Freeduino based robots: Difference between revisions

No edit summary |

|||

| Line 12: | Line 12: | ||

==Speed== | ==Speed== | ||

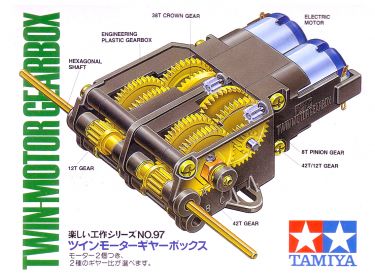

To control the speed and torque of the robot twin motor gearbox was chosen with several configurations ranging from 58:1 to 203:1 using an rpm of 72 to 374. This requirement has a direct link to the user requirement Care, the enterprise requirement | To control the speed and torque of the robot twin motor gearbox was chosen with several configurations ranging from 58:1 to 203:1 using an rpm of 72 to 374. This requirement has a direct link to the user requirement Care, the enterprise requirement Efficiency as can be found in the [[USE principles]]. | ||

[[File:gears.jpg]] | [[File:gears.jpg]] | ||

Revision as of 20:16, 29 November 2015

To make sure the software can be tested on a swarm of quality robots it was best to create our own. To do this first some requirements based on the USE principles needed to be set:

- Robustness: Robots need to break down as minimum as possible.

- Speed: Robots need to work at reasonable speed but still have enough torque to deal with obstacles etc.

- Tools: Because the robots need to move object some sort of shovel can be attached.

- Sensors: Robots need to be able to know where the others are, know where obstacles and objects are and be aware of current speed, acceleration and direction.

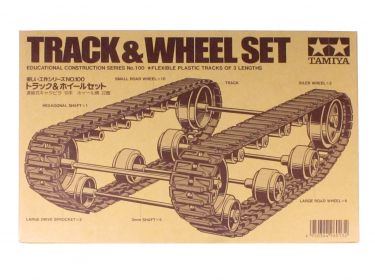

Robustness

To make sure the robot is robust a sturdy chassis was chosen and therefor tank treads will be attached instead of wheels. This requirement is of great importance for the design of the robots due to the terrain that they need to work and function in, as can be read in the scenario. This requirement also has a direct link with the Flexibility requirement for the enterprise and the Care requirement for the user, as can be found in the USE principles.

Speed

To control the speed and torque of the robot twin motor gearbox was chosen with several configurations ranging from 58:1 to 203:1 using an rpm of 72 to 374. This requirement has a direct link to the user requirement Care, the enterprise requirement Efficiency as can be found in the USE principles.

Tools

No Tools Chosen yet

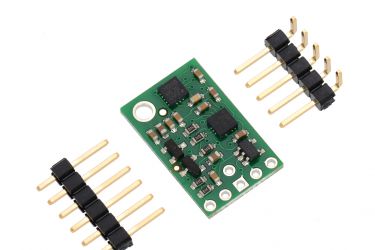

Sensors

To make sure the robot is aware of objects an analog distance measurer using infrared was chosen with a range of 100 to 800 milimeters and a response time of 38ms. File:Infrared.jpg

Also to track speed, acceleration and direction the Pololu MinIMU-9 Gyro, Accelerometer, and Compass can be attached.

Back to: PRE2015 2 Groep1