Viotar/Hardware Design: Difference between revisions

No edit summary |

|||

| (76 intermediate revisions by 4 users not shown) | |||

| Line 1: | Line 1: | ||

{|cellpadding="10" | {|cellpadding="10" | ||

|-valign="top" | |-valign="top" | ||

|width="100%" style="border:1px solid #fabd23; background-color:#FEF5DE;"| | |width="100%" style="border:1px solid #fabd23; background-color:#FEF5DE;text-align: justify;"| | ||

{| padding="0" cellspacing="0" style="margin-top:.2em; width:100%; background:none" | {| padding="0" cellspacing="0" style="margin-top:.2em; width:100%; background:none" | ||

| rowspan="32" width="5px" | | | rowspan="32" width="5px" | | ||

| Line 24: | Line 24: | ||

'''Subpages:''' | '''Subpages:''' | ||

</h1><br/> | </h1><br/> | ||

{{:Viotar_Menu}} | |||

|width="2%" style="background-color:#FEF5DE;"| | |width="2%" style="background-color:#FEF5DE;"| | ||

|width="49%" style="border:2px solid #fabd23;"| | |width="49%" style="border:2px solid #fabd23;text-align: justify;"| | ||

<h1 style="font-size:180%; border:none; margin:0; padding:0"> | <h1 style="font-size:180%; border:none; margin:0; padding:0"> | ||

'''Overview:''' | '''Overview:''' | ||

| Line 48: | Line 34: | ||

<br/> | <br/> | ||

|}<br/> | |}<br/> | ||

{| cellpadding="10" | |||

|-valign="top" | |||

| style="border:2px solid #00FF33; background-color:#CCFF99"| | |||

=Hardware design= | =Hardware design= | ||

==Design 0.1== | ==Design 0.1== | ||

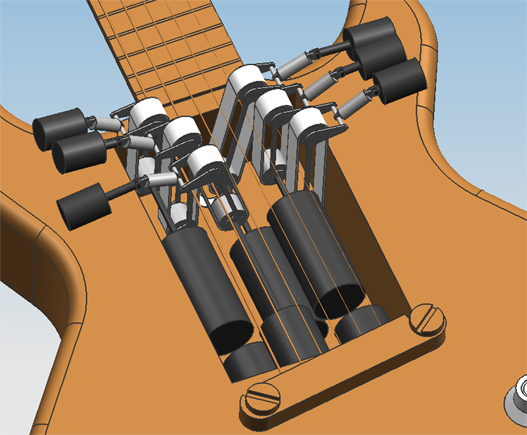

The first concept of a design was based on having the motors directly drive the bowing belts, to reduce noise coming from moving mechanicals. Because the engines can't move, and the belts have to be moved onto and off the string, the belts will rotate as a rigid body around the driveshaft. Frames that hold the belts so they behave like a rigid body are solely mounted on the driveshaft, with suitable bearings to prevent friction. | |||

On friday the 5th of november, the first attempt at a design was finished. Only geometric constraints were taken into account, meaning the size of the engines and actuators were solely adjusted to the amount of space that was available in the guitar. | On friday the 5th of november, the first attempt at a design was finished. Only geometric constraints were taken into account, meaning the size of the engines and actuators were solely adjusted to the amount of space that was available in the guitar. | ||

{| align=center padding=0 cellspacing=0 style="background:#f9f9f9" width="704px" | {| align=center padding=0 cellspacing=0 style="background:#f9f9f9" width="704px" | ||

| Line 62: | Line 53: | ||

|- | |- | ||

|} | |} | ||

As can be seen, there is a spring suspension between the linear actuator and the belt frame. This is put here, because in this stage we don't know whether we'll need this or not, so we just assumed that we do, because we can always remove them from the design. | |||

| Line 72: | Line 66: | ||

|- | |- | ||

|} | |} | ||

<br> | |||

==Design 0.2== | ==Design 0.2== | ||

| Line 78: | Line 73: | ||

*There shouldn't be motors on the neck side of the construction, because that forces the construction towards the bridge, leaving less space for the player to pluck the strings. | *There shouldn't be motors on the neck side of the construction, because that forces the construction towards the bridge, leaving less space for the player to pluck the strings. | ||

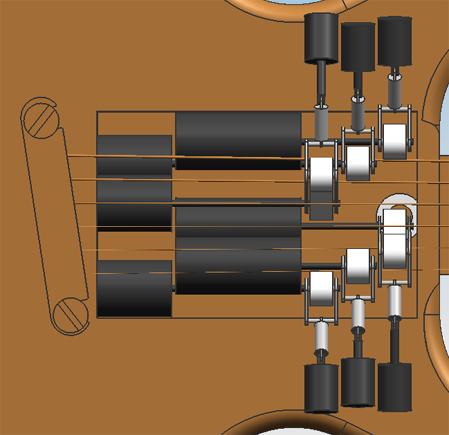

These improvements have been worked into design 0.2. | These improvements have been worked into design 0.2. Some CAD screenshots of this design are shown in the figure below. | ||

{| align=center padding=0 cellspacing=0 style="background:#f9f9f9" width="991px" | {| align=center padding=0 cellspacing=0 style="background:#f9f9f9" width="991px" | ||

| Line 88: | Line 84: | ||

|- | |- | ||

|} | |} | ||

<br> | |||

==Design 0.3 to 0.6== | ==Design 0.3 to 0.6== | ||

For the rest of the development of the design, many more considerations had to be made. For instance, we had to know what motors to use, what actuators to use, what roller bearings to use, shaft couplings, hinges, frames, etcetera. The most important design considerations are described in the paragraphs below. | |||

====Estimation of the required motor power==== | ====Estimation of the required motor power==== | ||

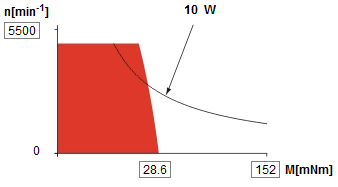

The needed motor power is calculated using <math>P=M_{T}\cdot\Omega</math>. For this, the total load <math>M_{T}</math> and the angular speed <math>\Omega</math> have to be calculated. | The needed motor power is calculated using <math>P=M_{T}\cdot\Omega</math>. For this, the total load <math>M_{T}</math> and the angular speed <math>\Omega</math> have to be calculated. The total motor load consists of the load coming from the friction of the bowing belt with the string <math>M_{bt}</math> and the friction of the bearing supporting the wheel that drives the belt, <math>M_{br}</math>. <math>M_{bt}</math> is calculated by <math>M_{w}=R\cdot F_{w,bt}=R\cdot F_{n}\cdot\mu_{w,bt}</math>, with <math>F_{n}=F_{b}</math> the normal force between the bowing belt and the string. This bow force has a maximum of <math>4 N</math>. The value of <math>\mu_{w,bt}</math> is estimated at a rather high <math>0.7</math>. The radius <math>R</math> at which the belt runs around the shafts is taken to be <math>7.5 mm</math>, on the actual design it will be smaller than this. This yields <math>M_{bt}=21.0 mNm</math>. | ||

<math>M_{br}</math> is calculated assuming cylindrical roller bearings will be used. For cylindrical roller bearings <math>M_{br}=F\mu_{w,br}d/2</math>, with <math>mu_{w,br}=0.002</math> the friction coëfficient for cylindrical roller bearings, <math>F</math> the lateral force on between the bearing and the shaft which is estimated at <math>30 N</math>, and <math>d</math> the shaft diameter, which is about <math>4 mm</math> for a bearing with a outer diameter of <math>11 mm</math>. This yields <math>M_{br}=0.12 mNm</math>. The angular speed of the motor shaft <math>\Omega</math> is determined to be <math>\Omega=v_b/R=2546 rpm</math>, with bow speed <math>v_b</math> the maximum occuring value, and <math>R</math> the radius at which the belt runs. Now combining the findings for <math>M_{bt}</math> and <math>M_{br}</math>, the total motor load <math>M_{T}</math> is estimated at <math>21.12 mNm</math>. The power then becomes: | |||

The total motor load consists of the load coming from the friction of the bowing belt with the string <math>M_{bt}</math> and the friction of the bearing supporting the wheel that drives the belt, <math>M_{br}</math>. | |||

<math>M_{bt}</math> is calculated by <math>M_{w}=R\cdot F_{w,bt}=R\cdot F_{n}\cdot\mu_{w,bt}</math>, with <math>F_{n}=F_{b}</math> the normal force between the bowing belt and the string. This bow force has a maximum of <math>4 N</math>. The value of <math>\mu_{w,bt}</math> is estimated at a rather high <math>0.7</math>. The radius <math>R</math> at which the belt runs around the shafts is taken to be <math>7.5 mm</math>, on the actual design it will be smaller than this. This yields <math>M_{bt}=21.0 mNm</math>. | |||

<math>M_{br}</math> is calculated assuming cylindrical roller bearings will be used. For cylindrical roller bearings <math>M_{br}=F\mu_{w,br}d/2</math>, with <math>mu_{w,br}=0.002</math> the friction coëfficient for cylindrical roller bearings, <math>F</math> the lateral force on between the bearing and the shaft which is estimated at <math>30 N</math>, and <math>d</math> the shaft diameter, which is about <math>4 mm</math> for a bearing with a outer diameter of <math>11 mm</math>. This yields <math>M_{br}=0.12 mNm</math>. | |||

The angular speed of the motor shaft <math>\Omega</math> is determined to be <math>\Omega=v_b/R=2546 rpm</math>, with bow speed <math>v_b</math> the maximum occuring value, and <math>R</math> the radius at which the belt runs. | |||

Now combining the findings for <math>M_{bt}</math> and <math>M_{br}</math>, the total motor load <math>M_{T}</math> is estimated at <math>21.12 mNm</math>. The power then becomes: | |||

<math>P=5.63 W</math>. | <math>P=5.63 W</math>. | ||

| Line 107: | Line 97: | ||

====Picking a motor==== | ====Picking a motor==== | ||

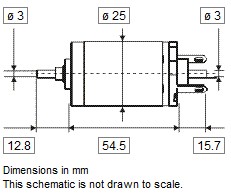

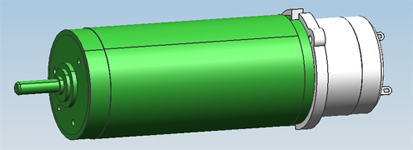

After looking at the catalogi of various manufacturers, we picked a motor from Maxon, article number 118747, that was fit for the job. Specifications are given in the figure below. | After looking at the catalogi of various manufacturers, we picked a motor from Maxon, article number 118747, that was fit for the job. Specifications are given in the figure below. | ||

{| align=center padding=0 cellspacing=0 style="background:#f9f9f9" width="584px" | {| align=center padding=0 cellspacing=0 style="background:#f9f9f9" width="584px" | ||

| Line 116: | Line 107: | ||

|- | |- | ||

|} | |} | ||

The motor has just the right operating range. This motor should be able to continuously handle the calculated load of 21.12 mNm at 2542 rpm. The dimensions are great, the motor has a very small diameter of 25mm, which is the most critical dimension for the design for being able to fit six motors. | The motor has just the right operating range. This motor should be able to continuously handle the calculated load of 21.12 mNm at 2542 rpm. The dimensions are great, the motor has a very small diameter of 25mm, which is the most critical dimension for the design for being able to fit six motors. | ||

A suitable encoder is offered by Maxon to fit the motor (article number 118909). It is fitted onto the back of the motor. CAD files of both the motor and the encoder are on the Maxon site, | A suitable encoder is offered by Maxon to fit the motor (article number 118909). It is fitted onto the back of the motor. CAD files of both the motor and the encoder are on the Maxon site, a picture of them is shown below. | ||

{| align=center padding=0 cellspacing=0 style="background:#f9f9f9" width="423px" | {| align=center padding=0 cellspacing=0 style="background:#f9f9f9" width="423px" | ||

| Line 129: | Line 122: | ||

|- | |- | ||

|} | |} | ||

<br> | |||

====Picking a linear motion actuator==== | |||

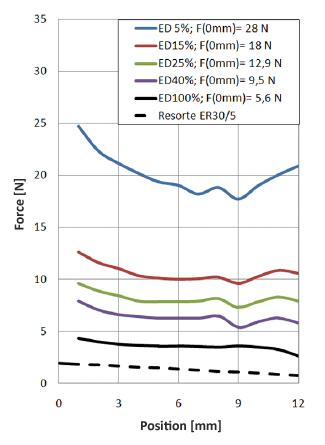

Six actuators are needed in order to push the revolving bowing belt onto the string. These actuators have to be able to push the belts against the string with a force of 4 N. We also want the Viotar to be able to play 16 notes per second, so the actuator has to be able to move out and retract fast, as well as adjusting its position to obtimise the bow force. This rules out screw- or wormwheel type actuators because of their lack of speed at which they can complete their stroke, and makes linear solenoids a good alternative. It is important to find an actuator that is small enough to fit into the viotar. After some research a linear solenoid was found, made by NAFSA, of type ERC 35/C ([http://www.nafsa-solenoids.com/electroiman-erc-serie-push-and-pull--high-duty--ip40-33.html page on NAFSA site]). This actuator is not too big can deliver just enough force on a stroke that is big enough, as the figure below, a plot of the excitable force of the solenoid versus the position of the moving part shows. | |||

{| align=center padding=0 cellspacing=0 style="background:#f9f9f9" width="335px" | |||

|- | |||

| style="font-size:85%; border:1px solid #cccccc; padding:3px 3px 0px 3px" | | |||

[[File:Linearsolenoidforce.jpg|border]] | |||

At the beginning of its stroke the actuator can excite a force of about 4.5 N, and at the end of its stroke about 2.5 N, for a duty cycle of 100%. | |||

|- | |||

|} | |||

There's one problem: at the end of the stroke, the biggest force is needed, because at this point the belt is pushed against the string the hardest. Turning the solenoid around solves this problem. As the NAFSA site says, it is a push/pull actuator, and since inverting a magnetic field doesn't change its intensity, we assume that the forces shown in the figure also hold when the actuator is reversed. | |||

Finally, the solenoids dimensions: | |||

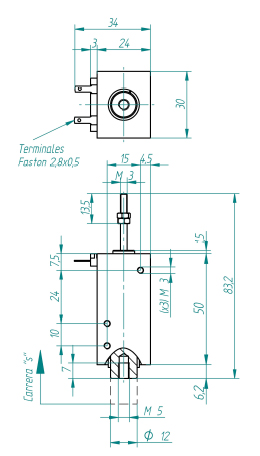

{| align=center padding=0 cellspacing=0 style="background:#f9f9f9" width="675px" | |||

|- | |||

| style="font-size:85%; border:1px solid #cccccc; padding:3px 3px 0px 3px" | | |||

[[File:Linearsolenoiddimensions.jpg|border]] [[File:LinearsolenoidCAD.jpg|border]] | |||

Left: The dimensions of the chosen solenoid in mm. Right: A CAD drawing of the solenoid based on these dimensions. | |||

|- | |||

|} | |||

Special attention has gone into having the stroke exactly at the right place in the design, meaning that it is able to take the bowing belts completely off the strings, and on the other hand push them far enough into the string to create a 4 N bow force. | |||

====Space between strings==== | ====Space between strings==== | ||

As the previous designs had parts running in between the strings, an examination on the feasability of this is necessary. | |||

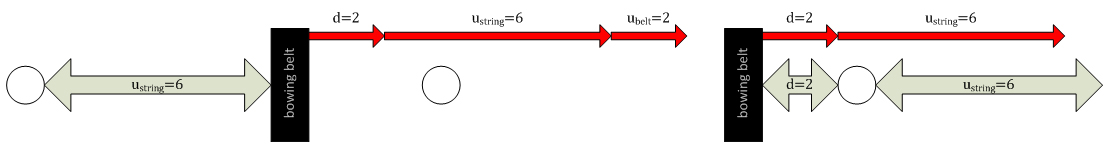

The situation is sketched in the figure below. | |||

{| align=center padding=0 cellspacing=0 style="background:#f9f9f9" width="480px" | |||

|- | |||

| style="font-size:85%; border:1px solid #cccccc; padding:3px 3px 0px 3px" | | |||

[[File:Stringspacing3.jpg|border]] | |||

All measures in mm. The white circles are strings. Olive-green arrows imply possible movement of the strings. Red arrows imply possible movement of the bowing belts. <math>u_{string}</math> is the displacement of the left hand string when it is pushed to the right with the maximum bow force of 4 N. <math>u_{belt}</math> is the displacement of the belt to the left, when it pushes the right hand string to the right with a bow force of 4 N. <math>d</math> is the distance that needs to be kept between the belt and the string when the belt is supposed to be loose from the string. The left side of the bowing belt moves in pair with the right side, but when the right side is pushed against the string, the left side moves an addition distance <math>u_{belt}</math>. | |||

|- | |||

|} | |||

The figure clearly shows that having the non-bowing side of the belt run back upwards between the strings is no option whatsover, because the non-bowing side will run into another string (the middle string in the picture). If this isn't possible, it ''certainly'' isn't possible to fit a frame in between the strings. | |||

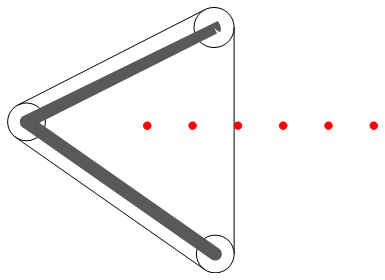

Therefore, this configuration is dropped and a new one is adopted: we let the frame that holds the bowing belt run around the outermost strings, and with a third pulley, let the bowing belt run this way too. This configuration is sketched in the figure below. | |||

{| align=center padding=0 cellspacing=0 style="background:#f9f9f9" width="395px" | |||

|- | |||

| style="font-size:85%; border:1px solid #cccccc; padding:3px 3px 0px 3px" | | |||

[[File:Clawconfig.jpg|border]] | |||

A claw-formed frame supports 3 pulleys on which the bowing belt runs. Only the necessary part of the belt and no frame runs in between the strings. | |||

|- | |||

|} | |||

<br> | |||

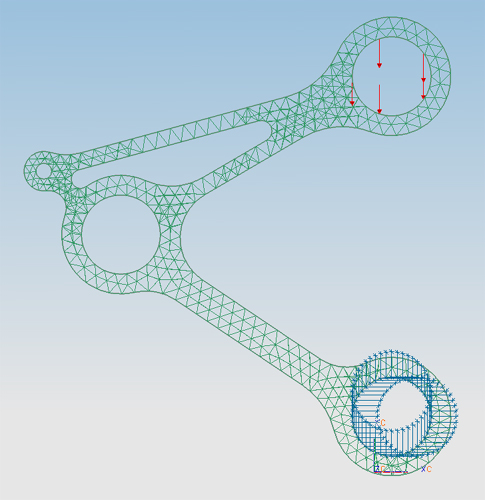

====Design of the claws==== | |||

The shape of the claws was designed in a very straightforward way. There were three pulleys, and a rod where a hinge can grip on, for the linear actuator. The lower and the "left" pulley are connected with a rib, and the "left" pulley with the upper pulley too. Then, the hinge rod is connected with the left pulley. Because this is the force path, the hinge rod is connected directly to the upper pulley too. For the "long" version of the claw, spacial restrictions dictate that the rib between the lower pulley and the left pully should be curved, to make place for a shaft of another mechanism. This doesn't cause problems, because there will be no direct compressing force between these pulleys. | |||

The claws were dimensioned in a number of steps: | |||

#We chose an estimate size for the claws, so that they fitted into the design. | |||

#We chose bowing belts that best fitted these claws. | |||

#We changed the size of the claws to fit the bowing belts exactly. | |||

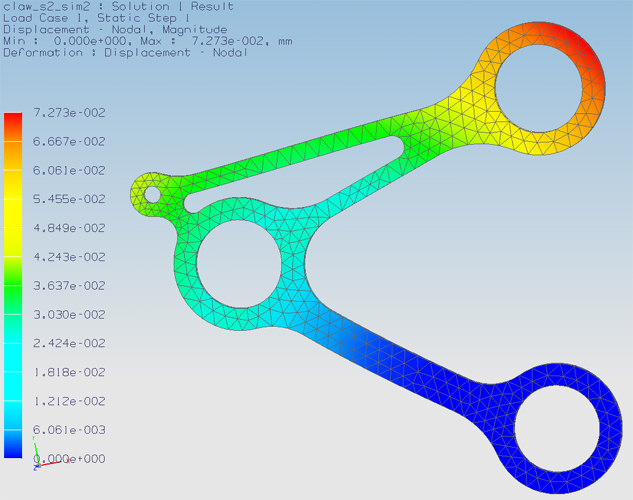

By fitting exactly, we mean that one pair of claws forming a sandwich should excite 4 N of force on the bowing belt, so it sits tightly around the pullies, and will be stiff enough when pressed against the string. This means one claw part will have to excite a force of 2 N. We made the claws a little too big. To be precise, we placed the hole for the upper pulley shaft 0.07 mm too high. FEM analysis in NX5 predicts that it will require a force of 2 N to bend the claw back to the propper dimensions. This result was achieved by varying the width of the rib between the lower and the left pulley. This is shown in the figure below. | |||

{| align=center padding=0 cellspacing=0 style="background:#f9f9f9" width="1133px" | |||

|- | |||

| style="font-size:85%; border:1px solid #cccccc; padding:3px 3px 0px 3px" | | |||

[[File:FEM_1N_lc.jpg|border]] [[File:FEM_1N_sc.jpg|border]] | |||

Left: The lower hole is fixed (to the motor shaft). The upper hole is pulled down with a force of 2 N. Right: The y-displacement. The upper hole bends down about 0.07 mm, as can be seen on the color scale. | |||

|- | |||

|} | |||

<br> | |||

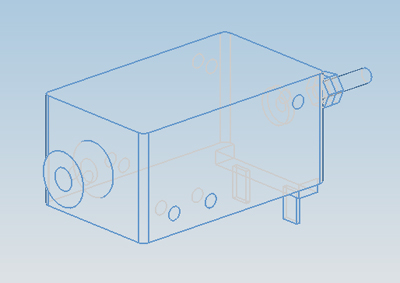

====Design 0.6==== | ====Design 0.6==== | ||

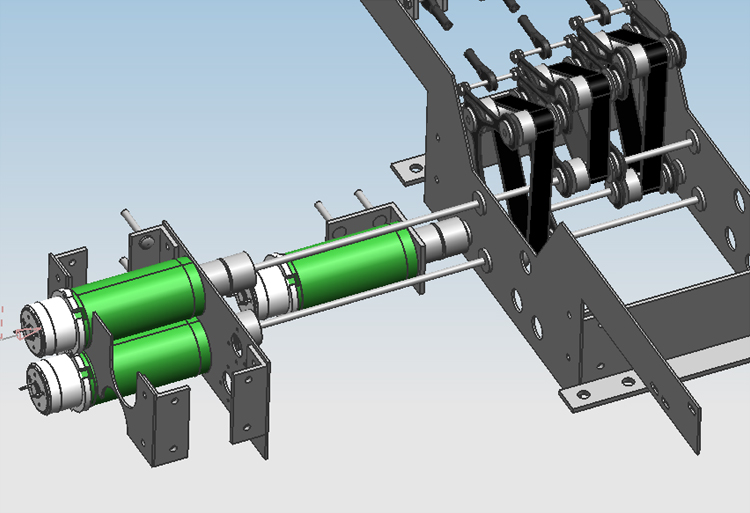

Below are many screenshots of the final design in CAD. Of this design, only 3 single-string mechanisms were actually realised, but the whole design is expandable to 6 mechanisms without problems. The frame has also been realized so that additional mechanisms can be assembled without alterations to the frame. | |||

{| align=center padding=0 cellspacing=0 style="background:#f9f9f9" width="395px" | |||

|- | |||

| style="font-size:85%; border:1px solid #cccccc; padding:3px 3px 0px 3px" | | |||

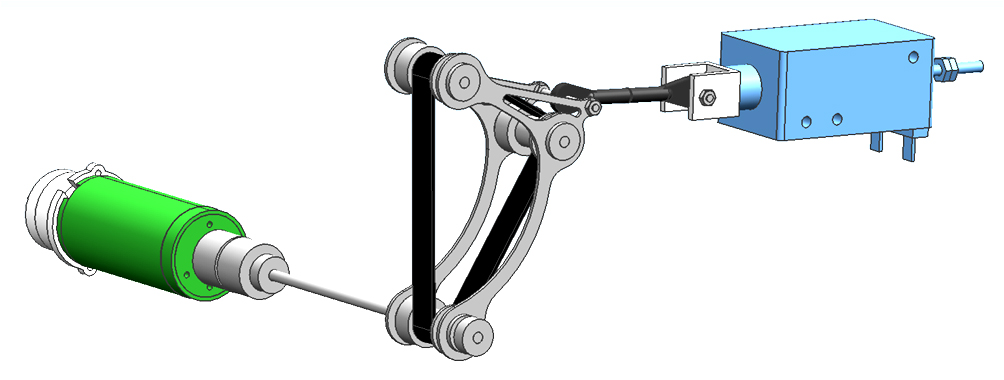

[[File:Design06img06.jpg|border]] | |||

The resulting mechanism for a single string. The motor (green) and the linear actuator (blue) are fixed. The shaft of the motor is lengthened with a shaft coupling. All shafts in the claw frame are mounted with roller bearings. Between the linear actuator and the claws is a set of hinges, that are connected with an M2 threaded rod. The length of the shaft and this rod differs for the different mechanisms used to play the different strings. | |||

|- | |||

|} | |||

{| align=center padding=0 cellspacing=0 style="background:#f9f9f9" width="395px" | |||

|- | |||

| style="font-size:85%; border:1px solid #cccccc; padding:3px 3px 0px 3px" | | |||

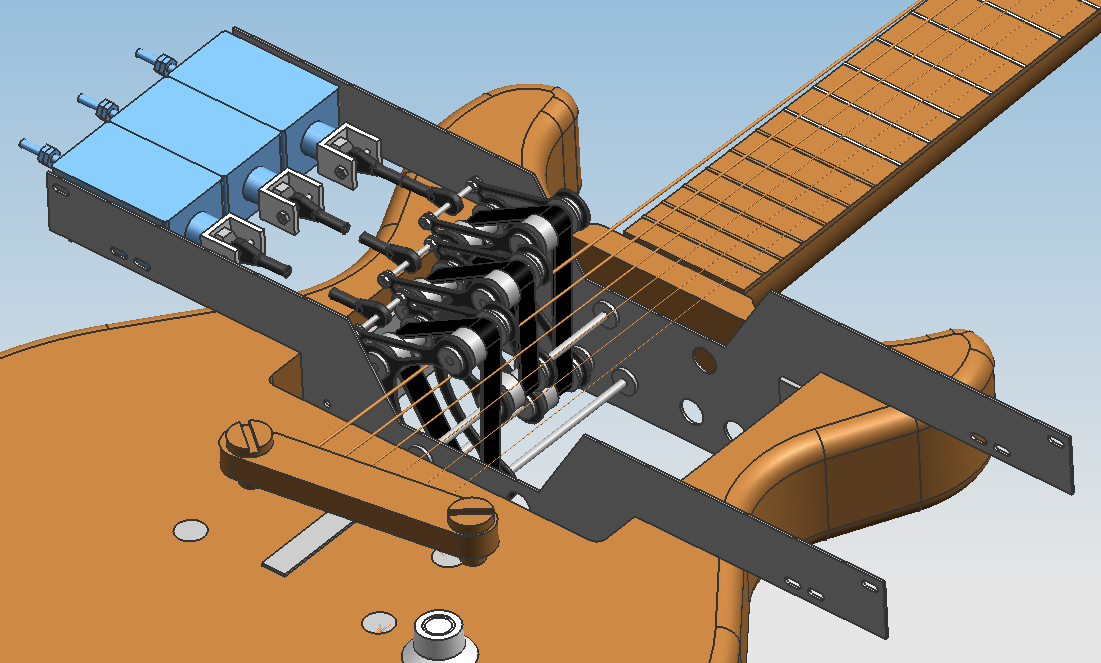

[[File:Design06img01.jpg|border]] | |||

The guitar with the mechanism. The frame as well as the spacial configuration of the motors allows for 6 single string mechanisms to be built in, but only 3 mechanisms were actually realised, for budgetary reasons. | |||

|- | |||

|} | |||

{| align=center padding=0 cellspacing=0 style="background:#f9f9f9" width="964px" | |||

|- | |||

| style="font-size:85%; border:1px solid #cccccc; padding:3px 3px 0px 3px" | | |||

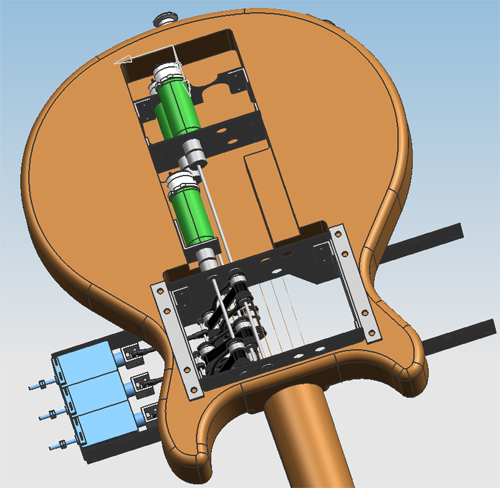

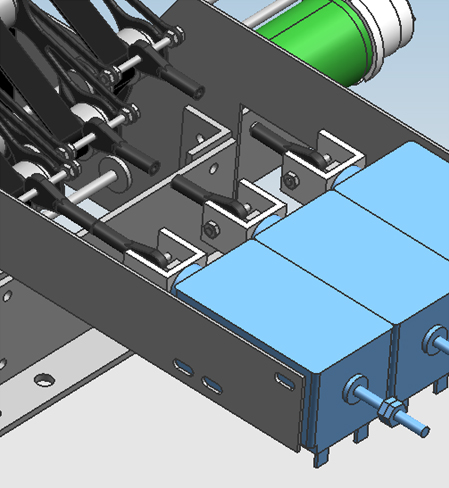

[[File:Design06img02.jpg|border]] [[File:Design06img03.jpg|border]] | |||

Left: The guitar shown from below. Right: Close up of the connection between the linear actuators and the claw frames. The rods between the hinges weren't modelled to keep the model more flexible, but the hinges are lined out as if the rods were there. | |||

|- | |||

|} | |||

{| align=center padding=0 cellspacing=0 style="background:#f9f9f9" width="395px" | |||

|- | |||

| style="font-size:85%; border:1px solid #cccccc; padding:3px 3px 0px 3px" | | |||

[[File:Design06img04.jpg|border]] | |||

The entire design including the frame shown without the guitar, shown from "below". | |||

|- | |||

|} | |||

<br> | |||

==Right-hand user interface== | ==Right-hand user interface== | ||

| Line 154: | Line 262: | ||

# The Viotar must be capable of playing 18 different notes on different string separately. | # The Viotar must be capable of playing 18 different notes on different string separately. | ||

====Concepts==== | |||

Two main concepts were conceived for this right-hand user interface. | Two main concepts were conceived for this right-hand user interface. | ||

====Turning handgrip==== | =====Turning handgrip===== | ||

The right hand holds on to a handgrip that can turn around the axis that coïncides with the player's forearm. Turning the hand around this axis comes very naturally to most people and can be done very fast with little tension. Turning this handgrip around this axis controls the <i>bowing speed</i>. Turning the grip counterclockwise makes the bowing belts go in counterclockwise direction. The further the grip is turned away from its initial position, the more intense the note. The same goes for clockwise direction. When the grip is in neutral position, the bowing belts stand still (but stay in contact with the string, damping it). Because the required turning movement of the hand is so natural, Requirement 3 and 4 of the above list can be met. Additionally, the grip is fitted with 6 ergonomically placed buttons (like on a computer mouse, for instance), each corresponding to it's own string. Holding down a button places the bowing belt on the string, releasing it moves the bowing belt away from the string. Although the player has only 5 fingers Requirement 1 on the above list is still met, because the thumb can control 2 buttons by 'rolling' over them. | The right hand holds on to a handgrip that can turn around the axis that coïncides with the player's forearm. Turning the hand around this axis comes very naturally to most people and can be done very fast with little tension. Turning this handgrip around this axis controls the <i>bowing speed</i>. Turning the grip counterclockwise makes the bowing belts go in counterclockwise direction. The further the grip is turned away from its initial position, the more intense the note. The same goes for clockwise direction. When the grip is in neutral position, the bowing belts stand still (but stay in contact with the string, damping it). Because the required turning movement of the hand is so natural, Requirement 3 and 4 of the above list can be met. Additionally, the grip is fitted with 6 ergonomically placed buttons (like on a computer mouse, for instance), each corresponding to it's own string. Holding down a button places the bowing belt on the string, releasing it moves the bowing belt away from the string. Although the player has only 5 fingers Requirement 1 on the above list is still met, because the thumb can control 2 buttons by 'rolling' over them. | ||

====Pressure sensitive keys==== | =====Pressure sensitive keys===== | ||

There are 6 pressure sensitive keys, each corresponding to a string. Holding a key down will place the bowing belt on the string, releasing a key will move the bowing belt away from the string. While the key is pressed down, the amount of pressure the user applies on the key defines the note intensity. The keys will be long (like spacebars on a laptop), so that the thumb and index-/middlefinger can alternate while tapping on them, making it possible to meet Requirement 3 and 4 in the above list. | There are 6 pressure sensitive keys, each corresponding to a string. Holding a key down will place the bowing belt on the string, releasing a key will move the bowing belt away from the string. While the key is pressed down, the amount of pressure the user applies on the key defines the note intensity. The keys will be long (like spacebars on a laptop), so that the thumb and index-/middlefinger can alternate while tapping on them, making it possible to meet Requirement 3 and 4 in the above list. | ||

Latest revision as of 15:58, 23 March 2011

|