PRE2017 3 Groep11: Difference between revisions

| (388 intermediate revisions by 5 users not shown) | |||

| Line 1: | Line 1: | ||

<table cellspacing=1 | |||

style="float:right; margin: 0 0 0 1em; border: 1px solid #a2a9b1;background-color: #f9f9f9; padding: .7em;"> | |||

<tr><td colspan="2" style="border-color: #a2a9b1; padding: 0.2em 0.4em; text-align: center;"><b>Members of group 11</b></td></tr> | |||

<tr><td style="border-color: #a2a9b1; padding: 0.2em 0.4em;">C.J.G. Cartignij</td><td style="border-color: #a2a9b1; padding: 0.2em 0.4em;">1014018</td></tr> | |||

<tr><td style="border-color: #a2a9b1; padding: 0.2em 0.4em;">K.D. van Kempen</td><td style="border-color: #a2a9b1; padding: 0.2em 0.4em;">1002991</td></tr> | |||

<tr><td style="border-color: #a2a9b1; padding: 0.2em 0.4em;">W.W.A. Verhaegen</td><td style="border-color: #a2a9b1; padding: 0.2em 0.4em;">1024053</td></tr> | |||

<tr><td style="border-color: #a2a9b1; padding: 0.2em 0.4em;">J.P. Versluijs</td><td style="border-color: #a2a9b1; padding: 0.2em 0.4em;">1019169</td></tr> | |||

<tr><td style="border-color: #a2a9b1; padding: 0.2em 0.4em;">M. van Wiggen</td><td style="border-color: #a2a9b1; padding: 0.2em 0.4em;">1020451</td></tr> | |||

</table> | |||

==Coaching Questions== | ==Coaching Questions== | ||

[[Coaching Questions Group 11]] | [[Coaching Questions Group 11]] | ||

==Problem statement and objectives== | ==Problem statement== | ||

Here, the current state of drone delivery technology will be explained. From this, a problem statement is derived in order to solve a current problem for the technology and objectives for this project will be stated. | |||

===State of the art=== | |||

[[State of the art research]] | |||

A lot of scientific research is currently being done on the implementation of drones for delivery purposes. However, this research mainly focuses on the routing of the drones<ref>Coelho, Bruno N.; Coelho, Vitor N.; Coelho, Igor M.; Ochi, Luiz S. ; Haghnazar K., Roozbeh; Zuidema, Demetrius;. Lima, Milton S.F; da Costa, Adilson R., "A multi-objective green UAV routing problem", Elsevier, (December, 2017) https://www.sciencedirect.com/science/article/pii/S0305054817301028?via%3Dihub</ref>, the avoidance of mid-air collisions<ref name="Vision paper">Anbaroğlu, B., " Parcel delivery in an urban environment using unmanned aerial systems: a vision paper", ISPRS, (November, 2017) https://www.isprs-ann-photogramm-remote-sens-spatial-inf-sci.net/IV-4-W4/73/2017/isprs-annals-IV-4-W4-73-2017.pdf</ref> and privacy aspects<ref>Lidynia, Chantal; Philipsen, Ralf; Ziefle, Martina, " The Sky’s (Not) the Limit - Influence of Expertise and Privacy Disposition on the Use of Multicopters ", Springer, (June 21, 2017) https://link.springer.com/chapter/10.1007/978-3-319-60384-1_26</ref>. There are almost no sources on the delivery itself. On the other hand, there are some conceptual US patents describing drone delivery receptacles<ref>Walsh, R., & Falesch, A. J. (2015). U.S. Patent Application No. 14/587,828. https://patents.google.com/patent/US20150183528A1/en</ref><ref>Shucker, Brian Daniel, and Brandon Kyle Trew. "Machine-readable delivery platform for automated package delivery." U.S. Patent No. 9,864,967. 9 Jan. 2018. https://patents.google.com/patent/US20150175276A1/en </ref><ref>Pleis, James. "Drone Operated Delivery Receptacle." U.S. Patent Application No. 15/289,295. https://patents.google.com/patent/US20170116568A1/en</ref><ref>van Dyke. J. (2016). Unattended Delivery Drop Box. Chicago (US). https://patents.google.com/patent/US20170091710A1/en</ref>. | |||

<br> The problem that is still present with these concepts, however, is that these concepts are mostly implementations for a smart home and can only be used in one specific situation. Thereby, these concepts are only applicable for people who have a house and not for, for example, flats. Therefore, it is needed to make a simpler system that can be used in multiple environments. | |||

===Problem statement=== | ===Problem statement=== | ||

The usage of drones has become popular in various fields of work and also for recreational use. Drones have a promising perspective in a lot of different areas, like military, surveillance and package delivery. | The usage of drones has become popular in various fields of work and also for recreational use. Drones have a promising perspective in a lot of different areas, like military, surveillance and package delivery. The problem that will be tried to solve in this project is the problem of the actual delivery around the house. In the current state of drone delivery, the buyer needs to place a landing pad in a place with enough free space around it<ref name="Prime air video">Amazon.(2015, November 29). Amazon Prime Air [Youtube]. Retrieved from https://www.youtube.com/watch?v=MXo_d6tNWuY </ref>. Thereby, the buyer needs to be home when the delivery is done, since the landing pad could be blown away due to wind for example. Furthermore, the way drones are delivering now can be harmful for bystanders, such as kids and pets that do not understand that the rotor blades could be harmful<ref name="Vision paper"/>. Also, the drones themselves can be broken if it collides with something. These problems make drone delivery far less easy than it would seem at first. Furthermore, the packages that are delivered are easily stolen and certain weather conditions could be harmful for the package. The last meters of the so-called “last mile delivery” contain multiple problems that need to be tackled before the drone delivery system can really become mainstream. A solution to these problems could convince governments and NGO's to legalize drone delivery<ref name="Vision paper"/>. A certain landing pad that has its own designated place, that can hold the package for a sufficient amount of time and is weather/theft proof could be a solution for these problems. The goal of this project is to make such a platform. | ||

===Objectives=== | ===Objectives=== | ||

* Develop a | * Develop a platform/device on/in which a drone can safely drop off a package, considering the following components: | ||

** The parcel | ** The dimensions of the parcel, which is carried by the drone | ||

** The landing platform for the drone at the delivery address | ** The landing platform for the drone at the delivery address | ||

* | ** Risk of theft | ||

* | ** Location of the landing platform | ||

* | ** Safety risks for bystanders | ||

** Risk of weather damage | |||

==Approach, milestones and deliverables== | |||

This chapter will discuss the approach of this project and will give an indication of what can be expected when the project is finished. | |||

===Approach=== | |||

Firstly, literature will be studied in order to figure out to what extent the project case has already been researched. After that, the present day problems with the technology will be determined. A list of RPC's will be made, based on USE analysis and technological requirements. With that list, concepts will be created, of which the best concept will be worked out and made into a prototype. In the design process, it is very probable that it is needed to go back a step to eventually make a better design. In the design phase it may be need to measure the drones that are available in Gemini to determine the final measurements of the design. Lastly, in the testing phase, a drone will be used to check if the system reacts to a flying drone like designed. | |||

===Milestones=== | |||

*Literature study | |||

*Sources read | |||

*Sources summarized | |||

*Conceptualize | |||

*RPC's | |||

*Concepts/drawings of concepts | |||

*Decide a final concept | |||

*Work out concept | |||

**Choose/order materials | |||

**Choose/order operating system/electronic parts | |||

**Costs overview | |||

**Building/assembling prototype | |||

*Test prototype | |||

*Conduct a survey about the prototype | |||

===Deliverables=== | |||

*An overview of the design process(Wiki) | |||

*A prototype of the landing pad | |||

*NX design of the prototype | |||

*Final presentation explaing the design process and showing the prototype | |||

==Who are the stakeholders and what do they require== | ==Who are the stakeholders and what do they require== | ||

=== | To be able to solve the problem statement the different stakeholders and their needs need to be taken into account. These stakeholders and their needs are discussed below. | ||

===User=== | |||

====Delivery services==== | |||

One user group of the new product will be delivery services. They can use the delivery box/platform as a faster and cheaper way to bring their packages to the customers<ref name ="Amazon prime air" >Welch, Adrienne (2015). "A cost-benefit analysis of Amazon Prime Air". University of Tennessee at Chattanooga. Retrieved from https://scholar.utc.edu/cgi/viewcontent.cgi?referer=https://www.google.nl/&httpsredir=1&article=1051&context=honors-theses</ref>. A problem of this is that not every country allows drones to fly everywhere, because of privacy. Because of this, the delivery services have to make sure and prove to the government that they do not save imagery. A benefit from the new technology is that the company can deliver packages way faster, namely in less than an hour. This is also very useful for customers because, if they need something quickly, they will no longer have to leave the house. As delivery services become more useful for customers, more people will use the delivery services and the delivery companies will grow. Another benefit for the delivery services is that by using a drone the delivery process will be much cheaper than when the company has to hire a driver. Another thing that makes the delivery cheaper is that the delivery time is way shorter. That means that more packages can be delivered in a shorter time. In short, more customers and faster delivery times ensure a huge growth for the delivery services. <br> | |||

====Package buyers (consumers)==== | |||

Consumers require a delivery method that does not | Consumers require a delivery method that is affordable, fast, reliable and does not damage the package during delivery. Drone delivery is a good solution for these requirements of the consumers. Since drone delivery is expected to reduce the cost of package delivery, they can deliver packages withing an hour and the package is safely stored in the drone<ref name="Amazon prime air" />. However, the consumer has to be home to make sure that the surroundings of the landing platform are clear from dangers to the drone. The consumer requires an alternative to these landing platforms that are currently used. Having to be at home takes away from the ease of the delivery drone service. People require a delivery system where they do not have to be home, without having to think about the safety of bystanders, potential theft of or damage to the package during delivery. Consumers are mostly concerned with the invasion of privacy that drones could possibly bring with them. People are scared that the drones can record their actions when the drones fly over their property. People can even feel oppressed or become paranoid because of the usage of drones<ref name = "Behavioral privacy" >Clarke, R. “The regulation of civilian drones impacts on behavioral privacy”, Elsevier (2014). Retrieved from https://www.sciencedirect.com/journal/computer-law-and-security-review</ref>. The landing platform has to take the privacy concerns of residents into account. Furthermore, the safety of drone delivery is often questioned<ref name = "Behavioral privacy" />. For people to be comfortable with using drone delivery system the safety of bystanders during the landing, drop-and take off has to be guaranteed. | ||

===Society=== | ===Society=== | ||

====Governments in urban planning==== | |||

Governments can have a huge impact on the success and eventual implementation of the delivery drones. Governments are in the position to make future neighborhoods, that still have to be build, delivery drone friendly | Governments can have a huge impact on the success and eventual implementation of the delivery drones. Governments are in the position to make future neighborhoods, that still have to be build, delivery drone friendly and change current neighborhoods to be delivery drone friendly as well. To be delivery drone friendly, the government can implement designated landing spots for delivery drones, that are easily accessible for the residents. There are multiple ways to add this functionality and different options may be chosen for different neighborhoods. Possible options are: Make a central point for all the drones to delivery its package, make landing spots between 2 houses as a shared depot or give every buyer of a future house the option to implement a landing spot in the roof. As can be seen the governmental influence in this new technology can be quite substantial. For the privacy issue explained in the previous section, the place of the landing pad can have a huge impact on how invasive residents find the delivery drones. For the government it is easier to implement this new function in all the newly build homes and neighborhoods without being invasive, then it is for individuals. E.g. the government can build more easily in the front side of the house, the place where people find the delivery drone technology less invasive. For the government itself, focusing on this technology in urban planning there is much profit to be made in the happiness of the residents. There are less delivery people on the street, which is good for the environment and helps to keep streets in living areas quiet and safe<ref name ="Amazon prime air" />. The governments stimulates the economy, because more people are able to quickly order products from enterprises<ref name ="Amazon prime air" />. Putting time in this system during urban planning can increase the feeling of privacy the residents in urban areas have. | ||

====Regulation of drones==== | |||

Privacy was mentioned in the part of consumers/buyers as an important issue against the use of drones. The government can enforce laws for delivery drones services to make sure that the delivery drones do not safe any visual input needed to move around. People would become reassured that the delivery drones that flies over their back garden | Privacy was mentioned in the part of consumers/buyers as an important issue against the use of drones. The government can enforce laws for delivery drones services to make sure that the delivery drones do not safe any visual input needed to move around. People would become reassured that the delivery drones that flies over their back garden does not make any recording of what they see, thus safeguarding privacy. The government can enforce other laws that the delivery drones are easily distinguishable from reacreational drones. This way people now what is flying over their property. One last point where the urban planning of the government is important is the regulation of the air traffic of the drones. Drone delivery as a new technology suddenly fill the air with a new form of transport that was not used in urban areas before. The government has to regulate the air traffic of the drones with clear laws, this to prevent annoyance of residents towards the drone delivery infratructure and system. | ||

===Enterprise=== | ===Enterprise=== | ||

====Delivery box manufacturers==== | |||

The manufacturers want to make a product that is cheap to make, so they can sell it for less and eventually sell more. The production of the designed delivery box isn’t a really cheap production. An advantage of this product is that it reaches a large target group, namely anyone who uses delivery services to order products. Because the target group for this product is so high, it is relatively easy to achieve a high turnover. And with a high turnover, no very high profit margin is needed, so that the product can be sold even cheaper. Another benefit from this delivery box is that it is applicable on any living situation, so every delivery box can be made exactly the same. The fact that the target group is large and the fact that the product can be used in every living situation ensures that mass production will be possible for this product, so it can be manufactured cheap and thus can it be sold relatively cheap. | The manufacturers want to make a product that is cheap to make, so they can sell it for less and eventually sell more. The production of the designed delivery box isn’t a really cheap production. An advantage of this product is that it reaches a large target group, namely anyone who uses delivery services to order products. Because the target group for this product is so high, it is relatively easy to achieve a high turnover. And with a high turnover, no very high profit margin is needed, so that the product can be sold even cheaper. Another benefit from this delivery box is that it is applicable on any living situation, so every delivery box can be made exactly the same. The fact that the target group is large and the fact that the product can be used in every living situation ensures that mass production will be possible for this product, so it can be manufactured cheap and thus can it be sold relatively cheap. | ||

====Delivery box installers==== | |||

The platforms where the package will be brought to has to be built in or around the place where the customer lives. For some customers this is easy, for example people with a large garden or a large balcony. But there are a lot of living situations, like flats or terraced houses where the customer can’t build the platform on his house himself. A benefit from this is that many people need to do a small renovation to their house, to place the platform. Many construction workers can , with a little extra training, learn how to install platforms on houses. With the ability to place platforms on houses, the target group of those companies gets a lot bigger, because a lot of people need them for the new technology. This means that there will be more work for construction workers and thus will those companies grow bigger and have increased sales. | The platforms where the package will be brought to has to be built in or around the place where the customer lives. For some customers this is easy, for example people with a large garden or a large balcony. But there are a lot of living situations, like flats or terraced houses where the customer can’t build the platform on his house himself. A benefit from this is that many people need to do a small renovation to their house, to place the platform. Many construction workers can, with a little extra training, learn how to install platforms on houses. With the ability to place platforms on houses, the target group of those companies gets a lot bigger, because a lot of people need them for the new technology. This means that there will be more work for construction workers and thus will those companies grow bigger and have increased sales. | ||

====Drone manufacturers==== | |||

If most of the delivery is done with drones, then drone manufacturers will have a larger market to sell their drones to. If this manufacturer needs sell more drones, then they have to produce more drones. The company has to find a cheap way to produce these drones, so they can sell them for less and eventually sell more of them. A way to produce the drones in a cheap way is mass production. The drones also have to be able to work with the new delivery system, so they can be used for that. The drones need to fly very careful because of possible fragile products and the drones need to have the correct dimensions for landing on the platform. Once the new delivery system has been implemented, the company must continue to develop the drones, so that the delivery continues to improve and the drones keep being sold. | |||

==RPC's== | ==RPC's== | ||

In this chapter the requirements, preferences and constraints for the final product are listed. | |||

===Requirements=== | ===Requirements=== | ||

* There should be a clearance of 50 cm from the center of the platform to any other object, so there is enough space to let a drone land | * There should be a clearance of 50 cm from the center of the platform to any other object, so there is enough space to let a drone land.* | ||

* The package casing must be | * The package casing must be weather resistant in normal conditions. | ||

**The package can’t be damaged by rain, wind, hail, snow and debris flying around | |||

**The package can’t be | * The platform must be able to be used by more than one person | ||

* | * Requirements of the government for unlicensed building**<ref name ="Building laws">Besluit omgevingsrecht. (2010, March 25). Consulted on March 14 2018, from http://wetten.overheid.nl/BWBR0027464/2018-01-01#BijlageII</ref> <ref>Wet en Regelgeving. (1991, August 29). Consulted on March 14 2018, from http://wetten.overheid.nl/BWBR0005181/2018-01-01</ref>: | ||

* Requirements of the government | |||

** Back/front garden | ** Back/front garden | ||

*** Maximum area of 2 m² | *** Maximum area of 2 m² | ||

** Roof on back side | ** Roof on back side | ||

| Line 74: | Line 119: | ||

* The platform must be able to cummunicate whether there is room for a new package | * The platform must be able to cummunicate whether there is room for a new package | ||

* The package casing must have a lock mechanism | * The package casing must have a lock mechanism | ||

* A drone must be able to | * A drone must be able to drop a package on/in the platform without damaging it | ||

* The drone may not cause harm to people/pets/other obstacles | * The drone may not cause harm to people/pets/other obstacles | ||

* The platform must be able to receive a package of max 2. | * The platform must be able to receive a package of max 2.25 kg<ref name ="Amazon prime air" /> and size of 40 x 40 x 40 cm<ref>DHL Packaging material and tips. Retrieved from https://www.dhl.de/en/privatkunden/pakete-versenden/verpacken.html</ref>. | ||

====Annotations==== | |||

The dimensions of the drone that, for instance, Amazon uses is not publicly availlable. The delivery drone system is still in development and is not publicly implemented yet. Due to the fact that the system is still in development, the information about the system and therefore drone size is very limited. The 50 cm clearance on all the sides seems to be a realistic value considering the estimated size of the drone, platform and packages.* | |||

These requirements are based on the unlicensed building criteria of the dutch government. There are not any specific building criteria for our landing platform, due to the fact that this is a fairly new idea and no existing patent has been fully worked out. These building requirements are often very case specific, thus certain requirements can be changed if our idea is implemented in the real world. The dimensions of the system may have to change to remain within the unlicensed building category. The current requirements are the best guesses for now.** | |||

==Concepts== | ==Concepts== | ||

Here, all potential concepts will be listed. They will be categorised for some parts of the design, since all things of all categories can be combined to make a final concept. | |||

===Interaction platform-parcel=== | ===Interaction platform-parcel=== | ||

# The platform is a locked box, in which a drone can drop a package; later, the customer can open this box itself and retrieve the parcel. | |||

# The done carries a box with a lock; the base will lock it in place with an arm / magnet / gripper / etc.; the box can be returned, so it can be reused (like a packaging deposit system) | |||

# Drone carries a waterproof box; the base will put a cage around it. | |||

# A hole in the ground that opens when the delivery is done. The rest of the time it's closed so it seems to be a normal tile. | |||

# The platform is raised high, for instance set on a pole, where the package is stored. The package can be retreived by lowering the platform to ground level. | |||

===Lock mechanism=== | ===Lock mechanism=== | ||

*The side of the box that can be opened is faced down, so potential thieves can't open it. | *Movable box carried by drone. | ||

* | **The side of the box that can be opened is faced down, so potential thieves can't open it. | ||

* | * Code lock (bar, QR, password), of which the code could be shared with the recipient via email for each parcel. | ||

*Fingerprint sensor | * RFID lock (using mobile phone NFC chip), of which the code is shared with the recipient via email for each parcel. | ||

* | * Physical key | ||

* | * Fingerprint sensor | ||

*Identification of | |||

===Location landing platform=== | |||

* Roof | |||

* Garden | |||

* Balcony | |||

* Out of a window(maybe attached to wall in order to keep window closed). | |||

* Drone can enter specific part of house. | |||

* Attached to the wall next to the front door. | |||

* For appartments: a room easily accesible for drones where a certain amount of landing platforms are(Package need to be retrieved in x minutes, so it can be used by other residents). | |||

===Identification of right platform and drone=== | |||

*QR code | *QR code | ||

*RFID | *RFID | ||

| Line 108: | Line 162: | ||

*Box opens after estimated delivery time has gone by. | *Box opens after estimated delivery time has gone by. | ||

==="MICHAEL system" <ref name = "Michael system">Young, L.A. “A Multi-Modality Mobility Concept for a Small Package Delivery UAV”. Retrieved from https://vtol.org/store/product/a-multimodality-mobility-concept-for-a-small-package-delivery-uav-11868.cfm </ref> === | |||

*Shared landing platforms for all the people in a neighborhood. | |||

==="MICHAEL system"= | |||

* | |||

*Flying drones to deliver to this point. | *Flying drones to deliver to this point. | ||

*Driving drones deliver to front door. | *Driving drones deliver to front door. | ||

| Line 126: | Line 169: | ||

==Final design== | ==Final design== | ||

This chapter will explain the chosen concept and give all considerations for this choice. | |||

=== Chosen Concept=== | |||

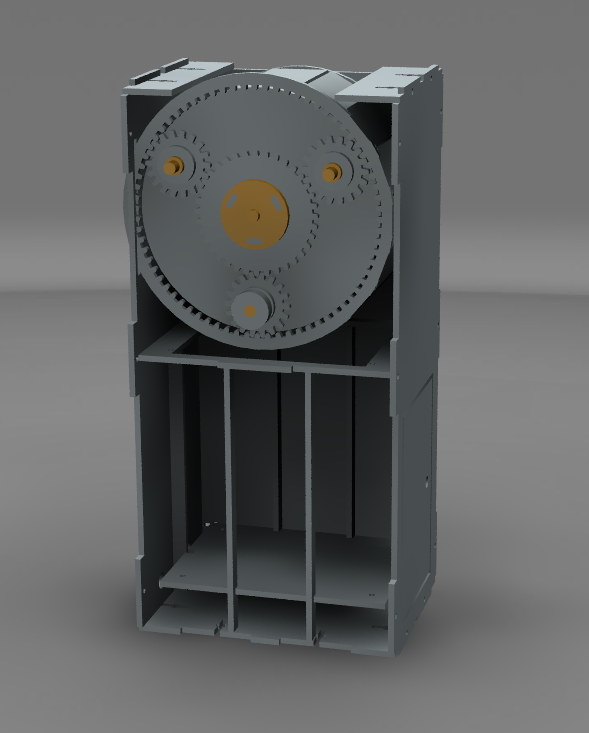

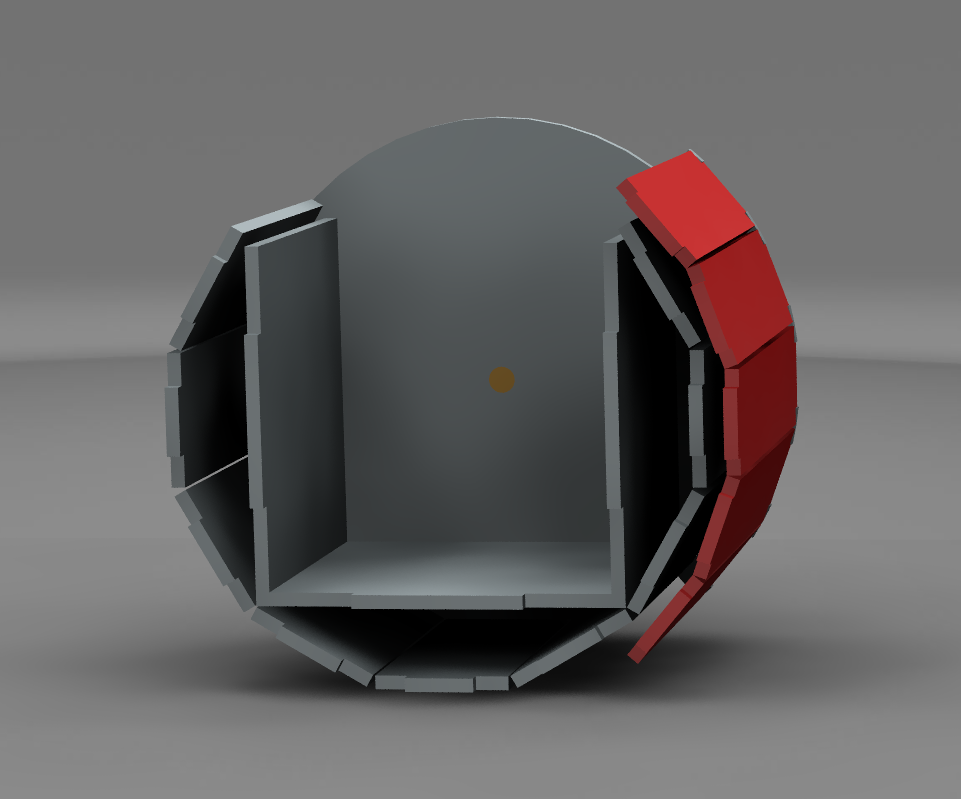

The concept is the one where the platform is a closed box, in which the parcel will be stored. This platform is shaped like a simple rectangular box, divided into two compartments. The top compartment contains two cylinders, one inside the other, rotating around the same axis. These cylinders act as the acces for the drone, through which the parcel is transfered to the bottom half. The outer cylinder acts as a door of the platform, closing the exterior of the housing. The inner cylinder has a vacancy to accept the packages and guides them to the bottom compartment. These cylinders turn simultaniously, but in opposite direction, in order to open or close the platform for package transferal. The second compartment is the storage area, which can be accessed by the user via a seperate locked door. This storage compartment also contains a lift on which the packages are placed by the cylinders. The lift lowers the package into the storage compartment, to make sure the package doesn't drop too far and to make room for another arrival if any space is left. The system can be placed on various locations, but most interesting is building it into the roof, since this adds additional protection and can help increase privacy and safety. | |||

=== | ===Functions=== | ||

* GPS | |||

** Communicating platform location | |||

* Inventory management system | |||

* Link to internet | |||

** Communication with ordering services | |||

** Notifying user(s) | |||

* QR code recognition | |||

** Identifing authorized drone(s) | |||

* Various options for lock mechanisms | |||

** Dependent on intended use | |||

* Optional: | |||

** Supporting multiple users | |||

** Suporting multiple packages | |||

===Advantages=== | |||

*The systems has no out / inward moving parts<br> | *The systems has no out / inward moving parts<br> | ||

**The drone can't be obstructed/blocked because of these parts<br> | **The drone can't be obstructed/blocked because of these parts<br> | ||

*This keeps the platform compact<br> | **This keeps the platform compact<br> | ||

*Can be placed in various environments<br> | *Can be placed in various environments<br> | ||

*The design is efficient and secure<br> | *The design is efficient and secure<br> | ||

*The system is anti-theft because of the identification codes and anti-theft casing<br> | *The system is anti-theft because of the identification codes and anti-theft casing<br> | ||

*The system can be shared with multiple people(depending on the location of the system) | *The system can be shared with multiple people(depending on the location of the system)<br> | ||

===Disadvantages=== | |||

* Relatively many and complex moving components. | |||

** Increases material demands | |||

** Increases costs | |||

* Optimal placement requires: | |||

** Possibly a building license | |||

*For existing homes: | |||

**Additional funds | |||

**Additional time | |||

===Considerations for choosing this concept=== | |||

The "MICHAEL system" | The "MICHAEL system"<ref name = "Michael system" /> seems to not be a viable concept to use for our landing pad. The designated landing pad that can be used for multiple people is hard to implement in already existing neigborhoods, since a decent area is needed to work out the concept, which may not be available. Then the person has to either walk to the landing spot to get their package, or they have to be home for the driving drone to deliver the package from the landing area to the front door. This takes away from the ease that is strived for when using the delivery drone service, since you have to be home for to obtain the package. Another way is to have your own box where the driving drone delivers the package into, but then it becomes even more expensive then it already is. Futhermore, the reason to have a shared landing spot in a neigborhood completely fails if people need to get their own safe box system as well.<br> | ||

<br> | <br> | ||

For the location the front side of the roof the best location for the landing pad, taking into account all the stakeholders. The front side of the house is considered less of a personal space as the back side of the house. Therefore placing the box on the front side of the house will safeguard the privacy more than placing the box on the back side of the house. The roof is a better location than placing the landing pad on the | For the location, the front side of the roof the best location for the landing pad, taking into account all the stakeholders. The front side of the house is considered less of a personal space as the back side of the house. Therefore placing the box on the front side of the house will safeguard the privacy more than placing the box on the back side of the house. The roof is a better location than placing the landing pad on the ground for multiple reasons. If the landing pad is placed on top of the roof, the package can't easily be stolen by thieves and the drone is less vulnerable during descent. The drone can spot the landing pad more easily on the roof than when it is on the ground<ref name = "Group 20">Technical Univesity Eindhoven 0LAUK0 Group 20 2016-2017 Quartile 3. Retrieved from http://cstwiki.wtb.tue.nl/index.php?title=PRE2016_3_Groep20</ref>. The safety of bystanders is taken into account as well, since there are no direct bystanders like excited pets or kids that can interfere with the system. The only downside is that for already existing homes, it will cost extra money to install the system onto the roof and a building license is needed for the front side.<ref name="Building laws"/> <br> | ||

homes it will cost extra money to install the system onto the roof and a building license is needed for the front side. <br> | <br> | ||

The enterprises want to have a reach that is as big as possible. Taking into account the whishes of the enterprise, the system is also usable in the front and back yard, and the back side of the roof. The system works in these locations in the same way, the difference is that it costs less money for people to use the system and a building license isn't needed. However, the system is less optimized in terms of privacy and safety for these locations. Therfore, the help of government in urban planning is asked. With the help of the government, people get the chance to build the system into their future house, getting an optimal service.<br> | |||

<br> | |||

Adding the protection of the box already before shipping will cause more problems than that it would solve. Examples of these system are concepts 2 and 3. These systems put too much of a burden to the enterprises. These enterprises need to invest a lot of money for all these boxes, and it costs an extra flight for every package to return these protecting boxes. Moreover, doubeling the amount of flights would quite possibly annoy consumers. And the extra weight of the protected boxes would either result in a change of drones or a lower maximum weight of the packages. Therefore, these systems aren't chosen for the final concept.<br> | |||

<br> | |||

Concepts 2 and 3 wouldn't be optimal, because the moving parts can easily obstruct the drone while delivering the package. Furthermore, these systems can only be used on the ground for save access to the package. Endangering people into these activities is counter productive and putting the system on the ground was a less optimal choice as explained earlier. Concept 4 seems to be a less optimal choice for the same reason. Concept 5 does not have this problem. However, the system would both be an eye catcher, which is not desired, and be realatively vulnerable.<br> | |||

<br> | <br> | ||

To realize the identification/lock of the system on the recipient side, several options are chosen. Depending on the situation one is favoured over the other. Bar/QR codes, RFID/NFC, passwords and physical keys have been selected as viable options. | |||

When the landing platform would be shared by multiple households/users, a bar-code, QR-code, RFID/NFC or a personal password could be used. For this situation, the preferred method is to use a bar or QR code. The code can be assigned to an individual person and stored in a physical or digital form. The physical form could be used in a system where the box is assigned to an individual for an extended period of time, so no additional device is needed to acces the box. However, this is a less secure option, for the code can be copied. If a more physical form is desirable, a NFC system would be more secure. In digital form, the code can easily be distributed to users, for instance via e-mail or a seperate app. In addition, the required code can be automaticly changed allowing for a one time acces. | |||

<br> | <br> | ||

When the landig platform would be used by a single household or individual, the disired form of identification is more dependent of personal preference. NFC, passwords and physical keys would be prefered solutions. Either of these systems have their own advantages and disadvantages, but it must be mentioned that lockes with physical keys are more vunerable. The user would choose its own prefered system.<br> | |||

<br> | <br> | ||

In order for the landing platform to be effective it needs to have interaction with the drone. It was chosen to outfit delivery drones with QR codes based on which they can be identified by the landing platform. From an average camera, the distance at which a QR code can be scanned is about 10 times the width of the QR code itself<ref name="Group 20"/>. It is the intention that the QR code can’t be scanned too soon, because then the platform will be open unnecessarily long. A QR code of 2 x 2 centimetres has been chosen, which means that the code can be scanned from 20cm distance. This way the QR code can only be scanned once the drone has landed on the platform. An automated system could keep track of which drone delivers a certain package, the corresponding identifier could be communicated to the platform in advance. | |||

<br> | <br> | ||

Because commercial GPS has a limited accuracy <ref>Ehsan Abdi, Hamid Soofi Mariv, Azade Deljouei & Hormoz Sohrabi(2014) | |||

Accuracy and precision of consumer-grade GPS positioning in an urban green space environment, | |||

Forest Science and Technology,10:3, 141-147, DOI. Retrieved from https://www.tandfonline.com/doi/pdf/10.1080/21580103.2014.887041?needAccess=true</ref> the drone needs to be able to identify a landing platform and preferable its orientation to ensure a smooth approach. For this purpose, the landing platform has visual markers from which the drone can gather this information. These visual markers would include a standard patern of colors and shapes that signal both the orientation and that it is a landing platform to the drone. In addition, the platform requires to communicate its identity to the drone. For this function, the landing platform could contain a RFID tag which can be accessed by the drone upon landing. The major disadvantage of such a system is the short range at which the RFID tag works, but it requires a little amount of energy. The drone could also access the landing platform's internet connection providing a much bigger range. A major advantage here is the ability to verify the platform's identity at a distance, leaving the drone less vunerable. In this situation, the platform would would act as a hotspot, requiring aditional power. | |||

==Prototype== | ==Prototype== | ||

In order to test the viability of the concept a prototype was constructed. Due to the limited time frame the focus lay on the most important functions: The cylinders responsible for accepting the package, The storage compartment including the lift and drone recognition. The shapes cylinders have been approached by discs seperated by multiple rectangular plates. They turn round the same axis using a set of planetary gears, chosen to keep the system as compact as possible whilst maintaining reliability. The lift is a simple platform held aloft by four kabels. These are wound up round an axel, connected to the platform, to lower or raise the platform allowing to lower items into the storage compartment. A simple webcam fullfilled the requirement to read QR codes, providing or denying access to the storage compartment. Items can be retrieved through a separate door closed by a simple lock. | |||

=== | ===NX drawings prototype=== | ||

Firstly, a 3D-sketch of the prototype has been made using Siemens NX. The 3D-sketches could be easilly evaluated by constructing a digital assembly containing repesentations of other elements such as the bearings. This enabled quick spotting of errors concerning the dimensions and clearances. It sped up designing whilst reducing errors and provided extra insight and understanding of the system. In these designed, construction is already accounted for, as can be seen in the edges, where holes and slits have been made, in order to bolt the parts to each other. Below, the final sketches of the prototype can be seen. The left image shows the outside of the prototype. In the middle picture, the side wall has been removed, so the planetary gears driving the cylinders can be seen, just as the platform that keeps a package from falling from too high. The right picture shows the inner cylinder (in grey) and the outer 'cylinder' (in red). The inner cylinder receives the package and rotates to drop it in the compartment below. The outer cylinder keeps the package from falling out of the inner cylinder before it has completely rotated and also serves as a roof. Only the electrical components haven't been added in the assembly. | |||

< | <gallery caption="3D sketches prototype" heights="500px" widths="400px" > | ||

File:Render_totaal.png|Total prototype | |||

File:Render_geen_zijkant.png|Prototype without side wall | |||

File:Render_cylinder.png|Cylinders | |||

</gallery> | |||

===Materials and components needed for prototype=== | |||

In order to make the assembly, several materials and components are needed. These things can be seen in the table below. | |||

{| class="wikitable" | border="2" style="border-collapse:collapse; text-align: center; width: 50%" | {| class="wikitable" | border="2" style="border-collapse:collapse; text-align: center; width: 50%" | ||

! style="width: 25%" | '''Part''' | ! style="width: 25%" | '''Part''' | ||

! style="width: | ! style="width: 6%" | '''Amount''' | ||

! style="width: 10%" | '''Costs''' | ! style="width: 10%" | '''Costs''' | ||

! style="width: 16%" | '''Store''' | ! style="width: 16%" | '''Store''' | ||

| Line 192: | Line 253: | ||

! style="width: 8%" | '''Paid By''' | ! style="width: 8%" | '''Paid By''' | ||

|- style="background-color: #d1d1d1;" | |- style="background-color: #d1d1d1;" | ||

| Raspberry Pi 3 Model B || 1 || € | | [https://www.sossolutions.nl/raspberry-pi-3b Raspberry Pi 3 Model B] || 1 || € 37.49 || Megekko || x || Camiel | ||

|- | |- | ||

| Micro SD Memory Card || 1 || € 0 || Borrowed (Camiel) || x || Camiel | |||

|- style="background-color: #d1d1d1;" | |||

| Raspberry Pi Case|| 1 || € 0 || Borrowed (Camiel) || x || Camiel | |||

|- | |||

| Raspberry Pi Power Supply || 1 || € 0 || Borrowed (Camiel) || x || Camiel | |||

|- style="background-color: #d1d1d1;" | |||

| [https://www.tinytronics.nl/shop/nl/voedingen/5v/5v-2a-adapter-met-dc-jack 5V 2A Adapter]|| 1 || € 8.00 || Tinytronics || x || Camiel | | [https://www.tinytronics.nl/shop/nl/voedingen/5v/5v-2a-adapter-met-dc-jack 5V 2A Adapter]|| 1 || € 8.00 || Tinytronics || x || Camiel | ||

|- | |||

| [https://www.tinytronics.nl/shop/nl/motoren/ds04-nfc-continuous-rotation-servo Continous servo] || 2 || € 16.00 || Tinytronics || x || Werner | |||

|- style="background-color: #d1d1d1;" | |- style="background-color: #d1d1d1;" | ||

| [https://www.tinytronics.nl/shop/nl/prototyping/breadboards/breadboard-170-points-wit?search=breadboard Breadboard]|| 1 || € 2.50 || Tinytronics || x || Werner | | [https://www.tinytronics.nl/shop/nl/prototyping/breadboards/breadboard-170-points-wit?search=breadboard Breadboard]|| 1 || € 2.50 || Tinytronics || x || Werner | ||

|- | |||

|[https://www.tinytronics.nl/shop/nl/kabels/prototype-draden/dupont-jumper-draad-male-female-20cm-10-draden Male-Female Jumper Cables]|| 20 || € 1.50 || Tinytronics || x || Werner | |||

|- style="background-color: #d1d1d1;" | |- style="background-color: #d1d1d1;" | ||

| [https://www.tinytronics.nl/shop/nl/kabels/prototype-draden/dupont-jumper-draad-male-male-20cm-10-draden Male-Male Jumper Cables] || 20 || € 1.50 || Tinytronics || x || Werner | | [https://www.tinytronics.nl/shop/nl/kabels/prototype-draden/dupont-jumper-draad-male-male-20cm-10-draden Male-Male Jumper Cables] || 20 || € 1.50 || Tinytronics || x || Werner | ||

|- | |||

| [https://www.tinytronics.nl/shop/nl/connectoren/jack-pluggen/dc-jack-female-5.5mm-naar-terminal-block DC Jack female adapter]|| 1 || € 1.00 || Tinytronics || x || Camiel | |||

|- style="background-color: #d1d1d1;" | |- style="background-color: #d1d1d1;" | ||

| [https://www. | | [https://www.conrad.nl/nl/aa-batterij-penlite-energizer-max-lr06-8-4-gratis-alkaline-15-v-12-stuks-1333055.html AA Battery] || 12 || € 6.99 || Conrad || x || Camiel | ||

|- | |- | ||

| [https://www.conrad.nl/nl/ | | [https://www.conrad.nl/nl/webcam-640-x-480-pix-trust-exis-klemhouder-1437981.html USB camera]|| 1 || € 13.49 || Conrad || x || Camiel | ||

|- style="background-color: #d1d1d1;" | |- style="background-color: #d1d1d1;" | ||

| [https://www.conrad.nl/nl/reely-rc-auto-kogellager-chroomstaal-binnendiameter-8-mm-buitendiameter-12-mm-toerental-max-40000-omwmin-295639.html Ball Bearings] || 6 || € 14.94 || Conrad || x || Camiel | | [https://www.conrad.nl/nl/reely-rc-auto-kogellager-chroomstaal-binnendiameter-8-mm-buitendiameter-12-mm-toerental-max-40000-omwmin-295639.html Ball Bearings] || 6 || € 14.94 || Conrad || x || Camiel | ||

|- | |- | ||

| [https://www.digifab.nl/lasersnijden/prijzen/ MDF (laser cut) (4x600x300mm)]|| 4 || € 44.35 || DigiFab || x || Jasper | | [https://www.digifab.nl/lasersnijden/prijzen/ MDF (laser cut) (4x600x300mm)]|| 4 || € 44.35 || DigiFab || x || Jasper | ||

|- | |- style="background-color: #d1d1d1;" | ||

| [https://www.hornbach.nl/shop/BURG-WAeCHTER-Brievenbusslot-voor-2-10-mm/750107/artikel.html Simple lock] || 1 || € 10.95 || Hornbach || x || Camiel | | [https://www.hornbach.nl/shop/BURG-WAeCHTER-Brievenbusslot-voor-2-10-mm/750107/artikel.html Simple lock] || 1 || € 10.95 || Hornbach || x || Camiel | ||

|- | |||

| [https://www.hornbach.nl/shop/Scharnier-smal-verzinkt-vaste-pen-40x32-mm/8014853/artikel.html Hinge] || 2 || € 3.40 || Hornbach || x || Camiel | |||

|- style="background-color: #d1d1d1;" | |- style="background-color: #d1d1d1;" | ||

| [https://www.hornbach.nl/shop/Gerild-beuken-8-mm-lengte-100-cm/4183450/artikel.html Dowel (8mm x 100 cm)] || 1 || € 0.50 || Hornbach|| x || Camiel | | [https://www.hornbach.nl/shop/Gerild-beuken-8-mm-lengte-100-cm/4183450/artikel.html Dowel (8mm x 100 cm)] || 1 || € 0.50 || Hornbach|| x || Camiel | ||

|- | |||

| [https://www.gamma.nl/assortiment/gamma-metaalschroef-m4-x-16mm-platkop-verzinkt-15-stuks/p/B458181 Bolts and Nuts (M4 x 16mm)] || 30 || € 4.58 || Gamma || x || Camiel | |||

|- style="background-color: #d1d1d1;" | |||

| [https://www.gamma.nl/assortiment/gamma-metaalschroef-m4-x-20mm-cilinderkop-verzinkt-15-stuks/p/B458192 Bolts and Nuts (M4 x 20 mm)] || 30 || € 4,98 || Gamma || x || Jasper | |||

|- | |||

| Kill Switch || 1 || € 0 || Borrowed (Camiel) || x || Camiel | |||

|- style="background-color: #d1d1d1;" | |- style="background-color: #d1d1d1;" | ||

| | | Fishing line || N/A || € 0 || Borrowed (Michael) || x || Michael | ||

|- | |- | ||

| colspan="2"| '''Total costs''' || € 172,17 | |||

| colspan="2"| '''Total costs''' || € | |||

|} | |} | ||

=== | ===Lasercut MDF=== | ||

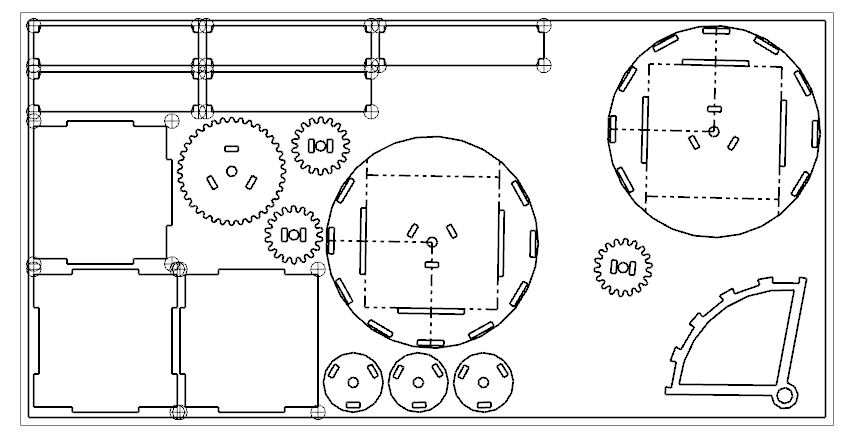

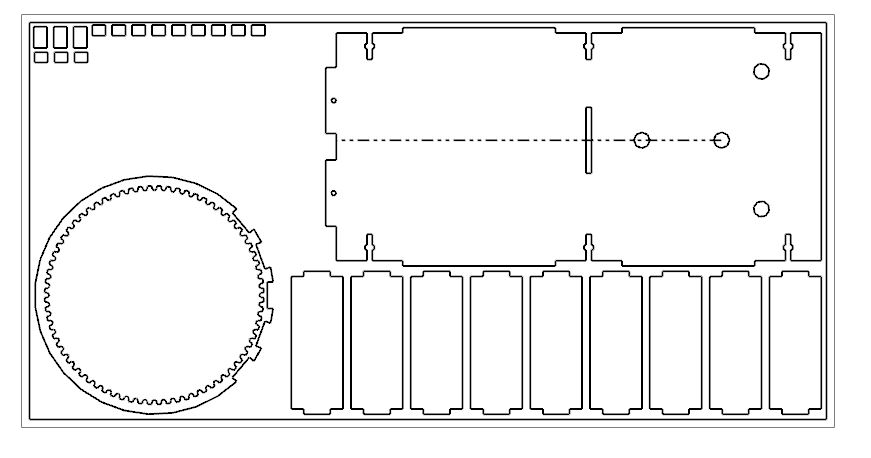

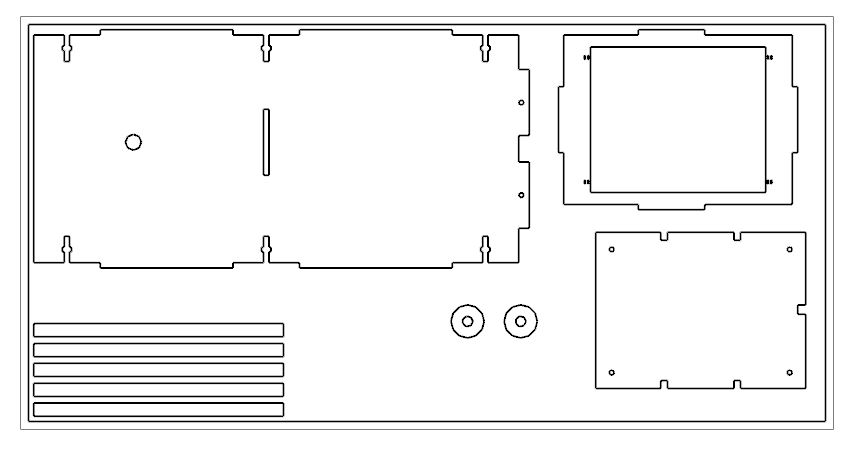

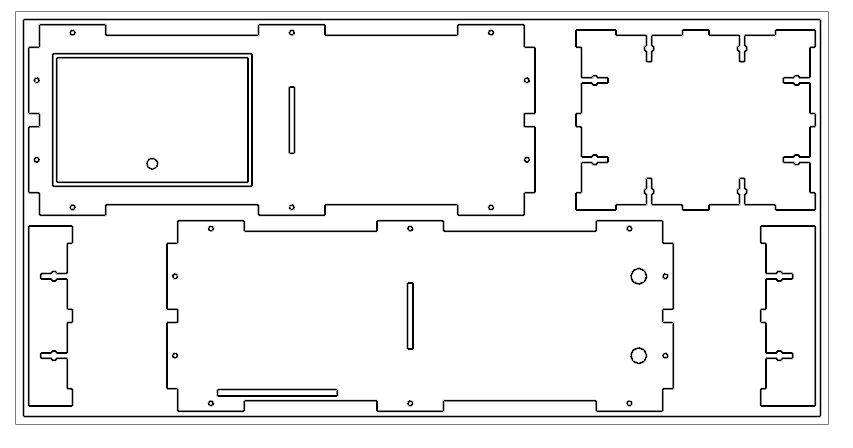

The prototype is made out of MDF, Medium Density Fibreboard. This MDF is lasercut into the correct shapes, as shown in the following figures. These sketches have been made by converting the 3D model to a series of 2D components, after which the components have been cut out in a laser cut machine. The resulting lasercut sheets that have followed from the conversion to 2D can be seen below here. The actual manufacturing of the parts was outsourced to an external company handeling laser cutting and CNC milling of various materials. | |||

<gallery caption="Lasercut MDF images" heights="300px" widths="600px" > | |||

File:Lasercut1.jpg | |||

File:Lasercut2.jpg | |||

</gallery> | |||

<gallery heights="300px" widths="600px" > | |||

File:Lasercut3.jpg | |||

File:Lasercut4.jpg | |||

</gallery> | |||

===Electrical circuit=== | |||

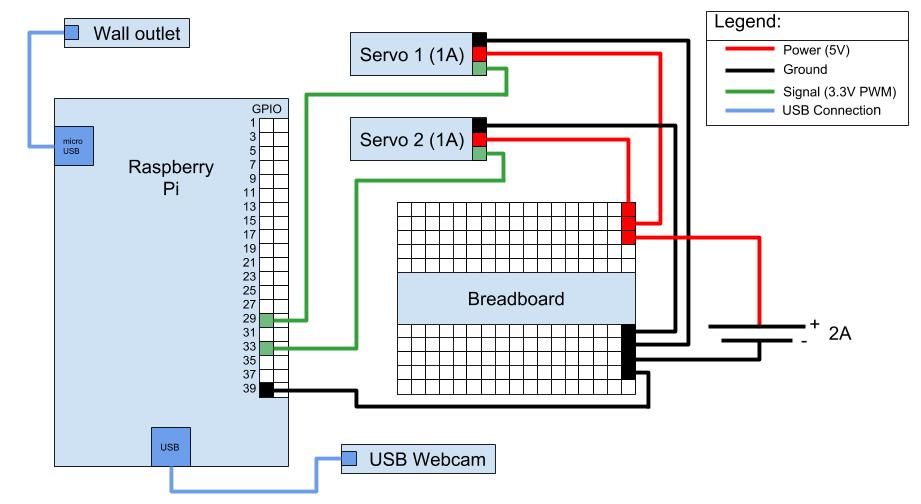

In order to be able to assemble the prototype safely and quickly, a schematic overview of the wiring of all electrical components has been made as well. This overview can be seen below. | |||

[[File:Electronic Connection Scheme 0LAUK0.jpg]] | |||

=== | ===Raspberry Pi=== | ||

<p>In order to control the electrical system of the prototype a raspberry pi model 3B is used. The prototype needs to have a QR-code scanner. A simple controller like an Arduino is not sufficient, since the graphical processing requires more processing/memory power than an Arduino can deliver. Therefore, the logical choice went to the Raspberry Pi 3B. The dimensions of the Raspberry Pi are 9x6x3 cm. With this system two continuous servo's and a camera are controlled. The two continuous servos are needed in order to rotate the cylinder and to move the lift. The camera is needed for checking the QR code on the drone to see if the drone is on the right platform, and to make sure the platform only opens when the QR code is verified. </p> | |||

<p>To control the raspberry and said system a program has been written with python. This program can be found here: [[PRE2017_3_11_Python_Code]]. In this code, the servos are controlled by sending a certain pulse width modulated voltage to them, by using the "RPi.GPIO" package. This only happens if a correct QR code is read. The QR code reader is defined as a function, which uses the "pyzbar", "Image" and "cv2" package. "pyzbar" is a QR code reader, "Image is an image reader" and "cv2" reads the feed from the webcam. If the QR code equals one of the codes in the database, the platform opens, if a code which is not correct is read, the platform stays closed and transmits a message.</p> | |||

=== | ====Simplifications==== | ||

Due to impracticality and high cost, the prototype misses some features the actual product will/could have, but aren't vital for a proper demonstration. These are listed here: | |||

#Currently, the program reads permitted codes from a file on the raspberry pi ("authcodes"). In a real life application, it could get these files from a secure web server which communicates with the delivery service. This way the program can be activated, only when a drone is on the way | |||

#The program currently closes the cylinder after a certain time interval. In a real life application, a sensor will be inserted in the cylinder, which detects when the package is dropped, gives off a signal, and immediately closes the cylinder. A sensor could for example be a [https://iprototype.nl/products/components/sensors/force-round?gclid=Cj0KCQjw-uzVBRDkARIsALkZAdllhaeonev2dCK4oGoeVQhdfzMGGTJy2cKc2lMqwDn73Tr58h7FczwaApSTEALw_wcB force sensor]. | |||

#In the prototype, the platform moves down all the way when a package is dropped on it. In a real life application, the platform could move down just far enough to clear the cylinder. This could be measured with a [https://nl.aliexpress.com/item/M18-NPN-beam-laser-switch-DC10-30V-visible-red-beam-laser-sensor-laser-photoelectric-switches-0/32580113771.html?src=google&albslr=202113973&isdl=y&aff_short_key=UneMJZVf&source=%7Bifdyn:dyn%7D%7Bifpla:pla%7D%7Bifdbm:DBM&albch=DID%7D&src=google&albch=shopping&acnt=494-037-6276&isdl=y&albcp=664365076&albag=32654332494&slnk=&trgt=61865531738&plac=&crea=nl32580113771&netw=g&device=c&mtctp=&gclid=Cj0KCQjw-uzVBRDkARIsALkZAdlneOc04Fa8CLG8XvE3kiL8PUYAPMAmV5Gevg5evw3dcGncyeMngUMaAnI5EALw_wcB&gclsrc=aw.ds laser sensor]. This laser could be located right below the cylinder, and get blocked a package. When the platform moved far enough down, the laser is no longer blocked, and a signal is sent to the controller, which stops the platform from moving down. This way, multiple packages can safely be stored in the box, without some of them falling a long way. Also, the receptacle can calculate the space left, in order to see if a new parcel can be delivered. | |||

=== | ===Realised prototype=== | ||

'''Youtube demonstration video''' | |||

<br> | |||

https:// | In the following link, a demonstration will be given of the functionalities of the prototype. | ||

<br> https://www.youtube.com/watch?v=O3DlDyHigvc | |||

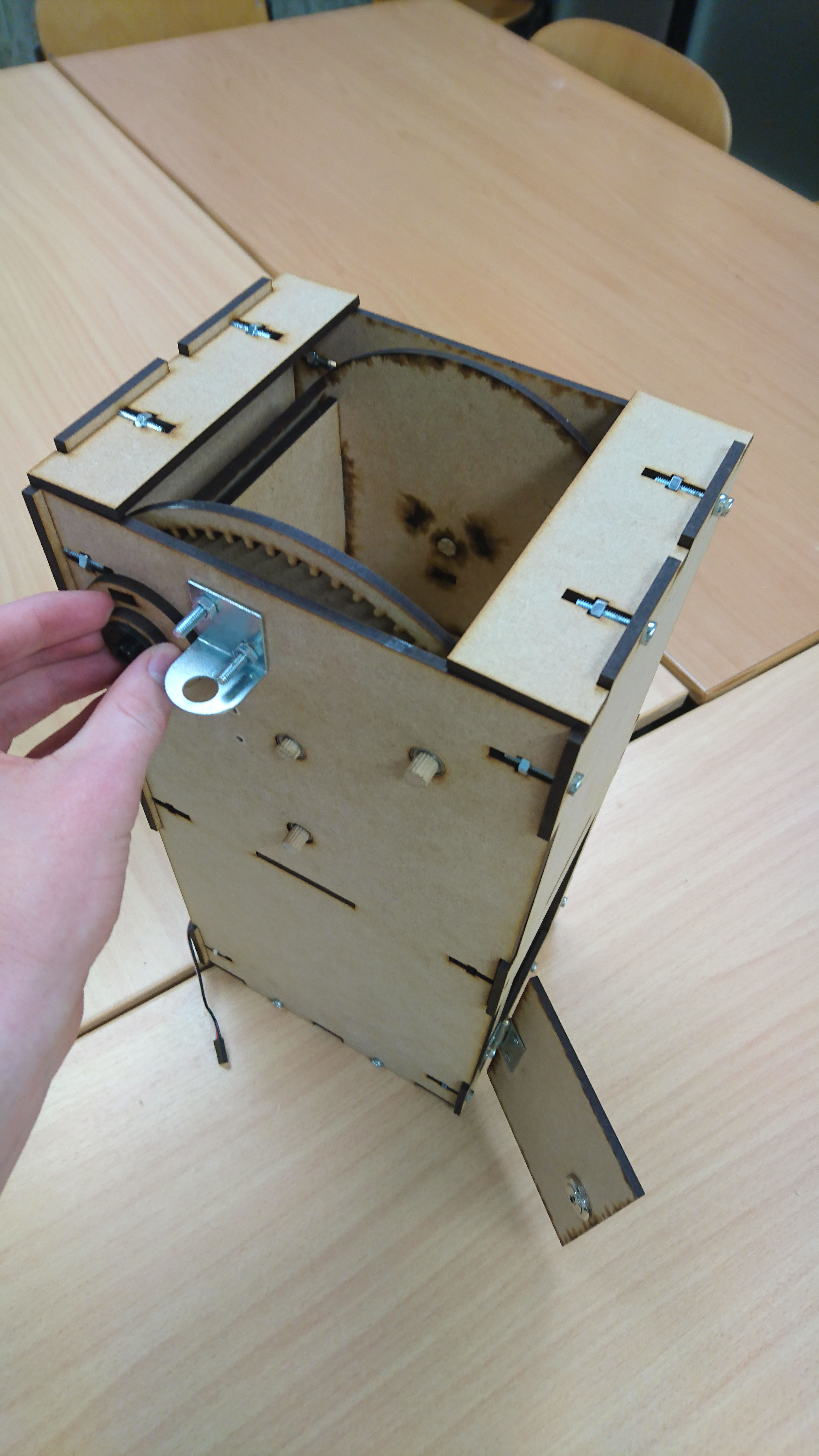

'''Photos of prototype and components'''<br> | |||

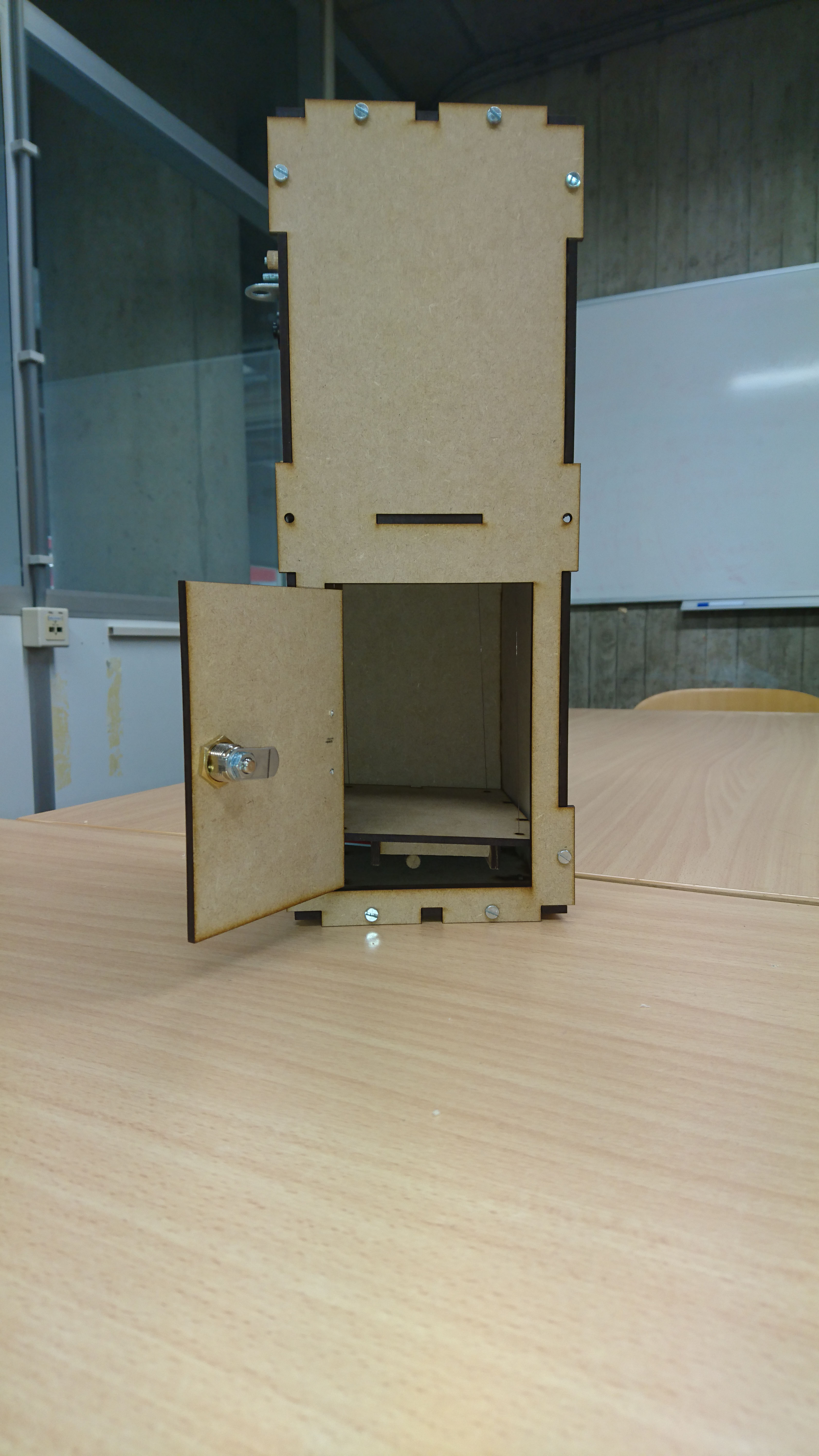

Below, a number of photos can be seen of the prototype during multiple stages of the building process: | |||

* The first three images show the finished product | |||

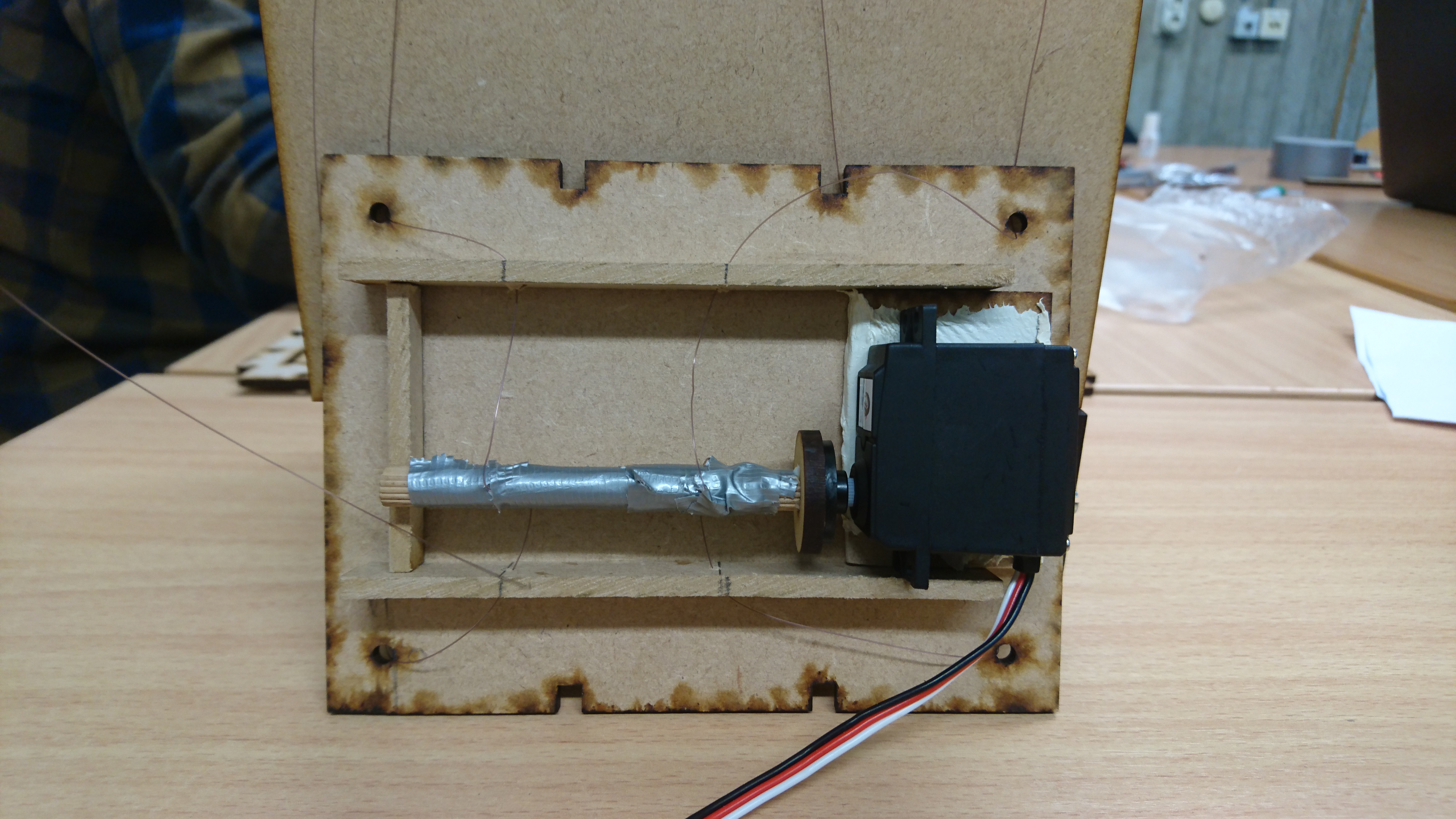

* The fourth image shows the bottom of the platform with the servo and axle, that will rotate to roll up the wires in the four corners of the platform, so the platform will move up (or down, when the servo and axle rotate back again) | |||

* The fifth image shows the inner cylinder with its gear | |||

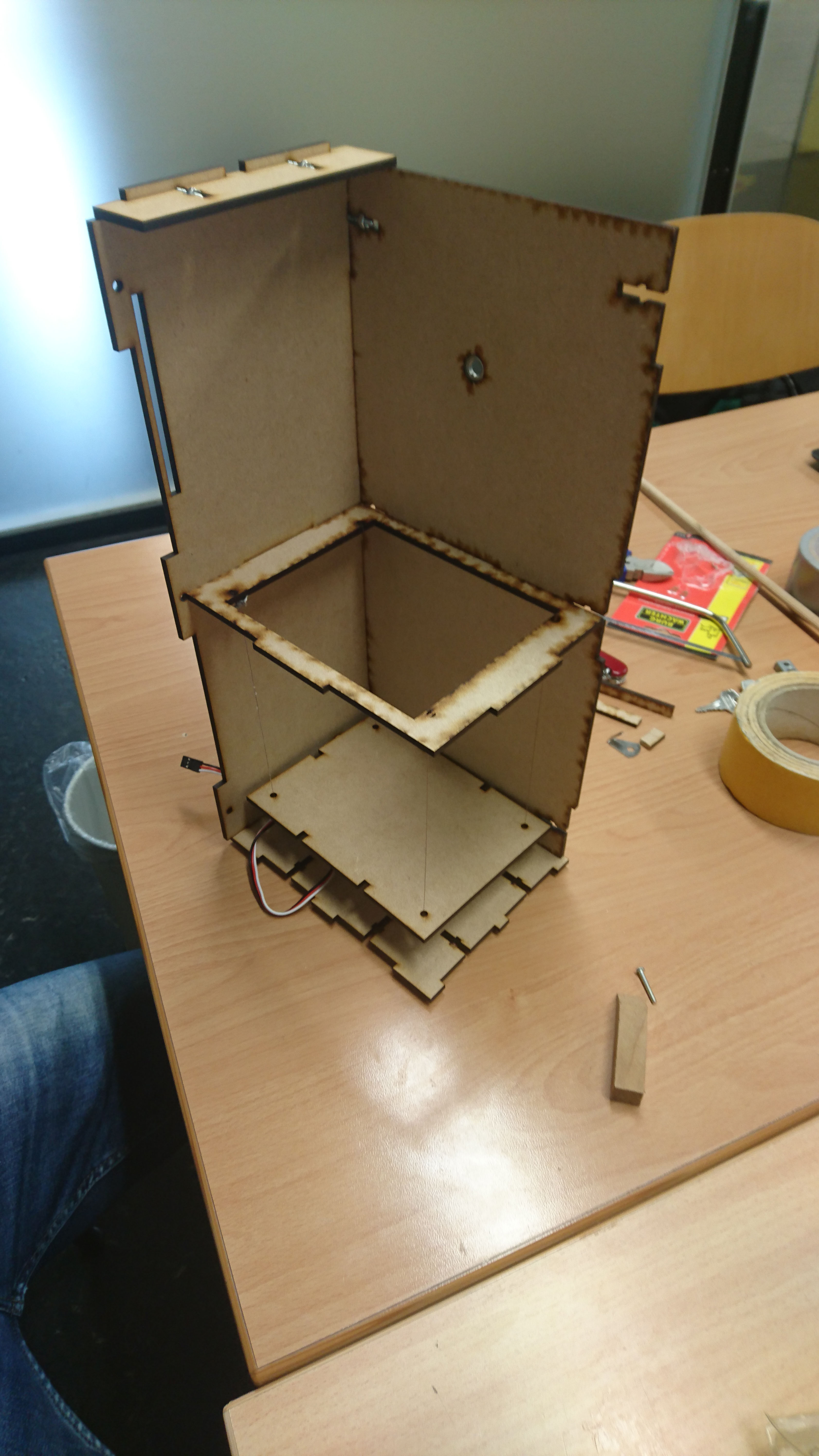

* Image six shows an isometric view of the inside of the receptacle without the cylinders; the platform can be seen on the bottom | |||

* Picture seven shows a sideview of the inside of the receptacle, without the cylinders and the platform | |||

* Picture eight shows a front view of the receptacle with the door opened. Also, the platform can be seen hanging. | |||

<br> | <br> | ||

== | <gallery caption="Realized prototype gallery" heights="400px" widths="300px" > | ||

File:Realprot1.jpg|1. Closed cylinder | |||

File:Realprot2.jpg|2. Half-open cylinder | |||

File:Realprot3.jpg|3. Opened cylinder | |||

</gallery> | |||

<gallery heights="300px" widths="472px" > | |||

File:Realprot5.jpg|4. Bottom view of the platform with servo and axle to move platform | |||

File:Realprot4.jpg|5. Inner cylinder | |||

[[ | </gallery> | ||

<gallery heights="400px" widths="300px" > | |||

File:Realprot7.jpg|6. Isometric platform view without cylinder | |||

File:Realprot6.jpg|7. Opened sideview without cylinder or platform | |||

File:Realprot8.jpg|8. Closed platform view | |||

</gallery> | |||

==Real product and pitch== | |||

The prototype shows the viability of the major systems discussed in the concept. However, it is not suited for real life application. Therefore, this part will discuss the various changes needed to make it applicable in a real situation. | |||

===Dimensions=== | |||

The ratio between the prototype and the real product is 1:4, which means that the dimensions of the real product are 65 x 65 x 130 cm (l x w x h). | |||

===Materials=== | |||

MDF would not resist the outdoor elements, thus different materials need to be chosen. The housing will be constructed out of stainless steel for durability and strenght. It would provide the product the resitance against damage to prevent theft. The housing will be covered by a layer of weather resistant, durable plastic, making the platform less of an eye catcher whilst limiting the steel's exposure to the elements, yielding more durability. Moving components, such as the gears and the cylinders would also be crafted from stainless steel for both strenght and durability whilst the platform can be made out of plastic. | |||

===Upgrades=== | |||

The finished product would naturaly have the functionality previously mentioned in the Concept chapter, but it would also recieve various upgrades compared to the prototype. The real product would need an aditional comparment to store components such as the electrics, which is not implemented in the prototype, because easy access was needed for bug fixing. This would result in a slight increase in width. The gears would have additional clearance from other components. The outer cylinder would be guided by aditional bearings reducing strain on the axle, improving strenght and structural integrity. In addition, the cylinder would receive its own mechanism to lock into place when closed, to help prevent possible damage. Also, the outer cylinder would be sealed with rubbers to make it waterproof. Another improvement for the inner cylinder is the installation of a pressure sensor, so the device will know that a parcel has been dropped, so the cylinders can close again. The cables in the lift would be either covered or replaced for additional protection from wear. The lift itself will receive additional guidance for a smoother motion. The inventory management sytem would be able to keep track of the available space in the storage compartment and the presence of packages in the cylinder and could inform the user of package arrival and space limitations via the link to internet. Lastly, the lock providing the user access to the storage compartment would be upgraded to the desired system and required standarts. | |||

===Product pitch=== | |||

The usage of drones has become popular in various fields of work and recreational use. One promising new field of use for drones is package delivery. However, there is still a number of problems that need to be solved. Therefore, a conceptual design of a package receptacle has been made, which tackles a veriety of problems concerning the actual delivery of packages at the customers address by drone. For example, Amazon currently uses a plastic sheet, which a customer should put on the ground, to indicate the place of delivery for the drone<ref name ="Prime air video"/>. This, however, shows various flaws:<br> | |||

* The package is not protected against theft or influences by the weather. This can lead to damaged or stolen goods, which is desired neither by the recipiant nor the shipper nor manufacturer. | |||

* The drone can not tell one plastic sheet from another beyond the general location, which could result in packages being delivered at wrong adresses when different people order products in close proximity. It could also be used as an easy method of intercepting both the package and the drone. | |||

* The recipient has to be at home for delivery and observe the sheet to prevent theft or damage. this is a major irritation for recipients with current delivery services as was concluded from the project of Group 10<ref>Technical University Eindhoven 0LAUK0 Group 10 2017-2018 Quartile 3. Retrieved from http://cstwiki.wtb.tue.nl/index.php?title=PRE2017_3_Groep10</ref>.<br> | |||

This design protects against theft and exposure to the elements by providing a safe and easily identifiable package receptacle in the form of a landing platform. It is permanently placed in private or restricted areas and developped mainly for usage by a single household or individual. However, with slight modifications that do not require aditional funds, it can be made suitable for shared access. For additional protection and convenience, the platform can be incorporated in the roof of a building. The storage compartment would be reachable from the inside of the house and intercepting the package or drone has become harder. In addition, the recipient does not need to wait for the package's arival. Besides adressing these problems, the system also has additional functionality such as notifying the recipient of package arrival and remaining storage capacity. The designs benefits are not limited to the recipient of the package, the shipper can serve his customers faster and more accurate, reducing costs and risks, whilst keeping their clientele satisfied. In addition it provides structure to the logistics of drone delivery. | |||

==Accountability == | |||

There are many situations where the producer of a product can be accountable for damage suffered by consumers. A lot of these forms of accountability aren’t described here, since these are forms of accountability that are not product specific for the landing platform. For example, a customer of the landing platform can be attacked by the installer of the platform. The company has accountability since the installer is their employee. The project focusses on the landing platform, therefore the product accountability will be explained further below. | |||

===Product accountability=== | |||

In problematic situations with a product, the producer of a product can be held accountable for the damage the consumer has suffered. There are several guidelines where the producer and customer have to pay attention to considering accountability. The customer is in the disadvantageous position, since there is only one guideline: <ref name="Accountability">Burgelijk wetboek Boek 6. (2017, January 9). Consulted on March 22 2018, from http://wetten.overheid.nl/BWBR0005289/2017-09-01#Boek6_Titeldeel1_Afdeling3 </ref> | |||

*The consumer that wants a compensation for the damage suffered has to prove that there is damage suffered, that the damage is caused by the product and that the product was used as intended while dealing the damage. | |||

For the producer the following guidelines in dealing with accountability are set up by the European Union<ref name="Accountability" />: | |||

* The producer has to deliver clear warning signs and a clear user manual. | |||

* The producer of the product is accountable if the product fails to meet safety standards, and that the product is dangerous to use. | |||

* The producer is not accountable if it was impossible to predict that the product was indeed dangerous to use, the product became dangerous because of deterioration or the damage was caused because of misuse of the product. | |||

===Accountability of the drone landing platform=== | |||

*In the situation that the consumer misuses the landing platform and ignores the warnings given on either the platform itself or the user instructions, then the consumer is at fault and is the one accountable for the damage. One could think of a situation where a person puts his or her hands between the rotating cylinders of the platform when a drone just opened them, or between the rotor blades of the drone. The consumer buys a platform to be able to safely use the delivery drone system, the action of the users is clearly misuse of the system and the first guideline for producers is followed. | |||

*In the situation where the package is stolen or damaged and the platform hasn’t taken too much damage, then the producer of the platform is accountable for the damage suffered. The producer claims to deliver a system that secures the package from damage and theft, in such a scenario the producer has failed to deliver what it claimed to deliver. However, if the landing platform is in a severely altered state then the producer isn’t accountable for the damage suffered. The landing platform is already on the roof to reduce risk of theft, when the platform has been altered in a significant way then the producer is not accountable. The owners and residents are expected to notice such an aggressive act towards the landing platform. In the same way that people are expected to notice when someones front door is damaged in such a way that the people can easily enter the house. In short, the system is anti-theft, but this is only to a certain point. After that point the producer can't do anything against the theft, and the producer isn't considered accountable. | |||

* The producer is not accountable for damage or privacy claims when the platform isn’t placed on the roof of the consumer. The product has a clear description that to be able to deliver complete safety for bystanders, safety against theft and safeguard privacy the system has to be placed on top of the roof. The system does work in other places, like the backyard, and the system is legally allowed to be placed there. The system isn’t on its optimal place and this is regarded as misuse of the system. | |||

*If the system opens when there is no drone, the wrong drone or stays open when a drone has left, then the producer is responsible for the damage the package has taken and possible the house of the consumer. The producer claims to deliver a system that secures the packages from theft and damage, in this case it has failed to deliver this claim. | |||

*If there is a communication problem with the drone and the landing platform and this causes damage then the producer is responsible for the damage. The same counts for when the consumers can’t open the door to retrieved its package, and a mechanic has to come. The costs of the repairs are our responsibility. The producer claims to deliver a system that is easy to use, in this case it has failed to deliver this claim. | |||

====Annotation==== | |||

The cases of accountability described above do still rely on the guidelines of the European Union, meaning that the consumer has to prove that certain damage is caused by the platform, that the platform is used appropriately and that no damage has been done earlier to the platform. | |||

==Planning== | |||

[[Planning Group 11]] | |||

==References== | |||

<references/> | |||

Latest revision as of 10:20, 30 May 2018

| Members of group 11 | |

| C.J.G. Cartignij | 1014018 |

| K.D. van Kempen | 1002991 |

| W.W.A. Verhaegen | 1024053 |

| J.P. Versluijs | 1019169 |

| M. van Wiggen | 1020451 |

Coaching Questions

Problem statement

Here, the current state of drone delivery technology will be explained. From this, a problem statement is derived in order to solve a current problem for the technology and objectives for this project will be stated.

State of the art

A lot of scientific research is currently being done on the implementation of drones for delivery purposes. However, this research mainly focuses on the routing of the drones[1], the avoidance of mid-air collisions[2] and privacy aspects[3]. There are almost no sources on the delivery itself. On the other hand, there are some conceptual US patents describing drone delivery receptacles[4][5][6][7].

The problem that is still present with these concepts, however, is that these concepts are mostly implementations for a smart home and can only be used in one specific situation. Thereby, these concepts are only applicable for people who have a house and not for, for example, flats. Therefore, it is needed to make a simpler system that can be used in multiple environments.

Problem statement

The usage of drones has become popular in various fields of work and also for recreational use. Drones have a promising perspective in a lot of different areas, like military, surveillance and package delivery. The problem that will be tried to solve in this project is the problem of the actual delivery around the house. In the current state of drone delivery, the buyer needs to place a landing pad in a place with enough free space around it[8]. Thereby, the buyer needs to be home when the delivery is done, since the landing pad could be blown away due to wind for example. Furthermore, the way drones are delivering now can be harmful for bystanders, such as kids and pets that do not understand that the rotor blades could be harmful[2]. Also, the drones themselves can be broken if it collides with something. These problems make drone delivery far less easy than it would seem at first. Furthermore, the packages that are delivered are easily stolen and certain weather conditions could be harmful for the package. The last meters of the so-called “last mile delivery” contain multiple problems that need to be tackled before the drone delivery system can really become mainstream. A solution to these problems could convince governments and NGO's to legalize drone delivery[2]. A certain landing pad that has its own designated place, that can hold the package for a sufficient amount of time and is weather/theft proof could be a solution for these problems. The goal of this project is to make such a platform.

Objectives

- Develop a platform/device on/in which a drone can safely drop off a package, considering the following components:

- The dimensions of the parcel, which is carried by the drone

- The landing platform for the drone at the delivery address

- Risk of theft

- Location of the landing platform

- Safety risks for bystanders

- Risk of weather damage

Approach, milestones and deliverables

This chapter will discuss the approach of this project and will give an indication of what can be expected when the project is finished.

Approach

Firstly, literature will be studied in order to figure out to what extent the project case has already been researched. After that, the present day problems with the technology will be determined. A list of RPC's will be made, based on USE analysis and technological requirements. With that list, concepts will be created, of which the best concept will be worked out and made into a prototype. In the design process, it is very probable that it is needed to go back a step to eventually make a better design. In the design phase it may be need to measure the drones that are available in Gemini to determine the final measurements of the design. Lastly, in the testing phase, a drone will be used to check if the system reacts to a flying drone like designed.

Milestones

- Literature study

- Sources read

- Sources summarized

- Conceptualize

- RPC's

- Concepts/drawings of concepts

- Decide a final concept

- Work out concept

- Choose/order materials

- Choose/order operating system/electronic parts

- Costs overview

- Building/assembling prototype

- Test prototype

- Conduct a survey about the prototype

Deliverables

- An overview of the design process(Wiki)

- A prototype of the landing pad

- NX design of the prototype

- Final presentation explaing the design process and showing the prototype

Who are the stakeholders and what do they require

To be able to solve the problem statement the different stakeholders and their needs need to be taken into account. These stakeholders and their needs are discussed below.

User

Delivery services

One user group of the new product will be delivery services. They can use the delivery box/platform as a faster and cheaper way to bring their packages to the customers[9]. A problem of this is that not every country allows drones to fly everywhere, because of privacy. Because of this, the delivery services have to make sure and prove to the government that they do not save imagery. A benefit from the new technology is that the company can deliver packages way faster, namely in less than an hour. This is also very useful for customers because, if they need something quickly, they will no longer have to leave the house. As delivery services become more useful for customers, more people will use the delivery services and the delivery companies will grow. Another benefit for the delivery services is that by using a drone the delivery process will be much cheaper than when the company has to hire a driver. Another thing that makes the delivery cheaper is that the delivery time is way shorter. That means that more packages can be delivered in a shorter time. In short, more customers and faster delivery times ensure a huge growth for the delivery services.

Package buyers (consumers)

Consumers require a delivery method that is affordable, fast, reliable and does not damage the package during delivery. Drone delivery is a good solution for these requirements of the consumers. Since drone delivery is expected to reduce the cost of package delivery, they can deliver packages withing an hour and the package is safely stored in the drone[9]. However, the consumer has to be home to make sure that the surroundings of the landing platform are clear from dangers to the drone. The consumer requires an alternative to these landing platforms that are currently used. Having to be at home takes away from the ease of the delivery drone service. People require a delivery system where they do not have to be home, without having to think about the safety of bystanders, potential theft of or damage to the package during delivery. Consumers are mostly concerned with the invasion of privacy that drones could possibly bring with them. People are scared that the drones can record their actions when the drones fly over their property. People can even feel oppressed or become paranoid because of the usage of drones[10]. The landing platform has to take the privacy concerns of residents into account. Furthermore, the safety of drone delivery is often questioned[10]. For people to be comfortable with using drone delivery system the safety of bystanders during the landing, drop-and take off has to be guaranteed.

Society

Governments in urban planning

Governments can have a huge impact on the success and eventual implementation of the delivery drones. Governments are in the position to make future neighborhoods, that still have to be build, delivery drone friendly and change current neighborhoods to be delivery drone friendly as well. To be delivery drone friendly, the government can implement designated landing spots for delivery drones, that are easily accessible for the residents. There are multiple ways to add this functionality and different options may be chosen for different neighborhoods. Possible options are: Make a central point for all the drones to delivery its package, make landing spots between 2 houses as a shared depot or give every buyer of a future house the option to implement a landing spot in the roof. As can be seen the governmental influence in this new technology can be quite substantial. For the privacy issue explained in the previous section, the place of the landing pad can have a huge impact on how invasive residents find the delivery drones. For the government it is easier to implement this new function in all the newly build homes and neighborhoods without being invasive, then it is for individuals. E.g. the government can build more easily in the front side of the house, the place where people find the delivery drone technology less invasive. For the government itself, focusing on this technology in urban planning there is much profit to be made in the happiness of the residents. There are less delivery people on the street, which is good for the environment and helps to keep streets in living areas quiet and safe[9]. The governments stimulates the economy, because more people are able to quickly order products from enterprises[9]. Putting time in this system during urban planning can increase the feeling of privacy the residents in urban areas have.

Regulation of drones

Privacy was mentioned in the part of consumers/buyers as an important issue against the use of drones. The government can enforce laws for delivery drones services to make sure that the delivery drones do not safe any visual input needed to move around. People would become reassured that the delivery drones that flies over their back garden does not make any recording of what they see, thus safeguarding privacy. The government can enforce other laws that the delivery drones are easily distinguishable from reacreational drones. This way people now what is flying over their property. One last point where the urban planning of the government is important is the regulation of the air traffic of the drones. Drone delivery as a new technology suddenly fill the air with a new form of transport that was not used in urban areas before. The government has to regulate the air traffic of the drones with clear laws, this to prevent annoyance of residents towards the drone delivery infratructure and system.

Enterprise

Delivery box manufacturers

The manufacturers want to make a product that is cheap to make, so they can sell it for less and eventually sell more. The production of the designed delivery box isn’t a really cheap production. An advantage of this product is that it reaches a large target group, namely anyone who uses delivery services to order products. Because the target group for this product is so high, it is relatively easy to achieve a high turnover. And with a high turnover, no very high profit margin is needed, so that the product can be sold even cheaper. Another benefit from this delivery box is that it is applicable on any living situation, so every delivery box can be made exactly the same. The fact that the target group is large and the fact that the product can be used in every living situation ensures that mass production will be possible for this product, so it can be manufactured cheap and thus can it be sold relatively cheap.

Delivery box installers

The platforms where the package will be brought to has to be built in or around the place where the customer lives. For some customers this is easy, for example people with a large garden or a large balcony. But there are a lot of living situations, like flats or terraced houses where the customer can’t build the platform on his house himself. A benefit from this is that many people need to do a small renovation to their house, to place the platform. Many construction workers can, with a little extra training, learn how to install platforms on houses. With the ability to place platforms on houses, the target group of those companies gets a lot bigger, because a lot of people need them for the new technology. This means that there will be more work for construction workers and thus will those companies grow bigger and have increased sales.

Drone manufacturers

If most of the delivery is done with drones, then drone manufacturers will have a larger market to sell their drones to. If this manufacturer needs sell more drones, then they have to produce more drones. The company has to find a cheap way to produce these drones, so they can sell them for less and eventually sell more of them. A way to produce the drones in a cheap way is mass production. The drones also have to be able to work with the new delivery system, so they can be used for that. The drones need to fly very careful because of possible fragile products and the drones need to have the correct dimensions for landing on the platform. Once the new delivery system has been implemented, the company must continue to develop the drones, so that the delivery continues to improve and the drones keep being sold.

RPC's

In this chapter the requirements, preferences and constraints for the final product are listed.

Requirements

- There should be a clearance of 50 cm from the center of the platform to any other object, so there is enough space to let a drone land.*

- The package casing must be weather resistant in normal conditions.

- The package can’t be damaged by rain, wind, hail, snow and debris flying around

- The platform must be able to be used by more than one person

- Requirements of the government for unlicensed building**[11] [12]:

- Back/front garden

- Maximum area of 2 m²

- Roof on back side

- Have a flat roof or,

- Can’t stick out of the roof more than 1.75 m

- 0.5 – 1 m of space to between all sides of the roof and the construction

- Back/front garden

Preferences

- The platform should be as compact as possible

- The platform must be placed in such a way that people can easily access it

- The package should not encounter too much impact

- The landing platform should be cheap

- Easy operation

- Notification should be send when package arrives