PRE2022 3 Group9: Difference between revisions

(→User) |

|||

| Line 117: | Line 117: | ||

===User=== | ===User=== | ||

Different users are involved such as oil spills manufacturers/ companies, government agencies, oil and gas companies and environmental | Different users are involved such as oil spills manufacturers/ companies, government agencies, oil and gas companies and environmental organizations. | ||

=====Oil spill manufacturers/ companies===== | =====Oil spill manufacturers/ companies===== | ||

Revision as of 09:56, 9 April 2023

Implementation and Simulation of Debris Recognition for Autonomous Drum Oil Skimmers

Group members

| Name | Student Number | |

|---|---|---|

| Eryk Gruszecki | 1731483 | e.s.gruszecki@student.tue.nl |

| Matilda Fogato | 1656376 | m.fogato@student.tue.nl |

| Oyku Sanlibayrak | 1654519 | o.a.sanlibayrak@student.tue.nl |

| Maud van Bokhoven | 1664387 | m.m.v.bokhoven@student.tue.nl |

| Siiri Jokiranta | 1614207 | s.h.jokiranta@student.tue.nl |

| Nika Tersteeg | 1750828 | n.n.q.y.tersteeg@student.tue.nl |

Introduction

Oil spills in oceans and other major bodies of water have a terrible impact on the ecosystem and people's health. With consequences ranging from physical pain to changes in behavior and reproduction, the hazardous compounds present in crude oil can disrupt marine ecosystems both temporarily and permanently. Fish, marine mammals and birds who come into touch with the oil spill or consume polluted prey may experience particularly severe effects. Oil spills can harm human health in addition to having a harmful effect on wildlife. For individuals working to clean up oil spills, exposure to the hazardous chemicals found in oil can lead to respiratory troubles, skin irritation, and other health problems [1]. Economic losses may also occur in coastal areas due to the impact on the fishing and tourism industries. It is therefore crucial to take action to stop and lessen the harm caused by oil spills. The most concerning oil spills are primarily maritime ones. Since oil is a major source of energy, it is utilized frequently and all over the world, which makes spills like these more frequent. The majority of oil that is spilt remains on the surface and spreads out quite rapidly. Although conventional methods of oil spill cleanup, such the use of booms and skimmers, have been successful in removing oil from the ocean, they are frequently expensive, time-consuming, and heavily labor-intensive.

Problem Statement

Oceanic oil spills can harm marine life and their ecosystems, among other serious environmental effects. The research conducted by R.Manivel and R. Sivakumar in the publication "Boat type oil recovery skimmer"[2] can be a useful source to understand why it is important to focus on oil spills. According to the publication, oil leakage is becoming a bigger issue due to an increase in ship mishaps and oil transportation, which endangers people's health. This is why it is so important to act and lower the impact of oil spills as soon as possible.

Modern methods for cleaning up oil spills, such as ordinary drum oil skimmers, are efficient in removing oil from the waters surface. Oil and water are separated by a spinning, floating drum in the water. When the oil sticks to the drums, wiper blades have to remove the oil from the drums. Since they are portable, dependable and effective, drum oil skimmers are said to be a good oil skimmer.[2] The oil skimmer, however, has its limitations. One of the main issues that stood out when examining the difficulties that oil skimmers encounter when collecting oil is the buildup of debris inside the machine, which wastes time and money. According to the School of Maritime Studies and Transport's research[3], this issue with debris entering the machine and clogging the drum oil skimmers occurs quite frequently.

Moreover, to substantiate this claim, we contacted several oil skimmer manufacturers to find out more about their own experiences of cleaning an oil spill using oil skimmers. A company called Desmi answered us that debris such as floating plastic blocks the entrance of the oil skimmer. This can lead to the pump breaking down.

In that situation, maintaining the oil skimmer will take a lot of time. Since oil disperses swiftly in water, it is critical that the oil be cleaned up as soon as a spill occurs. Also, as time goes on, cleaning up the spilled will become more and more difficult. To reduce the impact of the oil leak, it is crucial to respond and clean up the spill as soon as possible.

Another limitation of the regular oil skimmers that are currently available is the requirement of human supervision. In general, the oil skimmer operates automatic after it's been set up and calibrated or it is even needed to control the oil skimmer by hand. However, the oil skimmers are not autonomous and this implies that the oil skimmer cannot operate efficiently without human supervision. Especially when the oil skimmer is clogged with debris, it is important that the oil skimmer needs to be repaired quickly.

It can be concluded that while oil skimmers and, in particular, drum oil skimmers are efficient in cleaning up oil spills. The currently available oil skimmers have their limitations, such as the fact that human visibility is required while the skimmer is operating. Moreover, the oil skimmer needs to be properly maintained. However, in oceans where floating debris is common, it is common for the oil skimmer to get stuck due to the debris. This causes even more maintenance and more need for human supervision.

Final Goal

The goal of this project is to demonstrate the effectiveness of integrating object recognition and navigational path planning in oil skimmers for the purpose of improving the amount of oil collected and decreasing maintenance times. By creating a proof of concept, we aim to showcase the benefits of this technology and provide a basis for future development and implementation in the oil spill response industry. Through simulation, we will test the ability of the system to accurately recognize oil and navigate a path that maximizes oil collection while minimizing equipment wear and tear. Ultimately, the goal is to provide a more efficient and effective method for oil spill cleanup, reducing the impact on the environment and minimizing the costs associated with cleanup efforts.

Approach / methodology

Within this project, we want to minimize the effects after an oil spills occurs by solving the the issue that oil skimmers easily get clogged by floating debris. Using a machine vision camera with image recognition software that can identify debris and avoid it is one potential solution to this issue. This leads to extended working hours for the skimmer without the need for assistance of a second worker. A novel technology that has the ability to avoid trash while efficiently cleaning up oil spills is an automated drum oil skimmer outfitted with plastic identification software. Unfortunately, it is unknown how well this technique performs in practical situations when compared to a typical drum oil skimmer. This project's goal is to compare an autonomous drum oil skimmer with plastic detection software against a standard drum oil skimmer in order to determine which one performs better in terms of oil recovery, efficiency, and environmental impact.

During this project, the main focus was on the research of oil spills in oceans and the performance of oil skimmers in cleaning the oil spills. The research will be conducted by literature research, and simulating the oil skimmer in unity to visualize what the process will look like. First, literature research will be conducted to obtain relevant information on oil spills, the impact on the environment, current methods of oil clean-up and existing oil skimmers. This information is needed to provide a clear overview and possibly new insights to improve how the oil skimmers are working. Then, by contacting oil skimming companies another view will be obtained about the effectiveness of their current methods and machines. This will help to understand the perspective in the industry, which will give a deeper understanding on the problems that oil skimmers face. However, only one out of 8 companies that we approached responded with relevant information for our project. Then, all obtained information will be used for the creation of a simulation of the autonomous oil skimmer to obtain an insight how to robot eventually will work in an environment. The simulation will be conducted using Unity in order to vary different conditions and aspects to test and optimize the robot. A search method will be applied to the oil skimmer in the simulation, so the robot will locate the debris and move in a path. Finally, two simulations will be compared, one of a regular oil drum skimmer and one with the new autonomous design. These simulations will show how the oil skimmers work and the effectiveness of each design.

An important approach that should be pointed out is that the performance metrics play a big role in designing the robot to evaluate the performance and the effectiveness of the autonomous oil skimmer and compare the measurements with a "regular" oil skimmer. Performance metrics such as speed of cleaning, price/ production costs, lifespan and sustainable battery. These parameters will be taken all together in creating a simulation of the autonomous oil skimmer to obtain an insight how to robot eventually will work in an environment.

The unity simulation will show how the implementation of the suitable camera system to oil skimmers can lead to a more effective way of cleaning oil spills in the ocean. This research will be conducted mainly by literature research and finally creating a simulation.

Definitions

What is an oil spill?

Oil spills can be defined as the leak or spillage of petroleum, which is a mixture of hydrocarbons in a gaseous, liquid or solid form, into the environment. They are common in the sea and have been occurring for a long time, causing life-threatening scenarios. Some oil spills occur naturally due to the activity of earth movements that cause liquid or gas to escape on the surface. However, most oil spills occurs due to human involvement such as accidents in which tankers release oil, especially marine oil spills.

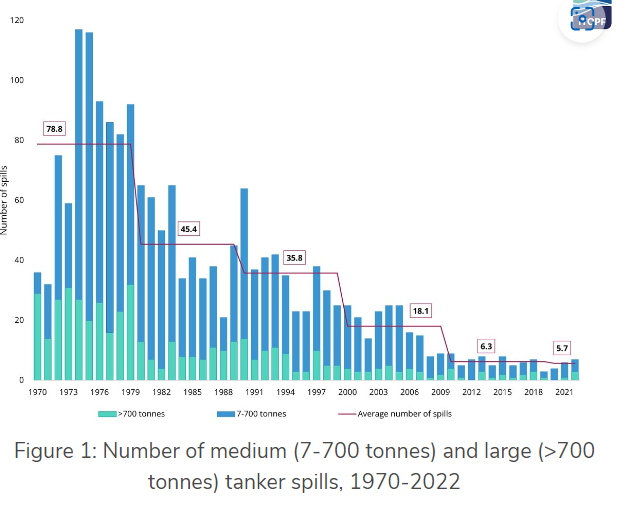

Nowadays, shipping and environmental regulations are in place to prevent oil spills, but still many oil spills occur. According to ITOPF, which is a company that maintains a database of oil spills from tank vessels, the average number of oil spills from 1970's till 2022 is reduced by almost 90% [4].

Figure 1 shows that the number of medium and large tanker spills is reduced from an average of 78.8 to 5.7 oil spills per year. Furthermore, ITOPF stated that the main causes of oil spills were caused by collisions and groundings.

The size and location of an oil spill are important factors in the overall impact. Larger spills require more oil to clean up and the process is expensive. However, it happened that small oil spills caused greater overall costs than larger spills, due to the lack of equipment and the difficulty of detecting such a small leak. Moreover, the cost of the spill depends on the distance from the coast, as the impact of the spill is greater when the oil hits the coast [5]. The type of oil and the concentration of chemicals also play a role in the severity of the leak. To sum up, the impact of an oil spill depends on a lot of factors. The main factors are the size, location and the type of oil, but also the cause the of accidents, the current and wind, the type of skimmers used and the effectiveness of the clean-up. These factors are all important for the maintenance time/cost and play a role in the seriousness of the leak. .

Another major aspect is planning and decision making to predict the distribution of oil after a spill occurs. Computer and mathematical models can provide insights to help this planning and decision making.

What are oil skimmers?

The type of skimmer that is the most effective at collecting oil depends on the type of water body (sea, lake), the type of oil (heavy, light) and environmental conditions such as wind speed, the strength of surface waves and the presence of debris. There are three main types of oil skimmers: weir skimmers, oleophilic skimmers and suction skimmers. Weir skimmers float on the surface of water and use a dam at the oil-water interface to separate oil from water whereas suction skimmers use a vacuum to pump the oil into a storage tank. Weir skimmers and suction skimmers are only effective in calm waters and get easily clogged by debris.

Oleophilic skimmers are the most effective type of skimmer for collecting oil in the ocean. This type of skimmer uses an oleophilic material that absorbs oil to separate oil from water. Drum skimmers are a specific type of oleophilic skimmer where a rotating drum is coated with an oil-absorbing material. Some oleophilic skimmers can deal with small amounts of debris but drum skimmers are sensitive to being clogged [4].

Drum skimmers were chosen as the type of oil skimmer to focus on because they are commonly used for cleaning up oil spills in an ocean environment and they face the problem of getting clogged by debris.

Debris

USE Assessment

When designing a new type of drum skimmer it is necessary to look at the USE assessment and take these different aspects into account.

Society

The repercussions of oil spills can range from long-term economic effects on communities and industry to harm to marine life and ecosystems. By coating marine animals with oil, oil spills can also affect the species by limiting their capacity to move, breathe and eat. Oil spills can also contaminate water, making it dangerous for both humans and marine life. However, because oil spills can disrupt supply networks and have an impact on oil prices, they can have long-term economic consequences on nearby towns that depend on fishing and tourism as well as the overall economy.

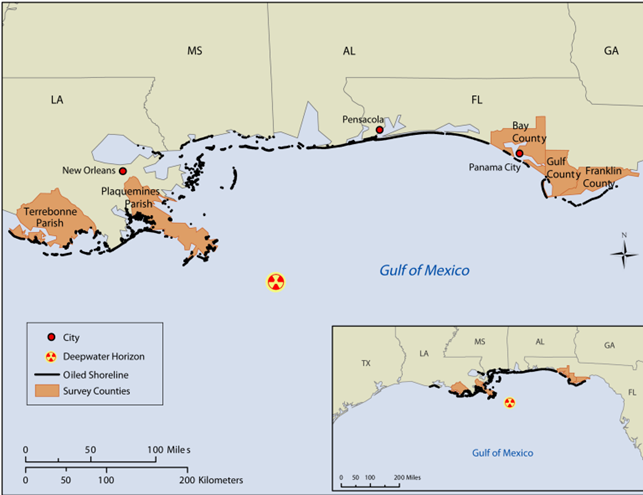

Real Case Example: The Gulf of Mexico oil spill in 2010

In 2010, a huge disaster occurred in the Gulf of Mexico, also known as the "BP oil spill", one of the largest oil spills in history with a total oil loss of 129000 m^3 and in which even 11 workers died. After the explosion, various clean-up strategies were implemented to clean up the oil spill and minimize the impact. However, the oil spill caused widespread environmental damage and social impacts on economies and cultures in the area. Almost half of all Gulf Coast residents experienced environmental damage and nearly 223000 km^2 of fishable waters were closed due to the oil spill, which had great socio-economical impact. Many fishing communities had to close their fishing grounds, causing huge economic losses. Besides, Floridians experienced the economic impact on the tourism industry [10]. The spill caused damage to the reputation of the area because of association with the oil spill. The total economic impact is about 23 billion [11].

The spill also affected the physical and mental health of the residents. After being exposed to crude oil containing chemicals that can cause cancer, brain damage and other illnesses[12], some residents reported health problems related to their lungs, kidneys and heart functions among the long-term effects. Not to be forgotten are the mental health impacts, such as increased anxiety and depression, and even PTSD. Long-term effects are still being researched as we do not know the effects of crude oil exposure.From the perspective of the oil company, BP was primarily responsible for the leak and was criticized by the media, environmental groups and the public.

BP responded to the leak and began a clean-up operation with oil skimmers and booms to remove all the oil. The total estimated cost was about 61.6 billion, most of which BP paid[13]. In addition, BPs reputation declined significantly, including a fall in its share price, loss of partnerships and a negative public image.

Environment

According to A. Clifton (2014), petroleum is one of the most consumed raw materials as an energy source and therefore transported in significantly large oil tankers. The annual estimated amount of petroleum that is spilled is between 10 million and 20 million ton and the petroleum spreads on the surface of the sea. When an oil spill occurs, there are great concerns to the environment on short term and long term. An oil spill harms ocean life by fouling or oiling, which means that the oil physically harms plants and animals such as coating bird’s wings due to oil and by oil toxicity, which means that the toxic particles cause health problems such as to the immune system and can even cause death. [14]

The impact of an oil spill has huge effects and even after a few years, it is proven that there were still high concentrations found in the sea.

To mitigate the effects, new techniques are developed concerning an oil spill clean-up and one of the most promising techniques is the remediation process for reversing environmental impacts. Another way to reduce long-term negative environmental impacts is to clean up oil quickly and efficiently as soon as possible after an oil spill. If there is a new oil skimmer design that is more efficient and takes less time to clean up oil, the long-term impacts will be reduced.

User

Different users are involved such as oil spills manufacturers/ companies, government agencies, oil and gas companies and environmental organizations.

Oil spill manufacturers/ companies

Oil companies play a crucial role in post-oil spill clean-up and management. It is vital that the oil spill is handled carefully and an effective technique is the use of oil skimmers in such a situation. Here, oil spill companies, such as those that design and sell oil skimmers, are considered an important user in the design and assessment of a new oil skimmer. Since oil skimmers are not only useful and efficient in cleaning up an oil spill, they are also necessary! However, the effectiveness of a skimmer depends on its design and capacity.

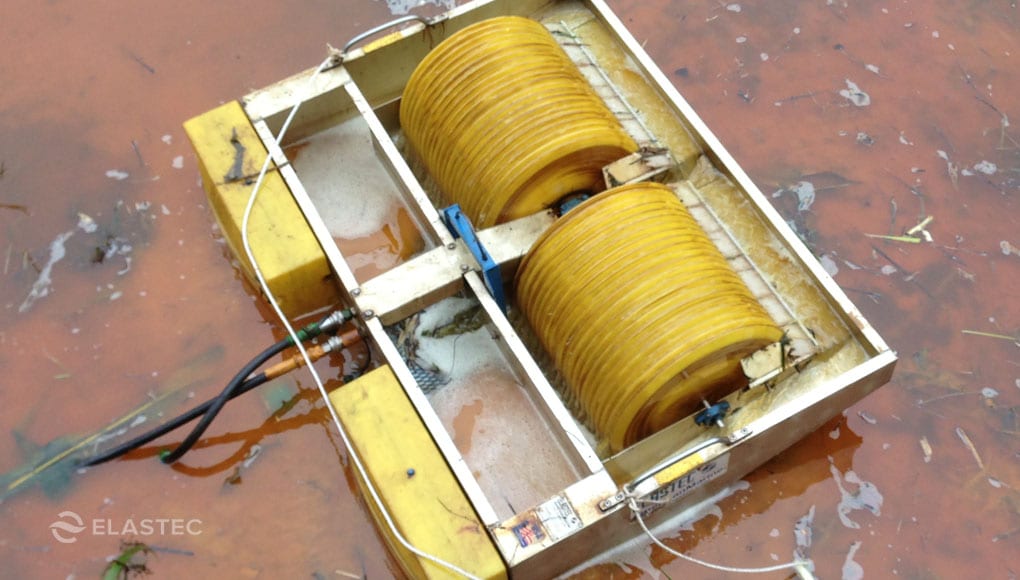

One oil skimmer company is Elastec which is an oil spill company since 1990 that invented the first efficient drum oil skimmer. The company is focused on oil skimmers, booms, turbidity curtains, work boats and vacuum systems to develop solutions for clean water.

The introduction of a new oil skimmer design could have a positive impact on oil skimmer companies. First, it could enhance a positive public image if oil skimmers are proven to be efficient and thus minimise environmental risk. Second, if there is high demand for the product in the market, the company could benefit. On the other hand, if another company introduces this new oil skimmer design, it could lead to a reduction in the use of older oil skimmers and other companies could drop out of the industry. This leads to higher prices.

In short, oil skimmer companies are needed to manage oil spills and minimise negative impacts.

In the gulf of Mexico, all help was needed to clean and manage the disaster. A mega ship “A whale” was designed by Taiwan came to the gulf of Mexico to rescue the leak. At least, that was the purpose of the gigantic oil skimmer and the sales pitch. With the capacity to collect 12.6 million gallons in 10 hour it could replace up to 500 medium oil skimmers which makes “ A Whale” the largest oil skimmer ever. According to P. Jonsson [15] "A whale" may not be efficient because the ship spreads the oil widely. Moreover, it would be very expensive to operate. After two weeks after the arrival of "A Whale", it was found that the oil skimmer was no longer collecting oil. Subsequently, the company TMT went bankrupt. This example highlights the importance of the effectiveness of an oil skimmer for a given oil spill. The use of an oil skimmer and its management to clean up an oil spill is dependent and unique to each situation. Designing new oil skimmers and creating new insights into management after an oil spill is necessary.

In short, our design with the camera and path navigation can provide a better understanding of reconnaissance and a faster way to clean up oil without human intervention. For oil skimmer manufacturers and companies, this means more competition in this market. However, it also depends on the skimmer's purpose, reliability, ease of use, efficiency and effectiveness to be successful in the market and thus profitable.

Government companies

Oil spills have negative impacts on public health, drinking water, natural resources, ecology and the economy. As the oil industry is huge and unavoidable, large quantities of oil are used and transported, sometimes resulting in an oil spill, putting public health and the environment at risk. The U.S. Environmental Protection Agency's Oil spill Program is a federal government agency and plays an important role in the protection from oil spills that occur in and around the U.S. The organization tries to prevent these oil spills and published a booklet containing information about oil spills which includes potential effects. The EPA proposed different techniques that may be used after an oil spill to minimize the impacts. The main response technique is the "mechanical containment or recovery". This includes the use of recovery equipment such as barriers, skimmers, booms and sorbent materials.

When there is a new design of an oil skimmer which shows to be more effective and efficient, organizations such as the EPA could implement this as a standard practice for oil spill response. This could lead to a better environment as the EPA aims to minimize the negative impacts of oil spills.

Oil and gas companies

Oil and gas companies play a major role in the production and supply of oil. However, when an oil spill occurs, it is crucial that it is cleaned up quickly. As illustrated by the 2010 Gulf of Mexico oil spill, BP was primarily responsible for the oil spill, which had a negative impact on the reputation and public image of the company. BP's response to the oil spill was to clean up the oil with oil skimmers, booms and other tools. From the oil and gas companies' point of view, it may be beneficial to their reputation to use our new design of autonomous oil skimmer when an oil spill accident occurs. The public image of the oil industry is often negative due to many environmental, economic and social concerns. Thus, applying a new design that is more effective and promotes sustainability could have a positive impact on the public image of these companies.

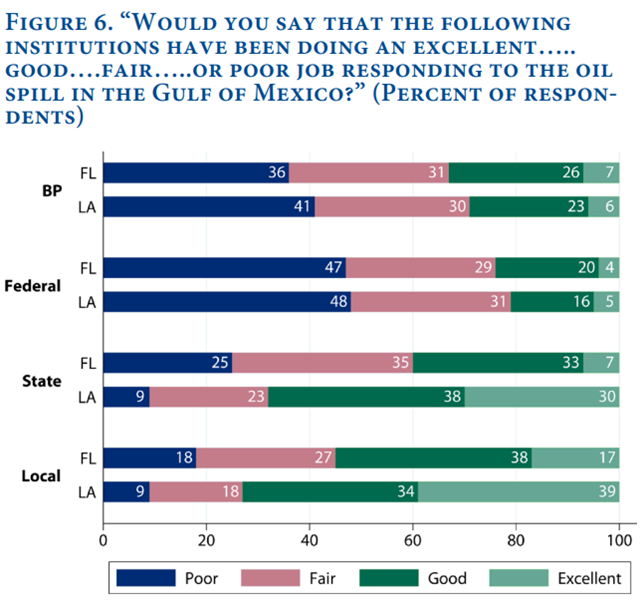

As shown in the figure from the Carsey Institute, more than 1/3 of respondents from Floridia and Lousiana said BP and the federal government's response to the oil spill was poor.

Enterprise

While oil spills continue to represent a serious threat to our ecosystem, governments and organizations throughout the world are investing more in cutting-edge technologies to lessen the dangers associated with them. The oil skimmers in the market face a lot of challenges while trying to perform their task.

One of the biggest problems that oil skimmers face is debris. If an oil skimmer comes in contact with to much debris, it needs to be cleaned, which costs the company cleaning up the oil spill time and money. If the skimmer could autonomously clean up the oil while avoiding as much debris as possible, the skimmer could work for longer periods of time before needing maintenance. Besides from saving the company money because the skimmer can keep working, this would also decrease labor costs. Most skimmers need to be manually controlled, so an autonomous skimmer does not only decrease the maintenance personnel needed, it also does not need as many people to control the skimmers, which can be beneficial for the company as they can either save money or deploy more skimmers for the same amount of money and finish the clean up in less time.

Specifications of Oil Skimmers

Types of oil skimmers

There are several different varieties of oil skimmers, each with unique advantages and limitations. Beginning with belt skimmers, these machines use a rotating belt to collect oil from the water surface and transport it to a collection container. They perform best when removing sizable amounts of oil from bodies of open water, such as lakes or harbors. Drum skimmers revolve a drum in order to gather oil from the water surface. They are good in removing both light and heavy oils, and they operate well in both calm and choppy waters. The best place to use disc skimmers is in shallow water since they use a rotating disc to remove oil from a surface. Weir skimmers are best employed in calm environments like ponds since they collect oil off the water surface. The drum skimmers will be the subject of this study, though. The reason behind this can be expressed in two key points: The ability of the drum oil skimmers to function in open ocean and sea is one of them. Focusing on a drum-type oil skimmer is an excellent idea because this research is concerned with debris in the open sea, which is a much more complex environment for the oil skimmer. Moreover, the drum oil skimmer is mobile. It can travel independently to get oil. This is an important factor to consider when selecting the oil skimmer that will be the subject of this study because our exploration of the oil skimmer needs to be mobile in order to avoid the detected debris in the ocean using the image recognition technology that will be used in the camera system.

How long does it take to clean oil with a drum skimmer?

In order to view the impact on the environment, the clean up costs can be estimated. The amount of oil spills have been decreased over the years. Especially medium, 7-700 tons, and large, >700 tons, oil spills has been decreased, however the small oil spills which occur 80% of the time occur more frequently. [16]. Therefore, it is needed to compare the impact of such a small oil spill

In the article “ by Calculation of oil droplet size distribution in ocean spills by L. Nissanka and P.Yapa, a model is being made to calculate the distribution of an oil droplet size in the ocean. Two models are used of which the equilibrium model is preferred to compare it in field situations. With these calculations and models that are provided in the article, it the impact can be calculated for different situations.[17].

As believed by I.Nissanka and Y.Yapa, modeling this DSD is complex and contains several processes.

In another article by J. Montewka a probabilistic and systematic model is presented to estimate the costs in “A probabilistic model estimating oil spill clean-up costs - A case study for the Gulf of Finland” [18]. The cost model includes utility, decision, independent and conditional variables such as oil type, spill size, season, wave height, evaporation, effect of booms, number of vessels and machine costs. The papers investigates how the user selects the location, size and type of an oil spill to estimate the total clean up costs.

Furthermore, the article shows that the total clean up costs will decrease when the recovery time decreases which makes the recovery time an important factor in the total costs. The recovery time is dependent of the type of oil, spill size and the clean-up method.

In the first scenario, an oil spill of 5000 tons of medium oil are investigated by their model. The model estimated total clean-up costs for 12.1 Million dollars. The second scenario contains an oil spill of 30000 tons of heave crude oil with a total cost estimation of 95 Million dollars.

It should be mentioned that this model does not include socioeconomic, environmental and waste management costs.

To investigate more in depth in our case about the effectiveness of drum oil skimmers. A. Hammoud an M. Khali did research to the effectiveness and predict the oil recovery rate of an drum oil skimmer in their study “Performance of rotating drum skimmer in oil spill recovery”. Their experiment was conducted for different oil thickness, varying distances between the drum and the surface, and varying drum velocity. [19]

Their results show that the oil recovery rate is mainly dependent on the drum rpm and the oil viscosity. The oil recovery rate increases with the drum velocity and the oil viscosity. It decreases with wave length for both low and high viscosity oil.

To sum up, models and simulations can help predict the impact of an oil spill and eventually how to manage an oil spill. It has shown that the effectiveness of the clean up method is important. Furthermore, by understanding the impact and the total costs of an oil spill, it is possible to optimize clean up methods to minimize the risks of an oil spill.

Operational parameters for recovery rate

Capacity of the drum oil skimmer

Drum oil skimmers operate on the principle of separating the oil from the water using rotating metal cylinder that "skims" the water surface. This oil that adheres itself to the surface of the drum is then collected in a tank that is then later pumped out to be processed. Of course there are different sizes to the drum oil skimmers which will result in different collection tank capacities however it is still important to research the current state of the art of drum oil skimmers. From Visco Engineers, their drum oil skimmer has the following dimensions:

| Model | DSKM-06 |

|---|---|

| Height | 500mm. Approx |

| Width | 750mm. Approx |

| Length | 1750mm. Approx. |

| Capacity | 500-700 LPH |

This capacity refers to the oil storage on the drum oil skimmer in liters per hour (LPH). Here this drum oil skimmer collects about 0.5m3 to 0.7m3 per hour [20].

Another drum oil skimmer for industrial uses is the TDS118 Oil Skimmer. It has the following specifications:

| Smooth Drum Nameplate Capacity | 35 gpm / 8 cu.m per hour |

|---|---|

| Number of Drums | 2 |

| Dimensions | 52.5 x 40.5 x 18 inch / 1.33 x 1.02 x 0.46 m |

Apparently this drum oil skimmer has a capacity of 8m3 per hour which is 8000 LPH. This capacity seems a bit large for the dimensions of the oil skimmer[21]. Through this research it can be seen that the capacity of drum oil skimmers have a very large range for various dimensions. However this research does lend itself useful as it can provide us with an idea for how large the drum oil skimmer can be.

Speed

The article “Effect of operational parameters on the recovery rate of an oleophilic drum skimmer” written by V.Broje and A. Keller shows the effects of different parameters on the recovery rate. Looking at the speed of the oil drum skimmer, the drum rotational speed was tested for 30, 40 and 65 rpm (rotations per minute). Varying the speed controlled the encounter rate of the oleophilic surface with the oil front. 30 rpm represents the minimal rotation speed and 65 rpm the maximal speed that could be achieved for average drum skimmers. A higher speed emulsifies the oil to a greater extent. It shows that the amount of entrained water will increase, especially in the case of thin oil slicks and/ or viscous oils. The amount of recovered oil can be increased by 50-100% using higher rotational speeds. 40 rpm seemed to be near the optimal rotational speed above which the drum starts to entrain significant amounts of water. If storage capacity is not limited, drums should be operated at their maximum speed. [22]

Another experiment, by Walaa Sabbar et. al. (2021), the impact of the temperature, viscosity, oil slick thickness and drum rotational was investigated. In addition, these parameters were tested for different types of oil such as light diesel, crude oil and heavy diesel oil. The optimal speed for the rotations is shown to be proportional to the increase in the drum rotation speed and this experiment predicted an optimal rotation speed of 56 rpm. Light diesel was shown to be the type of oil with the best recovery rate, with the recovery rate decreasing with increasing viscosity [23].

Maintenance

The use of drum oil skimmers has become an efficient method for cleaning up an oil spill. However, for an oil skimmer it is highly important to operate correctly and therefore it is necessary to regularly check for maintenance needs. First, the skimmer needs to be inspected to check for tear or leaks before it can be used for an operation. Second, the skimmer should be cleaned to remove stacked debris and oil. This is highly important for the skimmer and especially for the drum skimmer since the drum rotates to pick up the oil. If it doesn’t rotate, it doesn’t pick up any oil. Third, replacing damaged parts is needed to prevent further damage. According to an oil skimmer company, their oil skimmers have a life span of 25 years [24]. However, this lifespan is only realistic if the skimmer has the right maintenance.

To sum up, maintenance is critical to ensure that oil skimmer work properly. This include regular inspections, cleaning and recovering damaged parts to extend the lifespan of an skimmer. Decreasing the amount of debris the skimmer comes in contact with would help decrease the maintenance needed.

In literature, there are two search methods that have been implemented in autonomous water/ocean surface operating robots. Deep Reinforcement Learning (CARL-bot) and Coverage Path Planning (SMURF):

Deep reinforcement learning (DRL) is a machine learning technique that has made great advancements in robotics. One DRL algorithm that has been applied to autonomous submergible robots is called V-RACER (Value-based Reinforcement learning for Autonomous Cleaning and Environmental Restoration). V-RACER is a DRL based robot that combines deep learning and reinforcement learning to enable a robot to learn how to navigate an environment with a specific goal. The algorithm uses a neural network to map sensor inputs to actions, allowing the robot to learn how to navigate and perform tasks in a simulated environment.

In the V-RACER algorithm, the robot is first trained in a simulation environment. This environment is supposed to mimic the real-world conditions of the open ocean in order to develop a working framework for the algorithm. The algorithm utilizes a reward system to encourage the robot to take actions that lead to the successful completion of a task. This algorithm could be implemented into the design of drum oil skimmer to make the process autonomous and more efficient.The technique used in the algorithm is called experience replay, which involves storing and replaying past experiences to help the robot learn from its mistakes and improve its performance over time. The experience replay technique could be utilized to develop a robust and efficient cleaning strategy. One advantage of using DRL algorithms such as V-RACER in autonomous drum oil skimmer is that it is able to adapt to different environments and conditions. The algorithm can learn how to navigate and clean up spills in various conditions, such as rough seas, changing currents, and different types of oil."CARL-bot is the Caltech Autonomous Reinforcement Learning robot, which is a palm-sized, underwater robot for testing our RL-based navigation in the real world. It will show us how our recent results in a simulated fluid flow hold up for navigating in the real world with all of the associated challenges, such as imperfect sensors and motors, all while training on-board and in real-time[25]."

Another navigational search strategy commonly used in autonomous systems is coverage path planning. The objective of coverage path planning is to ensure that the robot systematically covers the entire area of interest while minimizing the distance traveled. This type of navigational method is very common within autonomous household devices such as vacuum cleaners, lawn mowers and many more[26]. Coverage path planning is an essential technique for modern-day robots, which involves developing algorithms and strategies to enable robots to navigate through an environment and cover a specified area.

This can be implemented in the autonomous system to maximize the cleaning efficiency. In the context of oil spill cleaning, coverage path planning can be used to guide the robot to cover the entire area of the spill while minimizing the amount of oil left behind. The robot can use various sensors and imaging technologies to detect the extent and location of the spill, and then use coverage path planning algorithms to plan the most efficient cleaning path.

There are several advantages to using coverage path planning in autonomous oil spill cleaning robots. First, it ensures that the entire area of the spill is covered, reducing the risk left behind oil. Second, it minimizes the distance traveled by the robot, reducing the amount of energy consumed and maximizing the battery life. Finally, it ensures that the cleaning process is carried out in a systematic and efficient manner, reducing the time and cost required for maintenance of the oil skimmer and to clean up the spill.

An existing fully autonomous water surface cleaning robot has been developed using a variation of the coverage path planning method SMURF by a research team in China. It is a trash collection robot that aims to efficiently clean the water surface that it is operating in.“The environment perception of SMURF relies on the fusion of mmWave radar point clouds and RGB images. SMURF is controlled through our improved NMPC controller to sail along the generated path. When there are obstacles on the path that are detected during the task, a local path will be generated to bypass the obstacles. In addition, the SMURF detects floating trash autonomously and collects the trash in time to avoid trash moving [27].”

For a successful implementation of a coverage path planning algorithm, the bounds of the environment need to be defined. In the case of an oil spill, it is customary to use floating barricades, also known as booms, to section off the contaminated area from the clean ocean water. These boundaries act as the enclosed environment for the oil skimmer. There are various algorithms and techniques that can be used for coverage path planning in autonomous systems. One common technique is the grid-based algorithm, which divides the area of interest into a grid and assigns the robot to cover each cell in a predetermined order. Another technique is the Voronoi diagram-based algorithm, which divides the area of interest into polygons that are covered by the robot in a predetermined order.

In the context of the drum oil skimmer, the best suited algorithm for the coverage path planning would be potential fields. The potential fields algorithm is based on having the robot navigate an environment and when an obstacle is encountered, the obstacle has a sort of ‘potential field’ that the system recognizes and simultaneously alters its previously planned path to avoid the obstacle. In this way, the oil skimmer is able to avoid the debris in the water and continue collecting oil.

Overall, the implementation of coverage path planning in modern-day robots requires careful planning, algorithm selection, and testing. Especially in the context of an autonomous drum oil skimmer, with the right approach, this technique can be a powerful tool for maximizing efficiency, productivity and reducing maintenance costs. However, CPP works well in static environments for example the inside of a home or the front lawn of house. In a dynamic environment, such as the ocean, environmental factors like wind and currents are huge challenges for CPP based robots. Therefore, the autonomous drum oil skimmer could only be deployed within a bounded area created by floating barriers.

In conclusion, the V-RACER algorithm is a powerful DRL technique that has shown great promise in the application of autonomous oil spill cleaning robots. By using a combination of deep learning and reinforcement learning, the algorithm enables the robot to learn how to navigate and clean up spills efficiently, even in challenging and changing conditions. The ability to adapt to different conditions and environments makes DRL algorithms such as V-RACER a valuable tool in the fight against oil spills. However, coverage path planning lends itself as the most effective search strategy for autonomous oil spill cleaning robots, as it ensures that the entire area of the spill is covered in a systematic and efficient manner. By using sensors and imaging technologies to detect the extent and location of the spill and applying coverage path planning algorithms, the robot can maximize cleaning efficiency while minimizing energy consumption and time required to clean up the spill.

Detection of debris with image recognition

Deep Learning

Deep learning is a subset of machine learning that involves training artificial neural networks to perform tasks like image recognition, natural language processing, and speech recognition. The term "deep" refers to the multiple layers in a neural network, which allows it to learn more complex features and patterns.

In deep learning for image recognition, the neural network is trained on a large dataset of images. During training, the network learns to identify the unique features of each image and classify it into one of several categories. This process involves a series of mathematical computations in which the network adjusts its internal parameters to minimize the difference between its predictions and the correct labels for each image.

One of the key advantages of deep learning for image recognition is its ability to identify low-level features like edges and corners and combine them into higher-level features like shapes and textures. This makes deep learning particularly effective for complex image recognition tasks like identifying objects in natural scenes, like in our case, debris floating in water.

Another advantage of deep learning for image recognition is its ability to generalize to new, unseen images. Once a neural network has been trained on a large dataset, it can make accurate predictions on new images that it has never seen before. Previous studies have shown, for example, that deep learning models can recognize plastic underwater after being trained only with pictures of plastic outside of the sea.

Industrial and academic applications

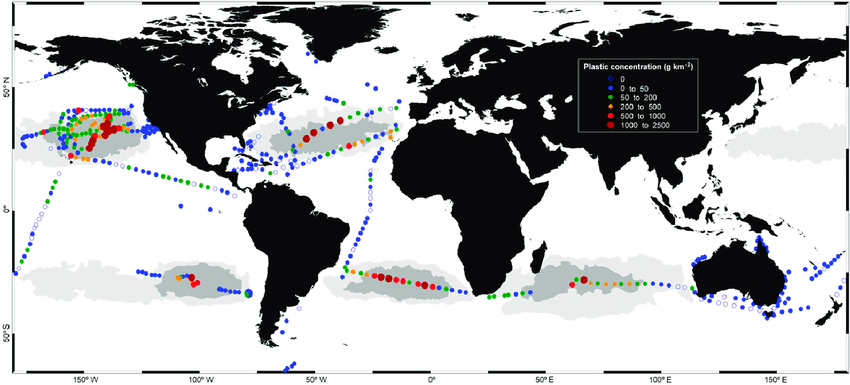

There are various applications of deep learning and computer vision in identifying and estimating plastic litter in oceans.

One such project is DeepPlastic[28], where a deep learning model was used to identify plastic underwater. The research found that the model was sufficiently accurate and fast enough to be used in applications like underwater autonomous plastic collectors.

Another study [29] applied deep learning to estimate the volume of macro-plastics in oceans, proposing a fast, scalable, and potentially cost-effective method for automatically identifying floating marine plastics. When trained on three categories of plastic marine litter, the classifier was able to successfully recognize the preceding floating objects at a success rate of ≈ 86%. The high level of accuracy and efficiency of the developed machine learning tool constitutes a leap towards unraveling the true scale of floating plastics.

Additionally, Vito [30] Remote Sensing is a company that uses satellites and AI vision for multiple applications, including the detection of marine plastic litter.

Design Research

Which camera to use?

The ocean environment presents unique challenges for industrial image recognition systems, as cameras must be able to withstand the harsh conditions of saltwater, strong currents, and changing light conditions.

The hardware used for image processing systems, namely cameras, are distinguished by two groups. The first group being industrial/machine vision (MV) cameras and the second group being network/IP (Internet Protocol) cameras.[31]

Industrial image recognition requires high-resolution cameras capable of capturing clear and detailed images even in low light conditions. High-resolution cameras can capture images up to 4K or 8K, allowing for detailed analysis of underwater images. Remote sensing cameras can capture images from a distance, allowing for long-range monitoring of underwater environments. They are useful for monitoring oceanic currents and weather patterns

The goal of this study is to implement the suitable camera system that can interact with a drum oil skimmer and record and identify photos of debris while the skimmer avoids debris that could clog the skimmer. In this situation, using a machine vision camera with picture recognition skills is necessary. There are numerous machine vision cameras available on the market. Various considerations need to be made while choosing a camera. Resolution is a crucial feature to consider. To get clear images of the floating waste in the water, the camera's resolution must be high enough. The frame rate is another significant feature. The number of video frames that the camera records each second is known as the frame rate. The camera's frame rate must be high enough for the real-time image processing to function effectively.[32] A decent camera system also needs to be able to process images. The camera should either have built-in image processing hardware or be compatible with external image processing units to enable accurate and effective trash detection. The lighting conditions should also be considered. The camera should be able to take crisp pictures in both bright and dim lighting conditions. Environmental resilience and strength features are crucial, too. The camera ought to be able to withstand exposure to severe weather, including exposure to moisture, salt, and extreme heat.

For our oil skimmer, we decided on the Sony XCG-H280CR machine vision camera due to its exceptional performance and cutting-edge capabilities. Even in difficult climate conditions, the camera's high resolution of 1920 x 1200 pixels and quick frame rate of up to 60 frames per second enables it to take clear and accurate photographs of the ocean surface [33]. Our skimmer can rapidly identify and remove oil from the water while leaving behind other items thanks to its excellent image processing capabilities, which include real-time debris identification and recognition. In addition, the Sony XCG-H280CR is a resilient camera designed to survive challenging environmental conditions, like those frequently present during oil spill cleanup efforts. While its industrial-grade components guarantee that it can withstand the demands of long-term usage, its waterproof and dustproof housing ensures that it operates reliably in wet and dusty circumstances. Overall, we've found that this camera's vision provides the perfect balance of performance, dependability, and longevity for our oil skimmer. We are certain that this camera will assist our skimmer to perform at its best, offering quick and effective oil spill cleanup services that contribute to the protection of our environment from oil spills.

Final Design

How to implement this camera system to the oil skimmer?

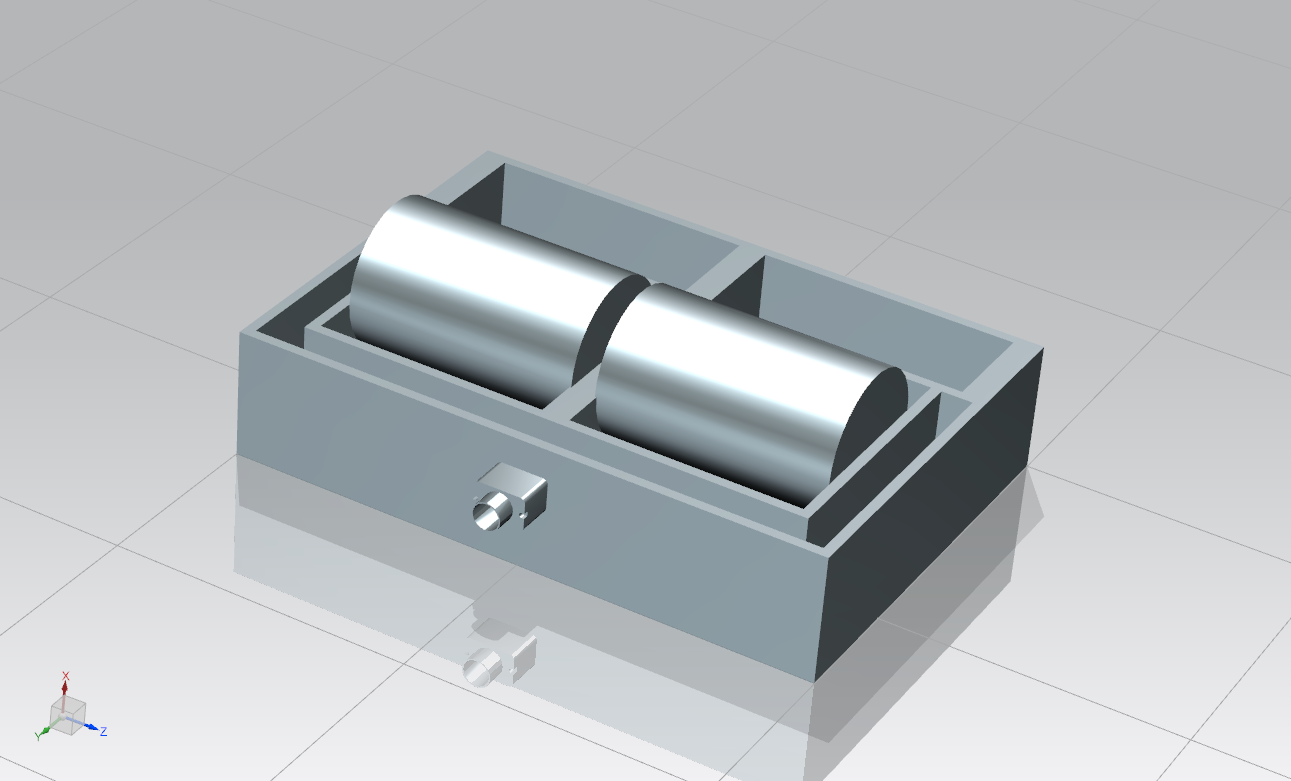

We chose the Sony XCG-H280CR machine vision camera for the oil skimmer, and therefore the implementation process of the camera system to the CAD design of oil skimmer needs to be explained. First of all, the position of where to implement the camera system is very important since the clear visual image of the debris in ocean should be detected easily. As the skimmer will need to avoid the debris in front of it, it was chosen to place the camera on the front of the skimmer, as can be seen from the picture of our CAD Design. After that, once the camera is mounted, you must connect it to the oil skimmer's control system so that it can handle real-time image processing. Installing specialist hardware and software, such as OpenCV, will allow the camera to connect with the control system. OpenCV can be used to process images in real time. It supports a wide range of image processing operations and may be used with C++, Python, and Java among other computer languages [33]. Secondly, the camera's settings must then be adjusted to maximize its efficiency during oil skimming activities. In order to ensure that the camera takes clear and accurate pictures of the trash on the water's surface, this process involves adjusting the resolution, frame rate, and other settings. Finally, in order for the skimmer to react to camera input and modify its operation as necessary, the camera system must be integrated with the skimmer's control system. This can entail installing an automated system that modifies the skimmer's speed and position in response to information from the camera.Simulation

Goal of the simulation

In addition to conducting research, we created a simulation of a drum skimmer with and without our proposed improvement. The purpose of the simulation was twofold: to better explain how our variation on the skimmer would function and to identify potential design flaws that we may have overlooked due to our limited knowledge about oil skimmers. By presenting the simulation to potential users, we can provide them with a more detailed understanding of how our proposal would work and why it would be an improvement over a regular oil skimmer.

Furthermore, the simulation can also help us engage potential users in the design process by allowing them to identify problems that we may have missed. This inclusive approach can help us create a more effective and user-friendly product.

Additionally, the simulations based on our research can help illustrate in which environments our proposed system would be most effective. By using the simulation as a proof of concept, we can demonstrate the benefits of our proposed improvement and provide evidence to support its effectiveness.

Unity simulation

To compare the traditional oil skimmer with the new design that incorporates a camera system, we created a realistic environment in Unity. The simulation included water, oil patches, and debris, which were designed to mimic real-world conditions. A CAD design of a drum skimmer was also implemented in Unity, which allowed us to test the skimmer's ability to move around the environment and collect oil as quickly as possible.

To simulate the difference between a traditional drum skimmer and a skimmer with a camera system, we created two different behaviors for the skimmer in the same environment. The traditional oil skimmer followed a simple path and did not try to avoid debris, while the skimmer with a camera system utilized a path planning algorithm to avoid debris and find the optimal path to the oil patches.

By creating a realistic environment and implementing these behaviors, the simulation provided valuable insights into the effectiveness of our proposed design. The simulation showed that the skimmer with a camera system was able to collect oil much faster than the traditional oil skimmer and was less likely to get stuck on debris.

Conclusion

In this project, the effectiveness of integrating image recognition and path planning to oil skimmers for improving oil collection rates and maintenance times was studied. Literature research was used to show that preventing oil skimmers from getting clogged with debris could improve the performance of the skimmer. A conceptual design and a simulation were created to demonstrate how this problem could be solved by implementing a camera on a drum oil skimmer and by using path planning and image recognition to avoid debris.

Results of the simulation

Our project aimed to design an oil skimmer that would be more effective in collecting oil spills, particularly in environments with debris. While we conducted extensive research and developed a design with a camera system that showed promise in simulations, our simulations were not accurate enough to definitively determine whether our design is better than traditional oil skimmers.

However, one key takeaway from our project is the need to tackle the problem of debris in oil spill cleanup efforts. Our simulations showed that debris can significantly impede the effectiveness of oil skimmers, and our proposed design aimed to address this issue. While further testing and refinement may be needed to fully realize the potential benefits of our proposed design, the problem of debris is a critical area that must be addressed in future oil spill cleanup efforts.

The research on oil spills and the design of our autonomous oil skimmer has its limitations that should be pointed out. First of all, designing a simulation could be an effective tool in showing the design and its advantages towards a regular oil skimmer. Although the environment of the simulation is designed to be as realistic as possible, it does not capture all the real-world scenarios such as the marine current, weather conditions, different type of oils. Therefore, the simulation is not generalizable to all situations and other research is needed to test the effectiveness in the real world.

In conclusion, while our project may not have yielded a definitive solution to the challenge of oil spill cleanup, it highlights the need for continued innovation and improvement in this field. We believe that our proposed design, along with continued research and development in this area, can help to improve the effectiveness of oil skimmers and ultimately minimize the environmental impact of oil spills.

Weekly Work

| Logbook | ||||||

|---|---|---|---|---|---|---|

| Who? | Eryk | Nika | Matilda | Oyku | Siiri | Maud |

| Week 1 + hours | Created structure of the report (1) | Thinking about subject and research question (4) | Researching about autonomous robots and AI-based navigation solutions (4) | Researching about ocean garbage collectors, and how they work (4) | Researching ocean garbage collectors | Researching the current state of the art of autonomous underwater garbage collectors (8) |

| Week 2 + hours | Problem Statement research (4) | Research to different type of oil skimmers (6) | Researching image recognition techniques and implementations for sea plastic collection (6) | Research about the types of oil skimmers, and their advantages (6) | Prototype research | Researching how oil skimmers work (6) |

| Week 3 + hours | Comparison of autonomous drum oil skimmer and non-autonomous drum oil skimmer (6) | Methodology + start problem statement (6) | Working on Unity simulation (6) | Getting in contact with oil skimmer companies and continue working on the report (6) | CAD design + research about oil skimmers | Working on netlogo-model (2) |

| Week 4 + hours | Naviagtional method for ocean surface robots (8) | Analyzing 3 papers that focuses on the oil recovery rate of drum skimmer / the number of oil spills/ the effects of a droplet oil spill (8) | Working on creation of a realistic environment for the Unity simulation (6) | Research about the camera system that is going to be implemented on the drum oil skimmer (8) | CAD design | Writing about why we chose to make a simulation (1) |

| Week 5 + hours | Literature Research on specific variables for drum oil skimmers such as collection capacity (8) | Working on the Unity simulation, implementation of scripts for navigation and interactions (6) | Finishing the "enterprise" part in the USE part. Work on the camera system, which one to use,why, how are we going to implement it (8) |

Helping with unity | Work on unity simulation (6) | |

| Week 6 + hours | Research and Explanation on Coverage Path Planning as a Navigational Method (6) | Working on the Unity simulation, improvement of scripts for navigation (8) | Research about How to implement this camera system to the oil skimmer. Proofread some part of the report to make it better (6) |

CAD design | Work on unity simulation (12) | |

| Week 7 + hours | Created the presentation and prepared to present results (12) | Working on the Unity simulation, preparing presentation (12) | Work on the structure of the report (especially work on the approach/methodology part) (4) | Report work | Work on unity simulation (2)

Read and edit report (6) | |

| Week 8 + hours | Report work (4) | Report Work (4) | Report Work (4) | Report work | Editing report (4) | |

| Bonus points | -0.1 | -0.1 | +0.5 | -0.1 | -0.1 | -0.1 |

References

- ↑ Anderson, S. E., & Meade, B. J. (2014a). Potential Health Effects Associated with Dermal Exposure to Occupational Chemicals. Environmental Health Insights, 8s1, EHI.S15258. https://doi.org/10.4137/ehi.s15258

- ↑ 2.0 2.1 Manivel, R., & Sivakumar, R. (2020). Boat type oil recovery skimmer. Materials Today: Proceedings, 21, 470–473. https://doi.org/10.1016/j.matpr.2019.06.632

- ↑ International Conference on Advanced Logistics and Transport. (2013). https://doi.org/10.1109/icalt31205.2013

- ↑ 4.0 4.1 4.2 ITOPF. (2012). Use of skimmers in oil pollution response.https://www.itopf.org/knowledge-resources/data-statistics/statistics/

- ↑ Ventikos, N. P., & Sotiropoulos, F. S. (2014). Disutility analysis of oil spills: Graphs and trends. Marine Pollution Bulletin. https://www.sciencedirect.com/science/article/pii/S0025326X14000885?casa_token=bWFwHBfla3QAAAAA:f0HyqpA2GQ5HRYl6E1Xt599zYGByy6tOKWTK_8pSGMp0LhzMPeD9EA6rIhc0tx5C80XgfMheeA#b0135

- ↑ Drum Oil Skimmers | Oleophilic Skimmer | Elastec. (2021c, May 14). Elastec. https://www.elastec.com/products/oil-spill-skimmers/drum-oil-skimmers/

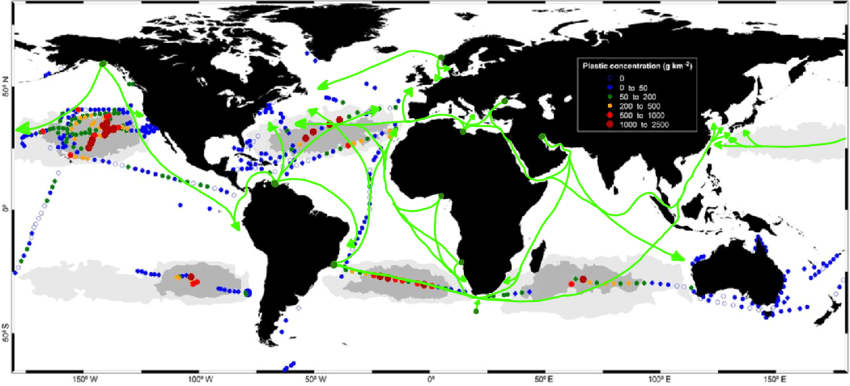

- ↑ 7.0 7.1 Cózar, Andrés & Echevarría, Fidel & González-Gordillo, Juan & Irigoien, Xabier & Úbeda, Bárbara & Hernandez-Leon, Santiago & Palma, Alvaro & Navarro, Sandra & Lomas, Juan & Ruiz, Andrea & Fernández-de-Puelles, María & Duarte, Carlos. (2014). Plastic debris in the open ocean. Proceedings of the National Academy of Sciences of the United States of America. https://www.researchgate.net/figure/Concentrations-of-plastic-debris-in-surface-waters-of-the-global-ocean-Colored-circles_fig1_263584861

- ↑ Nadeau R.J. (1977). Assessing the biological impact of oil spills: a new role for EPA [U.S. Environmental Protection Agency]. https://agris.fao.org/agris-search/search.do?recordID=US19780341544

- ↑ Ingpen, B. (n.d.) Crude Oil Tankers | Maritime Economics https://maritimesa.org/grade-10/crude-oil-tankers/

- ↑ Ulrich, J. D. (2011b). Social impact of the Gulf Oil Disaster: diverging views from communities in Florida and Louisiana. The Social Impact of the Gulf Oil Disaster Diverging Views From Communities in Florida and Louisiana. https://doi.org/10.34051/p/2020.133

- ↑ Ulrich, J. D. (2011). Social impact of the Gulf Oil Disaster: diverging views from communities in Florida and Louisiana. The Social Impact of the Gulf Oil Disaster Diverging Views From Communities in Florida and Louisiana. https://doi.org/10.34051/p/2020.133

- ↑ Ulrich, J. D. (2011). Social impact of the Gulf Oil Disaster: diverging views from communities in Florida and Louisiana. The Social Impact of the Gulf Oil Disaster Diverging Views From Communities in Florida and Louisiana. https://doi.org/10.34051/p/2020.133

- ↑ Update on Gulf of Mexico oil spill | News and insights | Home. (n.d.). Bp Global. https://www.bp.com/en/global/corporate/news-and-insights/press-releases/update-on-gulf-of-mexico-spill-3-september.html

- ↑ Oil spills. (n.d.-b). National Oceanic and Atmospheric Administration. https://www.noaa.gov/education/resource-collections/ocean-coasts/oil-spills#:~:text=Oil%20spills%20can%20harm%20sea,and%20help%20the%20ocean%20recover

- ↑ Jonsson, P. (2010, Jul 02). A whale to the rescue: Can super-skimmer turn tide of gulf oil spill? The Christian Science Monitor Retrieved. https://www.proquest.com/newspapers/whale-rescue-can-super-skimmer-turn-tide-gulf-oil/docview/577681716/se-2

- ↑ (n.d.). SAFETY4SEA | Shipping and maritime news. https://safety4sea.com/wp-content/uploads/2021/06/ITOPF-Oil-Tanker-Spill-Statistics-2020-2021_01.pdf

- ↑ Nissanka, I. D., & Yapa, P. D. (2018). Calculation of oil droplet size distribution in ocean oil spills: A review. Marine Pollution Bulletin, 135, 723-734. https://doi.org/10.1016/j.marpolbul.2018.07.048

- ↑ Montewka, J., Weckström, M., & Kujala, P. (2013). A probabilistic model estimating oil spill clean-up costs – A case study for the Gulf of Finland. Marine Pollution Bulletin, 76(1-2), 61-71. https://doi.org/10.1016/j.marpolbul.2013.09.031

- ↑ Hammoud, A. H., & Khalil, M. F. (2003). Performance of a rotating drum skimmer in oil spill recovery. Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering, 217(1), 49-57. https://doi.org/10.1243/09544080360562981

- ↑ Visco Engineers. (n.d.). Drum type oil skimmer manual. Visco Engineers. https://d3pcsg2wjq9izr.cloudfront.net/files/71401/download/437272/Drumtypeoilskimmermanual,Pictureanddatasheet.pdf

- ↑ TDS118 | Floating Drum Oil Skimmers | Elastec. (2022b, November 18). Elastec. https://www.elastec.com/products/oil-spill-skimmers/drum-oil-skimmers/tds-118/

- ↑ Khalil, M. F., Ibrahim El-Boghdady, and E. R. Lotfy. 2022. “Oil-Recovery Performance of a Sponge-Covered Drum Skimmer.” Alexandria Engineering Journal 61(12):12653–60.

- ↑ Sabbar, W. A., Mohammed, B., & Almudhaffar, M. A. (2021b). Influence of operational parameters on the recovery rate of polyester resin surface of locally designed drum oil skimmer. Journal of Physics, 1773(1), 012023. https://doi.org/10.1088/1742-6596/1773/1/012023

- ↑ Oil Skimmers, Inc. (n.d.). About Oil Skimmers, Inc. https://www.oilskim.com/contact/about-us#:~:text=With%20the%20highest%20quality%20products,of%20upwards%20of%2025%20years

- ↑ Davies, & Bethan. (2022, February 21). How artificial intelligence is taught to navigate oceans. AZoRobotics.com. https://www.azorobotics.com/Article.aspx?ArticleID=468

- ↑ Galceran, E., & Carreras, M. (2013). A survey on coverage path planning for robotics. Robotics and Autonomous Systems, 61(12), 1258–1276. https://doi.org/10.1016/j.robot.2013.09.004

- ↑ Zhu, J.; Yang, Y.; Cheng, Y. SMURF: A Fully Autonomous Water Surface Cleaning Robot with A Novel Coverage Path Planning Method. J. Mar. Sci. Eng. 2022, 10, 1620. https://+doi.org/10.3390/jmse10111620

- ↑ Tata, Gautam & Royer, Sarah-Jeanne & Poirion, Olivier Bertrand & Lowe, Jay. (2021). DeepPlastic: A Novel Approach to Detecting Epipelagic Bound Plastic Using Deep Visual Models.

- ↑ Kylili, K., Kyriakides, I., Artusi, A., & Hadjistassou, C. (2019, April 18). Identifying floating plastic marine debris using a deep learning approach - environmental science and Pollution Research. SpringerLink. Retrieved February 22, 2023, from https://link.springer.com/article/10.1007/s11356-019-05148-4

- ↑ Artificial intelligence to detect marine plastic litter: Vito Remote Sensing. Prism | Vito remote sensing. Retrieved February 22, 2023, from https://blog.vito.be/remotesensing/ai-marine-plastic-litter

- ↑ AG, B. (2017, July 12). Cutting through the noise: Camera selection | Vision campus. Basler AG. https://www.baslerweb.com/en/vision-campus/vision-systems-and-components/camera-selection/

- ↑ Holmes, T. (2023, February 7). What is Frame Rate for video? Wistia. https://wistia.com/learn/production/what-is-frame-rate

- ↑ 33.0 33.1 XCG-H280CR Color GigE Camera. (n.d.). https://www.image-sensing-solutions.eu/xcg_h280cr.html