skills they can help themselves and each other better. | |||

Testing the increase in independence and caring skills from 1 week of usages will be difficult since changes are expected to be small and these characteristics are not so simple to measure. Hence this will probably be assessed by the caretakers who will be present during the testing stage. | |||

'''Our third goal''' is to remove some workload from the caretakers. We know that it is not always easy to work in the (health)care sector and especially with the covid-19 situation the pressure on these people is high. If our product manages to independently keep the people with DS occupied, it will mean more free time for the caretakers to spend on others work or just relax a bit so this goal ties in with the second goal. | |||

This can be tested by comparing the time a caretaker spends on helping these people take care of normal plants VS the time spent installing and explaining our product. If our product proves to be too complicated to use, we can get feedback from the caretakers that it took too much time and energy to adapt to the new system and that it was not as independent as we had hoped. | |||

'''Our fourth and least important goal''' is to improve the health of the plants. Having healthy plants benefit the air quality and the overall look of a space. Secondly, it is nice if the care institution has to less regularly buy new plants, this saves time and money (which are already scarce resources). | |||

This can be tested by starting off with two plants of the same type and health. One will be the control plant and the other will be planted in our pot. Both will be placed in the care home. After the testing period, the health of both plants will be assed. We do realise that assessing plant health is a bit subjective and that the sample size is really low, but we have to make do with what we can do in the restricted time and budget. | |||

It is also interesting to note that a smart pot that improves plant health is also an interesting product for the agricultural sector and greenhouse industry, seeing how dutch farmers need to produce with high efficiency to compete in the market because of the high prices for ground. | |||

==Objectives== | |||

Besides these goals, we also defined the following more practical objectives to strive for. | |||

'''Cost efficient/Affordable''' | |||

The prototype should make optimal use of the available resources. Furthermore the components and assembly process should be as cheap as possible to reduce the total production cost, making the design cheaper for users (or obtaining a bigger profit margin for the vendor) | |||

'''Easy to use''' | |||

The prototype should be easy to install and operate. This is especially important considering the target audience of mentally handicap people. This product is designed to help these people with doing more complex tasks. If the operation of the product is not extreme straight forward it will only work counter effectively. | |||

'''Friendly/Positive reinforcement''' | |||

We want the product to interact nicely with the user. The product should communicate with the user in a friendly manner and compliment the users when they perform an action. This makes the product more pleasant to use. The explicit positive reinforcement confirms to the mentally disabled people that they are in fact doing a good job. | |||

==Deliverables== | |||

*The first deliverable will be this wiki page. It logs our progression and helps the tutors and other people with an interest in our project to follow the progression and developmental steps of the project. | |||

*The second deliverable will be 2 physical prototypes of our smart plant pot. | |||

*The third deliverable is the final presentation, in which we present our project to our teachers and peers. | |||

=Literary study= | |||

In order to gain broader perspectove on the field of plants, the effect of plants and people with Down Syndrome, we needed to do much literature study. in the last chapter before the appendices, a list of sources is present of the articles we read to gain this knowledge. | |||

=USEr analysis= | |||

This anaylysis of user, society and enterprice is made based on literature study as well as contact with caretakers of mentally disabled people among which people with Down Syndrome.We sent out an email with a questionnaire for hypothetical use. The mail together with the statements we asked to the caretakers and the results of those are given in appendix B. Next to the several emails we send to multiple carehouses, we held close contact with a specific caretakers that one of us knows personally. The result of the interview with the latter care taker can be found in appendix C. | |||

==User== | |||

The main target group for this product is people with a mental disability. The product is designed to help the users overcome some of the challenges that they face due to their disability. "Mental disability" is a very broad term and can out itself on a whole spectrum of problems, ranging from difficulty with speaking to recognising emotions. For the sake of making a more tailored product, we have decided to focus on people with Down syndrome. This decision allows us to gather more specific needs and requirements from the users (which can be found in its own section). | |||

Our robot will notify the user by speech when a plant needs more or less water, or more or less sunlight. This way the product helps the user take care of a plant without having to do complex tasks like remembering when and how often a plant needs water or sunlight. Our robot gives simple, chopped up clear instructions so that the user knows what is being expected from him/her. After a task is completed, the robots will give confirmation in the form of positive feedback to the user. This helps assure the user that a task has been successfully completed. This way our product makes caring for plants more accessible for people with Down syndrome. which has all types of benefits [11], [12], [13], [14] | |||

The secondary users are the caretakers. The product is meant to be used by people with Down syndrome but is meant to be bought and installed by the caretakers. This device helps relieve workload from the caretakers by automating a part of the managing and task distribution process in a social work environment. Therefore it is important to always be mindful of who the users of specific functions is and what their needs and capabilities are. | |||

===User Needs and Preferences=== | |||

People with Down syndrome have different needs and preferences compared to people without intellectual disabilities. A good product should address all of the user's needs and as many possible preferences. So in order to develop a good product one should have a clear idea of what these needs and preferences are. To gather this information we have called several care institutions asking them if they would be interested in helping us answer some questions and/or help test the first prototype. Secondly, we decided to also do a literary study into this subject to obtain even more information from other sources. | |||

From the literature, we have found that language development is moderate to severely compromised in some children with DS and that therefore most individuals with DS also have less developed language skills at all ages in life compared to people without an intellectual disability (Lemons, 2010) and (Chapman, 2000) To accommodate for this lack in linguistic skills there are a few things that one can do to improve communication with people with DS. 1)Use repetition 2)Show that you are pleased 3)Be patient. | |||

Of course, there are more items, but these were the ones that we identified to be the most important and the ones that we could play into. | |||

We also made a questionnaire which we sent to multiple care institutions, from the results we concluded that it is very important to call the attention of people with the syndrome of down via multiple channels. For example with sound, display on the screen and blinking LED lights, because it might be hard to hear something in a very noisy room. The most important approach to these people is being positive and cheerful and to keep the message simple and clear. It is very important to remove cables from sight, they love cables and seeing what happens when they pull on them. | |||

==Society== | |||

Some say that a society is measured by how it treats its weakest members. We realise that our product will not solve any world crisis or drastically improve the farming capacity of social workspaces, but it helps people who need a little bit more care. Our robot allows people with Down syndrome to perform work more easily and giving them a way to spend their day and make themselves (somewhat) useful. This benefits society by allowing better participation across all layers of society and show empathy and care towards those who need it the most. | |||

Secondly, this helps relieve some of the workload of social caregivers who are often overworked. Financing for this sector is generally low and our product might save some valuable time by automating some simple repetitive tasks. | |||

==Enterprise== | |||

This product of course has to be developed and manufactured. This creates jobs and potential revenue which is all good for the economy. Products of these types do already exist [1], [2], [25] but these are mainly focused on increasing greenhouse yield. This product has a different goal and is therefore unique enough to not have to deal with fierce competition in the market, giving it a fair shot at succeeding in our opinion. | |||

===Branding, themes, and names=== | |||

A good marketable product needs a brand name. With its own name, customers can more easily refer to your product and you create a more memorable experience. After a good reputation has been established your brand name can help sell other products since people know they can expect quality products from a reputable brand. Lastly, branding helps to set your product apart from competitors. There are entire studies and companies that solely focus on branding and marketing. Branding is not really an area on which we have decided to spend our limited resources for this assignment. However, we did brainstorm on some names and themes for our smart plant pot. We have concluded that theming the pot was unnecessary for this prototype. We considered giving it a pop-icon theme that would be recognised and liked by most users, but this very quickly leads to problems with copyright. Secondly, we feared that theming the pot would take away attention from the display and lights that the pot uses to gain the attention of the users in its surroundings. Thirdly, we thought that the caretakers might prefer a clean white design as opposed to a spiderman-pot with a tulip in it. The caretakers are the ones who have to purchase and install the system, so their preferences are also of interest. | |||

For the name of the product, we have considered a few options. In the end, we have decided to go with FLEUR. This is a common Dutch name that is easy to remember and pronounce. FLEUR is a name derived from words for flower or flowering, we found this to be fitting since our product is designed to house a plant, of which many have flowers. | |||

=RPC list= | |||

Before the actual assembling the system needs a design. To clearly have an idea of a good design it is important to have a list of requirements, preferences and constraints, in short RPC-list. | |||

===Requirements=== | |||

*The pot needs to be able to sense the moisture content of the ground | |||

*The pot needs to sense the amount of sunlight it receives | |||

*The pot has to be able to identify the plants' needs based on sensor input | |||

*The pot has to be able to notify the user what the plant requires | |||

*The pot needs to be able to hold a plant | |||

*The pot cannot harm the user via electronics or any other way | |||

*The pot has to be waterproof for when spill accidents happen | |||

*The pot has to be strong enough to withstand being moved around. This being gently or roughly. | |||

===Preferences=== | |||

*The pot should have a speaker to address the users in a positive and friendly way | |||

*The pot should make minimal small talk like asking how the other person is | |||

*The pot should tell the users what it requires "I am thirsty, could you give me half a glass of water?" | |||

*The pot should thank/compliment the users after a task is completed. | |||

*The pot should display a smiley face then the plant is happy | |||

*The pot should display a watering can when it is thirsty | |||

*The pot should display a sun when it needs more sun | |||

*The pot should display a fire when it needs more shade | |||

*The pot should have flash blue lights when it is thirsty | |||

*The pot should flash yellow lights when it needs sunlight | |||

*The pot should flash red lights when it needs shade | |||

*The pot should alarm the user when the batteries are nearly empty | |||

*The pot should be easy to set up and install | |||

===Constraints=== | |||

*The electronics and the housing cannot be too big so that the pot becomes unpractically big | |||

*The assembly of the pot cannot take more than a week to fit our 7-week planning | |||

*The components cannot be too expensive since we are on a uni-bound budget | |||

*The pot cannot be too big in order to fit the manufacturing process due to the limited 3D printer size available to us. | |||

=Electrical components= | |||

==Electrical circuits== | |||

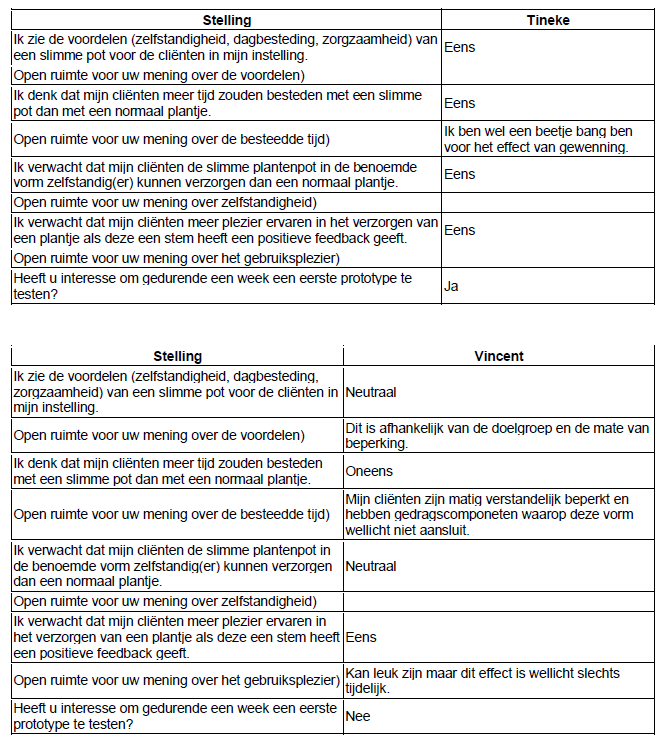

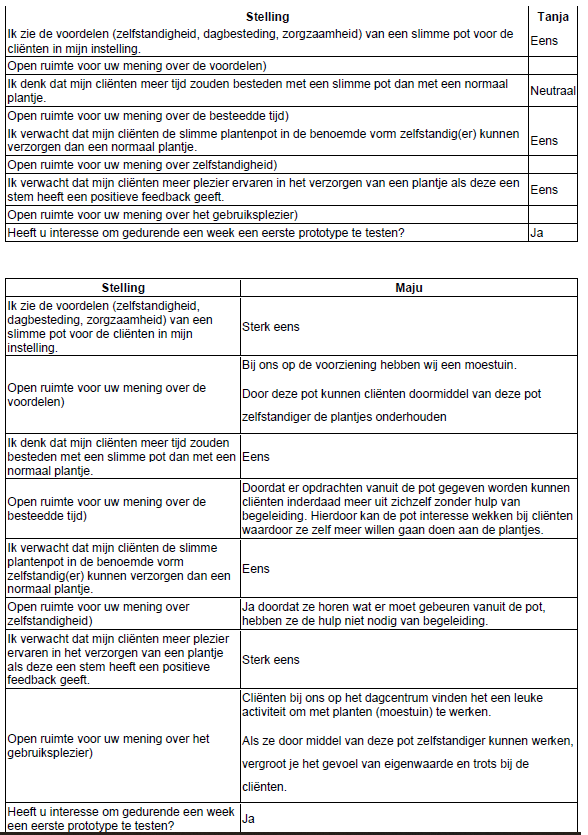

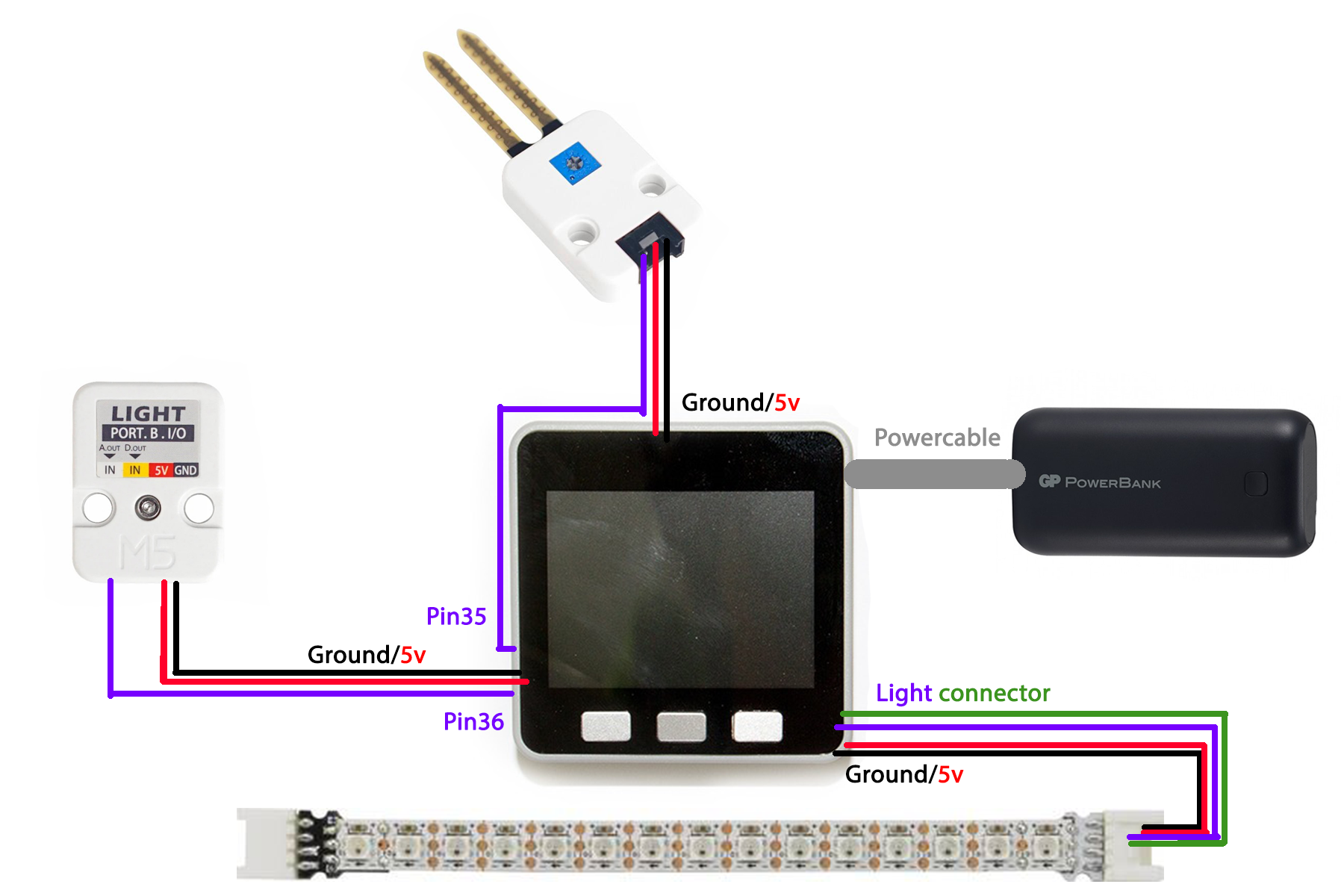

A design for the electrical circuit was made in the first phases of the designing process, See figure 1. When definite decisions about the hardware were made, a second reviewed schema was drawn, see figure 2. | |||

[[File:circuit1fleur.png|center|800px||thumb|Figure 1: 1st design of electrical circuit]] | |||

[[File:circuit2fleur.png|center|800px||thumb|Figure 2: 2nd design of electrical circuit]] | |||

==BoM== | |||

{| border=1 style="border-collapse: collapse;" cellpadding = 2 | |||

! Component | |||

! Costs | |||

! Amount | |||

! Total costs | |||

! Link to webshop | |||

|- | |||

| Earth Unit | |||

| € 4,- | |||

| 1 | |||

| € 4,- | |||

| https://www.tinytronics.nl/shop/nl/platforms/m5stack/unit/m5stack-earth-unit | |||

|- | |||

| Light Unit | |||

| € 4,- | |||

| 1 | |||

| € 4,- | |||

| https://www.tinytronics.nl/shop/nl/platforms/m5stack/unit/m5stack-light-unit | |||

|- | |||

| M5STACK M5Core Gray - ESP32 Development Kit | |||

| € 30,- | |||

| 1 | |||

| € 30,- | |||

| https://www.tinytronics.nl/shop/nl/platforms/m5stack/m5core/m5stack-m5core-gray-esp32-development-kit | |||

|- | |||

| DuPont Jumper wires Male-Female | |||

| € 0,75 | |||

| 2 | |||

| € 1,50 | |||

| https://www.tinytronics.nl/shop/nl/kabels/prototype-draden/dupont-jumper-draad-male-female-20cm-10-draden | |||

|- | |||

| M5Stack NeoPixel LED strip | |||

| € 10,49 | |||

| 1 | |||

| € 10,49 | |||

| https://www.conrad.nl/p/makerfactory-m5stack-neopixel-strip-mf-6324774-led-lamp-met-connectoren-malefemale-35-v-23-cm-na-tape-cut-2108258 | |||

|- | |||

| Material 3D printed pot and box | |||

| € 17,50 | |||

| 1 | |||

| € 17,50 | |||

| https://www.filamenten3d.nl/product/pla-filament-hotorange3d/ | |||

|} | |||

In the prototype, the wires were not connected correctly. This problem can easily be solved by adding an M5STACK 1-6 PaHub Unit. This unit costs around 6 euros and one of them is required for each design. This will end up with a final price of € 67.49 For every ‘Fleur’. In this project we made two prototypes, the final amount of money used for this course is, therefore, € 134.98. | |||

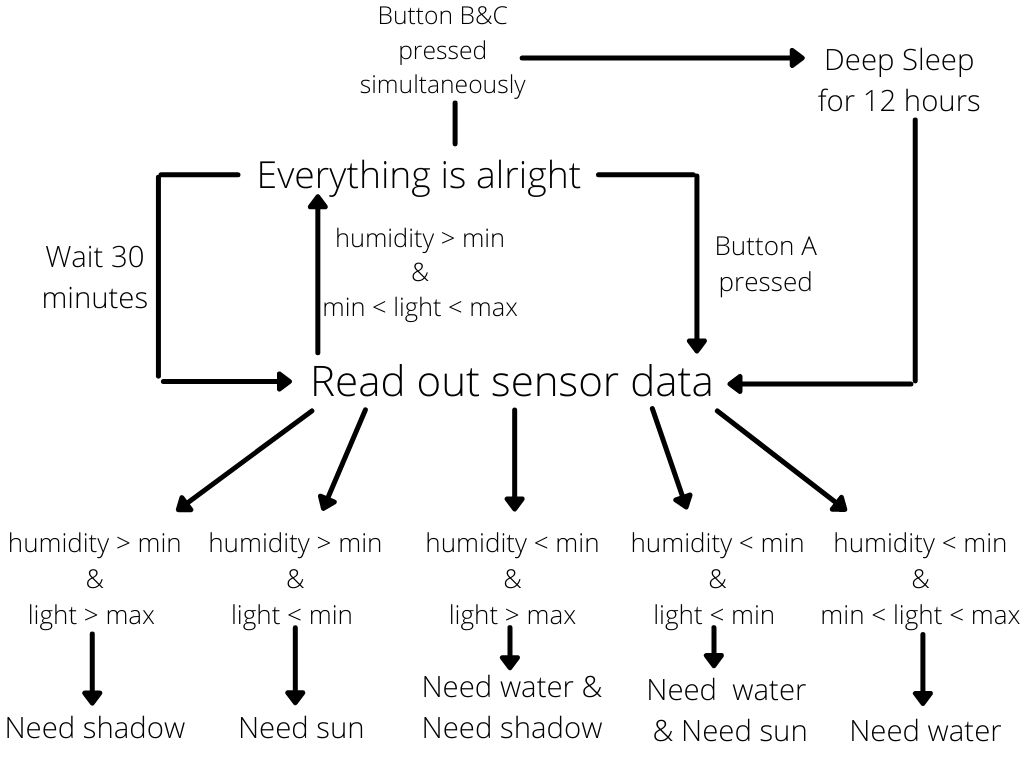

=Software= | |||

The first thing Fleur will do when she wakes up is checking her values from the sensors. She will check the humidity value is in above a certain threshold of humidity and check whether the light sensor detects a certain value within the right range. | |||

If everything is alright, the screen will show thumbs-up and the text that she is doing alright. She will then be put in a rest-situation and wait for half an hour for the next check. The time delay of thirty minutes was chosen, because if Fleur asks for attention more regular she would be very irritating. However, if the caretakers and the clients didn’t notice Fleur asking for anything and the system would wait any longer, it could be harmful. | |||

Considering the situation that during the check anything irregular would occur, like the plant needs water, or it wants more or less sun, Fleur will ask for attention by singing a certain tone and shine red LED-light. Depending on the situation, the screen will print the exact question the system has and a corresponding picture. In the case that the plant needs water, the screen shows a droplet-symbol. In case of the need for sun, a sun-symbol will be shown and if the plant wants shadow, a cloud-symbol will be visible. Moreover the combination ‘more-sun-more-water’ and ‘less-sun-more-water’ are situations the system can ask for. | |||

= | The symbols and question for the needs of the plant will be visible until the system detects that the plant has been given the proper attention. Therefore after helping Fleur (or if the user wants a direct update of the current situation), the most-left button should be pressed. By pressing that most-left button, the system will do an instant quick check of the sensors. | ||

In order to | |||

(These | At night, the system can be put manually to deep-sleep mode for 12 hours by pressing the middle and right-most button simultaneously. This is chosen because this way the system will not go to sleep-mode accidently for 12 hours. | ||

Below a flowchart of the code is drawn for a better overview of the code. | |||

The full final code (in a word document) can be found using the following link: https://drive.google.com/drive/folders/1F2kOWIv5RVl4_EYyO0mUUrJ0aGCaT1-m | |||

===Flowchart of the code=== | |||

[[File:flowchartfleur.jpeg|center|700px]] | |||

=3D-printing= | |||

When the idea of FLEUR came to enhance the joy of life of mentally disabled people, some challenges had to be overcome in the design phase of the prototype. As can be read in the section about the conversation that was held with a caretaker, all the wires have to be hidden away. Apparently, these wires are an incentive for the patients to pull on them, this may lead to dangerous situations. Besides this, there was a constraint for the size of the product. The size could give problems during manufacturing but the product can also become too large to be practical in use. There were many more challenges to overcome, these can be read below. | |||

==Making the prototype housing== | |||

When it came to deciding on how we would make the prototype, a decision was made quite quickly. The method of 3D printing was chosen. This was a feasible solution since one group member owns a 3D printer and thus it was very forgiving in lead/shipping times. And when problems would start to arise, this was a process that could be done at the university. | |||

For the whole process, a 3D design of the pot had to be made, this process can be read below, and also research had to be done on the plastics that were going to be used for the FDM printer. After the print was completed some post-processing had to be done before FLEUR was ready to be assembled. | |||

===Research on plastics=== | |||

When doing research on the plastics there were only 3 possible solutions for the printer set-up at hand. Some plastics had to be discarded since they would be too abrasive, some were discarded due to their properties after printing, some were discarded if the manufacturing process could not be met, there is a limit to the temperature the printer can reach, and some were discarded due to the fact of limited to no stock being available. | |||

What plastics remained? The 3 most common 3D printer plastics on the market: PLA, PET-G and ABS. They all have their own strengths and weaknesses and these will be elaborated on further. | |||

'''PLA [20]''' | |||

PLA is the most commonly used 3D printer filament due to its versatility. PLA is easy to print since it does not tend to warp1 and/or cause stringing2 during printing and it is relatively strong, it is available in many colours and it is very easy to work with during post processing. It also does not require high temperatures during printing. And one other side benefit is that PLA is biodegradable. | |||

On the other hand, PLA is not the strongest material on the market, but this is not that much of a concern for our project. What is of concern are the properties PLA has when it is in contact with sunlight and water. Since PLA is a bioplastic it is not hydrophobic for longer periods of time nor can it be in direct sunlight for longer periods of time. This seems catastrophic but while doing the research it was found that 'for longer periods of time' means more than 2-3 months. For this project the use will be around 1-2 weeks at most. Lastly it is needed to mention that PLA deforms at not the highest temperature, ~50-60C, it will not melt but the when applying pressure indentations and/or layer separation could occur. | |||

'''PET-G [20]''' | |||

PET-G is the little brother of the engineering plastic PET, PET is used for example in water bottles. PET-G is a ductile material, it is a hydrophobic material by itself, this does not mean that the print will be waterproof however, it has a good resistance to sunlight, it is relatively easy to print and it starts deforming at a temperature of ~70-75C. | |||

Some disadvantages are that PET-G is prone to cause stringing during printing and it is more inclined to warp than PLA, but these are minor issues with PET-G. The biggest problems with this plastic were two fold. The first major problem was availability, the source that was used to acquire the plastic only had 1 roll in stock and we needed 2. The second problem had to do with the print bed that was being used. The print bed is made of glass with a special coating, while printing there is a significant chance that the PET-G could fuse with the glass of the print bed. A solution would be a PEI sheet for the printbed but this could not be acquired in time. | |||

'''ABS [20]''' | |||

In general, is ABS the most ductile material of the 3. ABS is also very heat resistant, it starts deforming at a temperature of ~100C. But there are some major disadvantages. First of all, ABS is not the most resistant to UV light, in this aspect it has about the same properties as PLA. But the biggest drawback to ABS is its tendency to expanding and/or contracting during printing. This means that the print is not only very inaccurate, the tolerances are not met due to the expanding/contracting of the material, but it is also hard to make 2 3D printed parts that would need to interact with each other. | |||

'''Conclusion''' | |||

So what material was chosen to use for the 3D printing? The answer is PLA. It was readily available, it does not have the best properties but also not the worst. The only thing that might be a small concern is that it can deform at around 60C, this would be a problem when the pot is placed above a radiator of the central heating system when it is cranking out a lot of heat. But since the prototype is made during late spring/ early summer this would not be a problem. Also, since this project will use the pot for 1-2 weeks, it is no problem that the pot will start to break down after 2-3 months in continuous sunlight or being used as a water reservoir for that amount of time. | |||

''1) Warping is the tendency of a material to deform when it is being cooled. This can lead to structural inaccuracies, parts not being able to merge together for example.'' | |||

''2) Stringing can happen with certain 3D printers during printing. Thin lines of plastic are dragged across the part during manufacturing resulting in an end result that needs more post-processing in order to get a nice finish.'' | |||

===Post processing=== | |||

After a print is complete, it is likely that some post-processing has to be done. In our case this meant removing the support material, doing some finishing to the pot and making the pot waterproof. These processes are elaborated on below. | |||

'''Removing the support material''' | |||

When making a print like this it is important for the person managing the 3D printer to keep the orientation of the parts in mind in the slicer software. This can in turn greatly reduce or increase the amount of support material that has to be printed. Support material is sacrificial plastic that is used to make sure that the print can be made by the printer, this then can be easily broken off in the post-processing phase. In general this support material can be avoided by making some smart design choices as well. A 60 degree overhang for example is the most aggressive form that most printers can handle without printing any support material. This step is crucial in minimizing the amount of plastic that is used and in keeping the print time as low as possible. | |||

'''Finishing''' | |||

Now that the support material has been removed, the tedious work of finishing the parts begins. In general, a 3D printed part is quite smooth and has a nice look to it, but there can be some oozing on the side or the seam is visible to the outside. These are both the effect of the way an FDM printer works. Since the printer works in layers, the starting/end point of a layer gets over extruded plastic, or a seam, this can be filed down and sanded to match the rest of the print. | |||

'''Waterproofing.''' | |||

The last process would be waterproofing. Unlike some test prints, the pots were not completely waterproof. This was fixed by using a 2 part epoxy, this would ensure that the flower pot would not leak. | |||

==Designing the prototype housing== | |||

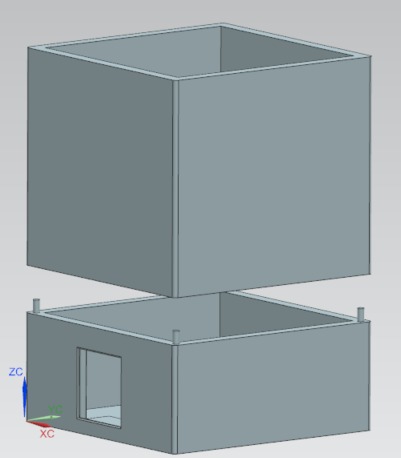

===First design=== | |||

When coming up with a design the first thought was to make a flower pot comprising of 2 compartments, 1 compartment for the electronics and 1 for the plant, see Figure 3. The idea was that the bottom compartment would be filled with all the electronics and the top compartment would function as a flower pot. The moisture sensor would stick up into the flower put and the light sensor would be sticking out of one of the compartments in order to sense light. In the end it was thought to be too difficult to make the flower pot water tight with a sensor sticking in from the bottom. This could be avoided with a designated rubber seal, but then still it would not be an ideal solution. Another hinderance with this design was its size, it would only have a couple of mm of clearance during manufacturing. | |||

[[File:WhatsApp Image 2021-05-06 at 16.55.32.jpeg|400px||none|thumb|Figure 3: First design implementation.]] | |||

===Second design=== | |||

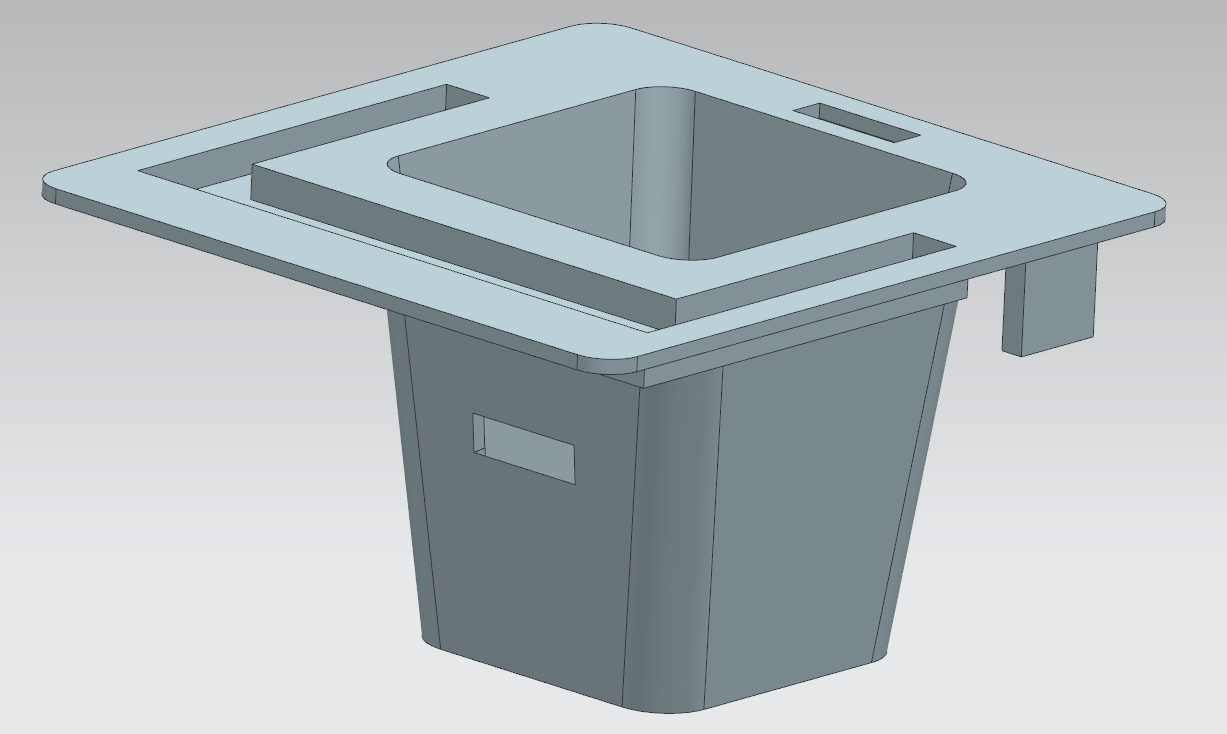

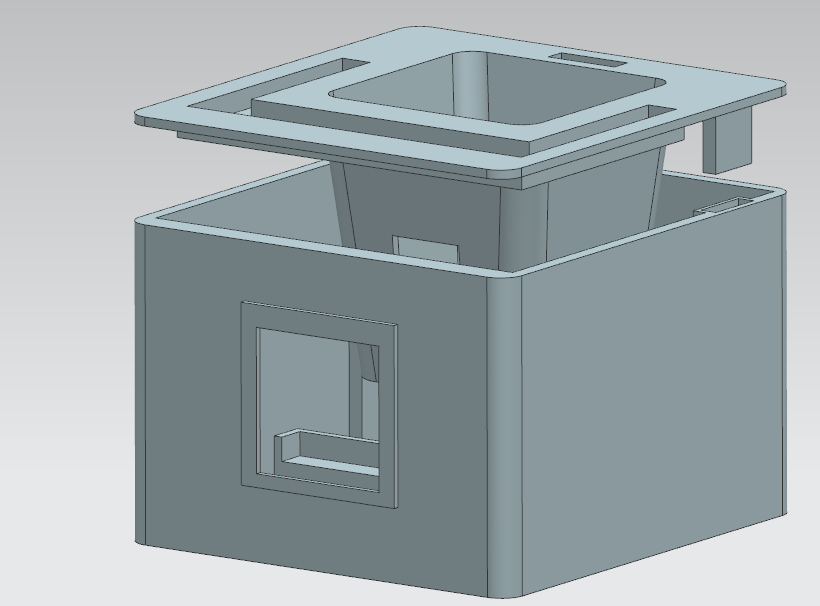

Learning from the design faults in the first iteration of the design sketch, a new concept was thought of. The main concept would remain the same, there would be 2 compartments. 1 compartment for the electronics and 1 compartment for the plant. The main difference between the first and second iteration of the design lies in the way how these compartments interact. Instead of making a sort of lid on a jar concept, the compartments would be 'merging' together. As can be seen in Figure 7. The 2 compartments for the design will be explained separately. This design was also used for the 1st prototype of FLEUR, during assembly of this prototype some minor design changes were made for the 2nd prototype. | |||

===The top compartment.=== | |||

The top compartment of the design has multiple functions, it has to hold the plant, it holds the sensors, the LED strip and it makes sure that the least amount of water can get to the bottom compartment. The design can be seen in Figure 4. | |||

In order to hold a plant and to make the design waterproof was quite challenging since the chosen manufacturing process was a 3D printer. When looking online how it could be done with the settings in the slicer software an article was found by a company called Prusa Research[XX], a leader in consumer 3D printers. This article stated that it would be possible with certain parameters but even then all the stars would have to align. When these parameters were changed, the end result was that the print was not waterproof. In the end, it had to be done during post-processing. As far as holding the plant itself was quite simple, a plastic flower pot from a retailer was used as an insert into the compartment, this way there would be an extra layer of protection between the electronics and the water. This also has the added benefit that changing a plant is a simple process, the inserted pot has regular dimensions, meaning that plants in similar pots can be found at retailers. But this is not necessary, some soil can be put in the compartment for the flower and FLEUR would still function as intended. | |||

For the sensors, cut-outs have been made. For the light sensor, a cut-out in the top was made so it can sense the amount of light. The placement is opposite to the screen, this was done for ease, the sensor would be able to sense sunlight through a window and then the screen would still be pointing towards the room. For the moisture sensor, a cut-out had to be made through the potholder. This gives the risk of compromising the waterproofing but this compromise had to be taken. As mentioned during design 1, all the cables had to be out of sight whilst trying to avoid making any holes in the bottom of the potholder. Thus it was chosen to make the hole in the side of the potholder, and the hole is placed under a 30-degree angle. The thought process being that the water on the sensor itself would follow the path of least resistance and pointing the sensor down would lead the water down giving the least amount of problems. The holes for the sensors are meant to be press fits, meaning that no adhesives or fasteners will be used. This is why they are designed to be as big as the dimensions of the sensors, with the tolerance clearance for the printer being ignored, this gives a hole that is slightly smaller than the sensor(+- 0.2mm) giving the chance to make the fit perfect with some files. If the fit turns out to be too loose, a piece of tape will be used as a gasket. Ideally, a rubber O-ring would be used but that is not feasible, unfortunately. | |||

Besides the sensors, also a designated spot has been chosen for the LED strip, this is a simple track in which this strip can be placed. | |||

[[File:fig2.png|400px||none|thumb|Figure 4: Top compartment second design]] | |||

Article Prusa research: https://help.prusa3d.com/en/article/watertight-prints_112324 | |||

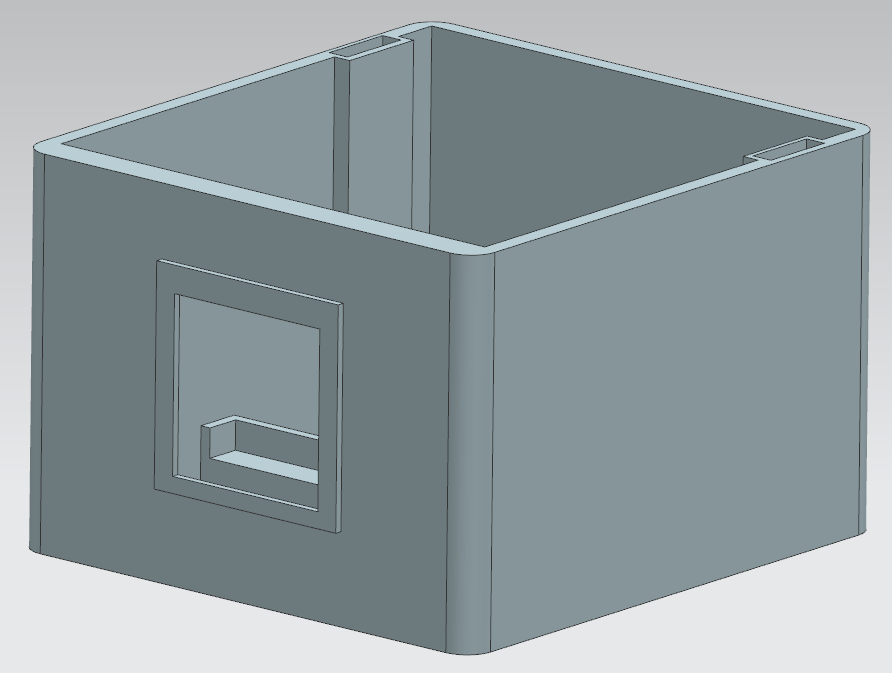

===The bottom compartment=== | |||

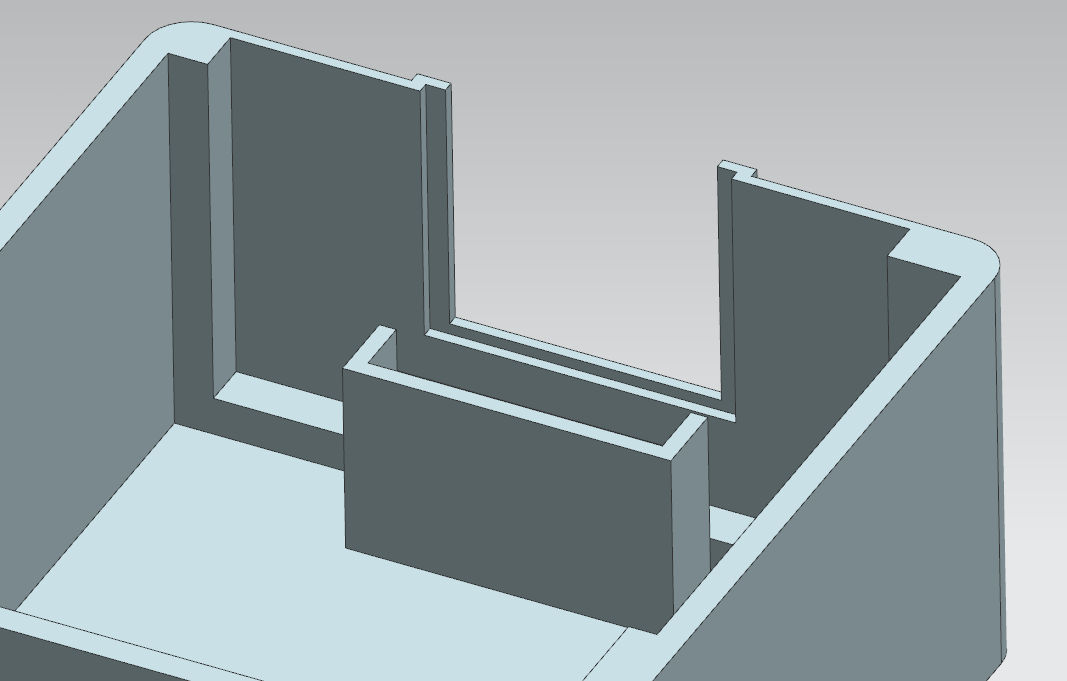

The bottom compartment needed to hold the M5Stack Core along with the powerbank and all the cables. And it had to give strength to the whole design. The design can be seen in Figure 5 | |||

When it came to holding the Core several cut-outs were made in a wall of the bottom compartment. Some cut-outs held the Core in place whilst others were there to accommodate for the cables that needed to be connected to the Core. in order to hold the screen in place, there is also a design feature at the back. This is a slot that fits around the BUS unit that is directly connected to the Core, this will neutralise movements in the horizontal-plane. Limitations in the vertical-direction are achieved by a combination of these cut-outs and this design feature. These can be seen in Figure 6. | |||

There is enough room to accommodate 1 of the 2 power banks that were used during the design process, there is no particular orientation that these need to have. | |||

[[File:fig3.png|400px||none|thumb|Figure 5: Bottom compartment second design]] | |||

[[File:fig4.png|400px||none|thumb|Figure 6: Bottom compartment second design, showing the cut-outs for the Core and all the wiring]] | |||

===Put together=== | |||

When both compartments are put together, there are 2 prongs in the top compartment and there are 2 holes in the bottom compartment. These holes and prongs limit the movement in the horizontal-plane, movement in the vertical direction will still be possible however, this was done to make it easy to charge the powerbanks if needed and to do repairs. | |||

[[File:fig5.png|400px||none|thumb|Figure 7: Second design put together]] | |||

[[File:fig6.png|400px||none|thumb|Figure 8: 1st prototype]] | |||

[[File:fig7.png|400px||none|thumb|Figure 9: 2nd prototype]] | |||

===The prototypes=== | |||

Also, 2 prototypes were made. One in white, the first prototype, and one in red, the second prototype. There are small changes between the 2, when putting prototype one together some minor mistakes were found in the design and these were changed for prototype 2. These changes were the length of the track for the LED strip and the height of the design feature for holding the BUS unit of the Core. | |||

=Promo Video= | |||

A promotion video was made in Kickstarter style. This video is useful for the final presentation, to convince the target audience that they needed to test our prototype, and to buy our product (''enterprise''). This video needs to be very short <100 seconds. Otherwise, people lose their attention. The video should clearly show what our product is, what it does, and how it looks. | |||

As an example, you could look to nearly every IndieGoGo/Kickstarter video. The following guide for making a video was found online: | |||

'''The hook''' | |||

Your Kickstarter videos have to get their attention. If you don’t do this, nothing else matters. This could be through the video title or those first few impactful seconds that draw the person in to learn more. | |||

'''Tell a memorable story''' | |||

Your video should tell a story. If you are trying to get funding for something that solves a problem. The problem should be demonstrated through a visual narrative. Stories hold attention. They show rather than tell. People want to find out what will happen next. Work the narrative to hold attention to the very end. And after the viewer walks away, they should be left with an imprint, an inability to forget what they just saw, and hopefully and urge to share. | |||

'''Get people excited''' | |||

Yes, you are very excited about the movie for which you need funding, but is this excitement translating to someone who knows nothing about you. What is unique and special about your idea? Why should the contributor want to be a part of your mission? And don’t underestimate the power of music to inspire excitement. | |||

'''Make sure visuals match the script''' | |||

If you reference a mouldy cheeseburger in the script for some strange reason, we need to see one. The visuals need to synch to what the actors are saying to reinforce your message. | |||

'''Don’t over-explain it''' | |||

You don’t want to be too vague. People should know what they are funding and need to know that you have a plan. But a lengthy video that explains every detail of the process will not serve you well. The most successful videos are concise 2-3 minutes. | |||

Our video can be viewed on youtube via this link https://youtu.be/aYFWqo6niwQ | |||

=The test= | |||

'''Finding test locations''' | |||

In order to test our 2 prototypes we needed two care institutions who were willing to test our product. This was hard since the caretakers are generally very protective of their clients. Covid-19 probably also played a role. We as students are statistically the most infected part of the population. Getting a corona infection inside a place filled with disabled people would be terrible. But eventually, 2 respondents from our general questionnaire agreed to test Fleur. After this, a phonecall was setup to discuss practical details and to make sure that these people knew what was going to happen and what we expected from them. Below is the contact information for the persons that agreed to test Fleur. | |||

''We will not post the contact information on this wikipedia page since we do not have their explicit permission to do so and it will be an invasion of the privacy of the people who were so willing to help us.'' | |||

==Experiment== | |||

To test whether our smart pot achieves the stated goal we will perform two simultaneous tests that are one week long. For each test, we will need two similar plants that are in similar health. The plant that we have chosen for this experiment is a tulip with a bulb. This was done because 1) they are available in this spring period. 2) They are flowers so we expect them to show relatively large changes over the short testing period of one week, e.g. they will hopefully bloom 3) Because they are flowers we hope that the caretakers and the clients like them. 4) The blub prolongs the life of the tulips compared to cut flowers. This way we want to prevent the tulips from dying naturally within a week. 5) bulb-in-pots need a bit of water once or twice a week. So the clients actually need to water the plants within that week. 6) Tulips require sunlight but not full sun. This is a bit more interesting in terms of programming our software and using the sensors. | |||

In the experiment, one plant will be placed in a regular pot and will serve as a control. The other plant will be placed in our smart pot. Both plants will then be placed in similar environments, with the same temperature and amount of light, but in different locations (as to not trigger care for the control plant by association with the smart plant). Then the caretakers will introduce the people with DS to the plants and the smart pot and tell them that they have to care for these plants during that week. The caretakers also mention that one plant is a magical talking plant and that it can communicate if it needs something so that the clients will not be scared or too confused. | |||

We know that one week is a very short time span and that a sample size of just 2 plants is small but we have to work with what we have. After the test period, we will assess the health of both plants to see if one is in better health than the other, suggesting the smart plant influenced the wellbeing of the plant. Due to the situation with Covid-19 we are not allowed to enter the care-houses in person. And due to the mental vulnerability of the clients, their privacy, and the fact that we are strangers to them, we are not allowed to set up a webcam feed to more scientifically measure some parameters like: time spent with the plant. Therefore we will gather results by questioning the caretakers (and the clients indirectly). The results from the two parallel tests will be combined while paying attention to any possibly interesting similarities and differences. From these combined results we will be able to judge whether our product achieved the goals we set for it, and what still needs to be improved. | |||

==Hypothesis== | |||

We expected that we will achieve our main goal of helping people with Down syndrome to have more ways to spend their time in a joyful manner, that is why we decided on this design. We are fairly confident we will reach this prioritized goal when the design experiences no malfunctions during the testing period. This concretely means that the caretakers will rate the “time spend” and “enjoyment” in the questionnaire higher for our smart pot than for the control plant. | |||

Our second goal is to take some workload from the caretakers. For this, we expected a negative result but that is due to an unresolvable flaw in the design of the experiment. We hypothesize that the installation process adds extra workload, and so does the becoming accustomed to using the product. We expect that the clients will need some time and guidance from the caretakers when using the smart pot for the first few times. However, we do expect the workload to drop after the product has been fully integrated. Therefore we will also ask the caretakers if they foresee a reduction in workload if the smart pot were to be used longer than a week, say a month. For this, we do expect a positive answer. | |||

Our third goal is to help the client become more independent and caring. We expect that these characteristics will be hard to measure with such a small sample size and test time. But we might be wrong. It could also be the same that some clients quickly develop a caring fondness for FLEUR. This again will have to be rated by the caretakers. We expected to measure some degree of increased independence. An increase in independence is defined as a report by the caretaker that the clients get activated by our system to perform a task that they had forgotten in the control plant. | |||

Our final goal was to improve the health of the tulip. For this, we expect an inconclusive result. We think that there will be no significant change between the control plant and the smart pot in one week, even if the control plant gets no care at all. On the other hand, it could also be the case that our plant model is not ideal or if the instructions aren't followed carefully enough by the client. Which may lead to drowning the smart pot tulip whilst the control plant lives. | |||

==Execution== | |||

The two prototypes were placed at the test locations on Monday. We gave the instructions to the caretakers to observe changes in behavior of the clients. Everyone was exited for the experiment. | |||

The manual of Fleur and the questionaire we prepared to give the caretakers afterwards will be posted in appendix D. | |||

==Review of the experiment== | |||

The two prototypes were placed at the test locations on a Monday. We instructed the caretakers to observe changes in the behaviour of the clients. Everyone was excited about the experiment. | |||

Unfortunately, the prototype in Veldhoven stopped working after two days due to a problem with the battery/power. | |||

Most probably the power bank stopped working, perhaps because of the heat that week which took more power from the power bank than it would have done in a regular week, or maybe there was still a bug in the system which drained the power. The caretakers did not have the correct charger cables to charge the power bank. | |||

The prototype in Roosendaal stopped working after three of the five days. The problem was easily resolved by rebooting the system. But the caretaker in Roosendaal did not understand what I was trying to explain to her. Unfortunately, Roosendaal is too far for us to fix it ourselves. Because of this short testing time, we decided to not use our questionnaire to gather the feedback of the testing week but decided to have a more informal chat at the end of the week. | |||

Despite the unfortunate circumstances, the prototypes had worked five days together. The first thing we learned from these tests is that the battery/power management was unreliable after a few days. When we retrieved the prototypes a mentally disabled person told us that she had a lot of fun with Fleur. She and the other mentally disabled had laughed a lot and she liked the pot very much. The caretakers themselves told us that they enjoyed the experiment although it ended prematurely. The disabled people spend more time on Fleur than on the other plants. Nearly every time it went off the clients went to check out the plant. | |||

In these 3 days, it was not really possible to measure any significant change in independence or caring behaviour. The health of the plant stayed the same. | |||

In conclusion, the execution of the experiment did not go as planned, and we probably do not have sufficient data to draw a conclusion on whether Fleur is a product to continue assembling. So as expected more testing and development has to be done. But the initial raw data shows that our target group is largely interested in the product and that they at least enjoyed using it. So this is not the end for Fleur. | |||

=Discussion= | |||

During such a project there are always things that could have gone better. Some of these things were anticipated and others were not. This section is dedicated to the things that went suboptimal, and how we would improve a second prototype. | |||

===Target audience=== | |||

The first big problem that we encountered had to do with our target audience, namely people with down syndrome. In order to obtain user “preferences and needs” we needed information from these people. Although Down syndrome is not a rare disability (7.7 per 10000 in the Netherlands [21]), we personally do not have contact with anyone suffering from this condition. This is because these people generally have fewer social contacts. So we tried getting in contact with care institutions. This was quite hard since these caretakers told us that they have busy jobs and people generally dislike spending time helping complete strangers when they are busy. Another factor that did not help is that the caretakers are very protective of their clients. Since the clients themselves are not able to properly fend for themselves. When I called these institutions I was usually redirected a few times until somebody did not answer the phone or said the could help us. Lastly, the coronavirus made it impossible for us to visit these places in real life. This would be a easier way to actual meet the disabled people and their caretakers. | |||

So in another project, we could think of better ways to get into contact with our target group (or decide upon an easier one during the first stages of development). | |||

===User-friendliness=== | |||

Our system reads out it sensor values every 30 minutes and checks whether those are in range. If they are, it is fine and the system will wait another 30 minutes for the next check. If it is not good if will ask for what it needs, that is water, or more or less sunlight. If it needs help, the user needs to push a button such that it will check every two seconds so that the system can give direct feedback to the user if it is being taken care of. | |||

A clear improvement would be that the user doesn’t have to push a button. This way it will cost the user an action less, which makes the product more user-friendly. An implementation could be that the system will automatically check every two seconds when it detects a problem. We chose not to do this, since it will consume a lot more power and the system needed to work for five days with one power bank. | |||

Another button-improvement would be that the system would automatically go do deep-sleep mode between certain times. The way the prototype is now put to sleep mode is when there are two buttons pressed simultaneously. We chose to do it the button-way because it was way to time consuming to program a timer on it. | |||

===Goals and experiment=== | |||

Another problem we encountered had to do with our goals and experiment. As a goal, we aimed to add a new joyful activity to the day of people with Down syndrome. The main problem here is the measurability of these results. Due to the coronavirus, we could not be present in persons to judge the effectiveness. And due to the privacy of the users, we also could not install camera’s for example to keep track of how the prototype performs. The result of this is that we had to ask the caretakers to pay attention and all the feedback had to come from questioning those caretakers. This is less than desirable because we want to ask as little as possible from these people since they are already being extremely friendly and helpful by testing our product. Secondly, it increases subjectivity in the results since both prototypes are judged by different observers. | |||

This could be solved by perhaps waiting until covid passes or by finding a different target audience that allows us to monitor the experiment ourselves. | |||

An additional problem of the experiment was the test period length. Due to the structure of this course, we could only permit 1 week of testing. This is really short when you want to monitor potential changes in behaviour and the health of plants. Expected changes are minimal in one week, and therefore the results might be inconclusive. We have no good fix for this. | |||

===Design=== | |||

The next thing that we would improve in a new version would be the design of the pot and how the sensors are placed inside. In the current design, the moisture sensor fits into a hole that is halfway down the pot. This was the only way everything would fit in the pot. Making the pot bigger was not an option since we were restricted by the size of the 3d printer and the print time. This low hole caused excess drained water to drip through the hole in the direction of the electronic core. This is obviously a problem. In the prototype, this was fixed by using some tape. But a more ideal permanent solution would be to redesign the pot with a bigger 3d printer. Or by using moisture sensors that are smaller since our model was quick large (8ish cm in length.) | |||

FLEUR now uses a powerbank as the source of power. We didn’t like to option of having a power cable since that would look less nice and would increase the risk of electrocution because we use electronics inside a flowerpot that is filled with water every week (and see the problem of the hole described above). The downside of using a battery is that you have to swap or charges them once in a while. So to minimize that labour and make our system more durable we should use power-efficient component. In the current design the display of the mstack 5 core uses most of the power, our sensors take a measurement once every thirty minutes and each two seconds after the button is pressed, to direct fast feedback). This power consumption is negligible in comparison. So to improve our design and make it run on smaller and fewer batteries we could swap the standard transmissive display for a so-called reflective display, these are the ones that are used in e-readers. These displays only use energy when the projected image on the screen has to be changed. Which is only a handful of times a day in our case. This would decrease our average power consumption allowing for smaller batteries. | |||

===3D printed design=== | |||

The next thing that would need improvement is the design of the pot itself. This can be split in 4 parts: holding the core and the electronics, masking the wiring and placement of the sensors, waterproofing and lastly making the prints. The improvements will be discussed separately. | |||

When it came to holding the core it was chosen to create a pressure fit within its designated socket. This was a good solution at the time since the core had multiple sockets that needed to be used for the sensors, these needed to be free of the structure. In the first design this gap was too tight and the sockets could not be used. In the second design the sockets could be used but the fit of the core was not ideal. The solution would be to make a structure with precise cut-outs where the cables would connect, make this structure separate from the pot so it can be bolted or screwed to the outside. Then make a second slightly bigger enclosure that fits over this structure to hide the wires. This way a secure and tight fit can be ensured for the core, all the wires can be hidden away whilst not compromising the required space. | |||

For the rest of the electronics no specific location was made in order to hold them down. This caused a rattling sound when moving the pot around, in the first design this was compromised due to the size limitations. But if the modification for holding the core would be made, this is a must. Not only will it make the wires more likely to entangle, come lose or even break, but it is also more professional to make sure that everything is securely put in place. | |||

The placement of the sensors can also be improved. Now there is a moisture sensor that is stuck in a hole that is halfway down the pot. This makes for quite a big risk, there is a big flood risk for the electronics if the seal between the pot and the sensor is not good enough. This could be solved by placing the moisture sensor in the top of the pot and making some sort of straw that can be used to reroute the wires into the bottom compartment. This would make sure that the leak risk is completely gone whilst still having no visible wires that can be pulled out by the clients. When it comes to the rest of the wiring, has been done in making channels that can route these wires. It is not a necessity, but it does make sure that the wires become less entangled and thus maintenance will be easier when the pot has to be disassembled. | |||

Lastly there are some improvements when it comes to waterproofing and making the prints. In this design, the only place that was not waterproof from the build plate of the printer was the bottom of the pot, where the plant would be placed in. This was solved by using a layer of epoxy for plastics on the inside and outside. For a build that was completed in 9 weeks a viable option but it is not ideal. It is expensive and not very easy to do on the inside of the pot. A better solution would be some sort of coating that could be sprayed on the outside in order to make it waterproof. Then, there is the water issue around the moisture sensor, as a quick fix a piece of tape was used to get a tighter seal. This is by no means an ideal solution. It would be a lot better to move the sensor or to make some sort of rubber seal, like an O-ring. This would make the seal tighter and it lasts longer than the piece of tape. | |||

For now the prints were made with PLA, this is a reasonable material to use in the spring and summer for this type of project. But it would be better if PET-G was used. PET-G can withstand a higher temperature than PLA and one if its useful properties is that it is hydrophobic. Meaning that in the winter when the central heater is on and the pot is placed above the heater, the pot will not deform due to the heat. This could be the case with PLA. And it would be more waterproof by itself than PLA, and that is not a bad thing when designing a plant pot. | |||

=Giving a presentation= | |||

When it came time to make the presentation it was important to keep in mind what the focus was on during this project. The focus was not on electronics, software, 3D printing or literary study. The focus was on getting the right message to the people with Down’s syndrome to get them excited to work with FLEUR and to contribute to their daily activities. The electronics, software and 3D printing were a key part but in the end, it was a case of choosing the right tools for the job. | |||

In the presentation, this was kept in mind. Many slides were dedicated to how the group would achieve projecting the right message to these people. So slides that included the questionnaires, the meeting we had with a caretaker, the literary study we performed and of course the USEr analysis. This is where the main focus during the presentation had to be in order for us to get our message across to the other groups. | |||

In the last couple of slides, attention was given to the ‘tools’ that we used. So the electronics and the 3D printing process. It was important to shed some light on how the information we had received from the caretakers had influenced our decision. So why did we use the Core platform and why choose that particular 3D design for FLEUR. This ultimately showed how we wanted to achieve that people with Down’s syndrome would be not only excited to work with FLEUR, but that it would help them in their daily life. | |||

When it came to giving the presentation this went quite well. How we intended to divide the time, despite the fact that we did not complete the whole presentation in 15 min, was achieved. Most of the time went to user interaction and how this was important for us with less time spent on the technical side of the project. In the end, the presentation had everything that the group wanted to share and the presentation can be found in the following link. | |||

https://drive.google.com/drive/folders/1F2kOWIv5RVl4_EYyO0mUUrJ0aGCaT1-m?usp=sharing | |||

=References= | |||

The following list of literature has been read to gain knowledge of the field of the problem | |||

===Sources on existing smart greenhouse control systems=== | |||

[1] Abbassy, M. M., & Ead, W. M. (2020). Intelligent Greenhouse Management System. 2020 6th International Conference on Advanced Computing and Communication Systems, ICACCS 2020. https://doi.org/10.1109/ICACCS48705.2020.9074345 | |||

This paper mentions an robotic intelligent greenhouse management system. Which reads out the water level, humidity, and measures the moisture content of the soil based on real-time area data. With arduino components. | |||

[2] Kaneda, Y., Ibayashi, H., Oishi, N., & Mineno, H. (2015). Greenhouse environmental control system based on SW-SVR. Procedia Computer Science, 60(1). https://doi.org/10.1016/j.procs.2015.08.249 | |||

This paper includes information about the general design of a greenhouse automatic environment control system. | |||

[3] Kokieva, G. E., Trofimova, V. S., & Fedorov, I. R. (2020). Greenhouse microclimate control. IOP Conference Series: Materials Science and Engineering, 1001(1). https://doi.org/10.1088/1757-899X/1001/1/012136 | |||

This paper discusses (the lack of) a mathematical model to control greenhouse temperature and heat transfer. | |||

[4] Kumar, A., Singh, V., Kumar, S., Jaiswal, S. P., & Bhadoria, V. S. (2020). IoT enabled system to monitor and control greenhouse. Materials Today: Proceedings. https://doi.org/10.1016/j.matpr.2020.11.040 | |||

This paper includes diagrams of arduino (components) and wiring to assemble a greenhouse management system. | |||

[5] Sri Jahnavi, V., & Ahamed, S. F. (2015). Smart wireless sensor network for automated greenhouse. IETE Journal of Research, 61(2). https://doi.org/10.1080/03772063.2014.999834 | |||

This source includes information on all types of smart sensors aimed at a smart greenhouse. | |||

[6] Von Borstel, F. D., Suárez, J., De La Rosa, E., & Gutiérrez, J. (2013). Feeding and water monitoring robot in aquaculture greenhouse. Industrial Robot, 40(1). https://doi.org/10.1108/01439911311294219 | |||

This paper contains the design of a robotic system to feed aquatic organisms and measure water physicochemical parameters in experimental aquaculture ponds. Our own system is focused on plants but the robotic monitoring of environmental parameters is of interest here. | |||

[7] Zhang, C. (2018). Greenhouse intelligent control system based on microcontroller. AIP Conference Proceedings, 1955. https://doi.org/10.1063/1.5033697 | |||

This paper contains a chart with components of a greenhouse control system, including information on the circuitry per module, and a flow chart of how the software should work. | |||

[8] Zhao, R., & Lu, L. (2020). Automatic Temperature and Humidity Detection and Alarm System for Greenhouse. IOP Conference Series: Earth and Environmental Science, 512(1). https://doi.org/10.1088/1755-1315/512/1/012099 | |||

This paper designs and implements the monitoring and alarm system of temperature and humidity of a greenhouse. | |||

[9] Carder, C. (2004). Irrigation systems. Rocky Mountain Construction, 85(20), 5. Retrieved from https://search-proquest-com.dianus.libr.tue.nl/trade-journals/irrigation-systems/docview/196317404/se-2?accountid=27128 | |||

A paper about the irrigation technology being used currently | |||

[10] Mudiyanti, R. (2019). Design watering system on greenhouse using microcontroller with matrix based. iopscience.iop.org. 1280 022067 | |||

This paper is about desiging a watering system on a greenhouse using microcontroller with matrix based | |||

===Effect of plant caring on health=== | |||

[11] Loram, A., Warren, P., Thompson, K., & Gaston, K. (2011). Urban Domestic Gardens: The Effects of Human Interventions on Garden Composition. Environmental Management, 48(4), 808–824. https://doi.org/10.1007/s00267-011-9723-3 | |||

This paper talks about how taking care of plants works stress-relieving. | |||

[12] Pedrinolla, A., Tamburin, S., Brasioli, A., Sollima, A., Fonte, C., Muti, E., Smania, N., Schena, F., & Venturelli, M. (2019). An Indoor Therapeutic Garden for Behavioral Symptoms in Alzheimer’s Disease: A Randomized Controlled Trial. Journal of Alzheimer’s Disease, 71(3), 813–823. https://doi.org/10.3233/jad-190394 | |||

This paper is about fardening as a therapy for people with Alheimers disease. | |||

[13] George, D. R. (2013). Harvesting the Biopsychosocial Benefits of Community Gardens. American Journal of Public Health, 103(8), e6. https://doi.org/10.2105/ajph.2013.301435 | |||

This paper is about how community gardens work for people with other mental illnesses, so it could also work on people with down syndrome. | |||

[14] George, D. R., Kraschnewski, J. L., & Rovniak, L. S. (2011). Public Health Potential of Farmers’ Markets on Medical Center Campuses: A Case Study From Penn State Milton S. Hershey Medical Center. American Journal of Public Health, 101(12), 2226–2232. https://doi.org/10.2105/ajph.2011.300197 | |||

This paper is about how farmer-markets work positively on the health of people. | |||

===Plants and how to care for them=== | |||

[15] Weatherley, P. E. (1976). Introduction: water movement through plants. Philosophical Transactions of the Royal Society of London. B, Biological Sciences, 273(927), 435–444. https://doi.org/10.1098/rstb.1976.0023 | |||

This paper explains how water movement in plants work. | |||

[16] Chao, D., & Lin, H. (2010). The tricks plants use to reach appropriate light. Science China Life Sciences, 53(8), 916–926. https://doi.org/10.1007/s11427-010-4047-8 | |||

This paper explains how plants make sure they get the right amount of light, so not too much and not too little. | |||

[17] Drury, & Sally. (2011). Watering, bedding plants and tubs. Horticulture week, 34. https://search-proquest-com.dianus.libr.tue.nl/trade-journals/watering-bedding-plants-tubs/docview/872335545/se-2?accountid=27128 | |||

This paper explains when it is the best time of day to water certain plants. | |||

[18] Rogers, P. (1993). Watering is crucial to plants: [ALL Edition]. Telegram & Gazette, G1. https://search-proquest-com.dianus.libr.tue.nl/newspapers/watering-is-crucial-plants/docview/268517145/se-2?accountid=27128 | |||

This paper explains why it is important that plants get the right amount of water. | |||

[19] Vanderbilt, V., & Grant, L. (1985). Plant Canopy Specular Reflectance Model. IEEE Transactions on Geoscience and Remote Sensing, GE-23(5), 722–730. https://doi.org/10.1109/tgrs.1985.289390 | |||

A model for the amount of light specularly reflected and polarised by a plant. | |||

[20] Roberts, E., & Burleigh, M. (2010). Watering Systems for Success in Growing Plants, Using Low pH and Ammonium Nitrogen. Cactus and Succulent Journal, 82(6), 266–275. https://doi.org/10.2985/0007-9367-82.6.266 | |||

The paper describes what changes should be made to the water that is used in the system in order to get the best results. | |||

===The syndrome of Down=== | |||

[21] Angela P. Presson, Ginger Partyka, … Edward R.B. McCabe, Current Estimate of Down Syndrome Population Prevalence in the United States, The Journal of Pediatrics, Volume 163, Issue 4, 2013, Pages 1163-1168, ISSN 0022-3476, https://doi.org/10.1016/j.jpeds.2013.06.013. | |||

A paper about how often the syndrome of down occurs | |||

[22] Robert A. Catalano, Down syndrome, Survey of Ophthalmology, Volume 34, Issue 5, 1990, Pages 385-398, ISSN 0039-6257, https://doi.org/10.1016/0039-6257(90)90116-D. | |||

This paper goes really deep into what the syndrome of down actually is | |||

[23] Mark Selikowitz. Down Syndrome. Vol 3rd ed. OUP Oxford; 2008. Accessed April 22, 2021. http://search.ebscohost.com/login.aspx?direct=true&db=nlebk&AN=467605&site=ehost-live | |||

This paper is about raising children with down syndrome | |||

[24] Chapman, Robin & Seung, Hye-Kyeung & Schwartz, Scott & Bird, Elizabeth. (2000). Predicting Language Production in Children and Adolescents With Down Syndrome. Journal of speech, language, and hearing research: JSLHR. 43. 340-50. 10.1044/jslhr.4302.340. | |||

This paper is about the language skills of adolescents with down syndrome. | |||

===Other sources=== | |||

[25] Wieseler, N. A., Hanson, R. H., Chamberlain, T. P., & Thompson, T. (1988). Stereotypic behavior of mentally retarded adults adjunctive to a positive reinforcement schedule. Research in Developmental Disabilities, 9(4), 393–403. https://doi.org/10.1016/0891-4222(88)90033-9 | |||

A paper about a study which evaluated the indirect effects on stereotypic frequency when the value of a concurrent fixed-interval reinforcement schedule for adaptive behaviour was varied. 13 | |||

[26] Vijendra Babu, D. (2020). Automatic Irrigation Systems for Efficient usage of Water using Embedded Control Systems. 993 012077 | |||

A paper about a similar project being done | |||

[27] Gafni, V. (1999). Robots: A Real-Time Systems Architectural Style. ACM SIGSOFT Software Engineering Notes, 24(6), 1–18. https://doi.org/10.1145/318774.318786 This paper gives a broad description of what robots are | |||

= | =Appendix A= | ||

The plan and task-division per week including a logbook of the work that was done per person of the group is listed below. | |||

==Week 1== | ==Week 1== | ||

*Brainstorming about possible subjects (all) | *Brainstorming about possible subjects (all) | ||

| Line 292: | Line 782: | ||

|- | |- | ||

| Nando | | Nando | ||

| | | 10.h | ||

| | | meetings(3h), getting a new 3D printer(3h), making changes to the design for the new printer(1h), meeting explaining the design for the printer(1.5h), working on the wiki(2h) | ||

|- | |- | ||

| Dorien | | Dorien | ||

| | | 14 | ||

| | | Meetings (4h), programming (10h) | ||

|} | |} | ||

| Line 327: | Line 817: | ||

|- | |- | ||

| Nando | | Nando | ||

| | | 9 | ||

| | | Meetings(3h), working on the final presentation(4h), preparing for the presentation(2h) | ||

|- | |- | ||

| Dorien | | Dorien | ||

| | | 15 | ||

| | | Meetings (4h), working with Marijn on campus (3h), debugging the code (6h), prepared the presentation (2h) | ||

|} | |} | ||

| Line 341: | Line 831: | ||

*Giving the final presentation (Dorien, Marijn, Nando) | *Giving the final presentation (Dorien, Marijn, Nando) | ||

*Processing the results of the test week ( | *Processing the results of the test week (Marijn, Dorien) | ||

{| border=1 style="border-collapse: collapse;" cellpadding = 2 | {| border=1 style="border-collapse: collapse;" cellpadding = 2 | ||

| Line 349: | Line 839: | ||

|- | |- | ||

| Marijn | | Marijn | ||

| | | 13.5 | ||

| | | Delivering and retrieving the prototype to SDW Roosendaal (3h), giving/watching presentations (2h), redesign the layout and bringing more structure to the wiki (1h), editing the wiki (6h), uploading the changes made by other group members who cannot access the wiki, and reformatting (1.5h) | ||

|- | |- | ||

| Bert | | Bert | ||

| | | 6 | ||

| | | Editing the wiki (4h), reading through the wiki (2h) | ||

|- | |- | ||

| Nando | | Nando | ||

| | | 6 | ||

| | | Giving/preparing the presentation (2h), working on the wiki(4h) | ||

|- | |- | ||

| Dorien | | Dorien | ||

| | | 15 | ||

| | | delivering and retrieving the prototype to Veldhoven (5h), giving/watching presentations (2h), editing the wiki (8h) | ||

|} | |} | ||

= | =Appendix B= | ||

This was the mail that was send to the care houses in order to broaden our perspective on the needs and preferences of people with Down Syndrome | |||

==Email with a questionnaire for hypothetical use== | |||

= | |||

=Email with a questionnaire for hypothetical use= | |||

Beste meneer/mevrouw, | Beste meneer/mevrouw, | ||

| Line 607: | Line 933: | ||

Marijn Borghouts | Marijn Borghouts | ||

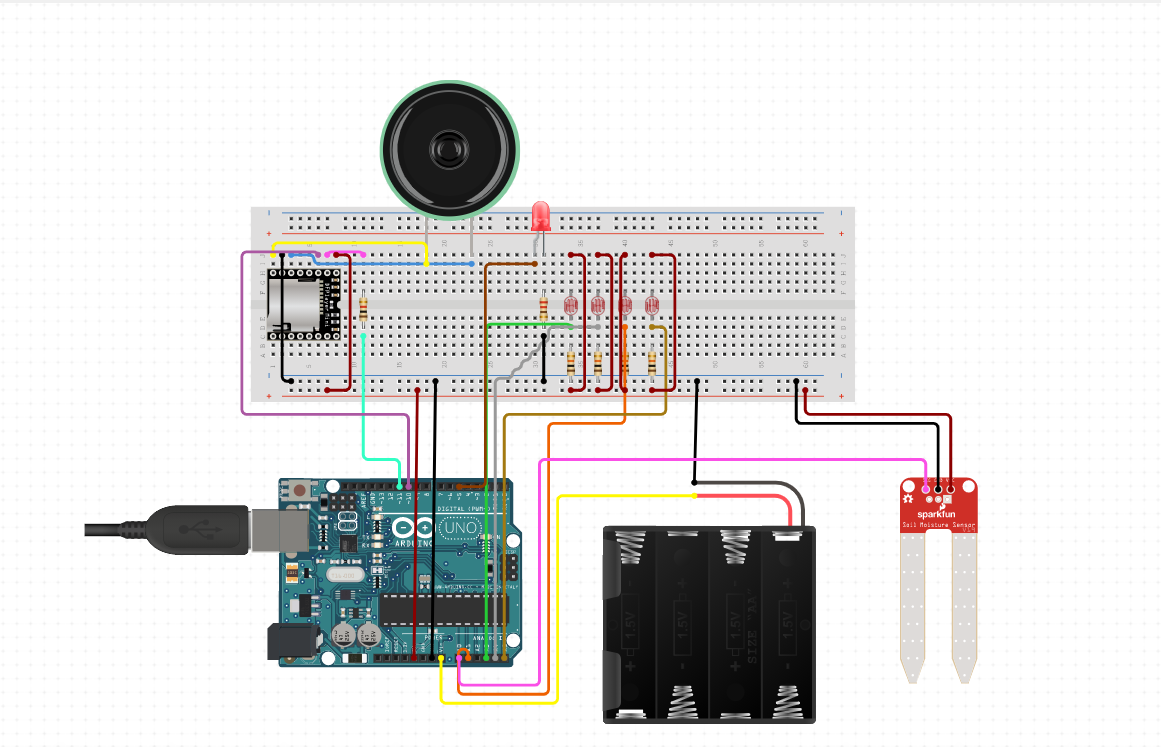

=Results of the questionnaire= | ==Results of the questionnaire== | ||

This questionnaire was sent out as an email on Thursday the 13th of May to 13 new, not yet approached, care institutions that were located in Brabant or Limburg. Unfortunately, we immediately got an automated reply that said that one of the persons we were trying to contact was on holiday. That was when we realized that our mails had been sent in the May holiday and that there was a chance that our mail would be far down in the recipient's inbox by the time somebody starts working again. We decided to wait until Wednesday the 19th to see if we would get a reaction. Unfortunately, we did not receive a single one. So on that Wednesday morning, we decided to call as many institutions as possible, you can see the results below. Unfortunately after 3h of work, we still had zero actual replies. | This questionnaire was sent out as an email on Thursday the 13th of May to 13 new, not yet approached, care institutions that were located in Brabant or Limburg. Unfortunately, we immediately got an automated reply that said that one of the persons we were trying to contact was on holiday. That was when we realized that our mails had been sent in the May holiday and that there was a chance that our mail would be far down in the recipient's inbox by the time somebody starts working again. We decided to wait until Wednesday the 19th to see if we would get a reaction. Unfortunately, we did not receive a single one. So on that Wednesday morning, we decided to call as many institutions as possible, you can see the results below. Unfortunately after 3h of work, we still had zero actual replies. | ||

| Line 628: | Line 954: | ||